|

Indentation Size Effect

The indentation size effect (ISE) is the observation that hardness tends to increase as the indent size decreases at small scales. When an indent (any small mark, but usually made with a special tool) is created during material testing, the hardness of the material is not constant. At the small scale, materials will actually be harder than at the macro-scale. For the conventional indentation size effect, the smaller the indentation, the larger the difference in hardness. The effect has been seen through nanoindentation and microindentation measurements at varying depths. Dislocations increase material hardness by increasing flow stress through dislocation blocking mechanisms. Materials contain statistically stored dislocations (SSD) which are created by homogeneous strain and are dependent upon the material and processing conditions. Geometrically necessary dislocations (GND) on the other hand are formed, in addition to the dislocations statistically present, to maintain continuit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Indentation Size Effect Fake Data

__FORCETOC__ In the written form of many languages, an indentation or indent is an empty space at the beginning of a line to signal the start of a new paragraph. Many computer languages have adopted this technique to designate "paragraphs" or other logical blocks in the program. For example, the following lines are indented, using between one and six spaces: This paragraph is indented by 1 space. This paragraph is indented by 3 spaces. This paragraph is indented by 6 spaces. In computer programming, the neologisms outdent, unindent and dedent are used to describe the reversal of the indentation process, realigning text with the page margin (or with previous, lesser, levels of indentation). In right-to-left languages (e.g. Hebrew and Arabic), indentation is used just the same, but from the right margin of the paper, where the line begins. Indentation in typesetting There are three main types of indentation, illustra ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hardness

In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation induced by either mechanical indentation or abrasion. In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as sodium and metallic tin, or wood and common plastics. Macroscopic hardness is generally characterized by strong intermolecular bonds, but the behavior of solid materials under force is complex; therefore, hardness can be measured in different ways, such as scratch hardness, indentation hardness, and rebound hardness. Hardness is dependent on ductility, elastic stiffness, plasticity, strain, strength, toughness, viscoelasticity, and viscosity. Common examples of hard matter are ceramics, concrete, certain metals, and superhard materials, which can be contrasted with soft matter. Measuring hardness There are three main types of hardness measurements: ''scratch' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Annual Review Of Materials Research

The ''Annual Review of Materials Research'' is a peer-reviewed journal that publishes review articles about materials science. It has been published by the nonprofit Annual Reviews since 1971, when it was first released under the title the ''Annual Review of Materials Science''. Three people have served as editors, with the current editor David R. Clarke serving in the position since 2001. It has an impact factor of 13.972 as of 2022. History The ''Annual Review of Materials Science'' was first published in 1971 by the nonprofit publisher Annual Reviews, making it their sixteenth journal. Its first editor was Robert Huggins. In 2001, its name was changed to the current form, the ''Annual Review of Materials Research''. The name change was intended "to better reflect the broad appeal that materials research has for so many diverse groups of scientists and not simply those who identify themselves with the academic discipline of materials science." As of 2020, it was published bo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanoindentation

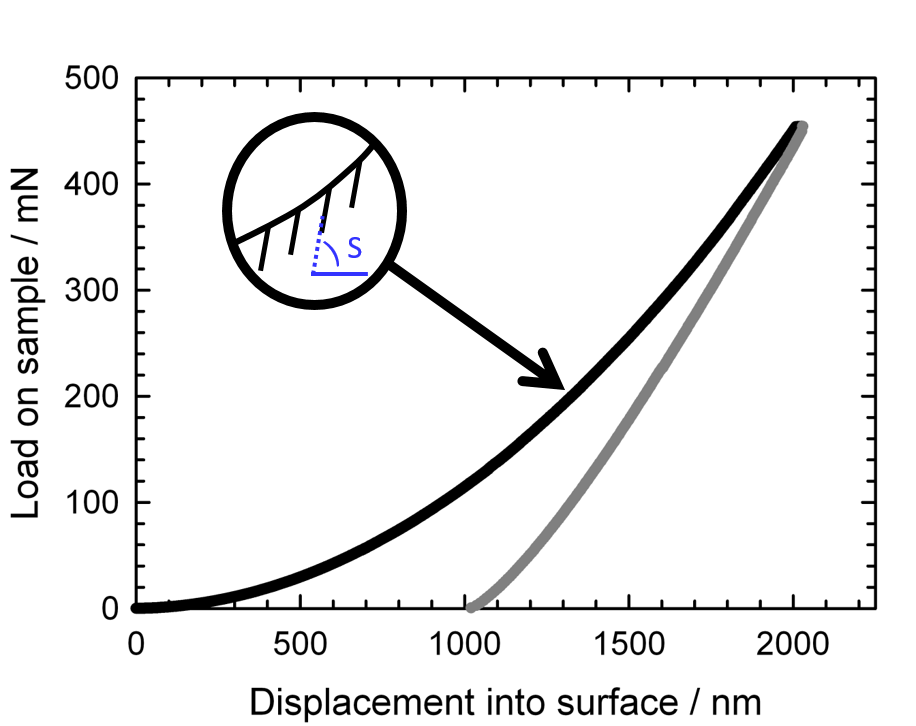

Nanoindentation, also called instrumented indentation testing, is a variety of indentation hardness tests applied to small volumes. Indentation is perhaps the most commonly applied means of testing the mechanical properties of materials. The nanoindentation technique was developed in the mid-1970s to measure the hardness of small volumes of material. Background In a traditional indentation test (macro or micro indentation), a hard tip whose mechanical properties are known (frequently made of a very hard material like diamond) is pressed into a sample whose properties are unknown. The load placed on the indenter tip is increased as the tip penetrates further into the specimen and soon reaches a user-defined value. At this point, the load may be held constant for a period or removed. The area of the residual indentation in the sample is measured and the hardness, H, is defined as the maximum load, P_, divided by the residual indentation area, A_r: :H=\frac . For most techniques, t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dislocation

In materials science, a dislocation or Taylor's dislocation is a linear crystallographic defect or irregularity within a crystal structure that contains an abrupt change in the arrangement of atoms. The movement of dislocations allow atoms to slide over each other at low stress levels and is known as ''glide'' or slip. The crystalline order is restored on either side of a ''glide dislocation'' but the atoms on one side have moved by one position. The crystalline order is not fully restored with a ''partial dislocation''. A dislocation defines the boundary between ''slipped'' and ''unslipped'' regions of material and as a result, must either form a complete loop, intersect other dislocations or defects, or extend to the edges of the crystal. A dislocation can be characterised by the distance and direction of movement it causes to atoms which is defined by the Burgers vector. Plastic deformation of a material occurs by the creation and movement of many dislocations. The number and a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flow Stress

In materials science the flow stress, typically denoted as Yf (or \sigma_\text), is defined as the instantaneous value of stress required to continue plastically deforming a material - to keep it flowing. It is most commonly, though not exclusively, used in reference to metals. On a stress-strain curve, the flow stress can be found anywhere within the plastic regime; more explicitly, a flow stress can be found for any value of strain between and including yield point (\sigma_\text) and excluding fracture (\sigma_\text): \sigma_\text \leq Y_\text < \sigma_\text. The flow stress changes as deformation proceeds and usually increases as strain accumulates due to , although the flow stress could decrease due to any recovery process. In continuum ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Geometrically Necessary Dislocations

Geometrically necessary dislocations are like-signed dislocations needed to accommodate for plastic bending in a crystalline material. They are present when a material's plastic deformation is accompanied by internal plastic strain gradients. They are in contrast to statistically stored dislocations, with statistics of equal positive and negative signs, which arise during plastic flow from multiplication processes like the Frank-Read source. Dislocations in crystalline materials Statistically stored dislocations As straining progresses, the dislocation density increases and the dislocation mobility decreases during plastic flow. There are different ways through which dislocations can accumulate. Many of the dislocations are accumulated by multiplication, where dislocations encounters each other by chance. Dislocations stored in such progresses are called statistically stored dislocations, with corresponding density \rho_. In other words, they are dislocations evolved from rand ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Deformation (mechanics)

In physics, deformation is the continuum mechanics transformation of a body from a ''reference'' configuration to a ''current'' configuration. A configuration is a set containing the positions of all particles of the body. A deformation can occur because of external loads, intrinsic activity (e.g. muscle contraction), body forces (such as gravity or electromagnetic forces), or changes in temperature, moisture content, or chemical reactions, etc. Strain is related to deformation in terms of ''relative'' displacement of particles in the body that excludes rigid-body motions. Different equivalent choices may be made for the expression of a strain field depending on whether it is defined with respect to the initial or the final configuration of the body and on whether the metric tensor or its dual is considered. In a continuous body, a deformation field results from a stress field due to applied forces or because of some changes in the temperature field of the body. The rel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Geometrical Necessary Dislocations During Indent

Geometry (; ) is, with arithmetic, one of the oldest branches of mathematics. It is concerned with properties of space such as the distance, shape, size, and relative position of figures. A mathematician who works in the field of geometry is called a ''geometer''. Until the 19th century, geometry was almost exclusively devoted to Euclidean geometry, which includes the notions of point, line, plane, distance, angle, surface, and curve, as fundamental concepts. During the 19th century several discoveries enlarged dramatically the scope of geometry. One of the oldest such discoveries is Carl Friedrich Gauss' ("remarkable theorem") that asserts roughly that the Gaussian curvature of a surface is independent from any specific embedding in a Euclidean space. This implies that surfaces can be studied ''intrinsically'', that is, as stand-alone spaces, and has been expanded into the theory of manifolds and Riemannian geometry. Later in the 19th century, it appeared that geometries wit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plasticity (physics)

In physics and materials science, plasticity, also known as plastic deformation, is the ability of a solid material to undergo permanent Deformation (engineering), deformation, a non-reversible change of shape in response to applied forces. For example, a solid piece of metal being bent or pounded into a new shape displays plasticity as permanent changes occur within the material itself. In engineering, the transition from Elasticity (physics), elastic behavior to plastic behavior is known as Yield (engineering), yielding. Plastic deformation is observed in most materials, particularly metals, soils, Rock (geology), rocks, concrete, and foams. However, the physical mechanisms that cause plastic deformation can vary widely. At a crystalline scale, plasticity in metals is usually a consequence of dislocations. Such defects are relatively rare in most crystalline materials, but are numerous in some and part of their crystal structure; in such cases, plastic crystallinity can res ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hardness Tests

In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation induced by either mechanical indentation or abrasion. In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as sodium and metallic tin, or wood and common plastics. Macroscopic hardness is generally characterized by strong intermolecular bonds, but the behavior of solid materials under force is complex; therefore, hardness can be measured in different ways, such as scratch hardness, indentation hardness, and rebound hardness. Hardness is dependent on ductility, elastic stiffness, plasticity, strain, strength, toughness, viscoelasticity, and viscosity. Common examples of hard matter are ceramics, concrete, certain metals, and superhard materials, which can be contrasted with soft matter. Measuring hardness There are three main types of hardness measurements: ''scratch'', ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |