|

Hayes-Wheelwright Matrix

The Hayes-Wheelwright Matrix, also known as the product-process matrix, is a tool to analyze the fit between a chosen product positioning and manufacturing process. The first dimension of the matrix, the product lifecycle, is a measure of the maturity of the product or market. It ranges from highly customized products with low volumes, to highly standardized products with high volume. The second dimension, the process lifecycle, is a measure of the maturity of the manufacturing process. It ranges from highly manual processes with high unit costs (job shop) to highly automated process with low unit costs ( continuous flow). Companies can occupy any position in the matrix. However, according to the framework, they can only be successful if their product lifecycle stage is consistent with their process lifecycle stage. It was developed by Robert H. Hayes and Steven C. Wheelwright and published in the ''Harvard Business Review'' in 1979, in the articles titled "''Link Manufacturin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Printed Circuit Board

A printed circuit board (PCB; also printed wiring board or PWB) is a medium used in Electrical engineering, electrical and electronic engineering to connect electronic components to one another in a controlled manner. It takes the form of a Lamination, laminated sandwich structure of conductive and insulating layers: each of the conductive layers is designed with an artwork pattern of traces, planes and other features (similar to wires on a flat surface) Chemical milling, etched from one or more sheet layers of copper Lamination, laminated onto and/or between sheet layers of a Insulator (electricity), non-conductive substrate. Electrical components may be fixed to conductive pads on the outer layers in the shape designed to accept the component's terminals, generally by means of soldering, to both electrically connect and mechanically fasten them to it. Another manufacturing process adds Via (electronics), vias: plated-through holes that allow interconnections between layers. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Product Lifecycle Management

In industry, Product Lifecycle Management (PLM) is the process of managing the entire lifecycle of a product from its inception through the engineering, design and manufacture, as well as the service and disposal of manufactured products. PLM integrates people, data, processes and business systems and provides a product information backbone for companies and their extended enterprises. History The inspiration for the burgeoning business process now known as PLM came from American Motors Corporation (AMC). The automaker was looking for a way to speed up its product development process to compete better against its larger competitors in 1985, according to François Castaing, Vice President for Product Engineering and Development. Lacking the "massive budgets of General Motors, Ford, and foreign competitors … AMC placed R&D emphasis on bolstering the product lifecycle of its prime products (particularly Jeeps)." After introducing its compact Jeep Cherokee (XJ), the vehicle th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Management Cybernetics

Management cybernetics is concerned with the application of cybernetics to management and organizations. "Management cybernetics" was first introduced by Stafford Beer in the late 1950s and introduces the various mechanisms of self-regulation applied by and to organizational settings, as seen through a cybernetics perspective. Beer developed the theory through a combination of practical applications and a series of influential books. The practical applications involved steel production, publishing and operations research in a large variety of different industries. Some consider that the full flowering of management cybernetics is represented in Beer's books. However, learning continues (see below). Research into operations As practiced by Beer, research into operations involved multidisciplinary teams seeking practical assistance for difficult managerial issues. It often involved the development of models borrowed from basic sciences and put into an isomorphic relationships with ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brand Management

In marketing, brand management begins with an analysis on how a brand is currently perceived in the market, proceeds to planning how the brand should be perceived if it is to achieve its objectives and continues with ensuring that the brand is perceived as planned and secures its objectives. Developing a good relationship with target markets is essential for brand management. Tangible elements of brand management include the product itself; its look, price, and packaging, etc. The intangible elements are the experiences that the target markets share with the brand, and also the relationships they have with the brand. A brand manager would oversee all aspects of the consumer's brand association as well as relationships with members of the supply chain. Definitions In 2001, Hislop defined branding as "the process of creating a relationship or a connection between a company's product and emotional perception of the customer for the purpose of generating segregation among competiti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Continuous Production

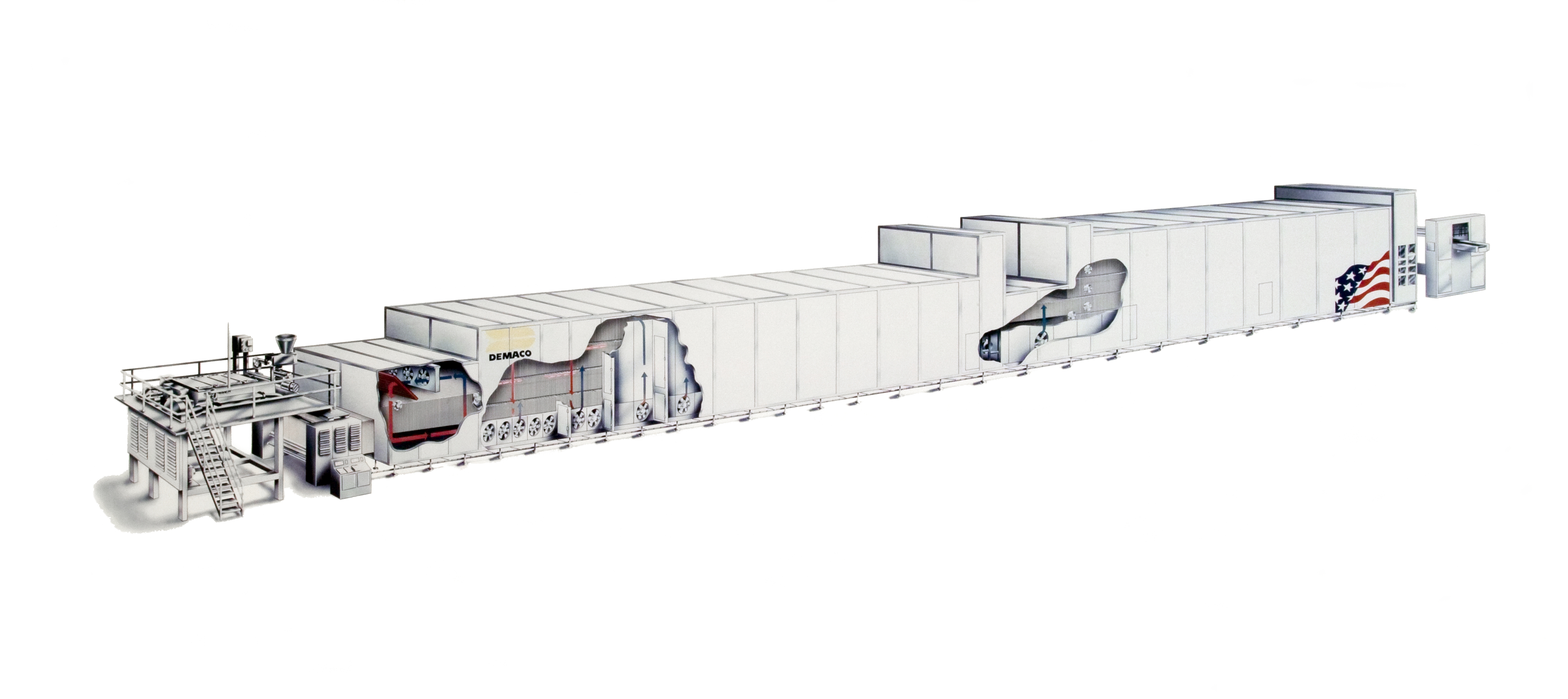

Continuous production is a flow production method used to manufacture, produce, or process materials without interruption. Continuous production is called a continuous process or a continuous flow process because the materials, either dry bulk or fluids that are being processed are continuously in motion, undergoing chemical reactions or subject to mechanical or heat treatment. Continuous processing is contrasted with batch production. Continuous usually means operating 24 hours per day, seven days per week with infrequent maintenance shutdowns, such as semi-annual or annual. Some chemical plants can operate for more than one to two years without a shutdown. Blast furnaces can run from four to ten years without stopping. Common processes Some common continuous processes are the following: * Oil refining *Chemicals *Synthetic fibers *Fertilizers *Pulp and paper *Blast furnace (iron) *Metal smelting *Power stations *Natural gas processing *Sanitary waste water treatment *Con ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Batch Processing

Computerized batch processing is a method of running software programs called jobs in batches automatically. While users are required to submit the jobs, no other interaction by the user is required to process the batch. Batches may automatically be run at scheduled times as well as being run contingent on the availability of computer resources. History The term "batch processing" originates in the traditional classification of methods of production as job production (one-off production), batch production (production of a "batch" of multiple items at once, one stage at a time), and flow production (mass production, all stages in process at once). Early history Early computers were capable of running only one program at a time. Each user had sole control of the machine for a scheduled period of time. They would arrive at the computer with program and data, often on punched paper cards and magnetic or paper tape, and would load their program, run and debug it, and carry off their ou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Job Shop

Job shops are typically small manufacturing systems that handle job production, that is, custom/bespoke or semi-custom/bespoke manufacturing processes such as small to medium-size customer orders or batch jobs. Job shops typically move on to different jobs (possibly with different customers) when each job is completed. Job shops machines are aggregated in shops by the nature of skills and technological processes involved, each shop therefore may contain different machines, which gives this production system processing flexibility, since jobs are not necessarily constrained to a single machine. In computer science the problem of job shop scheduling is considered strongly NP-hard. A typical example would be a machine shop, which may make parts for local industrial machinery, farm machinery and implements, boats and ships, or even batches of specialized components for the aircraft industry. Other types of common job shops are grinding, honing, jig-boring, gear manufacturing, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strategic Management

In the field of management, strategic management involves the formulation and implementation of the major goals and initiatives taken by an organization's managers on behalf of stakeholders, based on consideration of Resource management, resources and an assessment of the internal and external Market environment, environments in which the organization operates.qn, date=June 2018 Strategic management provides overall direction to an enterprise and involves specifying the organization's goal, objectives, developing policy, policies and plans to achieve those objectives, and then allocating resources to implement the plans. Academics and practicing managers have developed numerous models and frameworks to assist in strategic decision-making in the context of complex environments and competitive dynamics. Strategic management is not static in nature; the models can include a feedback, feedback loop to monitor execution and to inform the next round of planning. Michael Porter identif ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lean Manufacturing

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to demand by only supplying goods which have been ordered and focuses on efficiency, productivity (with a commitment to continuous improvement) and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow and throughput times by further eliminating activities which do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service. Lean manufacturing is particularly related to the operational model implemented in the post-war 1950s and 1960s by the Japa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Just-in-time Manufacturing

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to demand by only supplying goods which have been ordered and focuses on efficiency, productivity (with a commitment to continuous improvement) and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow and throughput times by further eliminating activities which do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service. Lean manufacturing is particularly related to the operational model implemented in the post-war In Western usage, the ph ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flexible Manufacturing System

A flexible manufacturing system (FMS) is a manufacturing system in which there is some amount of flexibility that allows the system to react in case of changes, whether predicted or unpredicted. This flexibility is generally considered to fall into two categories, which both contain numerous subcategories. The first category is called as ''Routing Flexibility'' which covers the system's ability to be changed to produce new product types, and ability to change the order of operations executed on a part. The second category is called ''Machine Flexibility'' which consists of the ability to use multiple machines to perform the same operation on a part, as well as the system's ability to absorb large-scale changes, such as in volume, capacity, or capability. Most FMS consist of three main systems: 1) The "Work Machines" which are often automated "CNC machines" are connected by 2) By a "Material handling" system to optimize parts flow and 3) The "Central Control Computer" which ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |