Fillet Weld on:

[Wikipedia]

[Google]

[Amazon]

Fillet  There are two main types of fillet weld: transverse fillet weld and parallel fillet weld.

There are two main types of fillet weld: transverse fillet weld and parallel fillet weld.

There are 5 pieces to each fillet weld known as the root, toe, face, leg and throat. The root of the weld is the part of deepest penetration which is the opposite angle of the

There are 5 pieces to each fillet weld known as the root, toe, face, leg and throat. The root of the weld is the part of deepest penetration which is the opposite angle of the

Fillet

Fillet

welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing Fusion welding, fusion. Welding is distinct from lower ...

refers to the process of joining two pieces of metal together when they are perpendicular or at an angle. These welds are commonly referred to as tee joints, which are two pieces of metal perpendicular to each other, or lap joints, which are two pieces of metal that overlap and are welded at the edges. The weld is triangular in shape and may have a concave, flat or convex surface depending on the welder's technique. Welders use fillet welds when connecting flanges to pipes and welding cross sections of infrastructure, and when bolts are not strong enough and will wear off easily.Althouse p.185

There are two main types of fillet weld: transverse fillet weld and parallel fillet weld.

There are two main types of fillet weld: transverse fillet weld and parallel fillet weld.

Aspects

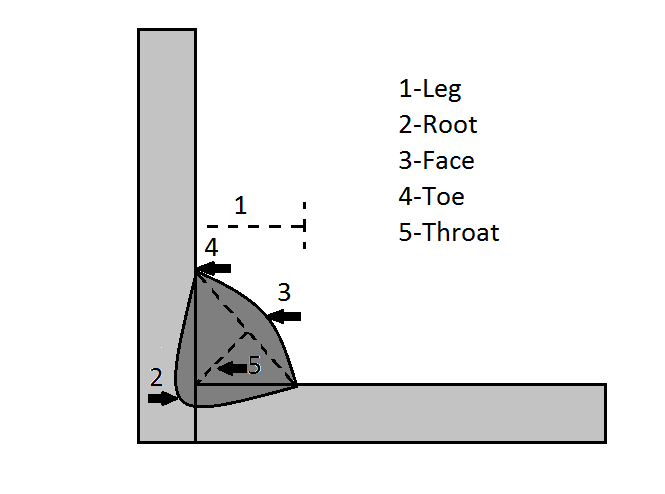

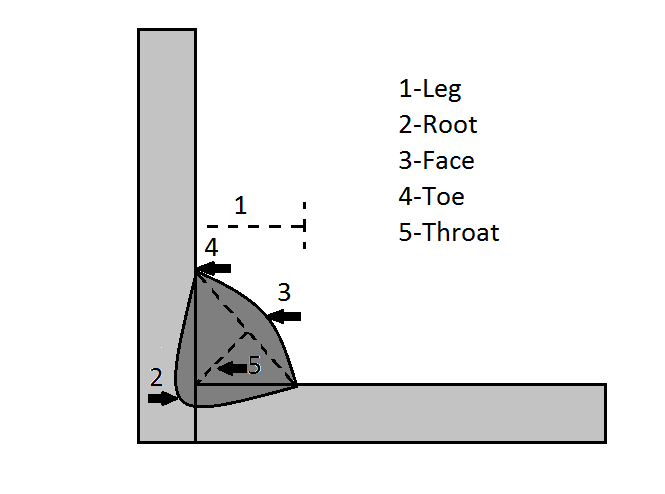

There are 5 pieces to each fillet weld known as the root, toe, face, leg and throat. The root of the weld is the part of deepest penetration which is the opposite angle of the

There are 5 pieces to each fillet weld known as the root, toe, face, leg and throat. The root of the weld is the part of deepest penetration which is the opposite angle of the hypotenuse

In geometry, a hypotenuse is the longest side of a right-angled triangle, the side opposite the right angle. The length of the hypotenuse can be found using the Pythagorean theorem, which states that the square of the length of the hypotenuse equa ...

. The toes of the weld are essentially the edges or the points of the hypotenuse. The face of the weld is the outer visual or hypotenuse that you see when looking at a fillet weld. The legs are the other two sides of the triangular fillet weld. The leg length is usually designated as the size of the weld. The throat of the weld is the distance from the center of the face to the root of the weld. Typically the depth of the throat should be at least as thick as the thickness of metal you are welding.

Notation

Fillet

Fillet welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing Fusion welding, fusion. Welding is distinct from lower ...

notation is important to recognize when reading technical drawings

Technical drawing, drafting or drawing, is the act and discipline of composing drawings that visually communicate how something functions or is constructed.

Technical drawing is essential for communicating ideas in industry and engineering.

...

. The use of this notation tells the welder exactly what is expected by the fabricator. The symbol for a fillet weld is in the shape of a triangle. This triangle will lie either below a flat line or above it with an arrow coming off of the flat line pointing to a joint. The flat line is called "reference line". The side on which the triangle symbol is placed is important because it gives an indication which side of the joint is to be intersected by the weld. It is recognized that there are two different approaches in the global market to designate the arrow side and other side on drawings; a description of the two approaches is contained in International Standard

international standard is a technical standard developed by one or more international standards organizations. International standards are available for consideration and use worldwide. The most prominent such organization is the International Or ...

ISO 2553, they are called "A-System" (which is more commonly used in Europe) and "B-System" (which is basically the ANSI/AWS system used in the US). In "A-System" two parallel lines are used as reference line: one is a continuous line, the other is a dashed line. In the "B-System", there is only one reference line, which is a continuous line. If there is a single reference line (B-System) and the triangle is positioned below the line, then the weld is going to be on the arrow side. If there is a single reference line ("B-System") and the triangle is positioned above the line, then the weld is going to be on the opposite side of the arrow. When you find an arrow pointing to a joint with two triangles, one sitting below and one sitting above the line even with each other, then there is intended to be a fillet weld on the arrow side of the joint as well as the opposite side of the joint. If the weld is to be continuous around a piece of metal such as a pipe or square, then a small circle will be around the point where the flat line and arrow pointing to the joint are connected. Manufacturers also include the strength that the weld must be. This is indicated by a letter and number combination just before the flat line. Examples of this are "E70" meaning the arc electrode

An electrode is an electrical conductor used to make contact with a nonmetallic part of a circuit (e.g. a semiconductor, an electrolyte, a vacuum or air). Electrodes are essential parts of batteries that can consist of a variety of materials de ...

must have a tensile strength

Ultimate tensile strength (UTS), often shortened to tensile strength (TS), ultimate strength, or F_\text within equations, is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials t ...

of . There are also symbols that describe the aesthetics of the weld. A gentle curve pointing away from the hypotenuse means a concave

Concave or concavity may refer to:

Science and technology

* Concave lens

* Concave mirror

Mathematics

* Concave function, the negative of a convex function

* Concave polygon, a polygon which is not convex

* Concave set

* The concavity

In ca ...

weld is required, a straight line parallel with the hypotenuse calls for a flat faced weld, and a gentle curve towards the hypotenuse calls for a convex

Convex or convexity may refer to:

Science and technology

* Convex lens, in optics

Mathematics

* Convex set, containing the whole line segment that joins points

** Convex polygon, a polygon which encloses a convex set of points

** Convex polytope ...

weld. The surface of the weld can be manipulated either by welding technique or by use of machining

Machining is a process in which a material (often metal) is cut to a desired final shape and size by a controlled material-removal process. The processes that have this common theme are collectively called subtractive manufacturing, which utilizes ...

or grinding

Grind is the cross-sectional shape of a blade.

Grind, grinds, or grinding may also refer to:

Grinding action

* Grinding (abrasive cutting), a method of crafting

* Grinding (dance), suggestive club dancing

* Grinding (video gaming), repetitive and ...

tools after the weld is completed. When reading a manufacturers technical drawings, you might also come across weld dimensions

In physics and mathematics, the dimension of a mathematical space (or object) is informally defined as the minimum number of coordinates needed to specify any point within it. Thus, a line has a dimension of one (1D) because only one coordina ...

. The weld can be sized in many different ways such as the length of the weld, the measurements of the legs of the weld, and the spaces between welds. Along with a triangle, there will usually be a size for the weld for example (”x”) to the left of the triangle. This means that the vertical leg of the weld is to be ” whereas the horizontal leg is to ”. To the right of the triangle, there will be a measurement of exactly how long the weld is supposed to be.

If the measurements of the drawing are in mm the welds are likewise measured in mm. For example, the weld would be 3 x 10, the mm being understood automatically.

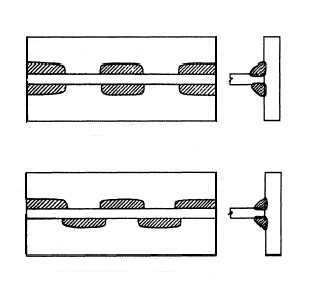

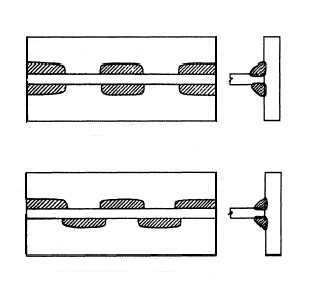

Intermittent fillet welds

An intermittent fillet weld is one that is not continuous across ajoint

A joint or articulation (or articular surface) is the connection made between bones, ossicles, or other hard structures in the body which link an animal's skeletal system into a functional whole.Saladin, Ken. Anatomy & Physiology. 7th ed. McGraw ...

. These welds are portrayed as a set of two numbers to the right of the triangle

A triangle is a polygon with three Edge (geometry), edges and three Vertex (geometry), vertices. It is one of the basic shapes in geometry. A triangle with vertices ''A'', ''B'', and ''C'' is denoted \triangle ABC.

In Euclidean geometry, an ...

instead of just one. The first number as mentioned earlier refers to the length of the weld. The second number, separated from the first by a “-”, refers to the pitch. The pitch is a measurement from midpoint

In geometry, the midpoint is the middle point of a line segment. It is equidistant from both endpoints, and it is the centroid both of the segment and of the endpoints. It bisects the segment.

Formula

The midpoint of a segment in ''n''-dimens ...

to midpoint of the intermittent welds. Intermittent welding is used when either a continuous weld is not necessary, or when a continuous weld threatens the joint by warping. In some cases intermittent welds are staggered on both sides of the joint. In this case, the notation of the two triangles are not directly on top of each other. Instead, the side of the joint to receive the first weld will have a triangle further to the left than the following side’s triangle notation. As an end result of alternating intermittent fillet welds at each side, the space between welds on one side of the joint will be the midpoint of the opposite side’s weld.Althouse p.189

See also

*Butt welding

Butt welding is when two pieces of metal are placed end-to-end without overlap and then welded along the joint (as opposed to lap joint weld, where one piece of metal is laid on top of the other, or plug welding, where one piece of metal is ins ...

* Welding joint

In metalworking, a welding joint is a point or edge where two or more pieces of metal or plastic are joined together. They are formed by welding two or more workpieces according to a particular geometry. There are five types of joints referred t ...

* Fillet (mechanics)

In mechanical engineering, a fillet is a rounding of an interior or exterior corner of a part design. An interior or exterior corner, with an angle or type of bevel, is called a " chamfer". Fillet geometry, when on an interior corner is a line ...

Notes

References

*Hultenius, D. (2008). ''Lecture 14 – Welded Connections''. *Weman, Klas (2003). Welding processes handbook. New York, NY: CRC Press LLC. *ISO 2553:2013, Welding and allied processes - Symbolic representation on drawings - Welded joints *Cary, Howard B; Scott C. Helzer (2005). Modern Welding Technology. Upper Saddle River, New Jersey: Pearson Education. . *Haque, M. E. (2010). Weld connections. Informally published manuscript, Department of Construction Science, Texas A&M University, College Station, Retrieved from http://faculty.arch.tamu.edu/mhaque/cosc421/Weld.pdf. *Althouse, A. D. (1997). Modern welding. Tinley Park, Ill: Goodheart-Willcox. {{ISBN, 978-1-60525-795-2 Welding Metalworking