|

Hydrogen Damage

Hydrogen damage is the generic name given to a large number of metal degradation processes due to interaction with hydrogen atoms. Note that molecular gaseous hydrogen does not have the same effect as atoms or ions released into solid solution in the metal. Creation of internal defects Carbon steels exposed to hydrogen at high temperatures experience high temperature hydrogen attack which leads to internal decarburization and weakening. Blistering Atomic hydrogen diffusing through metals may collect at internal defects like inclusions and laminations and form molecular hydrogen. High pressures may be built up at such locations due to continued absorption of hydrogen leading to blister formation, growth and eventual bursting of the blister. Such hydrogen induced blister cracking has been observed in steels, aluminium alloys, titanium alloys and nuclear structural materials. Metals with low hydrogen solubility (such as tungsten) are more susceptible to blister formation. While i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metal

A metal (from Greek μέταλλον ''métallon'', "mine, quarry, metal") is a material that, when freshly prepared, polished, or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. Metals are typically ductile (can be drawn into wires) and malleable (they can be hammered into thin sheets). These properties are the result of the ''metallic bond'' between the atoms or molecules of the metal. A metal may be a chemical element such as iron; an alloy such as stainless steel; or a molecular compound such as polymeric sulfur nitride. In physics, a metal is generally regarded as any substance capable of conducting electricity at a temperature of absolute zero. Many elements and compounds that are not normally classified as metals become metallic under high pressures. For example, the nonmetal iodine gradually becomes a metal at a pressure of between 40 and 170 thousand times atmospheric pressure. Equally, some materials regarded as metals ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrogen

Hydrogen is the chemical element with the symbol H and atomic number 1. Hydrogen is the lightest element. At standard conditions hydrogen is a gas of diatomic molecules having the formula . It is colorless, odorless, tasteless, non-toxic, and highly combustible. Hydrogen is the most abundant chemical substance in the universe, constituting roughly 75% of all normal matter.However, most of the universe's mass is not in the form of baryons or chemical elements. See dark matter and dark energy. Stars such as the Sun are mainly composed of hydrogen in the plasma state. Most of the hydrogen on Earth exists in molecular forms such as water and organic compounds. For the most common isotope of hydrogen (symbol 1H) each atom has one proton, one electron, and no neutrons. In the early universe, the formation of protons, the nuclei of hydrogen, occurred during the first second after the Big Bang. The emergence of neutral hydrogen atoms throughout the universe occurred about 370,000 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

High Temperature Hydrogen Attack

High temperature hydrogen attack (HTHA), also called hot hydrogen attack or methane reaction, is a problem which concerns steels operating at elevated temperatures (typically above ) in hydrogen-rich atmospheres, such as refineries, petrochemical and other chemical facilities and, possibly, high pressure steam boilers. It is not to be confused with hydrogen embrittlement. If a steel is exposed to very hot hydrogen, the high temperature enables the hydrogen molecules to dissociate and to diffuse into the alloy as individual ''diffusible'' atoms. There are two stages to the damage: # First, dissolved carbon in the steel reacts with the surface hydrogen and escapes into the gas as methane. This leads to superficial decarburization and a loss of strength in the surface. Initially, the damage is not visible. # Second, the reduction in the concentration of dissolved carbon creates a driving force which dissolves the carbides in the steel. This leads to a loss of strength deeper in the ste ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Decarburization

Decarburization (or decarbonization) is the process of decreasing carbon content, which is the opposite of carburization. The term is typically used in metallurgy, describing the decrease of the content of carbon in metals (usually steel). Decarburization occurs when the metal is heated to temperatures of 700 °C or above when carbon in the metal reacts with gases containing oxygen or hydrogen. The removal of carbon removes hard carbide phases resulting in a softening of the metal, primarily at the surfaces which are in contact with the decarburizing gas. Decarburization can be either advantageous or detrimental, depending on the application for which the metal will be used. It is thus both something that can be done intentionally as a step in a manufacturing process, or something that happens as a side effect of a process (such as rolling) and must be either prevented or later reversed (such as via a carburization step). The decarburization mechanism can be described as t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

American Society For Metals

ASM International, formerly known as the American Society for Metals, is an association of materials-centric engineers and scientists. ASM provides several information resources, including technical books, various digital databases, and ASM Handbooks, a series of reference books that cover a range of topics and contain peer-reviewed information. These handbooks are recognized as a standard reference in the field of materials science. Examples of topics covered by the ASM Handbooks are mechanical properties of metals, corrosion studies, failure analysis, materials characterization, and much more. Other publications include technical journals such as Journal of Thermal Spray Technology and Journal of Materials Engineering and Performance. ASM also hosts numerous international conferences each year, including ASM's Annual Meeting: International Materials, Applications, and Technologies Conference and Exposition (IMAT). Six affiliate societies focused on specific areas of materia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

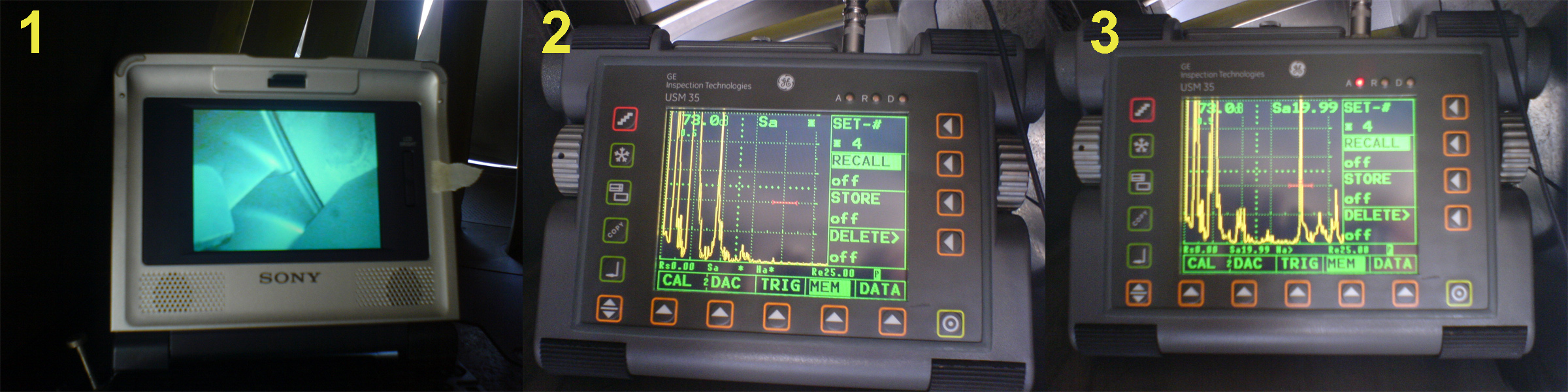

Ultrasonic Echo Attenuation

Ultrasonic testing (UT) is a family of non-destructive testing techniques based on the propagation of ultrasonic waves in the object or material tested. In most common UT applications, very short ultrasonic pulse-waves with center frequencies ranging from 0.1-15 MHz, and occasionally up to 50 MHz, are transmitted into materials to detect internal flaws or to characterize materials. A common example is ultrasonic thickness measurement, which tests the thickness of the test object, for example, to monitor pipework corrosion. Ultrasonic testing is often performed on steel and other metals and alloys, though it can also be used on concrete, wood and composites, albeit with less resolution. It is used in many industries including steel and aluminium construction, metallurgy, manufacturing, aerospace, automotive and other transportation sectors. History The first efforts to use ultrasonic testing to detect flaws in solid material occurred in the 1930s.''Nondestructive F ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Backscatter

In physics, backscatter (or backscattering) is the reflection of waves, particles, or signals back to the direction from which they came. It is usually a diffuse reflection due to scattering, as opposed to specular reflection as from a mirror, although specular backscattering can occur at normal incidence with a surface. Backscattering has important applications in astronomy, photography, and medical ultrasonography. The opposite effect is forward scatter, e.g. when a translucent material like a cloud diffuses sunlight, giving soft light. Backscatter of waves in physical space Backscattering can occur in quite different physical situations, where the incoming waves or particles are deflected from their original direction by different mechanisms: *Diffuse reflection from large particles and Mie scattering, causing alpenglow and gegenschein, and showing up in weather radar; * Inelastic collisions between electromagnetic waves and the transmitting medium (Brillouin scattering and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Creeping Waves

According to the principle of diffraction, when a wave front passes an obstruction, it spreads out into the shadowed space. A creeping wave in electromagnetism or acoustics is the wave that is diffracted around the shadowed surface of a smooth body such as a sphere. Creeping waves greatly extend the ground wave propagation of long wavelength (low frequency) radio. They also cause both of a person's ears to hear a sound, rather than only the ear on the side of the head facing the origin of the sound. In radar ranging, the creeping wave return appears to come from behind the target. Vladimir Fock made important contributions to the understanding and calculation of creeping waves. They are described by Airy function In the physical sciences, the Airy function (or Airy function of the first kind) is a special function named after the British astronomer George Biddell Airy (1801–1892). The function and the related function , are linearly independent solutio ...s. Electromagn ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Time Of Flight Diffraction Ultrasonics

Time-of-flight diffraction (TOFD) method of ultrasonic testing is a sensitive and accurate method for the nondestructive testing of welds for defects. TOFD originated from tip diffraction techniques which were first published by Silk and Liddington in 1975 which paved the way for TOFD. Later works on this technique are given in a number of sources which include Harumi et al. (1989), Avioli et al. (1991), and Bray and Stanley (1997). Bray and Stanley (1997) summarized TOFD as tip-diffraction techniques which utilized the principle that the tips of a crack when struck by a wave will diffract the signals back to the other location on the surface. The depth of these tips can be determined from the diffracted energy. TOFD was invented in the UK in the 1970s initially as a research tool. The use of TOFD enabled crack sizes to be measured more accurately, so that expensive components could be kept in operation as long as possible with minimal risk of failure. Principle of operation M ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metallography

Metallography is the study of the physical structure and components of metals, by using microscopy. Ceramic and polymeric materials may also be prepared using metallographic techniques, hence the terms ceramography, plastography and, collectively, materialography. Preparing metallographic specimens The surface of a metallographic specimen is prepared by various methods of grinding, polishing, and etching. After preparation, it is often analyzed using optical or electron microscopy. Using only metallographic techniques, a skilled technician can identify alloys and predict material properties. Mechanical preparation is the most common preparation method. Successively finer abrasive particles are used to remove material from the sample surface until the desired surface quality is achieved. Many different machines are available for doing this grinding and polishing, which are able to meet different demands for quality, capacity, and reproducibility. A systematic preparation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microcrack

Fracture is the separation of an object or material into two or more pieces under the action of stress. The fracture of a solid usually occurs due to the development of certain displacement discontinuity surfaces within the solid. If a displacement develops perpendicular to the surface, it is called a normal tensile crack or simply a crack; if a displacement develops tangentially, it is called a shear crack, slip band or dislocation. Brittle fractures occur with no apparent deformation before fracture. Ductile fractures occur after visible deformation. Fracture strength, or breaking strength, is the stress when a specimen fails or fractures. The detailed understanding of how a fracture occurs and develops in materials is the object of fracture mechanics. Strength Fracture strength, also known as breaking strength, is the stress at which a specimen fails via fracture. This is usually determined for a given specimen by a tensile test, which charts the stress–strain cu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Macro Cracks

Macro (or MACRO) may refer to: Science and technology * Macroscopic, subjects visible to the eye * Macro photography, a type of close-up photography * Image macro, a picture with text superimposed * Monopole, Astrophysics and Cosmic Ray Observatory (MACRO), a particle physics experiment * Macronutrients, classes of chemical compounds humans consume in the largest quantities (i.e., proteins, fats, and carbohydrates) Sociology * Macrosociology, sociology at the national level * Macroeconomics, economics at a higher level, above individual markets * Macromanagement in business, the idea of "managing from afar" Computing * Macro (computer science), a set of instructions that is represented in an abbreviated format * Macro instruction, a statement, typically for an assembler, that invokes a macro definition to generate a sequence of instructions or other outputs * Macro key, a key found on some keyboards, particularly older keyboards. Media and entertainment * Macromanagement (game ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |