|

Hazard Analysis And Risk-based Preventive Controls

Hazard analysis and risk-based preventive controls or HARPC is a successor to the Hazard analysis and critical control points (HACCP) food safety system, mandated in the United States by the FDA Food Safety Modernization Act (FSMA) of 2010. Preventive control systems emphasize prevention of risks before they occur rather than their detection after they occur. The FDA released the rules in the Federal Register from September 2015 onwards. The first release of rules addressed Preventive Controls for Human Food and Preventive Controls for Foods for Animals. The Produce Safety Final Rule, the Foreign Supplier Verification Programs (FSVP) Final Rule and the Accredited Third-Party Certification Final Rule were issued on November 13, 2015. The Sanitary Transportation of Human and Animal Food final rule was issued on April 6, 2016, and the Mitigation Strategies To Protect Food Against Intentional Adulteration (Food Defense) final rule was issued on May 27, 2016. Scope All food companies ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Hazard Analysis And Critical Control Points

Hazard analysis and critical control points, or HACCP (), is a systematic preventive approach to food safety from biological hazard, biological, chemical hazard, chemical, and physical hazards in production processes that can cause the finished product to be unsafe and designs measures to reduce these risks to a safe level. In this manner, HACCP attempts to avoid hazards rather than attempting to inspect finished products for the effects of those hazards. The HACCP system can be used at all stages of a food chain, from food processing, food production and preparation processes including packaging, distribution, etc. The United States Food and Drug Administration, Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA) require mandatory HACCP programs for juice and meat as an effective approach to food safety and protecting public health. Meat HACCP systems are regulated by the USDA, while seafood and juice are regulated by the FDA. All other food ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Failure Mode, Effects, And Criticality Analysis

Failure mode effects and criticality analysis (FMECA) is an extension of failure mode and effects analysis (FMEA). FMEA is a bottom-up, inductive analytical method which may be performed at either the functional or piece-part level. FMECA extends FMEA by including a ''criticality analysis'', which is used to chart the probability of failure modes against the severity of their consequences. The result highlights failure modes with relatively high probability and severity of consequences, allowing remedial effort to be directed where it will produce the greatest value. FMECA tends to be preferred over FMEA in space and NATO military applications, while various forms of FMEA predominate in other industries. History FMECA was originally developed in the 1940s by the U.S military, which published MIL–P–1629 in 1949. By the early 1960s, contractors for the U.S. National Aeronautics and Space Administration (NASA) were using variations of FMECA under a variety of names. I ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Total Quality Management

Total quality management (TQM) is an organization-wide effort to "install and make a permanent climate where employees continuously improve their ability to provide on-demand products and services that customers will find of particular value." ''Total'' emphasizes that departments in addition to production (for example sales and marketing, accounting and finance, engineering and design) are obligated to improve their operations; ''management'' emphasizes that executives are obligated to actively manage quality through funding, training, staffing, and goal setting. While there is no widely agreed-upon approach, TQM efforts typically draw heavily on the previously developed tools and techniques of quality control. TQM received widespread attention during the late 1980s and early 1990s before being overshadowed by ISO 9000, Lean manufacturing, and Six Sigma. History In the late 1970s and early 1980s, the developed countries of North America and Western Europe suffered economic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Codex Alimentarius

The is a collection of internationally recognized standards, codes of practice, guidelines, and other recommendations published by the Food and Agriculture Organization (FAO) and World Health Organization (WHO) of the United Nations relating to food, food production, food labeling, and food safety. History and governance Its name is derived from the Codex Alimentarius Austriacus. Its texts are developed and maintained by the Codex Alimentarius Commission (CAC), a body established in early November 1961 by the Food and Agriculture Organization of the United Nations (FAO). Joined by the World Health Organization (WHO) in June 1962, the CAC held its first session in Rome in October 1963. The Commission's main goals are to protect the health of consumers, to facilitate international trade, and to ensure fair practices in the international food trade.Understanding Codex', World Health Organization and the Food and Agriculture Organization of the United Nations (5th ed. Sept. 2018) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Sanitation Standard Operating Procedures

Sanitation Standard Operating Procedures is the common name, in the United States, given to the sanitation procedures in food production plants which are required by the Food Safety and Inspection Service of the USDA and regulated by 9 CFR part 416 in conjunction with 21 CFR part 178.1010. It is considered one of the prerequisite programs of HACCP. SSOPs are generally documented steps that must be followed to ensure adequate cleaning of product contact and non-product surfaces. These cleaning procedures must be detailed enough to make certain that adulteration of product will not occur. All HACCP plans require SSOPs to be documented and reviewed periodically to incorporate changes to the physical plant. This reviewing procedure can take on many forms, from annual formal reviews to random reviews, but any review should be done by "responsible educated management". As these procedures can make their way into the public record if there are serious failures, they might be looked ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

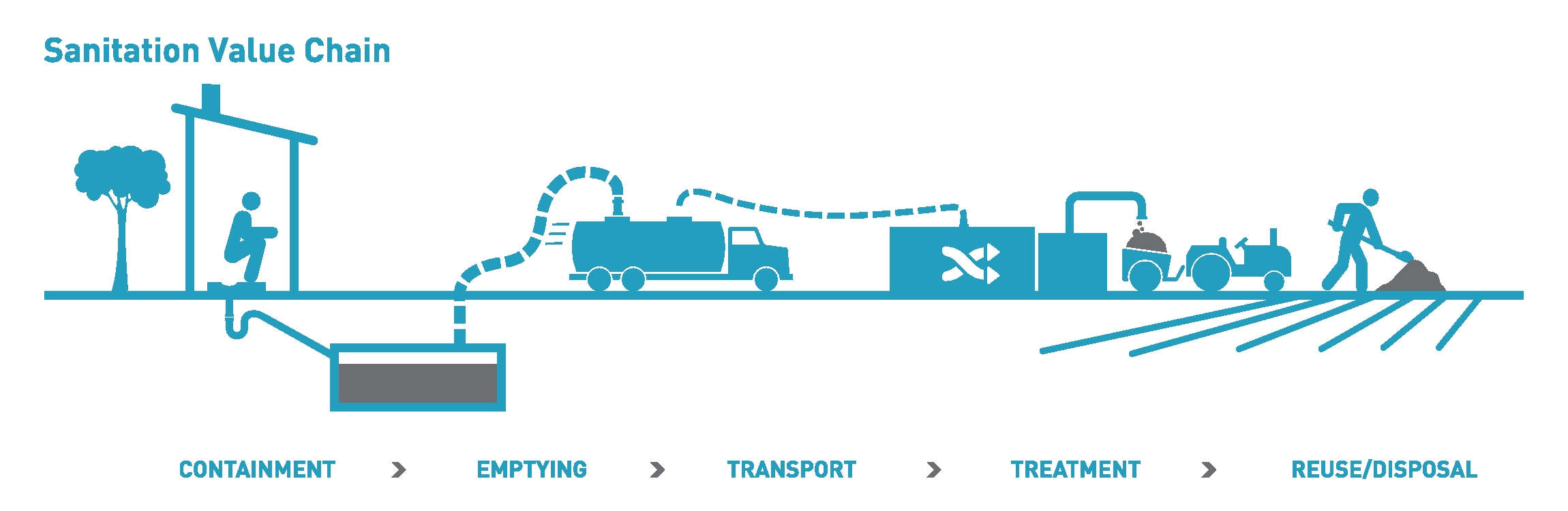

Sanitation

Sanitation refers to public health conditions related to clean drinking water and treatment and disposal of human excreta and sewage. Preventing human contact with feces is part of sanitation, as is hand washing with soap. Sanitation systems aim to protect human health by providing a clean environment that will stop the transmission of disease, especially through the fecal–oral route.SuSanA (2008)Towards more sustainable sanitation solutions . Sustainable Sanitation Alliance (SuSanA) For example, diarrhea, a main cause of malnutrition and stunted growth in children, can be reduced through adequate sanitation. There are many other diseases which are easily transmitted in communities that have low levels of sanitation, such as ascariasis (a type of intestinal worm infection or helminthiasis), cholera, hepatitis, polio, schistosomiasis, and trachoma, to name just a few. A range of sanitation technologies and approaches exists. Some examples are community-led total sanita ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Hygiene

Hygiene is a set of practices performed to preserve health. According to the World Health Organization (WHO), "Hygiene refers to conditions and practices that help to maintain health and prevent the spread of diseases." Personal hygiene refers to maintaining the body's cleanliness. Hygiene activities can be grouped into the following: home and everyday hygiene, personal hygiene, medical hygiene, sleep hygiene, and Food safety, food hygiene. Home and every day hygiene includes hand washing, respiratory hygiene, food hygiene at home, hygiene in the kitchen, hygiene in the bathroom, laundry hygiene, and medical hygiene at home. And also environmental hygiene in the society to prevent all kinds of bacterias from penetrating into our homes. Many people equate hygiene with "cleanliness", but hygiene is a broad term. It includes such personal habit choices as how frequently to take a shower or bath, wash hands, trim Nail (anatomy), fingernails, and wash clothes. It also includes atte ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Hazop

A hazard and operability study (HAZOP) is a structured and systematic examination of a complex system, usually a process facility, in order to identify hazards to personnel, equipment or the environment, as well as operability problems that could affect operations efficiency. It is the foremost hazard identification tool in the domain of process safety. The intention of performing a HAZOP is to review the design to pick up design and engineering issues that may otherwise not have been found. The technique is based on breaking the overall complex design of the process into a number of simpler sections called ''nodes'' which are then individually reviewed. It is carried out by a suitably experienced multi-disciplinary team during a series of meetings. The HAZOP technique is qualitative and aims to stimulate the imagination of participants to identify potential hazards and operability problems. Structure and direction are given to the review process by applying standardized guideword ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Hazard Analysis

A hazard analysis is one of many methods that may be used to assess risk. At its core, the process entails describing a system object (such as a person or machine) that intends to conduct some activity. During the performance of that activity, an adverse event (referred to as a “ factor”) may be encountered that could cause or contribute to an occurrence (mishap, incident, accident). Finally, that occurrence will result in some outcome that may be measured in terms of the degree of loss or harm. This outcome may be measured on a continuous scale, such as an amount of monetary loss, or the outcomes may be categorized into various levels of severity. A Simple Hazard Analysis The first step in hazard analysis is to identify the hazards. If an automobile is an object performing an activity such as driving over a bridge, and that bridge may become icy, then an icy bridge might be identified as a hazard. If this hazard is encountered, it could cause or contribute to the occur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

ISO 22000

ISO 22000 is a food safety management system by the International Organization for Standardization (ISO) which is outcome focused, providing requirements for any organization in the food industry with objective to help to improve overall performance in food safety. These standards are intended to ensure safety in the global food supply chain. The standards involve the overall guidelines for food safety management and also focuses on traceability in the feed and food chain. Food safety Food safety refers to all those hazards, whether chronic or , that may make food injurious to the health of the consumer. ISO 22000 standard ISO 22000 is the most popular voluntary food safety international standard in the food industry with 51,535 total number of sites (as per thISO Survey 2022. The ISO 22000 family are international voluntary consensus standards which align to Good Standardization Practices (GSP) and the World Trade Organization (WTO) Principles for the Development of Internation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Fast Food Restaurant

A fast-food restaurant, also known as a quick-service restaurant (QSR) within the industry, is a specific type of restaurant that serves fast food, fast-food cuisine and has minimal Foodservice#Table service, table service. The food served in fast-food restaurants is typically part of a "Western pattern diet, meat-sweet diet", offered from a limited menu, cooked in bulk in advance and kept hot, finished and packaged to order, and usually available for Take-out, take away, though seating may be provided. Fast-food restaurants are typically part of a chain store#Restaurant chains, restaurant chain or Franchising, franchise operation that provides standardized ingredients and/or partially prepared foods and supplies to each restaurant through controlled supply channels. The term "fast food" was recognized in a dictionary by Merriam–Webster in 1951. While the first fast-food restaurant in the United States was a White Castle (restaurant), White Castle in 1921, fast-food resta ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |