|

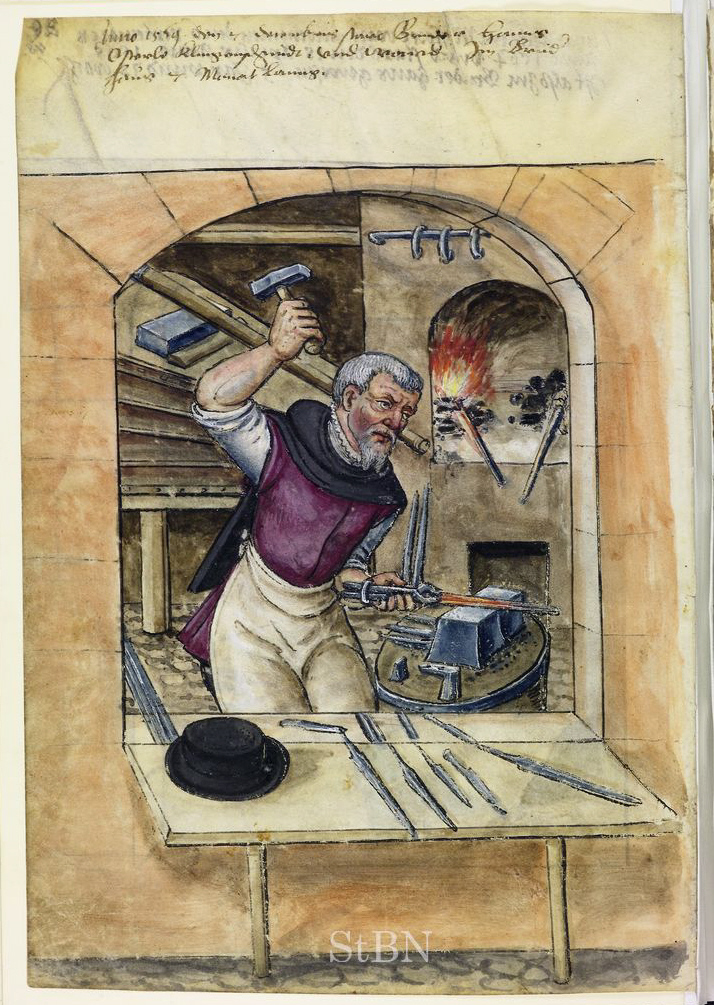

Knifemaker

Knife making is the process of manufacturing a knife by any one or a combination of processes: stock removal, forging to shape, welded lamination or investment cast. Typical metals used come from the carbon steel, tool, or stainless steel families. Primitive knives have been made from bronze, copper, brass, iron, obsidian, and flint. Materials for blades Different steels are suited to different applications. There is a trade off between hardness, toughness, edge retention, corrosion resistance, and achievable sharpness. Some examples of blade material and their relative trade offs: *The newest powder metallurgy steels can be made very hard, but can quickly wear out abrasives and tooling. *A blade made from low carbon or mild steel would be inexpensive to produce and of poor quality. A low carbon blade would be very hard to break, but would bend easily and be too soft to hold an edge. High carbon (or high alloy, in some listings) can take a much higher hardness but must be te ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bladesmith

Bladesmithing is the art of making knives, swords, daggers and other blades using a forge, hammer, anvil, and other smithing tools. Bladesmiths employ a variety of metalworking techniques similar to those used by blacksmiths, as well as woodworking for knife and sword handles, and often leatherworking for sheaths. Bladesmithing is an art that is thousands of years old and found in cultures as diverse as China, Japan, India, Germany, Korea, the Middle East, Spain and the British Isles. As with any art shrouded in history, there are myths and misconceptions about the process. While traditionally bladesmithing referred to the manufacture of any blade by any means, the majority of contemporary craftsmen referred to as bladesmiths are those who primarily manufacture blades by means of using a forge to shape the blade as opposed to knifemakers who form blades by use of the stock removal method, although there is some overlap between both crafts. Related trades Many blade smiths were kn ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Damascus Steel

Damascus steel was the forged steel of the blades of swords smithed in the Near East from ingots of Wootz steel either imported from Southern India or made in production centres in Sri Lanka, or Khorasan, Iran. These swords are characterized by distinctive patterns of banding and mottling reminiscent of flowing water, sometimes in a "ladder" or "rose" pattern. Such blades were reputed to be tough, resistant to shattering, and capable of being honed to a sharp, resilient edge. Wootz (Indian), Pulad (Persian), Fuladh (Arabic), Bulat (Russian) and Bintie (Chinese) are all names for historical ultra-high carbon crucible steel typified by carbide segregation. "Wootz" is an erroneous transliteration of "utsa" or "fountain" in Sanskrit, however since 1794 it has been the primary word used to refer to historical hypereutectoid crucible steel. History Origins The origin of the name "Damascus Steel" is contentious: the Islamic scholars al-Kindi (full name Abu Ya'qub ibn Ishaq al-K ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jere Davidson ENGRAVING A Large Knife , a list of people with the masculine given name or surname

{{dab ...

Jere may refer to: * Jere, Borno, a Local Government Area in Nigeria * Jere, West Virginia, United States, an unincorporated community * Jere language, a Nigerian dialect cluster * Jere (name) Jere is a masculine given name and a surname. The given name is often a short form of names such as Jerald or Jeremiah. Given name * Empress Xiaoduanwen (1600–1649), personal name Jere (or Jerjer), Empress Consort of Hong Taiji of the Qing Dynas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blanking (metalworking)

Blanking and piercing are shearing processes in which a punch and die are used to produce parts from coil or sheet stock. Blanking produces the outside features of the component, while piercing produces internal holes or shapes. The web is created after multiple components have been produced and is considered scrap material. The "slugs" produced by piercing internal features are also considered scrap. The terms "piercing" and "punching" can be used interchangeably. Die roll and burr formation Burrs and die roll are typical features of stamped components. Die roll is created when the material being stamped in compressed before the material begins to shear. Die roll takes the form of a radius around the outside edge of the blank and the pierced holes. After compression, the part shears for about 10% of the part thickness, and then fractures free of the strip or sheet. This fracturing produces a raised, jagged edge which is called a "burr". Burrs are typically removed by tumbling ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tang (tools)

A tang or shank is the back portion of the blade component of a tool where it extends into stock material or connects to a handle – as on a knife, sword, spear, arrowhead, chisel, file, coulter, pike, scythe, screwdriver, etc. One can classify various tang designs by their appearance, by the manner in which they attach to a handle, and by their length in relation to the handle. ''Nakago'' is the term in Japanese, used especially when referring to the tang of the katana or the wakizashi. Full vs partial tang A full tang extends the full length of the grip-portion of a handle, versus a ''partial'' tang which does not. A full tang may or may not be as wide as the handle itself, but will still run the full length of the handle. There are a wide variety of full and partial tang designs. In perhaps the most common design in full tang knives, the handle is cut in the shape of the tang and handle scales are then fastened to the tang by means of pins, screws, bolts, metal tubing, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Belt Grinder With A Small Wheel Attachment For Making Handles

Belt may refer to: Apparel * Belt (clothing), a leather or fabric band worn around the waist * Championship belt, a type of trophy used primarily in combat sports * Colored belts, such as a black belt or red belt, worn by martial arts practitioners to signify rank in the kyū ranking system Geology * A synonym for orogen (e.g. orogenic belt) * Greenstone belt * A large-scale linear or curved array of belt of igneous rocks (e.g. Transscandinavian Igneous Belt) * A large-scale linear or curved array of mineral deposits (e.g. Bolivian tin belt) * Metamorphic belt :* Paired metamorphic belts Mechanical and vehicular * Belt (mechanical), a looped strip of material used to link multiple rotating shafts * Conveyor belt, a device for transporting goods along a fixed track * Belt manlift, a device for moving people between floors in a building or grain elevator. * Seat belt, a safety device in automobiles and on the plane * Timing belt, part of an internal combustion engine * Serpe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Knife Makers Grinder -- With A 14" Contact Wheel

A knife ( : knives; from Old Norse 'knife, dirk') is a tool or weapon with a cutting edge or blade, usually attached to a handle or hilt. One of the earliest tools used by humanity, knives appeared at least 2.5 million years ago, as evidenced by the Oldowan tools. Originally made of wood, bone, and stone (such as flint and obsidian), over the centuries, in step with improvements in both metallurgy and manufacturing, knife blades have been made from copper, bronze, iron, steel, ceramic, and titanium. Most modern knives have either fixed or folding blades; blade patterns and styles vary by maker and country of origin. Knives can serve various purposes. Hunters use a hunting knife, soldiers use the combat knife, scouts, campers, and hikers carry a pocket knife; there are kitchen knives for preparing foods (the chef's knife, the paring knife, bread knife, cleaver), table knives (butter knives and steak knives), weapons (daggers or switchblades), knives for throwing or juggling, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grinding Machine

A grinding machine, often shortened to grinder, is a power tool (or machine tool) used for grinding. It is a type of machining using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel's surface cuts a small chip from the workpiece via shear deformation. Grinding is used to finish workpieces that must show high surface quality (e.g., low surface roughness) and high accuracy of shape and dimension. As the accuracy in dimensions in grinding is of the order of 0.000025 mm, in most applications it tends to be a finishing operation and removes comparatively little metal, about 0.25 to 0.50 mm depth. However, there are some roughing applications in which grinding removes high volumes of metal quite rapidly. Thus, grinding is a diverse field. Overview The grinding machine consists of a bed with a fixture to guide and hold the workpiece, and a power-driven grinding wheel spinning at the required speed. The speed is determined by the wheel’s diameter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

File (tool)

A file is a tool used to remove fine amounts of material from a workpiece. It is common in woodworking, metalworking, and other similar trade and hobby tasks. Most are hand tools, made of a case hardened steel bar of rectangular, square, triangular, or round cross-section, with one or more surfaces cut with sharp, generally parallel teeth. A narrow, pointed tang is common at one end, to which a handle may be fitted.. A rasp is a form of file with distinct, individually cut teeth used for coarsely removing large amounts of material. Files have also been developed with abrasive surfaces, such as natural or synthetic diamond grains or silicon carbide, allowing removal of material that would dull or resist steel files, such as ceramic. History Early filing or rasping has prehistoric roots and grew naturally out of the blending of the twin inspirations of cutting with stone cutting tools (such as hand axes) and abrading using natural abrasives, such as well-suited types of st ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hacksaw

A hacksaw is a fine-toothed saw, originally and mainly made for cutting metal. The equivalent saw for cutting wood is usually called a bow saw. Most hacksaws are hand saws with a C-shaped walking frame that holds a blade under tension. Such hacksaws have a handle, usually a pistol grip, with pins for attaching a narrow disposable blade. The frames may also be adjustable to accommodate blades of different sizes. A screw or other mechanism is used to put the thin blade under tension. On hacksaws, as with most frame saws, the blade can be mounted with the teeth facing toward or away from the handle, resulting in cutting action on either the push or pull stroke. In normal use, cutting vertically downwards with work held in a bench vise, hacksaw blades are set to be facing forwards. History While saws for cutting metal had been in use for many years, significant improvements in longevity and efficiency were made in the 1880s by Max Flower-Nash. George N. Clemson, a founder of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bandsaw

A bandsaw (also written band saw) is a power saw with a long, sharp blade consisting of a continuous band of toothed metal stretched between two or more wheels to cut material. They are used principally in woodworking, metalworking, and lumbering, but may cut a variety of materials. Advantages include uniform cutting action as a result of an evenly distributed tooth load, and the ability to cut irregular or curved shapes like a jigsaw.. The minimum radius of a curve is determined by the width of the band and its kerf. Most bandsaws have two wheels rotating in the same plane, one of which is powered, although some may have three or four to distribute the load. The blade itself can come in a variety of sizes and tooth pitches (teeth per inch, or TPI), which enables the machine to be highly versatile and able to cut a wide variety of materials including wood, metal and plastic. Almost all bandsaws today are powered by an electric motor. Line shaft versions were once common but ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electron-beam Machining

Electron-beam machining (EBM) is a process where high-velocity electrons concentrated into a narrow beam that are directed towards the work piece, creating heat and vaporizing the material. EBM can be used for very precise cutting or boring of a wide variety of metals. Surface finish is better and kerf width is narrower than those for other thermal cutting processes. EBM process is best suitable for high melting point and high thermal conductivity material pammi The EBM beam is operated in pulse mode. This is achieved by appropriately biasing the biased grid located just after the cathode. Switching pulses are given to the bias grid so as to achieve pulse duration of as low as 50 μs to as long as 15 ms. Beam current is directly related to the number of electrons emitted by the cathode or available in the beam. Beam current can be as low as 200 μamp to 1 amp. Increasing the beam current directly increases the energy per pulse. Similarly, increase in pulse duration also enhance ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |