|

Lap Joint

A lap joint or overlap joint is a joint in which the members overlap. Lap joints can be used to join wood, plastic, or metal. A lap joint can be used in woodworking for joining wood together. A lap joint may be a full lap or half lap. In a full lap, no material is removed from either of the members that will be joined, resulting in a joint which is the combined thickness of the two members. In a half lap joint or halving joint, material is removed from both of the members so that the resulting joint is the thickness of the thickest member. Most commonly in half lap joints, the members are of the same thickness and half the thickness of each is removed. With respect to wood joinery, this joint, where two long-grain wood faces are joined with glue, is among the strongest in ability to resist shear forces, exceeding even mortise and tenon and other commonly-known "strong" joints. With respect to metal welding, this joint, made by overlapping the edges of the plate, is not recomm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodworking Lap Joints

Woodworking is the skill of making items from wood, and includes cabinet making (cabinetry and furniture), wood carving, joinery, carpentry, and woodturning. History Along with stone, clay and animal parts, wood was one of the first materials worked by early humans. Microwear analysis of the Mousterian stone tools used by the Neanderthals show that many were used to work wood. The development of civilization was closely tied to the development of increasingly greater degrees of skill in working these materials. Among early finds of wooden tools are the worked sticks from Kalambo Falls, Clacton-on-Sea and Lehringen. The spears from Schöningen (Germany) provide some of the first examples of wooden hunting gear. Flint tools were used for carving. Since Neolithic times, carved wooden vessels are known, for example, from the Linear Pottery culture wells at Kückhofen and Eythra. Examples of Bronze Age wood-carving include tree trunks worked into coffins from northern German ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scarf Joint

A scarf joint (also known as a scarph joint) is a method of joining two members end to end in woodworking or metalworking. The scarf joint is used when the material being joined is not available in the length required. It is an alternative to other joints such as the butt joint and the splice joint and is often favored over these in joinery because it yields a barely visible glue line. The scarf joint in wood In woodworking, there are two distinctly different categories of scarf, based on whether the joint has interlocking faces or not. A ''plain'' scarf is simply two flat planes meeting on an angle relative to the axis of the stock being joined, and depends entirely on adhesive and/or mechanical fasteners (such as screws, nails, or bolts) for all strength. ''Interlocking'' scarf joints, such as a hooked, keyed, and nibbed scarves, offer varying degrees of tensile and compressive strength, though most still depend on mechanical fastening to keep the joint closed. The plain ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Splice Joint

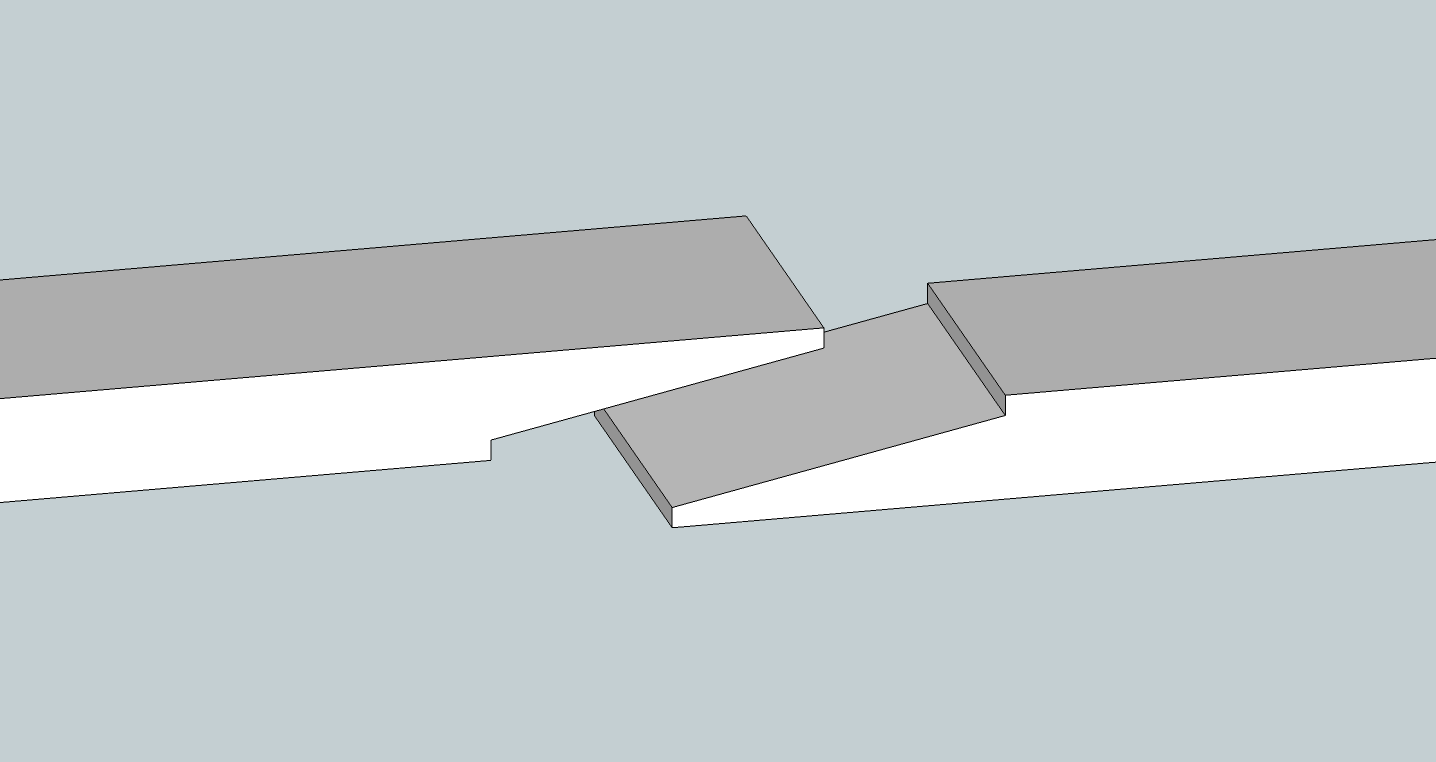

A splice joint is a method of joining two members end to end in woodworking. The splice joint is used when the material being joined is not available in the length required. It is an alternative to other joints such as the butt joint and the scarf joint. Splice joints are stronger than unenforced butt joints and have the potential to be stronger than a scarf joint. Splices are therefore most often used when structural elements are required in longer lengths than the available material. The most common form of the splice joint is the half lap splice, which is common in building construction, where it is used to join shorter lengths of timber into longer beams. Applications * Joining structural members end to end Types of splice joints There are four main types of splice joints: half lap, bevel lap, tabled, and tapered finger. Half lap splice joint The half lap splice joint is the simplest form of the splice joint and is commonly used to join structural members where either great ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scarf Joint

A scarf joint (also known as a scarph joint) is a method of joining two members end to end in woodworking or metalworking. The scarf joint is used when the material being joined is not available in the length required. It is an alternative to other joints such as the butt joint and the splice joint and is often favored over these in joinery because it yields a barely visible glue line. The scarf joint in wood In woodworking, there are two distinctly different categories of scarf, based on whether the joint has interlocking faces or not. A ''plain'' scarf is simply two flat planes meeting on an angle relative to the axis of the stock being joined, and depends entirely on adhesive and/or mechanical fasteners (such as screws, nails, or bolts) for all strength. ''Interlocking'' scarf joints, such as a hooked, keyed, and nibbed scarves, offer varying degrees of tensile and compressive strength, though most still depend on mechanical fastening to keep the joint closed. The plain ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bridle Joint

A bridle joint is a woodworking joint, similar to a mortise and tenon, in that a tenon is cut on the end of one member and a mortise is cut into the other to accept it. The distinguishing feature is that the tenon and the mortise are cut to the full width of the tenon member. The corner bridle joint (also known as a slot mortise and tenon) joins two members at their respective ends, forming a corner. This form of the joint is commonly used to house a rail in uprights, such as legs. It provides good strength in compression and is fairly resistant to racking, although a mechanical fastener or pin is often required. The bridle joint is very popular in workbench construction. Corner bridles are often used to join frame components when the frame is to be shaped. Material can be removed from the joined members after assembly without sacrificing joint integrity. A variation of the bridle joint is the T-bridle, which joins the end of one member to the middle of another.Woodwork Joint ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shiplap

Shiplap is a type of wooden board used commonly as exterior siding in the construction of residences, barns, sheds, and outbuildings. Exterior walls Shiplap is either rough-sawn or milled pine or similarly inexpensive wood between wide with a rabbet on opposite sides of each edge. The rabbet allows the boards to overlap in this area. The profile of each board partially overlaps that of the board next to it creating a channel that gives shadow line effects, provides excellent weather protection and allows for dimensional movement. Useful for its strength as a supporting member, and its ability to form a relatively tight seal when lapped, shiplap is usually used as a type of siding for buildings that do not require extensive maintenance and must withstand cold and aggressive climates. Rough-sawn shiplap is attached vertically in post and beam construction, usually with 51–65 mm (6d–8d) common nails, while milled versions, providing a tighter seal, are more commonly ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Joinery Terms

When material is removed to create a woodworking joint, the resulting surfaces have the following names: * Cheek, the flat surface parallel to the face of the joint member which exposes long grain * Shoulder, the surface perpendicular to the face or edge of the joint member which exposes end grain See also * Carpentry * Woodworking Woodworking is the skill of making items from wood, and includes cabinet making (cabinetry and furniture), wood carving, joinery, carpentry, and woodturning. History Along with stone, clay and animal parts, wood was one of the first mate ... References Joinery {{Woodworking-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Splice Joint

A splice joint is a method of joining two members end to end in woodworking. The splice joint is used when the material being joined is not available in the length required. It is an alternative to other joints such as the butt joint and the scarf joint. Splice joints are stronger than unenforced butt joints and have the potential to be stronger than a scarf joint. Splices are therefore most often used when structural elements are required in longer lengths than the available material. The most common form of the splice joint is the half lap splice, which is common in building construction, where it is used to join shorter lengths of timber into longer beams. Applications * Joining structural members end to end Types of splice joints There are four main types of splice joints: half lap, bevel lap, tabled, and tapered finger. Half lap splice joint The half lap splice joint is the simplest form of the splice joint and is commonly used to join structural members where either great ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodworking Joint

Joinery is a part of woodworking that involves joining pieces of wood, engineered lumber, or synthetic substitutes (such as laminate), to produce more complex items. Some woodworking joints employ mechanical fasteners, bindings, or adhesives, while others use only wood elements (such as dowels or plain mortise and tenon fittings). The characteristics of wooden joints - strength, flexibility, toughness, appearance, etc. - derive from the properties of the materials involved and the purpose of the joint. Therefore, different joinery techniques are used to meet differing requirements. For example, the joinery used to construct a house can be different from that used to make cabinetry or furniture, although some concepts overlap. While a form of carpentry elsewhere, in British English usage it is distinguished from it, which is considered to be a form of structural timber work. History Many traditional wood joinery techniques use the distinctive material properties of wood, oft ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fastener

A fastener (US English) or fastening (UK English) is a hardware device that mechanically joins or affixes two or more objects together. In general, fasteners are used to create non-permanent joints; that is, joints that can be removed or dismantled without damaging the joining components. Welding is an example of creating permanent joints. Steel fasteners are usually made of stainless steel, carbon steel, or alloy steel. Other alternative methods of joining materials include: crimping, welding, soldering, brazing, taping, gluing, cement, or the use of other adhesives. Force may also be used, such as with magnets, vacuum (like suction cups), or even friction (like sticky pads). Some types of woodworking joints make use of separate internal reinforcements, such as dowels or biscuits, which in a sense can be considered fasteners within the scope of the joint system, although on their own they are not general purpose fasteners. Furniture supplied in flat-pack form often uses ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dowel

A dowel is a cylindrical rod, usually made of wood, plastic, or metal. In its original manufactured form, a dowel is called a ''dowel rod''. Dowel rods are often cut into short lengths called dowel pins. Dowels are commonly used as structural reinforcements in cabinet making and in numerous other applications, including: * Furniture shelf supports * Moveable game pieces (i.e. pegs) * Hangers for items such as clothing, key rings, and tools * Wheel axles in toys * Detents in gymnastics grips * Supports for tiered wedding cakes Wood dowel Manufacturing process The traditional tool for making dowels is a ''dowel plate'', an iron (or better, hardened tool steel) plate with a hole having the size of the desired dowel. To make a dowel, a piece of wood is split or whittled to a size slightly bigger than desired and then driven through the hole in the dowel plate. The sharp edges of the hole shear off the excess wood.Ivin SickelsExercises in Wood-Working American Book Company ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |