|

Gauge (engineering)

A gauge, in science and engineering, is a device used to make measurements or in order to display certain dimensional information. A wide variety of tools exist which serve such functions, ranging from simple pieces of material against which sizes can be measured to complex pieces of machinery. Depending on usage, a gauge can be described as "a device for measuring a physical quantity",Richard Talman, ''Geometric Mechanics'' (2008), p. 255-56: "a "gauge" is a device for measuring a physical quantity—a thermometer is a temperature gauge, a ruler is a length gauge".. for example "to determine thickness, gap in space, diameter of materials, or pressure of flow",Ray Herren, ''Agricultural Mechanics: Fundamentals & Applications'' (2009), p. 109: "A gauge is a device used to determine thickness, gap in space, diameter of materials, or pressure of flow". or "a device that displays the measurement of a monitored system by the use of a needle or pointer that moves along a calibrated scale" ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Science

Science is a systematic endeavor that builds and organizes knowledge in the form of testable explanations and predictions about the universe. Science may be as old as the human species, and some of the earliest archeological evidence for scientific reasoning is tens of thousands of years old. The earliest written records in the history of science come from Ancient Egypt and Mesopotamia in around 3000 to 1200 BCE. Their contributions to mathematics, astronomy, and medicine entered and shaped Greek natural philosophy of classical antiquity, whereby formal attempts were made to provide explanations of events in the physical world based on natural causes. After the fall of the Western Roman Empire, knowledge of Greek conceptions of the world deteriorated in Western Europe during the early centuries (400 to 1000 CE) of the Middle Ages, but was preserved in the Muslim world during the Islamic Golden Age and later by the efforts of Byzantine Greek scholars who brought Greek ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gauge Block

Gauge blocks (also known as gage blocks, Johansson gauges, slip gauges, or Jo blocks) are a system for producing precision lengths. The individual gauge block is a metal or ceramic block that has been precision ground and lapped to a specific thickness. Gauge blocks come in sets of blocks with a range of standard lengths. In use, the blocks are stacked to make up a desired length (or height). An important feature of gauge blocks is that they can be joined together with very little dimensional uncertainty. The blocks are joined by a sliding process called ''wringing'', which causes their ultra-flat surfaces to cling together. A small number of gauge blocks can be used to create accurate lengths within a wide range. By using three blocks at a time taken from a set of 30 blocks, one may create any of the 1000 lengths from 3.000 to 3.999 mm in 0.001 mm steps (or .3000 to .3999 inches in 0.0001 inch steps). Gauge blocks were invented in 1896 by Swedish machinist ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Force

In physics, a force is an influence that can change the motion of an object. A force can cause an object with mass to change its velocity (e.g. moving from a state of rest), i.e., to accelerate. Force can also be described intuitively as a push or a pull. A force has both magnitude and direction, making it a vector quantity. It is measured in the SI unit of newton (N). Force is represented by the symbol (formerly ). The original form of Newton's second law states that the net force acting upon an object is equal to the rate at which its momentum changes with time. If the mass of the object is constant, this law implies that the acceleration of an object is directly proportional to the net force acting on the object, is in the direction of the net force, and is inversely proportional to the mass of the object. Concepts related to force include: thrust, which increases the velocity of an object; drag, which decreases the velocity of an object; and torque, which produce ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

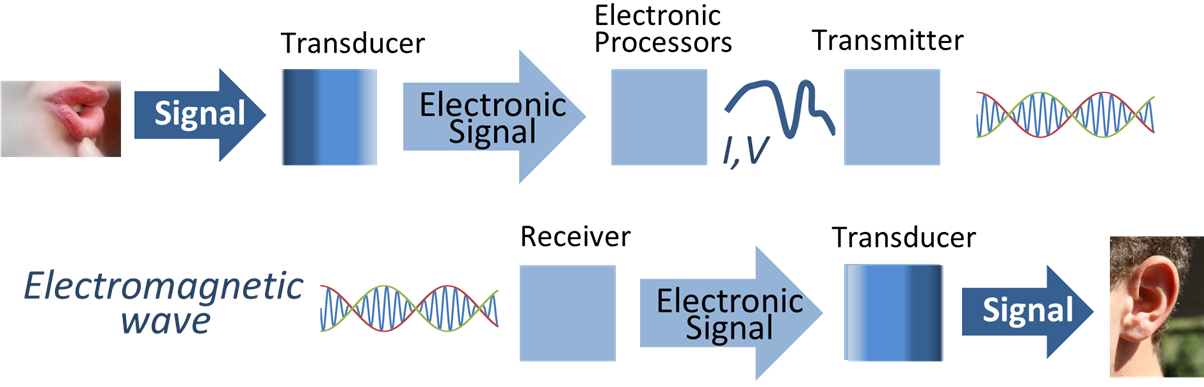

Transducer

A transducer is a device that converts energy from one form to another. Usually a transducer converts a signal in one form of energy to a signal in another. Transducers are often employed at the boundaries of automation, measurement, and control systems, where electrical signals are converted to and from other physical quantities (energy, force, torque, light, motion, position, etc.). The process of converting one form of energy to another is known as transduction. Types * Mechanical transducers, so-called as they convert physical quantities into mechanical outputs or vice versa; * Electrical transducers however convert physical quantities into electrical outputs or signals. Examples of these are: ** a thermocouple that changes temperature differences into a small voltage; ** a linear variable differential transformer (LVDT), used to measure displacement (position) changes by means of electrical signals. Sensors, actuators and transceivers Transducers can be categorized by wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Load Cell

A load cell converts a force such as tension, compression, pressure, or torque into an electrical signal that can be measured and standardized. It is a force transducer. As the force applied to the load cell increases, the electrical signal changes proportionally. The most common types of load cell are pneumatic, hydraulic, and strain gauges. Strain gauge load cell Strain gauge load cells are the kind most often found in industrial settings. It is ideal as it is highly accurate, versatile, and cost-effective. Structurally, a load cell has a metal body to which strain gauges have been secured. The body is usually made of aluminum, alloy steel, or stainless steel which makes it very sturdy but also minimally elastic. This elasticity gives rise to the term "spring element", referring to the body of the load cell. When force is exerted on the load cell, the spring element is slightly deformed, and unless overloaded, always returns to its original shape. As the spring element defor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grind Gage

A blade's grind is its cross-sectional shape in a plane normal to the edge. Grind differs from blade profile, which is the blade's cross-sectional shape in the plane containing the blade's edge and the centre contour of the blade's back (meaning the shape of the blade when viewed from the side, i.e. clip point, spear point, etc.). The ''grind'' of a blade should not be confused with the bevel forming the sharpened edge; it more usually describes the overall cross-section of the blade, not inclusive of the beveled cutting edge which is typically of a different, less acute angle as the bevel ground onto the blade to give it a cross-sectional shape. For example, the famous Buck 110 hunting knife has a "hollow ground" blade, with concave blade faces (which aid in slicing through materials), but the cutting edge itself is a simple, flat-ground bevel of lesser angle. It would be difficult, if not impossible, to put a "hollow grind" onto the actual cutting edge of the blade itself, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Go/no Go Gauge

A go/no-go gauge refers to an inspection tool used to check a workpiece against its allowed tolerances via a go/no-go test. Its name is derived from two tests: the check involves the workpiece having to pass one test (''go'') and fail the other (''no-go''). For example, ISO 1502 sets a standard for screw threads and gauging to test them. It establishes the attribute ''T'' as ''go'' for the major diameter and the attribute ''Z'' as ''no-go'' for the pitch diameter. The inspection tool has two threaded components. For example, there would be two female sections on a gauge to test a threaded male workpiece such as a screw. If the major diameter of a screw is too large, it will not fit in the ''T'' test thread at all (fail). If the major diameter is too small, the fit is sloppy (fail). If the thread has been cut too deep, it screws into the ''Z'' test thread (fail). If it is the right size and only does about three turns, the fit is right (pass). A go/no-go gauge is an integral par ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gauge Pin

Gauge blocks (also known as gage blocks, Johansson gauges, slip gauges, or Jo blocks) are a system for producing precision lengths. The individual gauge block is a metal or ceramic block that has been precision ground and lapped to a specific thickness. Gauge blocks come in sets of blocks with a range of standard lengths. In use, the blocks are stacked to make up a desired length (or height). An important feature of gauge blocks is that they can be joined together with very little dimensional uncertainty. The blocks are joined by a sliding process called ''wringing'', which causes their ultra-flat surfaces to cling together. A small number of gauge blocks can be used to create accurate lengths within a wide range. By using three blocks at a time taken from a set of 30 blocks, one may create any of the 1000 lengths from 3.000 to 3.999 mm in 0.001 mm steps (or .3000 to .3999 inches in 0.0001 inch steps). Gauge blocks were invented in 1896 by Swedish machinist ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quality Control

Quality control (QC) is a process by which entities review the quality of all factors involved in production. ISO 9000 defines quality control as "a part of quality management focused on fulfilling quality requirements". This approach places emphasis on three aspects (enshrined in standards such as ISO 9001): # Elements such as controls, job management, defined and well managed processes, performance and integrity criteria, and identification of records # Competence, such as knowledge, skills, experience, and qualifications # Soft elements, such as personnel, integrity, confidence, organizational culture, motivation, team spirit, and quality relationships. Inspection is a major component of quality control, where physical product is examined visually (or the end results of a service are analyzed). Product inspectors will be provided with lists and descriptions of unacceptable product defects such as cracks or surface blemishes for example. History and introduction Ea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dial Gauge

In various contexts of science, technology, and manufacturing (such as machining, fabricating, and additive manufacturing), an indicator is any of various instruments used to accurately measure small distances and angles, and amplify them to make them more obvious. The name comes from the concept of '' indicating'' to the user that which their naked eye cannot discern; such as the presence, or exact quantity, of some small distance (for example, a small height difference between two flat surfaces, a slight lack of concentricity between two cylinders, or other small physical deviations). The classic mechanical version, called a dial indicator, provides a dial display similar to a clock face with clock hands; the hands point to graduations in a circular scales on the dial which represent the distance of the probe tip from a zero setting. The internal works of a mechanical dial indicator are similar to the precision clockworks of a mechanical wristwatch, employing a rack and pi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Calipers

A caliper (British spelling also calliper, or in plurale tantum sense a pair of calipers) is a device used to measure the dimensions of an object. Many types of calipers permit reading out a measurement on a ruled scale, a dial, or a digital display. Some calipers can be as simple as a compass with inward or outward-facing points, but no scale. The tips of the caliper are adjusted to fit across the points to be measured and the dimension read by measuring between the tips with another measuring tool, such as a ruler. It is used in many fields such as mechanical engineering, metalworking, forestry, woodworking, science and medicine. Plural vs. singular A single tool might be referred to as a "caliper" or as "calipers", like a pair of scissors or glasses (a "plural only" or ''plurale tantum'' form). In colloquial usage, the phrase "pair of verniers" or just " vernier" might refer to a vernier caliper. Colloquially these phrases can also refer to dial calipers, although they in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sine Bar

A sine bar consists of a hardened, precision ground body with two precision ground cylinders fixed at the ends. The distance between the centers of the cylinders is precisely controlled, and the top of the bar is parallel to a line through the centers of the two rollers. The dimension between the two rollers is chosen to be a whole number (for ease of later calculations) and forms the hypotenuse of a triangle when in use. When a sine bar is placed on a level surface the top edge will be parallel to that surface. If one roller is raised by a known distance, usually using gauge blocks, then the top edge of the bar will be tilted by the same amount forming an angle that may be calculated by the application of the sine rule. * The hypotenuse is a constant dimension—(100 mm or 10 inches in the examples shown). * The height is obtained from the dimension between the bottom of one roller and the table's surface. * The angle is calculated by using the sine rule (a trigonom ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |