|

Iron Plantation

Iron plantations were rural localities emergent in the late-18th century and predominant in the early-19th century that specialized in the production of pig iron and bar iron from crude iron ore. Such plantations derive their name from two sources: first, because they were nearly self-sufficient communities despite an almost singular focus on the production of iron to be sold on the market, and second, because of the large swaths of forest and land necessary to provide charcoal fuel and ore for their operations. The first plantations stretched across the Northeast, Midwest, and Southern United States, “the chief charcoal iron producing states [being] Pennsylvania, Ohio, New York, Virginia, Connecticut, Maryland, Missouri, Tennessee, and Kentucky." Many produced raw materials used in the American Revolution or to be exported to England. Throughout the remainder of the 19th century, however, only locations that adopted new technologies first introduced by competing coal- and co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hopewell Furnace National Historical Site Iron Plantation

Hopewell may refer to: Places Barbados *Hopewell, Christ Church *Hopewell, Saint Thomas Canada * Hopewell Parish, New Brunswick * Hopewell Cape, New Brunswick * Hopewell Rocks, a tourist attraction new Hopewell Cape * Hopewell, Newfoundland and Labrador * Hopewell, Nova Scotia Jamaica *Hopewell, Clarendon *Hopewell, Hanover *Hopewell, Manchester *Hopewell, Saint Andrew *Hopewell, Saint Ann *Hopewell, Saint Elizabeth *Hopewell, Westmoreland South Africa *Hopewell, KwaZulu-Natal United States Alabama *Hopeful, Alabama, formerly Hopewell *Hopewell, Blount County, Alabama *Hopewell, Cherokee County, Alabama *Hopewell, Cleburne County, Alabama *Hopewell, DeKalb County, Alabama *Hopewell, Jefferson County, Alabama *Hopewell, Lee County, Alabama *McCord Crossroads, Alabama, formerly Hopewell *West Greene, Alabama, formerly Hopewell Arkansas *Hopewell, Baxter County, Arkansas *Hopewell, Boone County, Arkansas *Hopewell, Cleburne County, Arkansas *Hopewell, Greene County, A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pig Iron

Pig iron, also known as crude iron, is an intermediate product of the iron industry in the production of steel which is obtained by smelting iron ore in a blast furnace. Pig iron has a high carbon content, typically 3.8–4.7%, along with silica and other constituents of dross, which makes it brittle and not useful directly as a material except for limited applications. The traditional shape of the molds used for pig iron ingots is a branching structure formed in sand, with many individual ingots at right angles to a central channel or "runner", resembling a litter of piglets being nursed by a sow. When the metal had cooled and hardened, the smaller ingots (the "pigs") were simply broken from the runner (the "sow"), hence the name "pig iron". As pig iron is intended for remelting, the uneven size of the ingots and the inclusion of small amounts of sand cause only insignificant problems considering the ease of casting and handling them. History Smelting and producing wroug ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Iron Ore

Iron ores are rocks and minerals from which metallic iron can be economically extracted. The ores are usually rich in iron oxides and vary in color from dark grey, bright yellow, or deep purple to rusty red. The iron is usually found in the form of magnetite (, 72.4% Fe), hematite (, 69.9% Fe), goethite (, 62.9% Fe), limonite (, 55% Fe) or siderite (, 48.2% Fe). Ores containing very high quantities of hematite or magnetite (greater than about 60% iron) are known as "natural ore" or "direct shipping ore", meaning they can be fed directly into iron-making blast furnaces. Iron ore is the raw material used to make pig iron, which is one of the main raw materials to make steel—98% of the mined iron ore is used to make steel. In 2011 the ''Financial Times'' quoted Christopher LaFemina, mining analyst at Barclays Capital, saying that iron ore is "more integral to the global economy than any other commodity, except perhaps oil". Sources Metallic iron is virtually unknown on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

American Revolution

The American Revolution was an ideological and political revolution that occurred in British America between 1765 and 1791. The Americans in the Thirteen Colonies formed independent states that defeated the British in the American Revolutionary War (1775–1783), gaining independence from the British Crown and establishing the United States of America as the first nation-state founded on Enlightenment principles of liberal democracy. American colonists objected to being taxed by the Parliament of Great Britain, a body in which they had no direct representation. Before the 1760s, Britain's American colonies had enjoyed a high level of autonomy in their internal affairs, which were locally governed by colonial legislatures. During the 1760s, however, the British Parliament passed a number of acts that were intended to bring the American colonies under more direct rule from the British metropole and increasingly intertwine the economies of the colonies with those of Brit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Saugus Iron Works National Historic Site

Saugus Iron Works National Historic Site is a National Historic Site about 10 miles (16 kilometers) northeast of Downtown Boston in Saugus, Massachusetts. It is the site of the first integrated ironworks in North America, founded by John Winthrop the Younger and in operation between 1646 and approximately 1670. It includes the reconstructed blast furnace, forge, rolling mill, shear, slitter and a quarter-ton trip hammer. The facility is powered by seven large waterwheels, some of which are rigged to work in tandem with huge wooden gears connecting them. It has a wharf to load the iron onto ocean-going vessels, as well as a large, restored 17th-century house. History During the 17th century, iron was used to manufacture a number of indispensable goods, including nails, horseshoes, cookware, tools, and weapons. The production of iron required a complex manufacturing process that could only be done by an industrial enterprise. This process was not available in North America durin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sterling Iron Works

The Sterling Iron Works owned by Peter Townsend was one of the first steel and iron manufacturers in the Thirteen Colonies and the first steel producer in the Province of New York. The company was most famous for forging the Hudson River Chain that kept the British Navy from sailing up the Hudson during the American Revolution, and served to protect the strategically important fort at West Point. The works were operational from 1761 to 1842. Initial ore discovery In 1750 the first discovery was made of a rich superficial deposit of iron ore at the south end of Sterling Mountain, in the town of Monroe, New York. In the following year, Ward & Colton erected at the outlet of mine and Sterling Pond, in the extreme southern part of Warwick, near the Monroe line, a charcoal blast-furnace, which was the first in Warwick. These works were called the Sterling Iron-works, honoring General William Alexander known as Lord Stirling, the owner of the land, and later an officer in the Revolutiona ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Principio Furnace

Principio Furnace and village is in Cecil County, Maryland, 4 miles (6.4 km) northeast of Havre de Grace, MD. The Principio Iron Works were started here in 1719 by Joseph Farmer with British capital and an ironmaster, John England, who made it one of the most successful in the colonial ironworks by the 1740s, producing pig iron for sale in London. Thomas Russell, Jr., England's successor, produced cannonballs for the Continental Army during the Revolution. The works were part of the (larger) Principio Company, whose other holdings included the Accokeek or Potomac Ironworks on the land of George Washington's father, Augustine Washington (north of Ferry Farm near Fredericksburg, Virginia). This works was developed by the ironmaster England originally as a source of iron ore. As early as 1726, it may have included a cold blast charcoal furnace. Accokeek/Potomac served as the headquarters of the Principio Company until it was closed sometime in the mid-1750s. The Maryland works ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alliance Furnace

Alliance Furnace, also known as Jacob's Creek Furnace and Alliance Iron Works, is a historic iron furnace located at Perry Township, Fayette County, Pennsylvania. It was built in 1789, and is a stone structure measuring 25 feet square and 15 feet high. Also on the property is a charcoal house measuring 40 feet by 25 feet by 20 feet. It was built as a blast furnace, placed in blast in 1792 and closed in 1802. ''Note:'' This includes It was added to the National Register of Historic Places The National Register of Historic Places (NRHP) is the United States federal government's official list of districts, sites, buildings, structures and objects deemed worthy of preservation for their historical significance or "great artistic ... in 1991. References Industrial buildings and structures on the National Register of Historic Places in Pennsylvania Industrial buildings completed in 1789 Buildings and structures in Fayette County, Pennsylvania Pennsylvania state ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cornwall Iron Furnace

Cornwall Iron Furnace is a designated National Historic Landmark that is administered by the Pennsylvania Historical and Museum Commission in Cornwall, Lebanon County, Pennsylvania in the United States. The furnace was a leading Pennsylvania iron producer from 1742 until it was shut down in 1883. The furnaces, support buildings and surrounding community have been preserved as a historical site and museum, providing a glimpse into Lebanon County's industrial past. The site is the only intact charcoal-burning iron blast furnace in its original plantation in the western hemisphere. Established by Peter Grubb in 1742, Cornwall Furnace was operated during the Revolution by his sons Curtis and Peter Jr. who were major arms providers to George Washington. Robert Coleman acquired Cornwall Furnace after the Revolution and became Pennsylvania's first millionaire. Ownership of the furnace and its surroundings was transferred to the Commonwealth of Pennsylvania in 1932. Overview Cornwa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Joanna Furnace Complex

The Joanna Furnace Complex was an iron furnace that operated from to in Robeson Township, Berks County, Pennsylvania. It was founded by Samuel Potts and Thomas Rutter III (grandson of Thomas Rutter) and named for Potts's wife Joanna.Charles Jacob, 1979, NRHP Nomination Form for Joanna Furnace ComplexEnter "public" for ID and "public" for password to access the site. The furnace and its associated buildings were listed as a historic district by the National Register of Historic Places in 1980. History After the Civil War ended, the charcoal-fired furnace was owned by Clement Grubb's son-in-law, L. Heber Smith, a former colonel who married Clement's daughter Ella Jane Brooke Grubb in 1868. It then passed through several hands before Smith took ownership, possibly after the war and before his marriage to Ella Jane. It is likely that the Grubbs assisted with the furnace's major technological upgrade in 1889, when his wife inherited her father's sizable estate that year. The fu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

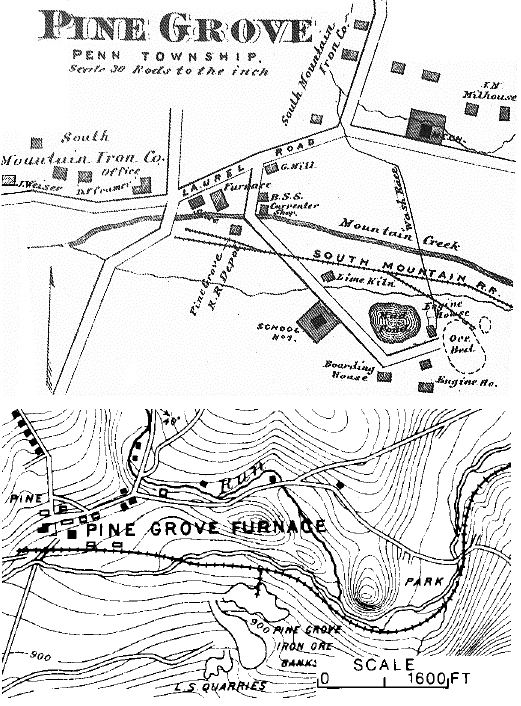

Pine Grove Iron Works

The Pine Grove Iron Works was a southcentral Pennsylvania smelting facility during the Industrial Revolution. The works is notable for remaining structures that are historical visitor attractions of Pine Grove Furnace State Park, including the furnace stack of the Pine Grove Furnace. The site was listed on the National Register of Historic Places on April 13, 1977 for its significance in architecture and industry. It includes seven contributing buildings, two structures, fourteen sites, and two objects. Geography The works occupied the small area around the furnace stack a "''quarter of a mile from the''" quarry.similarly-worded Franklin Institute journal of 1899)/ref> Notable geographic points near the works include the Mountain Creek distributary point for the furnace water race on the west, the wash race distributary point from Tom's Run (north), and the confluence of the furnace's water race with the creek (east). Also to the east and southeast were the railroad brid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Catoctin Furnace

Catoctin Furnace (also known as Catoctin Iron Furnace) is an historic iron forge located on Route 15 between Frederick and Thurmont in Catoctin Furnace, Maryland. Since it was closed in 1903, no forge has been at the site. History Catoctin Furnace was constructed in 1774 by four brothers Thomas, Baker, Roger and James Johnson to produce pig iron from locally mined hematite. In blast by 1776, the furnace provided ammunition (cannonballs) for the American Revolutionary War. Some sources state that it also provided cannon. They also state that iron from this furnace was (much later) used to make plates for the ; however that is considered unlikely by researchers. Slaves operated the furnace during this time. In 2023 a research project identified 41799 descendants of these slaves and is considering to notify them. The Johnson brothers owned the furnaces at the site at first collectively, and after 1793 singly, until 1811. Ultimately, three furnaces were built at the site, each ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |