|

HRSG

A heat recovery steam generator (''HRSG'') is an energy recovery heat exchanger that recovers heat from a hot gas stream, such as a combustion turbine or other waste gas stream. It produces steam that can be used in a process (cogeneration) or used to drive a steam turbine ( combined cycle). HRSGs HRSGs consist of four major components: the economizer, evaporator, superheater and water preheater . The different components are put together to meet the operating requirements of the unit. See the attached illustration of a Modular HRSG General Arrangement. Modular HRSGs can be categorized by a number of ways such as direction of exhaust gases flow or number of pressure levels. Based on the flow of exhaust gases, HRSGs are categorized into vertical and horizontal types. In horizontal type HRSGs, exhaust gas flows horizontally over vertical tubes whereas in vertical type HRSGs, exhaust gas flow vertically over horizontal tubes. Based on pressure levels, HRSGs can be categorized into ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

HRSG Cycle

A heat recovery steam generator (''HRSG'') is an energy recovery heat exchanger that recovers heat from a hot gas stream, such as a combustion turbine or other waste gas stream. It produces steam that can be used in a process (cogeneration) or used to drive a steam turbine (combined cycle). HRSGs HRSGs consist of four major components: the economizer, evaporator, superheater and water preheater . The different components are put together to meet the operating requirements of the unit. See the attached illustration of a Modular HRSG General Arrangement. Modular HRSGs can be categorized by a number of ways such as direction of exhaust gases flow or number of pressure levels. Based on the flow of exhaust gases, HRSGs are categorized into vertical and horizontal types. In horizontal type HRSGs, exhaust gas flows horizontally over vertical tubes whereas in vertical type HRSGs, exhaust gas flow vertically over horizontal tubes. Based on pressure levels, HRSGs can be categorized into ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Combined Cycle

A combined cycle power plant is an assembly of heat engines that work in tandem from the same source of heat, converting it into mechanical energy. On land, when used to make electricity the most common type is called a combined cycle gas turbine (CCGT) plant. The same principle is also used for marine propulsion, where it is called a combined gas and steam (COGAS) plant. Combining two or more thermodynamic cycles improves overall efficiency, which reduces fuel costs. The principle is that after completing its cycle in the first engine, the working fluid (the exhaust) is still hot enough that a second subsequent heat engine can extract energy from the heat in the exhaust. Usually the heat passes through a heat exchanger so that the two engines can use different working fluids. By generating power from multiple streams of work, the overall efficiency can be increased by 50–60%. That is, from an overall efficiency of the system of say 34% for a simple cycle, to as much as 64% ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oxygenated Treatment

Oxygenated treatment (OT) is a technique used to reduce corrosion in a boiler and its associated feedwater system in flow-through boilers. With oxygenated treatment, oxygen is injected into the feedwater to keep the oxygen level between 30-50 ppb. OT programs are most commonly used in supercritical (ie >3250psi) power boilers. The ability to change an existing sub-critical boiler over to an OT program is very limited. "Common injection points are just after the condensate polisher and again at the deaerator outlet." This forms a thicker protective layer of hematite (Fe2O3) on top of the magnetite. This is a denser, flatter film (vs. the undulation scale with OT) so that there is less resistance to water flow compared to AVT. Also, OT reduces the risk of flow-accelerated corrosion. When OT is used, conductivity after cation exchange (CACE) at the economiser inlet must be maintained below 0.15μS/cm this can be achieved by the use of a full-flow condensate polisher.Frank Gabriell ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

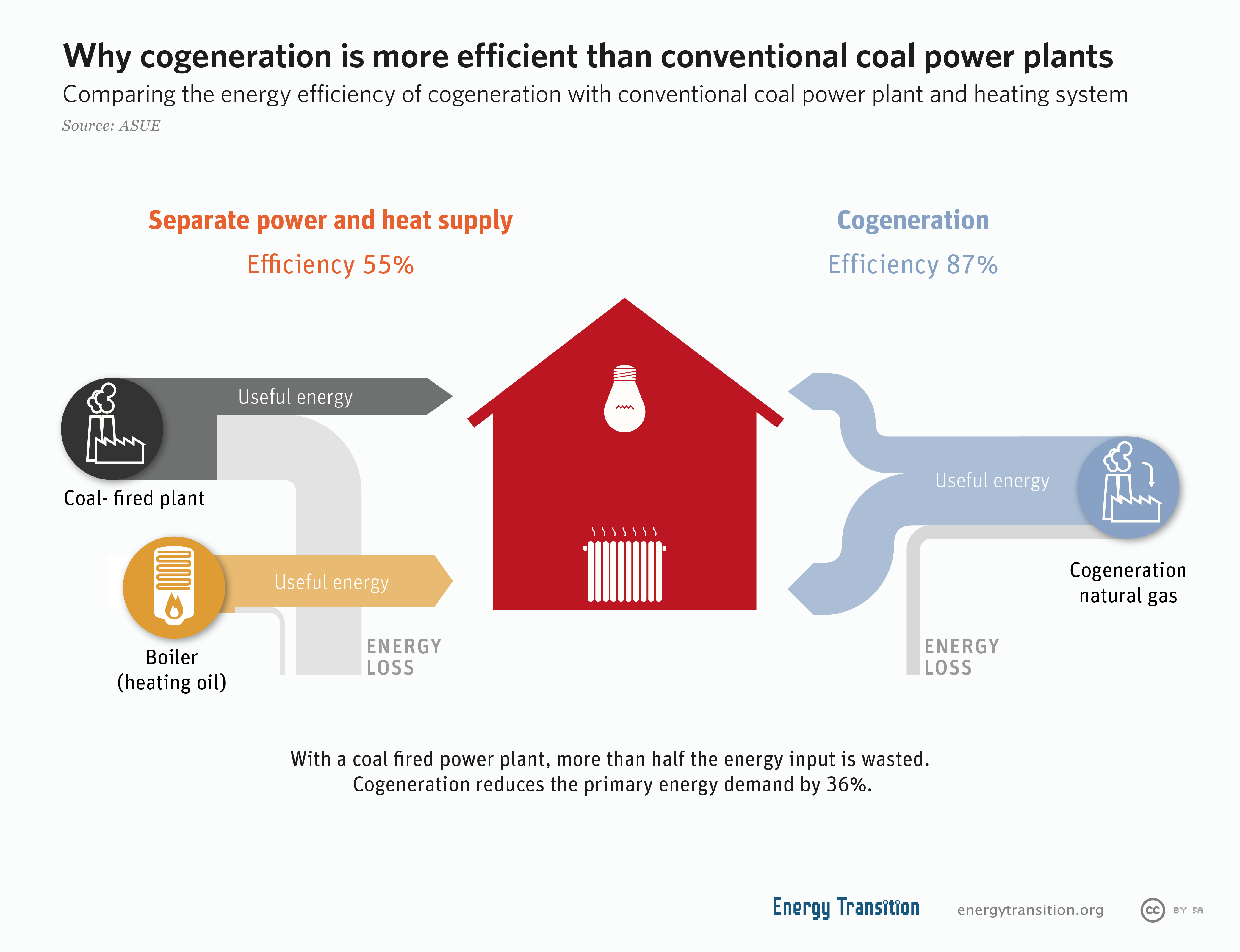

Cogeneration

Cogeneration or combined heat and power (CHP) is the use of a heat engine or power station to generate electricity and useful heat at the same time. Cogeneration is a more efficient use of fuel or heat, because otherwise- wasted heat from electricity generation is put to some productive use. Combined heat and power (CHP) plants recover otherwise wasted thermal energy for heating. This is also called combined heat and power district heating. Small CHP plants are an example of decentralized energy. By-product heat at moderate temperatures (100–180 °C, 212–356 °F) can also be used in absorption refrigerators for cooling. The supply of high-temperature heat first drives a gas or steam turbine-powered generator. The resulting low-temperature waste heat is then used for water or space heating. At smaller scales (typically below 1 MW), a gas engine or diesel engine may be used. Cogeneration is also common with geothermal power plants as they often produce relatively lo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Economizer

Economizers (US and Oxford spelling), or economisers (UK), are mechanical devices intended to reduce energy consumption, or to perform useful function such as preheating a fluid. The term economizer is used for other purposes as well. Boiler, power plant, heating, refrigeration, ventilating, and air conditioning (HVAC) uses are discussed in this article. In simple terms, an economizer is a heat exchanger. Stirling engine Robert Stirling's innovative contribution to the design of hot air engines of 1816 was what he called the 'Economiser'. Now known as the regenerator, it stored heat from the hot portion of the engine as the air passed to the cold side, and released heat to the cooled air as it returned to the hot side. This innovation improved the efficiency of Stirling engine enough to make it commercially successful in particular applications, and has since been a component of every air engine that is called a Stirling engine. Boilers In boilers, economizers are heat exchange ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exhaust Heat Recovery System

An exhaust heat recovery system turns waste heat energy in exhaust gases into electric energy for batteries or mechanical energy reintroduced on the crankshaft. The technology is of increasing interest as car and heavy-duty vehicle manufacturers continue to increase efficiency, saving fuel and reducing emissions. Thermal losses of an internal combustion engine While technological improvements have greatly reduced the fuel consumption of internal combustion engines, the peak thermal efficiency of a 4-stroke Otto cycle engine is around 35%, which means that 65% of the energy released from the fuel is lost as heat. High speed Diesel cycle engines fare better with around 45% peak efficiency, but are still far from the maximum theoretical efficiency, with 55% of the fuel energy content rejected as heat. Exhaust heat recovery technologies Rankine Rankine cycle systems vaporize pressurised water using a steam generator located in the exhaust pipe. As a result of the heating by e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbosteamer

A turbosteamer is a term used by BMW to describe a combined cycle engine. Waste heat energy from the internal combustion engine would be used to generate steam (see Waste Heat Recovery Unit) for a steam engine which would create supplemental power for the vehicle. The turbosteamer device is affixed to the exhaust and cooling system. It salvages the heat wasted in the exhaust and radiator (as much as 80% of heat energy) and uses a steam piston or turbine to relay that power to the crankshaft. The steam circuit produces and of torque at peak (for a 1.8 Straight-4 engine), yielding an estimated 15% gain in fuel efficiency. Unlike gasoline-electric hybrids, these gains increase at higher, steadier speeds. Timescale BMW has been the pioneer of this concept as early as 2000 under the direction of Dr. Raymond Freymann, and while they were designing this system to fit to most current BMW models, the technology didn't reach production. See also * COGAS * Cogeneration * Combined cycle * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

IGCC Diagram

IGCC may refer to: * Integrated gasification combined cycle, a power generation technology * International Green Construction Code * UC Institute on Global Conflict and Cooperation The University of California, San Diego (UC San Diego or colloquially, UCSD) is a public land-grant research university in San Diego, California. Established in 1960 near the pre-existing Scripps Institution of Oceanography, UC San Diego is th ... * International Grid Control Cooperation * Intel Graphics Command Center {{Disambig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Waste Heat

Waste heat is heat that is produced by a machine, or other process that uses energy, as a byproduct of doing work. All such processes give off some waste heat as a fundamental result of the laws of thermodynamics. Waste heat has lower utility (or in thermodynamics lexicon a lower exergy or higher entropy) than the original energy source. Sources of waste heat include all manner of human activities, natural systems, and all organisms, for example, incandescent light bulbs get hot, a refrigerator warms the room air, a building gets hot during peak hours, an internal combustion engine generates high-temperature exhaust gases, and electronic components get warm when in operation. Instead of being "wasted" by release into the ambient environment, sometimes waste heat (or cold) can be used by another process (such as using hot engine coolant to heat a vehicle), or a portion of heat that would otherwise be wasted can be reused in the same process if make-up heat is added to the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Emma Maersk

Emma may refer to: * Emma (given name) Film * ''Emma'' (1932 film), a comedy-drama film by Clarence Brown * ''Emma'' (1996 theatrical film), a film starring Gwyneth Paltrow * ''Emma'' (1996 TV film), a British television film starring Kate Beckinsale * ''Emma'' (2020 film), a British drama film starring Anya Taylor-Joy Literature * ''Emma'' (novel), an 1815 novel by Jane Austen * ''Emma Brown'', a fragment of a novel by Charlotte Brontë, completed by Clare Boylan in 2003 * ''Emma'', a 1955 novel by F. W. Kenyon * ''Emma: A Modern Retelling'', a 2015 novel by Alexander McCall Smith * ''Emma'' (manga), a 2002 manga by Kaoru Mori and the adapted Japanese animated series * ''EMMA'' (magazine), a German feminist journal, published by Alice Schwarzer Music Artists * E.M.M.A., a 2001–2005 Swedish girl group * Emma (Welsh singer) (born 1974) * Emma Bunton (born 1976), English singer * Emma Marrone or Emma (born 1984), Italian singer Songs * "Emma" (Hot Chocolate song), 1974 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

District Heating

District heating (also known as heat networks or teleheating) is a system for distributing heat generated in a centralized location through a system of insulated pipes for residential and commercial heating requirements such as space heating and water heating. The heat is often obtained from a cogeneration plant burning fossil fuels or biomass, but heat-only boiler stations, geothermal heating, heat pumps and central solar heating are also used, as well as heat waste from factories and nuclear power electricity generation. District heating plants can provide higher efficiencies and better pollution control than localized boilers. According to some research, district heating with combined heat and power (CHPDH) is the cheapest method of cutting carbon emissions, and has one of the lowest carbon footprints of all fossil generation plants. Fifth-generation district heat networks do not use combustion on-site and have zero emissions of CO and NO on-site; they employ heat transfer u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Desalination

Desalination is a process that takes away mineral components from saline water. More generally, desalination refers to the removal of salts and minerals from a target substance, as in Soil salinity control, soil desalination, which is an issue for agriculture. Saline water, Saltwater (especially Seawater, sea water) is desalinated to produce water suitable for Drinking water, human consumption or irrigation. The by-product of the desalination process is brine. Desalination is used on many seagoing ships and submarines. Most of the modern interest in desalination is focused on cost-effective provision of fresh water for human use. Along with recycled wastewater, it is one of the few rainfall-independent water resources. Due to its energy consumption, desalinating sea water is generally more costly than fresh water from surface water or groundwater, Reclaimed water, water recycling and water conservation. However, these alternatives are not always available and depletion of reserve ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |