|

Fillet Weld

Fillet welding refers to the process of joining two pieces of metal together when they are perpendicular or at an angle. These welds are commonly referred to as tee joints, which are two pieces of metal perpendicular to each other, or lap joints, which are two pieces of metal that overlap and are welded at the edges. The weld is triangular in shape and may have a concave, flat or convex surface depending on the welder's technique. Welders use fillet welds when connecting flanges to pipes and welding cross sections of infrastructure, and when bolts are not strong enough and will wear off easily.Althouse p.185 There are two main types of fillet weld: transverse fillet weld and parallel fillet weld. Aspects There are 5 pieces to each fillet weld known as the root, toe, face, leg and throat. The root of the weld is the part of deepest penetration which is the opposite angle of the hypotenuse. The toes of the weld are essentially the edges or the points of the hypotenuse. The face of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing Fusion welding, fusion. Welding is distinct from lower temperature techniques such as brazing and soldering, which do not melting, melt the base metal (parent metal). In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that, based on weld configuration (butt, full penetration, fillet, etc.), can be stronger than the base material. Pressure may also be used in conjunction with heat or by itself to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from being contaminated or Oxidation, oxidized. Many different energy sources can be used for welding, including a gas flame (chemical), an electric arc (electrical), a laser, an electron ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes machine tools, in contrast to ''additive manufacturing'' (3D printing), which uses controlled addition of material. Machining is a part of the manufacture of many metal products, but it can also be used on other materials such as wood, plastic, ceramic, and composite material. A person who specializes in machining is called a machinist. A room, building, or company where machining is done is called a machine shop. Much of modern-day machining is carried out by computer numerical control (CNC), in which computers are used to control the movement and operation of the mills, lathes, and other cutting machines. This increases efficiency, as the CNC machine runs unmanned therefore reducing labour costs for machine shops. History and ter ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fillet (mechanics)

In mechanical engineering, a fillet is a rounding of an interior or exterior corner of a part design. An interior or exterior corner, with an angle or type of bevel, is called a " chamfer". Fillet geometry, when on an interior corner is a line of concave function, whereas a fillet on an exterior corner is a line of convex function (in these cases, fillets are typically referred to as rounds). Fillets commonly appear on welded, soldered, or brazed joints. Applications * Stress concentration is a problem of load-bearing mechanical parts which is reduced by employing fillets on points and lines of expected high stress. The fillets distribute the stress over a broader area and effectively make the parts more durable and capable of bearing larger loads. * For considerations in aerodynamics, fillets are employed to reduce interference drag where aircraft components such as wings, struts, and other surfaces meet one another. * For manufacturing, concave corners are sometimes fillet ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding Joint

In metalworking, a welding joint is a point or edge where two or more pieces of metal or plastic are joined together. They are formed by welding two or more workpieces according to a particular geometry. There are five types of joints referred to by the American Welding Society: Butt welding, butt, corner, edge, Lap joint, lap, and tee. These configurations may have various configurations at the joint where actual welding can occur. Butt welds Butt welds are welds where two pieces of metal to be joined are in the same plane. These types of welds require only some kind of preparation and are used with thin sheet metals that can be welded with a single pass. Common issues that can weaken a butt weld are the entrapment of slag, excessive porosity, or cracking. For strong welds, the goal is to use the least amount of welding material possible. Butt welds are prevalent in automated welding processes, such as submerged-arc welding, due to their relative ease of preparation. When met ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Butt Welding

Butt welding is when two pieces of metal are placed end-to-end without overlap and then welded along the joint (as opposed to lap joint weld, where one piece of metal is laid on top of the other, or plug welding, where one piece of metal is inserted into the other). Importantly, in a butt joint, the surfaces of the workpieces being joined are on the same plane and the weld metal remains within the planes of the surfaces. Common uses Butt welding is a commonly used technique in welding that can either be automated or done by hand on steel pieces. Butt welding can also be done with brazing for copper pieces. It is used to attach two pieces of metal together such as pipe, framework in factories, and also flanges. A flange is something that either is internal or external that provided to strengthen a piece of material. In factories butt welding has shown how economical it can be for companies to use when building things out of metal. This is because if they wanted to make something ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Midpoint

In geometry, the midpoint is the middle point of a line segment. It is equidistant from both endpoints, and it is the centroid both of the segment and of the endpoints. It bisects the segment. Formula The midpoint of a segment in ''n''-dimensional space whose endpoints are A = (a_1, a_2, \dots , a_n) and B = (b_1, b_2, \dots , b_n) is given by :\frac. That is, the ''i''th coordinate of the midpoint (''i'' = 1, 2, ..., ''n'') is :\frac 2. Construction Given two points of interest, finding the midpoint of the line segment they determine can be accomplished by a compass and straightedge construction. The midpoint of a line segment, embedded in a plane, can be located by first constructing a lens using circular arcs of equal (and large enough) radii centered at the two endpoints, then connecting the cusps of the lens (the two points where the arcs intersect). The point where the line connecting the cusps intersects the segment is then the midpoint of the segment. It is more ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

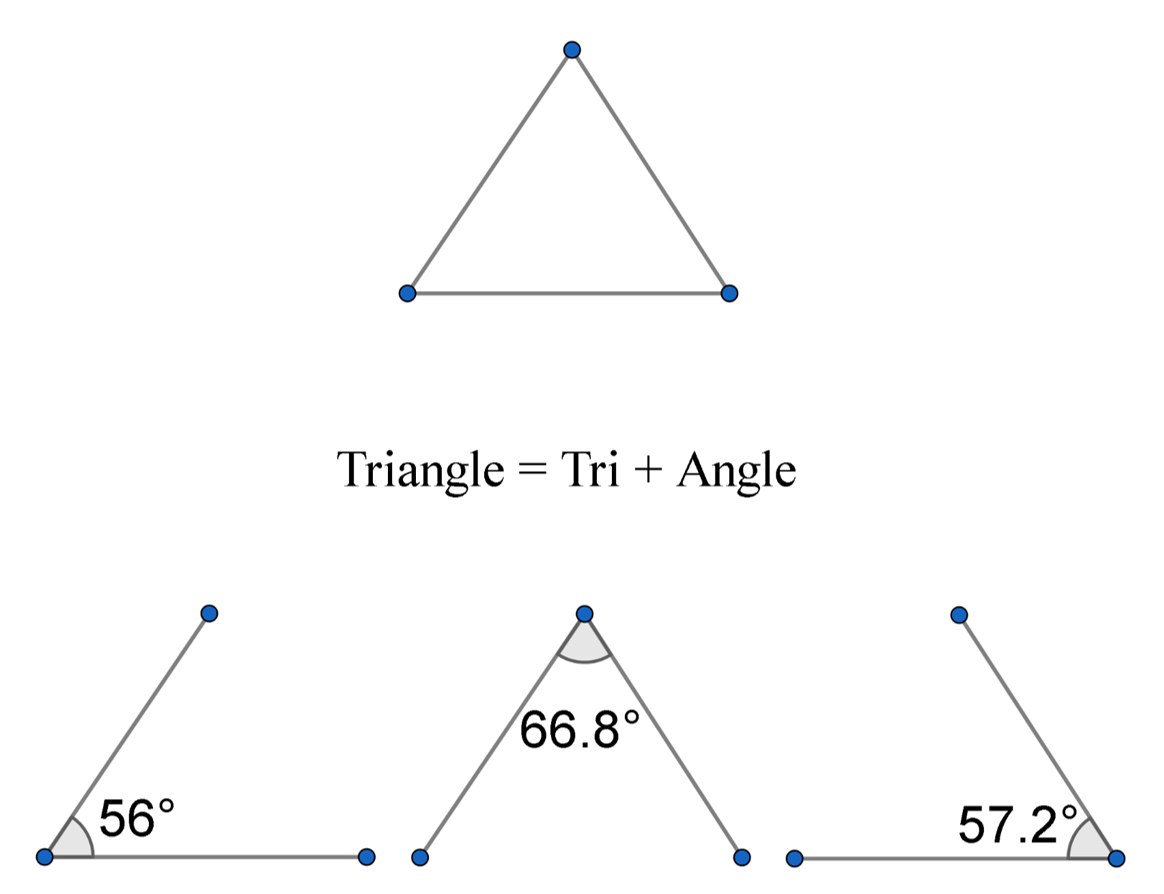

Triangle

A triangle is a polygon with three Edge (geometry), edges and three Vertex (geometry), vertices. It is one of the basic shapes in geometry. A triangle with vertices ''A'', ''B'', and ''C'' is denoted \triangle ABC. In Euclidean geometry, any three points, when non-Collinearity, collinear, determine a unique triangle and simultaneously, a unique Plane (mathematics), plane (i.e. a two-dimensional Euclidean space). In other words, there is only one plane that contains that triangle, and every triangle is contained in some plane. If the entire geometry is only the Euclidean plane, there is only one plane and all triangles are contained in it; however, in higher-dimensional Euclidean spaces, this is no longer true. This article is about triangles in Euclidean geometry, and in particular, the Euclidean plane, except where otherwise noted. Types of triangle The terminology for categorizing triangles is more than two thousand years old, having been defined on the very first page of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Joint

A joint or articulation (or articular surface) is the connection made between bones, ossicles, or other hard structures in the body which link an animal's skeletal system into a functional whole.Saladin, Ken. Anatomy & Physiology. 7th ed. McGraw-Hill Connect. Webp.274/ref> They are constructed to allow for different degrees and types of movement. Some joints, such as the knee, elbow, and shoulder, are self-lubricating, almost frictionless, and are able to withstand compression and maintain heavy loads while still executing smooth and precise movements. Other joints such as sutures between the bones of the skull permit very little movement (only during birth) in order to protect the brain and the sense organs. The connection between a tooth and the jawbone is also called a joint, and is described as a fibrous joint known as a gomphosis. Joints are classified both structurally and functionally. Classification The number of joints depends on if sesamoids are included, age of the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Intermittent

Intermittency is a behavior of dynamical systems: regular alternation of phases of apparently periodic and chaotic dynamics. Intermittent or intermittency may also refer to: *Intermittent river or stream, the one that ceases to flow every year or at least twice every five years *Intermittent energy source, renewable energy sources that are not dispatchable due to their fluctuating nature *Intermittent fault, malfunction of a device or system that occurs at intervals, usually irregular *Fluorescence intermittency Fluorescence intermittency, or blinking, is the phenomenon of random switching between ON (bright) and OFF (dark) states of the emitter under its continuous excitation. It is a common property of the nanoscale emitters (molecular fluorophores, collo ..., or blinking, is random switching between ON (bright) and OFF (dark) states * Intermittent control, possibilities between the two extremes of continuous-time and discrete-time control: the control signal See also * * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Millimetre

330px, Different lengths as in respect to the electromagnetic spectrum, measured by the metre and its derived scales. The microwave is between 1 meter to 1 millimeter. The millimetre (American and British English spelling differences#-re, -er, international spelling; International System of Units, SI unit symbol mm) or millimeter (American and British English spelling differences#-re, -er, American spelling) is a Units of measurement, unit of length in the International System of Units (SI), equal to one thousandth of a metre, which is the SI base unit of length. Therefore, there are one thousand millimetres in a metre. There are ten millimetres in a centimetre. One millimetre is equal to micrometres or nanometres. Since an inch is officially defined as exactly 25.4 millimetres, a millimetre is equal to exactly (≈ 0.03937) of an inch. Definition Since 1983, the metre has been defined as "the length of the path travelled by light in vacuum during a time interval of of a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dimensions

In physics and mathematics, the dimension of a mathematical space (or object) is informally defined as the minimum number of coordinates needed to specify any point within it. Thus, a line has a dimension of one (1D) because only one coordinate is needed to specify a point on itfor example, the point at 5 on a number line. A surface, such as the boundary of a cylinder or sphere, has a dimension of two (2D) because two coordinates are needed to specify a point on itfor example, both a latitude and longitude are required to locate a point on the surface of a sphere. A two-dimensional Euclidean space is a two-dimensional space on the plane. The inside of a cube, a cylinder or a sphere is three-dimensional (3D) because three coordinates are needed to locate a point within these spaces. In classical mechanics, space and time are different categories and refer to absolute space and time. That conception of the world is a four-dimensional space but not the one that was found necessa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grinding (abrasive Cutting)

Grinding is a type of abrasive machining process which uses a grinding wheel as Cutting tool (machining), cutting tool. A wide variety of machines are used for grinding, best classified as portable or stationary: * Portable power tools such as angle grinders, die grinders and abrasive saw, cut-off saws * Stationary power tools such as bench grinders and abrasive saw, cut-off saws * Stationary hydropower, hydro- or human power, hand-powered grindstone (tool), sharpening stones Milling practice is a large and diverse area of manufacturing and Tool and die maker, toolmaking. It can produce very fine finishes and very accurate dimensions; yet in mass production contexts, it can also rough out large volumes of metal quite rapidly. It is usually better suited to the machining of very Hardness, hard materials than is "regular" machining (that is, cutting larger chips with cutting tools such as tool bits or milling cutters), and until recent decades it was the only practical way to mach ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |