|

GM Family 0 Engine

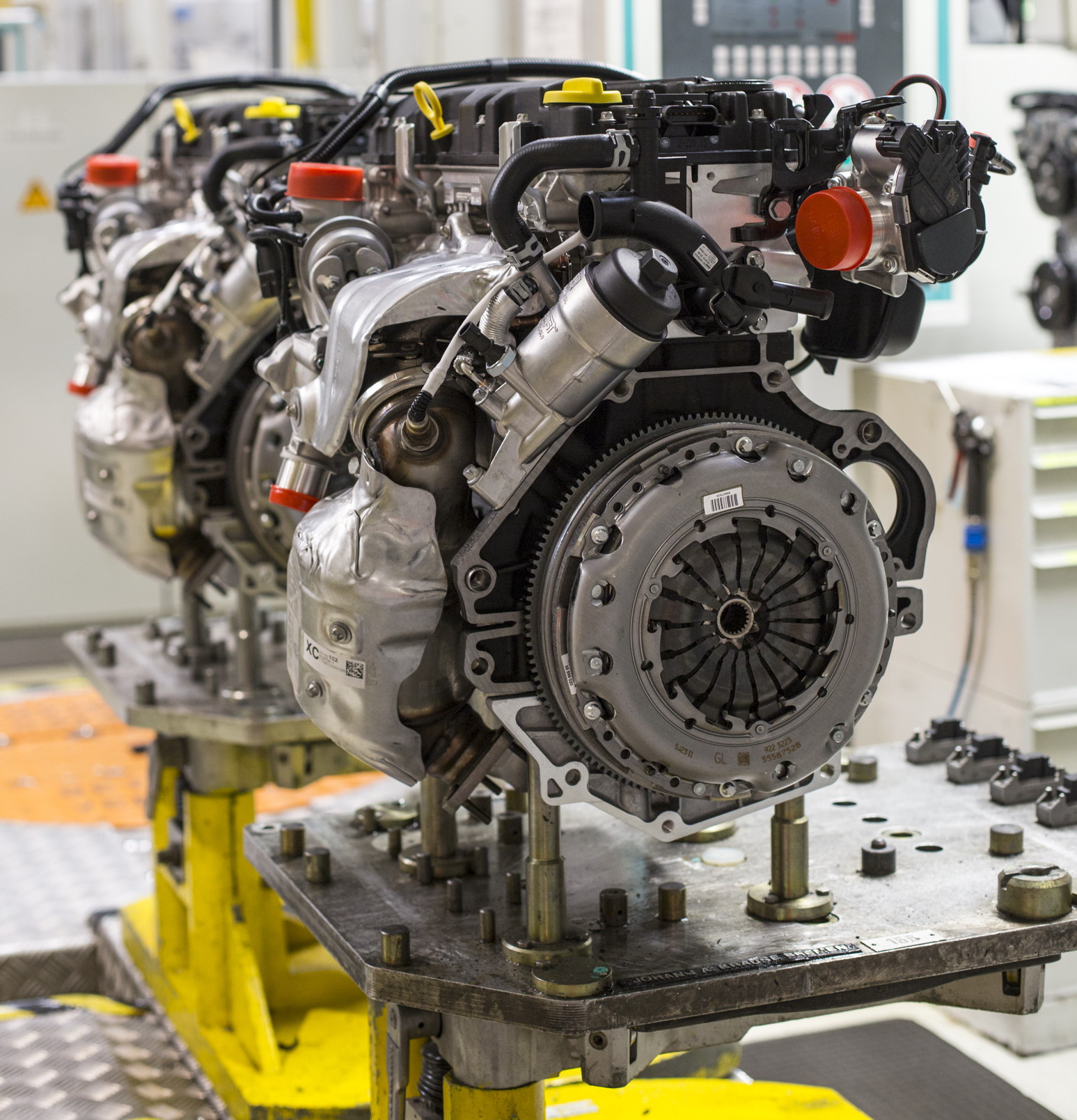

The Family 0 is a family of inline piston engines that was developed by Opel, at the time a subsidiary of General Motors, as a low-displacement engine for use on entry-level subcompact cars from Opel/Vauxhall. These engines feature a light-weight cast-iron semi-closed deck engine block with an aluminum cylinder head. The valvetrain consists of chain-driven hollowcast dual overhead camshafts (DOHC) that actuate 4-valves per cylinder via roller finger followers with hydraulic tappets. These engines also feature a bore spacing and fracture-split connecting rods. Later versions also incorporate a variable length intake manifold (VLIM) and variable valve timing (VVT). Originally debuting as either a straight-3 or straight-4; a I4 variant was added with the introduction of the second generation, replacing the 1.4 L Family 1 engine. The ''Family 0'' engines were produced by Opel Wien in Vienna/Aspern (Austria), by GM in Bupyeong (Korea) and Flint (Michigan, USA). Generation I ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

General Motors

The General Motors Company (GM) is an American Multinational corporation, multinational Automotive industry, automotive manufacturing company headquartered in Detroit, Michigan, United States. It is the largest automaker in the United States and was the largest in the world for 77 years before losing the top spot to Toyota in 2008. General Motors operates manufacturing plants in eight countries. Its four core automobile brands are Chevrolet, Buick, GMC (automobile), GMC, and Cadillac. It also holds interests in Chinese brands Wuling Motors and Baojun as well as DMAX (engines), DMAX via joint ventures. Additionally, GM also owns the BrightDrop delivery vehicle manufacturer, GM Defense, a namesake Defense vehicles division which produces military vehicles for the United States government and military; the vehicle safety, security, and information services provider OnStar; the auto parts company ACDelco, a GM Financial, namesake financial lending service; and majority ownership in t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piston Engine

A reciprocating engine, also often known as a piston engine, is typically a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common features of all types. The main types are: the internal combustion engine, used extensively in motor vehicles; the steam engine, the mainstay of the Industrial Revolution; and the Stirling engine for niche applications. Internal combustion engines are further classified in two ways: either a spark-ignition (SI) engine, where the spark plug initiates the combustion; or a compression-ignition (CI) engine, where the air within the cylinder is compressed, thus heating it, so that the heated air ignites fuel that is injected then or earlier.''Thermodynamics: An Engineering Approach'' by Yunus A. Cengal and Michael A. Boles Common features in all types There may be one or more pistons. Each piston is inside a cylinder, into which a gas is intro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

VLIM

In internal combustion engines, a variable-length intake manifold (VLIM),variable intake manifold (VIM), or variable intake system (VIS) is an automobile internal combustion engine manifold technology. As the name implies, VLIM/VIM/VIS can vary the length of the intake tract - in order to optimise power and torque across the range of engine speed operation, as well as help provide better fuel efficiency. This effect is often achieved by having two separate intake ports, each controlled by a valve, that open two different manifolds - one with a short path that operates at full engine load, and another with a significantly longer path that operates at lower load. The first patent issued for a variable length intake manifold was published in 1958, US Patent US2835235 by Daimler Benz AG. There are two main effects of variable intake geometry: ;Swirl: Variable geometry can create a beneficial air swirl pattern, or turbulence in the combustion chamber. The swirling helps distribute t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Connecting Rod

A connecting rod, also called a 'con rod', is the part of a piston engine which connects the piston to the crankshaft. Together with the crank, the connecting rod converts the reciprocating motion of the piston into the rotation of the crankshaft. The connecting rod is required to transmit the compressive and tensile forces from the piston. In its most common form, in an internal combustion engine, it allows pivoting on the piston end and rotation on the shaft end. The predecessor to the connecting rod is a mechanic linkage used by water mills to convert rotating motion of the water wheel into reciprocating motion. The most common usage of connecting rods is in internal combustion engines or on steam engines. __TOC__ Origins The predecessor to the connecting length is the mechanical linkage used by Roman-era watermills. The earliest known example of this linkage has been found at the late 3rd century Hierapolis sawmill in Roman Asia (modern Turkey) and the 6th century ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Tappet

A hydraulic tappet, also known as a hydraulic valve lifter or hydraulic lash adjuster, is a device for maintaining zero valve clearance in an internal combustion engine. Conventional solid valve lifters require regular adjusting to maintain a small clearance between the valve and its rocker or cam follower. This space prevents the parts from binding as they expand with the engine's heat, but can also lead to noisy operation and increased wear as the parts rattle against one another until they reach operating temperature. The hydraulic lifter was designed to compensate for this small tolerance, allowing the valve train to operate with zero clearance—leading to quieter operation, longer engine life, and eliminating the need for periodic adjustment of valve clearance. The hydraulic lifter, situated between the camshaft and each engine's valve, is a hollow steel cylinder encasing an internal piston. This piston is held at the outer limit of its travel with a strong spring. The l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

DOHC

An overhead camshaft (OHC) engine is a piston engine where the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combustion chamber in the engine block. ''Single overhead camshaft'' (SOHC) engines have one camshaft per bank of cylinders. ''Dual overhead camshaft'' (DOHC, also known as "twin-cam".) engines have two camshafts per bank. The first production car to use a DOHC engine was built in 1910. Use of DOHC engines slowly increased from the 1940s, leading to many automobiles by the early 2000s using DOHC engines. Design In an OHC engine, the camshaft is located at the top of the engine, above the combustion chamber. This contrasts the earlier overhead valve engine (OHV) and flathead engine configurations, where the camshaft is located down in the engine block. The valves in both OHC and OHV engines are located above the combustion chamber; however an OHV ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hollowcast

Permanent mold casting is a metal casting process that employs reusable molds ("permanent molds"), usually made from metal. The most common process uses gravity to fill the mold, however gas pressure or a vacuum are also used. A variation on the typical gravity casting process, called slush casting, produces hollow castings. Common casting metals are aluminium, magnesium, and copper alloys. Other materials include tin, zinc, and lead alloys and iron and steel are also cast in graphite molds.. Typical products are components such as gears, splines, wheels, gear housings, pipe fittings, fuel injection housings, and automotive engine pistons. Process There are four main types of permanent mold casting: gravity, slush, low-pressure, and vacuum. Gravity process The gravity process begins by preheating the mold to 150–200 °C (300–400 °F). to ease the flow and reduce thermal damage to the casting. The mold cavity is then coated with a refractory material or a mold ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roller Chain

Roller chain or bush roller chain is the type of chain drive most commonly used for transmission of mechanical power on many kinds of domestic, industrial and agricultural machinery, including conveyors, wire- and tube-drawing machines, printing presses, cars, motorcycles, and bicycles. It consists of a series of short cylindrical rollers held together by side links. It is driven by a toothed wheel called a sprocket. It is a simple, reliable, and efficientAs much as 98% efficient under ideal conditions, according to means of power transmission. Sketches by Leonardo da Vinci in the 16th century show a chain with a roller bearing. In 1800, James Fussell patented a roller chain on development of his balance lock and in 1880 Hans Renold patented a bush roller chain. Construction There are two types of links alternating in the bush roller chain. The first type is inner links, having two inner plates held together by two sleeves or bushings upon which rotate two rollers. I ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Valvetrain

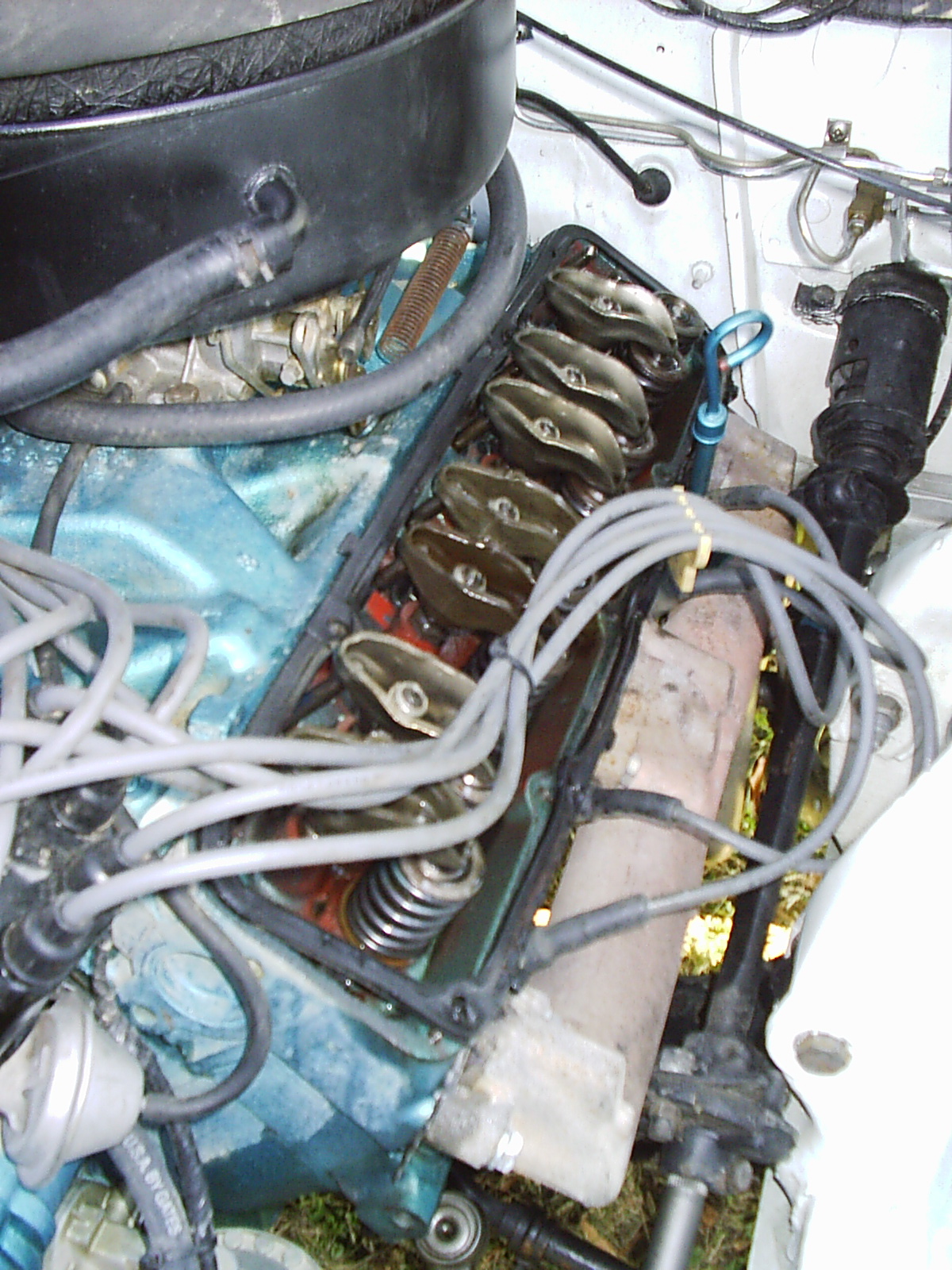

A valvetrain or valve train is a mechanical system that controls the operation of the intake and exhaust valves in an internal combustion engine. The intake valves control the flow of air/fuel mixture (or air alone for direct-injected engines) into the combustion chamber, while the exhaust valves control the flow of spent exhaust gasses out of the combustion chamber once combustion is completed. Layout The valvetrain layout is largely dependent on the location of the camshaft. The common valvetrain configurations for piston engines - in order from oldest to newest - are: * Flathead engine: The camshaft and the valves are located in the engine block below the combustion chamber. * Overhead valve engine: The camshaft remains in the block, however the valves are located in the cylinder head above the combustion chamber. * Overhead camshaft engine: The valves and camshaft(s) are in the cylinder head above the combustion chamber. Components The valvetrain consists of all the compo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Head

In an internal combustion engine, the cylinder head (often abbreviated to simply "head") sits above the cylinders and forms the roof of the combustion chamber. In sidevalve engines, the head is a simple sheet of metal; whereas in more modern overhead valve and overhead camshaft engines, the cylinder head is a more complicated block often containing inlet and exhaust passages, coolant passages, valves, camshafts, spark plugs and fuel injectors. Most straight engines have a single cylinder head shared by all of the cylinders and most V engines have two cylinder heads (one per bank of cylinders). Design A summary of engine designs is shown below, in chronological order for automobile usage. Sidevalve engines In a flathead (''sidevalve'') engine, all of the valvetrain components are contained within the block, therefore the head is usually a simple sheet of metal bolted to the top of the engine block. Sidevalve engines were once universal in automobiles but are now lar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminum

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It has a great affinity towards oxygen, and forms a protective layer of oxide on the surface when exposed to air. Aluminium visually resembles silver, both in its color and in its great ability to reflect light. It is soft, non-magnetic and ductile. It has one stable isotope, 27Al; this isotope is very common, making aluminium the twelfth most common element in the Universe. The radioactivity of 26Al is used in radiodating. Chemically, aluminium is a post-transition metal in the boron group; as is common for the group, aluminium forms compounds primarily in the +3 oxidation state. The aluminium cation Al3+ is small and highly charged; as such, it is polarizing, and bonds aluminium forms tend towards covalency. The strong affinity towards ox ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engine Block

In an internal combustion engine, the engine block is the structure which contains the cylinders and other components. In an early automotive engine, the engine block consisted of just the cylinder block, to which a separate crankcase was attached. Modern engine blocks typically have the crankcase integrated with the cylinder block as a single component. Engine blocks often also include elements such as coolant passages and oil galleries. The term "cylinder block" is often used interchangeably with "engine block", although technically, the block of a modern engine (i.e. multiple cylinders integrated with another component) would be classified as a monobloc. __TOC__ Construction The main structure of an engine typically consists of the cylinders, coolant passages, oil galleries, crankcase, and cylinder head(s). The first production engines of the 1880s to 1920s usually used separate components for each of these elements, which were bolted together during engine assembly. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.png)