|

Koenigsegg TFG

The Koenigsegg TFG is an Inline-3 engine. The TFG stands for "Tiny Friendly Giant." It is a Freevalve (Camless piston engine), thus it does not have a camshaft. Instead it uses pneumatic actuators that allows it to open each valve (both intake and exhaust) independently to maximise performance and minimise fuel consumption depending on driving conditions. The pneumatic actuators also have the ability to switch the engine between 2-stroke cycles and 4-stroke cycles by controlling the number of power strokes in relation to the number of idle strokes. The patent for this system was bought by Koenigsegg's sister company Cargine Engineering in 2002. The Variable displacement system allows fuel economy to be 15%-20% higher than a variable camshaft engine. Cold start emissions are also drastically reduced by 60% over a variable camshaft engine. The engine is equipped with a small turbo for one set of exhaust valves, and a larger turbo for the other set of exhaust valves. However thi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Koenigsegg

Koenigsegg Automotive AB () is a Swedish manufacturer of high-performance sports cars based in Ängelholm, Skåne County, Sweden. Company The company was founded in 1994 in Sweden by Christian von Koenigsegg, with the intention of producing a "world-class" sports car. Many years of development and testing led to the CC8S, the company's first street-legal production car which was introduced in 2002. In 2006, Koenigsegg began production of the CCX, which uses an engine created in-house specifically for the car. The goal was to develop a car homologated for use worldwide, particularly the United States whose strict regulations did not allow the import of earlier Koenigsegg models. In March 2009, the CCXR was listed by ''Forbes'' as one of "the world's most beautiful cars". In December 2010, the Agera won the BBC Top Gear Hypercar of the Year Award. Apart from developing, manufacturing and selling the Koenigsegg line of sports cars, Koenigsegg is also involved in "green te ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Variable Displacement

Variable displacement is an automobile engine technology that allows the engine displacement to change, usually by deactivating cylinders, for improved fuel economy. The technology is primarily used in large, multi-cylinder engines. Many automobile manufacturers have adopted this technology as of 2005, although the concept has existed for some time prior to this. Theory of operation Cylinder deactivation is used to reduce the fuel consumption and emissions of an internal combustion engine during light-load operation. In typical light-load driving the driver uses only around 30 percent of an engine’s maximum power. In these conditions, the throttle valve is nearly closed, and the engine needs to work to draw air. This causes an inefficiency known as pumping loss. Some large capacity engines need to be throttled so much at light load that the cylinder pressure at top dead centre is approximately half that of a small 4-cylinder engine. Low cylinder pressure results in lower fuel e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Throttle

A throttle is the mechanism by which fluid flow is managed by constriction or obstruction. An engine's power can be increased or decreased by the restriction of inlet gases (by the use of a throttle), but usually decreased. The term ''throttle'' has come to refer, informally, to any mechanism by which the power or speed of an engine is regulated, such as a car's accelerator pedal. What is often termed a ''throttle'' (in an aviation context) is also called a thrust lever, particularly for jet engine powered aircraft. For a steam locomotive, the valve which controls the steam is known as the regulator. Internal combustion engines In an internal combustion engine, the throttle is a means of controlling an engine's power by regulating the amount of fuel or air entering the engine. In a motor vehicle the control used by the driver to regulate power is sometimes called the throttle, accelerator, or gas Automobile pedal, pedal. For a gasoline engine, the throttle most commonly regul ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Atkinson Cycle

The Atkinson-cycle engine is a type of internal combustion engine invented by James Atkinson in 1882. The Atkinson cycle is designed to provide efficiency at the expense of power density. A variation of this approach is used in some modern automobile engines. While originally seen exclusively in hybrid electric applications such as the earlier-generation Toyota Prius, later hybrids and some non-hybrid vehicles now feature engines with variable valve timing, which can run in the Atkinson cycle as a part-time operating regimen, giving good economy while running in Atkinson cycle, and conventional power density when running as a conventional, Otto cycle engine. Design Atkinson produced three different designs that had a short compression stroke and a longer expansion stroke. The first Atkinson-cycle engine, the ''differential engine'', used opposed pistons. The second and best-known design was the ''cycle engine'', which used an over-center arm to create four piston strokes in one ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Miller Cycle

In engineering, the Miller cycle is a thermodynamic cycle used in a type of internal combustion engine. The Miller cycle was patented by Ralph Miller, an American engineer, dated Dec 24, 1957. The engine may be two- or four-stroke and may be run on diesel fuel, gases, or dual fuel. This type of engine was first used in ships and stationary power-generating plants, and is now used for some railway locomotives such as the GE PowerHaul. It was adapted by Mazda for their KJ-ZEM V6, used in the Millenia sedan, and in their Eunos 800 sedan (Australia) luxury cars. More recently, Subaru has combined a Miller-cycle flat-4 with a hybrid driveline for their concept "Turbo Parallel Hybrid" car, known as the Subaru B5-TPH, and Nissan has introduced a small three-cylinder engine with variable intake valve timing that claims to operate an Atkinson cycle at low load (thus the lower power density is not a handicap), or a Miller cycle when under light boost in the low-pressure, supercharge ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Otto Cycle

An Otto cycle is an idealized thermodynamic cycle that describes the functioning of a typical spark ignition piston engine. It is the thermodynamic cycle most commonly found in automobile engines. The Otto cycle is a description of what happens to a gas as it is subjected to changes of pressure, temperature, volume, addition of heat, and removal of heat. The gas that is subjected to those changes is called the system. The system, in this case, is defined to be the fluid (gas) within the cylinder. By describing the changes that take place within the system, it will also describe in inverse, the system's effect on the environment. In the case of the Otto cycle, the effect will be to produce enough net work from the system so as to propel an automobile and its occupants in the environment. The Otto cycle is constructed from: :Top and bottom of the loop: a pair of quasi-parallel and isentropic processes (frictionless, adiabatic reversible). :Left and right sides of the loop: ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Twin-turbo

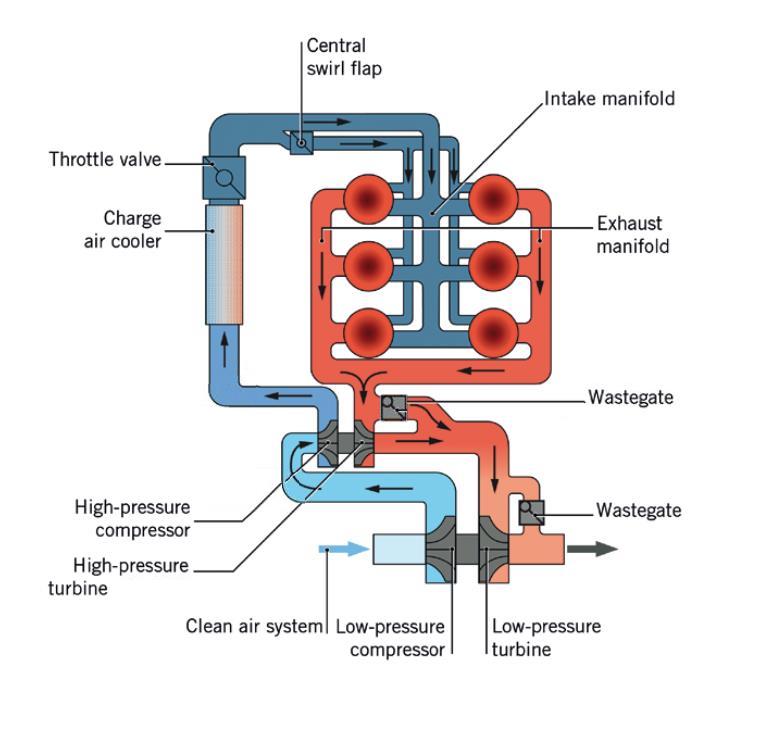

Twin-turbo (not to be confused with a twincharger setup, which is a combination of a supercharger and a turbocharger) refers to an engine in which two turbochargers work in tandem to compress the intake fuel/air mixture (or intake air, in the case of a direct-injection engine). The most common layout features two identical or mirrored turbochargers in parallel, each processing half of a V engine's produced exhaust through independent piping. The two turbochargers can either be matching or different sizes. Types and combinations There are three types of turbine setups used for twin-turbo setups: * Parallel * Sequential * Series These can be applied to any of the five types of compressor setups (which theoretically could have 15 different setups): * Compound Compressors * Staged Compound Compressors * Staged Sequential Compressors * Parallel Sequential Compressors * Parallel Compressors Parallel A parallel configuration refers to using two equally-sized turbochargers which ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Variable Valve Timing

In internal combustion engines, variable valve timing (VVT) is the process of altering the timing of a valve lift event, and is often used to improve performance, fuel economy or emissions. It is increasingly being used in combination with variable valve lift systems. There are many ways in which this can be achieved, ranging from mechanical devices to electro-hydraulic and camless systems. Increasingly strict emissions regulations are causing many automotive manufacturers to use VVT systems. Two-stroke engines use a power valve system to get similar results to VVT. Background theory The valves within an internal combustion engine are used to control the flow of the intake and exhaust gases into and out of the combustion chamber. The timing, duration and lift of these valve events has a significant impact on engine performance. Without variable valve timing or variable valve lift, the valve timing is the same for all engine speeds and conditions, therefore compromises are neces ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pneumatic Actuator

A pneumatic control valve actuator converts energy (typically in the form of compressed air) into mechanical motion. The motion can be rotary or linear, depending on the type of actuator. Principle of operation A Pneumatic actuator mainly consists of a piston or a diaphragm which develops the motive power. It keeps the air in the upper portion of the cylinder, allowing air pressure to force the diaphragm or piston to move the valve stem or rotate the valve control element. Valves require little pressure to operate and usually double or ''triple'' the input force. The larger the size of the piston, the larger the output pressure can be. Having a larger piston can also be good if the air supply is low, allowing the same forces with less input. These pressures are large enough to crush objects in the pipe. On 100 kPa input, you could lift a small car (upwards of 1,000 lbs) easily, and this is only a basic, small pneumatic valve. However, the resulting forces required o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Straight-three Engine

A straight-three engine (also called an inline-triple or inline-three) is a three-cylinder piston engine where cylinders are arranged in a line along a common crankshaft. Less common than straight-four engines, straight-three engines have nonetheless been used in various motorcycles, cars and agricultural machinery. Design A crankshaft angle of 120 degrees is typically used by straight-three engines, since this results in an evenly spaced firing interval. Another benefit of this configuration is perfect primary balance and secondary balance, however an end-to-end rocking couple is induced because there is no symmetry in the piston velocities about the middle piston. A balance shaft is sometimes used to reduce the vibrations caused by the rocking couple. Other crankshaft angles have been used occasionally. The 1976-1981 Laverda Jota motorcycle used a 180 degree crankshaft, where the outer pistons rise and fall together and inner cylinder is offset from them by 180 degrees. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pneumatic Actuator

A pneumatic control valve actuator converts energy (typically in the form of compressed air) into mechanical motion. The motion can be rotary or linear, depending on the type of actuator. Principle of operation A Pneumatic actuator mainly consists of a piston or a diaphragm which develops the motive power. It keeps the air in the upper portion of the cylinder, allowing air pressure to force the diaphragm or piston to move the valve stem or rotate the valve control element. Valves require little pressure to operate and usually double or ''triple'' the input force. The larger the size of the piston, the larger the output pressure can be. Having a larger piston can also be good if the air supply is low, allowing the same forces with less input. These pressures are large enough to crush objects in the pipe. On 100 kPa input, you could lift a small car (upwards of 1,000 lbs) easily, and this is only a basic, small pneumatic valve. However, the resulting forces required o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Camshaft

A camshaft is a shaft that contains a row of pointed cams, in order to convert rotational motion to reciprocating motion. Camshafts are used in piston engines (to operate the intake and exhaust valves), mechanically controlled ignition systems and early electric motor speed controllers. Camshafts in piston engines are usually made from steel or cast iron, and the shape of the cams greatly affects the engine's characteristics. History Trip hammers are one of the early uses of a form of cam to convert rotating motion, e.g. from a waterwheel, into the reciprocating motion of a hammer used in forging or to pound grain. Evidence for these exists back to the Han Dynasty in China, and they were widespread by the medieval period. The camshaft was described in 1206 by engineer Al-Jazari. He employed it as part of his automata, water-raising machines, and water clocks such as the castle clock. Once the rotative version of the steam engine was developed in the late 18th century, the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)