|

Level Of Repair Analysis

Level of Repair Analysis (LORA) is used as an analytical methodology used to determine where an item will be replaced, repaired, or discarded based on cost considerations and operational readiness requirements. For a complex engineering system containing thousands of assemblies, sub-assemblies, components, organized into several levels of indenture and with a number of possible repair decisions, LORA seeks to determine an optimal provision of repair and maintenance facilities to minimize overall system life-cycle costs. Logistics personnel examine not only the cost of the part to be replaced or repaired but all of the elements required to make sure the job is done correctly. This includes the skill level of personnel, support equipment required to perform the task, test equipment required to test the repaired product, and the facilities required to house the entire operation. Process LORA establishes when and where each unit will be repaired and determines if it is more cost ef ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Availability

In reliability engineering, the term availability has the following meanings: * The degree to which a system, subsystem or equipment is in a specified operable and committable state at the start of a mission, when the mission is called for at an unknown, ''i.e.'' a random, time. * The probability that an item will operate satisfactorily at a given point in time when used under stated conditions in an ideal support environment. Normally high availability systems might be specified as 99.98%, 99.999% or 99.9996%. Representation The simplest representation of availability (''A'') is a ratio of the expected value of the uptime of a system to the aggregate of the expected values of up and down time (that results in the "total amont of time" ''C'' of the observation window) : A = \frac = \frac Another equation for availability (''A'') is a ratio of the Mean Time To Failure (MTTF) and Mean Time To Repair (MTTR), or : A = \frac = \frac If we define the status function X(t) as : X( ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inventory

Inventory (American English) or stock (British English) refers to the goods and materials that a business holds for the ultimate goal of resale, production or utilisation. Inventory management is a discipline primarily about specifying the shape and placement of stocked goods. It is required at different locations within a facility or within many locations of a supply network to precede the regular and planned course of production and stock of materials. The concept of inventory, stock or work in process (or work in progress) has been extended from manufacturing systems to service businesses and projects, by generalizing the definition to be "all work within the process of production—all work that is or has occurred prior to the completion of production". In the context of a manufacturing production system, inventory refers to all work that has occurred—raw materials, partially finished products, finished products prior to sale and departure from the manufacturing system. I ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

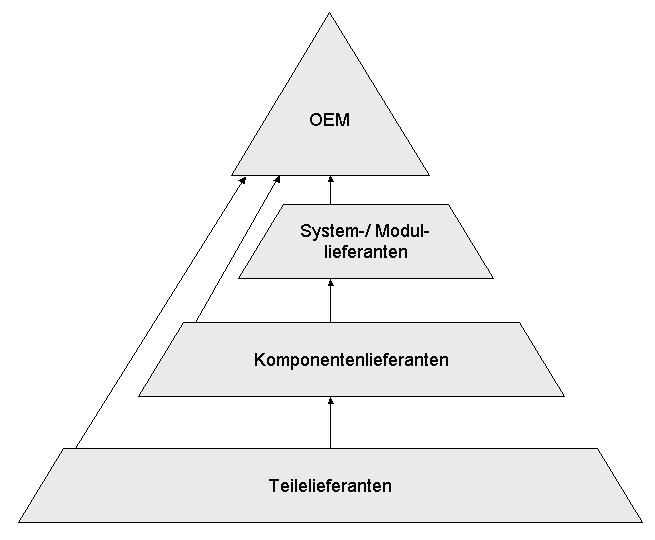

Original Equipment Manufacturer

An original equipment manufacturer (OEM) is generally perceived as a company that produces non-aftermarket parts and equipment that may be marketed by another manufacturer. It is a common industry term recognized and used by many professional organizations such as SAE International, ISO, and others. However, the term is also used in several other ways, which causes ambiguity. It sometimes means the maker of a system that includes other companies' subsystems, an end-product producer, an automotive part that is manufactured by the same company that produced the original part used in the automobile's assembly, or a value-added reseller.Ken Olsen: PDP-1 and PDP-8 (page 3) , economicadventure.com Automotive parts When referring to auto parts, OEM refers to the manufactur ...[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Repair Depot

The technical meaning of maintenance involves functional checks, servicing, repairing or replacing of necessary devices, equipment, machinery, building infrastructure, and supporting utilities in industrial, business, and residential installations. Over time, this has come to include multiple wordings that describe various cost-effective practices to keep equipment operational; these activities occur either before or after a failure. Definitions Maintenance functions can defined as maintenance, repair and overhaul (MRO), and MRO is also used for maintenance, repair and operations. Over time, the terminology of maintenance and MRO has begun to become standardized. The United States Department of Defense uses the following definitions:Federal Standard 1037C and from MIL-STD-188 and from the Department of Defense Dictionary of Military and Associated Terms * Any activity—such as tests, measurements, replacements, adjustments, and repairs—intended to retain or restore a fun ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Maintenance Concept

Maintenance may refer to: Biological science * Maintenance of an organism * Maintenance respiration Non-technical maintenance * Alimony, also called ''maintenance'' in British English * Champerty and maintenance, two related legal doctrines * Child support, also commonly called "child maintenance" * Feudal maintenance, system of funding armies Technical maintenance * Maintenance (technical) * Aircraft maintenance * Bicycle maintenance * Bus maintenance * Car maintenance * Train maintenance * Property maintenance * Railroad track maintenance * Software maintenance Some kinds of technical maintenance * Condition-based maintenance * Corrective maintenance * Planned maintenance * Predictive maintenance * Preventive maintenance * Total productive maintenance Total Productive Maintenance (TPM) started as a method of physical asset management focused on maintaining and improving manufacturing machinery, in order to reduce the operating cost to an organization. After the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

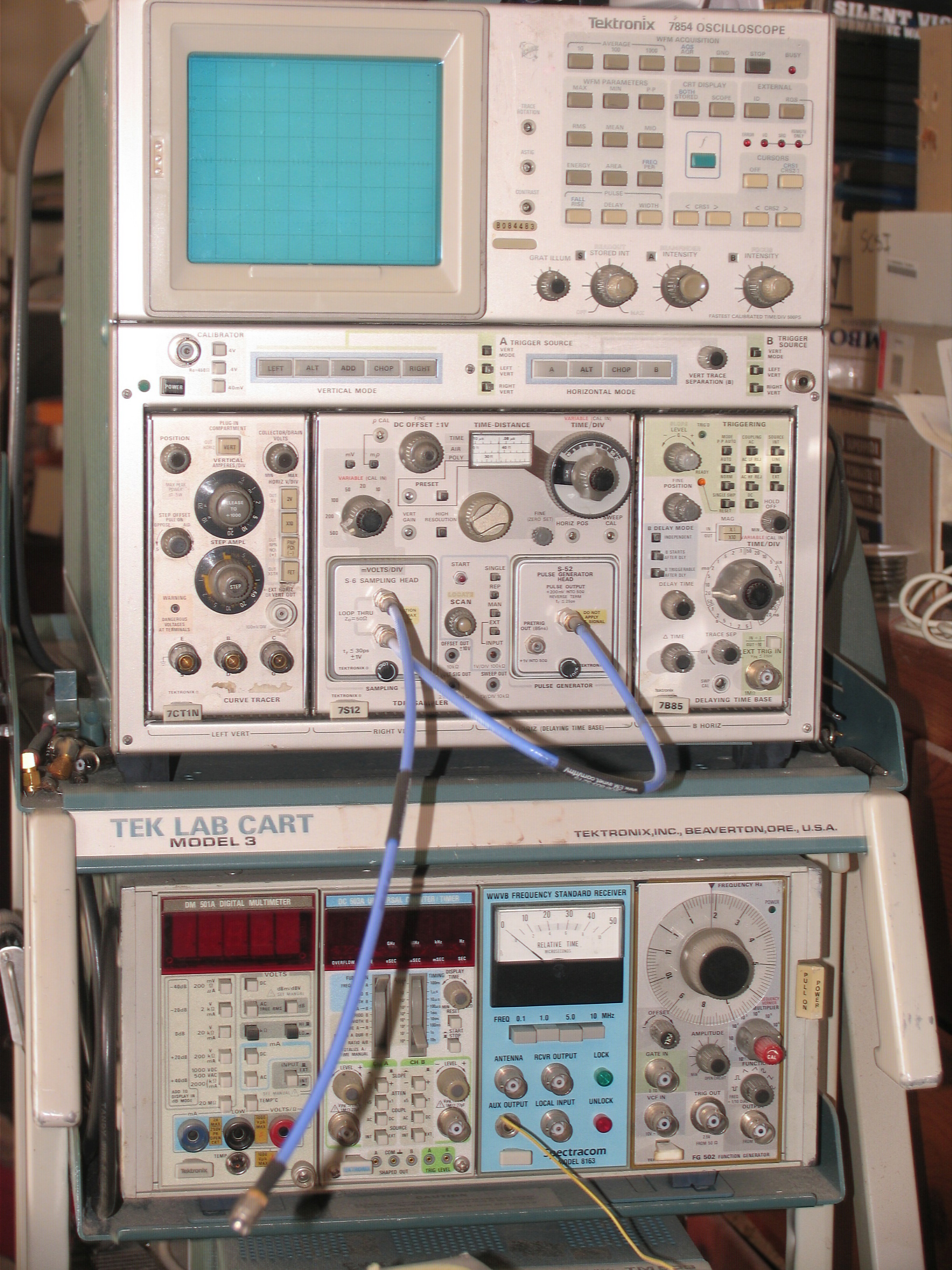

Electronic Test Equipment

Electronic test equipment is used to create signals and capture responses from electronic devices under test (DUTs). In this way, the proper operation of the DUT can be proven or faults in the device can be traced. Use of electronic test equipment is essential to any serious work on electronics systems. Practical electronics engineering and assembly requires the use of many different kinds of electronic test equipment ranging from the very simple and inexpensive (such as a test light consisting of just a light bulb and a test lead) to extremely complex and sophisticated such as automatic test equipment (ATE). ATE often includes many of these instruments in real and simulated forms. Generally, more advanced test gear is necessary when developing circuits and systems than is needed when doing production testing or when troubleshooting existing production units in the field. Types of test equipment Basic equipment The following items are used for basic measurement of voltages, cu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Main Operating Base

Main operating base (MOB) is a term used by the United States military defined as a "permanently manned, well protected base, used to support permanently deployed forces, and with robust sea and/or air access". This term was used to differentiate major strategic overseas military facilities versus smaller, less secure or temporarily manned contingency tactical locations such as forward operating bases, forward operating sites or cooperative security locations. The differentiation was established as the Pentagon began to address regional threats primarily in Africa, Asia and Latin America following its 2004 global posture review. MOBs in Afghanistan * Kandahar International Airport, Helmand Province. * Camp Bastion, Helmand Province. * Bagram Airfield, Parwan Province Parwan (Dari: ), also spelled Parvan, is one of the 34 provinces of Afghanistan. It has a population of about 751,000. The province is multi-ethnic and mostly rural society. The province is divided into ten dist ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Backshop

A backshop or back-shop is a specialized store or workshop found in service industries, such as locomotive and aircraft repair. Most repairs are carried out in small workshops, except where an industrial service is needed. In the military, backshops repair parts are known as shop-replaceable units (SRUs). These are commonly-stocked subassemblies of a larger system, such as circuit cards components of a line-replaceable unit (LRU), designed to be repaired at the field level. Repair at this level is known as field-level maintenance or intermediate-level (I-level) maintenance. Calibration and repair of United States Air Force test equipment is conducted at shops known as precision measurement equipment laboratories. See also * Armory (military) * Back office * Railway workshop Railway workshops are railway facilities in which rolling stock is repaired. While often colocated with engine sheds to perform routine tasks as well as major repairs, in some countries separated co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spare Part

A spare part, spare, service part, repair part, or replacement part, is an interchangeable part that is kept in an inventory and used for the repair or refurbishment of defective equipment/units. Spare parts are an important feature of logistics engineering and supply chain management, often comprising dedicated spare parts management systems. Spare parts are an outgrowth of the industrial development of interchangeable parts and mass production. In an industrial environment, spare parts are described in several manner to distinguish key features of various spare parts. The following describes spare part types and their typically functionality. 1. Capital parts are spare parts which, although acknowledged to have a long life or a small chance of failure, would cause a long shutdown of equipment because it would take a long time to get a replacement for them. Capital parts are typically repaired or replaced during planned overhauls/scheduled inspections. As description imp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Whole-life Cost

Whole-life cost is the total cost of ownership over the life of an asset. The concept is also known as life-cycle cost (LCC) or lifetime cost, and is commonly referred to as "cradle to grave" or "womb to tomb" costs. Costs considered include the financial cost which is relatively simple to calculate and also the environmental and social costs which are more difficult to quantify and assign numerical values. Typical areas of expenditure which are included in calculating the whole-life cost include planning, design, construction and acquisition, operations, maintenance, renewal and rehabilitation, depreciation and cost of finance and replacement or disposal. Financial Whole-life cost analysis is often used for option evaluation when procuring new assets and for decision-making to minimize whole-life costs throughout the life of an asset. It is also applied to comparisons of actual costs for similar asset types and as feedback into future design and acquisition decisions. The prima ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Line-replaceable Unit

A line-replaceable unit (LRU), lower line-replaceable unit (LLRU), line-replaceable component (LRC), or line-replaceable item (LRI) is a modular component of an airplane, ship or spacecraft (or any other manufactured device) that is designed to be replaced quickly at an operating location (1st line). The different lines (distances) are essential for logistics planning and operation. An LRU is usually a sealed unit such as a radio or other auxiliary equipment. LRUs are typically assigned logistics control numbers (LCNs) or work unit codes (WUCs) to manage logistics operations. LRUs can improve maintenance operations, because they can be stocked and replaced quickly from distributed nearby on-site inventories (sometimes mobile storage), restoring the mobile systems to service, while the failed (unserviceable) LRU is undergoing complicated repair and overhaul actions in other support locations (lines). Because of their modularity, LRUs also can contribute reducing system costs and i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |