|

Fiberglass Spray Lay-up Process

Spray-Up also known as chop method of creating fiberglass objects by spraying short strands of glass out of a pneumatic gun. This method is used often when one side of the finished product is not seen, or when large quantities of a product must be made cheaply and quickly without regards to strength. Corvette fenders and boat dinghies are commonly manufactured this way. It is very different from the hand lay-up process. The difference comes from the application of the fibre and resin material to the mould. Spray-up is an open-moulding composites fabrication process where resin and reinforcements are sprayed onto a reusable mould. The resin and glass may be applied separately or simultaneously "chopped" in a combined stream from a chopper gun. Workers roll out the spray-up to compact the laminate. Wood, foam, or other core material may then be added, and a secondary spray-up layer embeds the core between the laminates. The part is then cured, cooled, and removed from the mould. Ap ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fiberglass

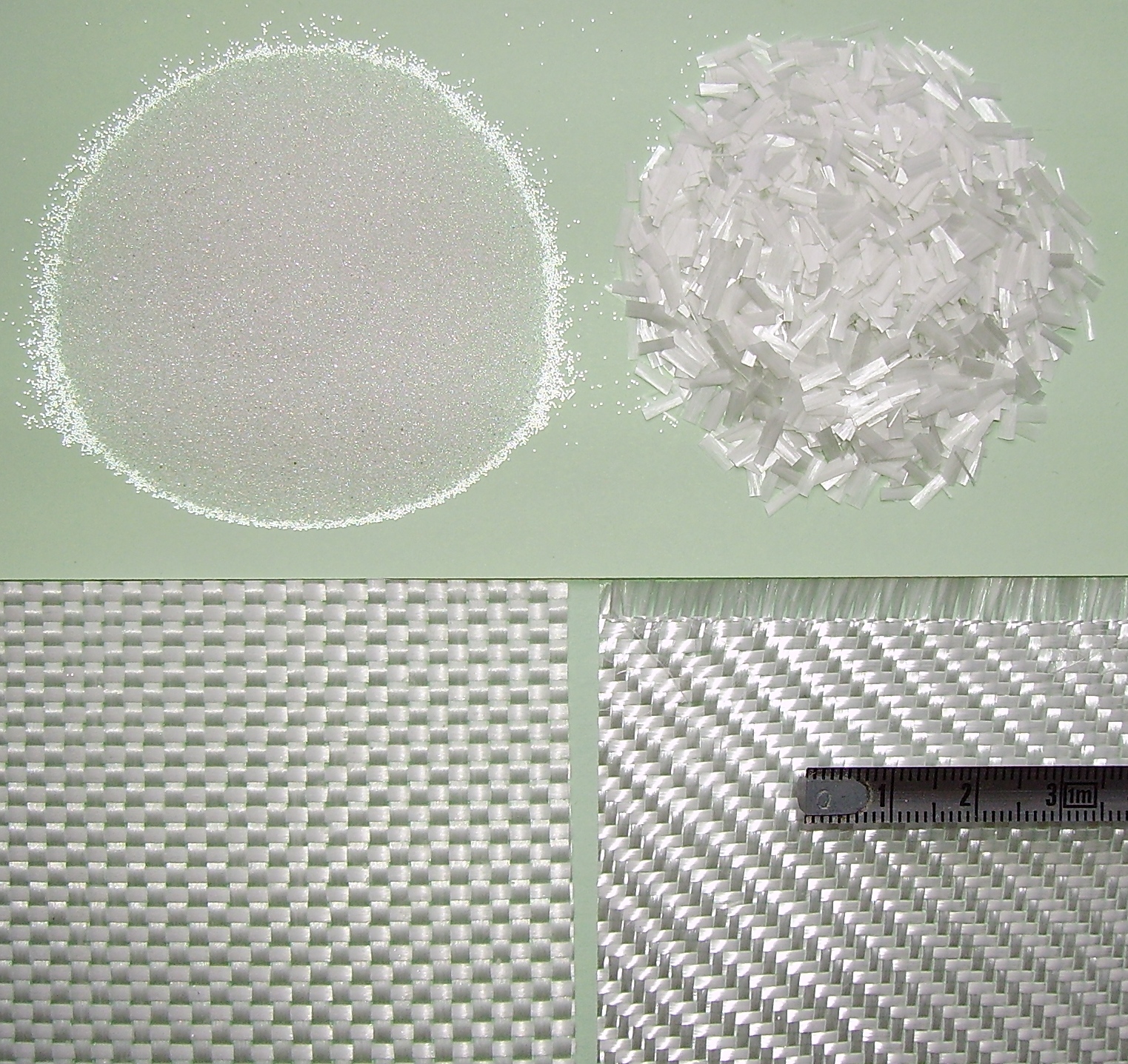

Fiberglass (American English) or fibreglass (Commonwealth English) is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass cloth. The plastic matrix may be a thermoset polymer matrix—most often based on thermosetting polymers such as epoxy, polyester resin, or vinyl ester resin—or a thermoplastic. Cheaper and more flexible than carbon fiber, it is stronger than many metals by weight, non- magnetic, non- conductive, transparent to electromagnetic radiation, can be molded into complex shapes, and is chemically inert under many circumstances. Applications include aircraft, boats, automobiles, bath tubs and enclosures, swimming pools, hot tubs, septic tanks, water tanks, roofing, pipes, cladding, orthopedic casts, surfboards, and external door skins. Other common names for fiberglass are glass-reinforced plastic (GRP), glass-fiber reinforced plastic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyester

Polyester is a category of polymers that contain the ester functional group in every repeat unit of their main chain. As a specific material, it most commonly refers to a type called polyethylene terephthalate (PET). Polyesters include naturally occurring chemicals, such as in plants and insects, as well as synthetics such as polybutyrate. Natural polyesters and a few synthetic ones are biodegradable, but most synthetic polyesters are not. Synthetic polyesters are used extensively in clothing. Polyester fibers are sometimes spun together with natural fibers to produce a cloth with blended properties. Cotton-polyester blends can be strong, wrinkle- and tear-resistant, and reduce shrinking. Synthetic fibers using polyester have high water, wind and environmental resistance compared to plant-derived fibers. They are less fire-resistant and can melt when ignited. Liquid crystalline polyesters are among the first industrially used liquid crystal polymers. They are used f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fibre-reinforced Plastic

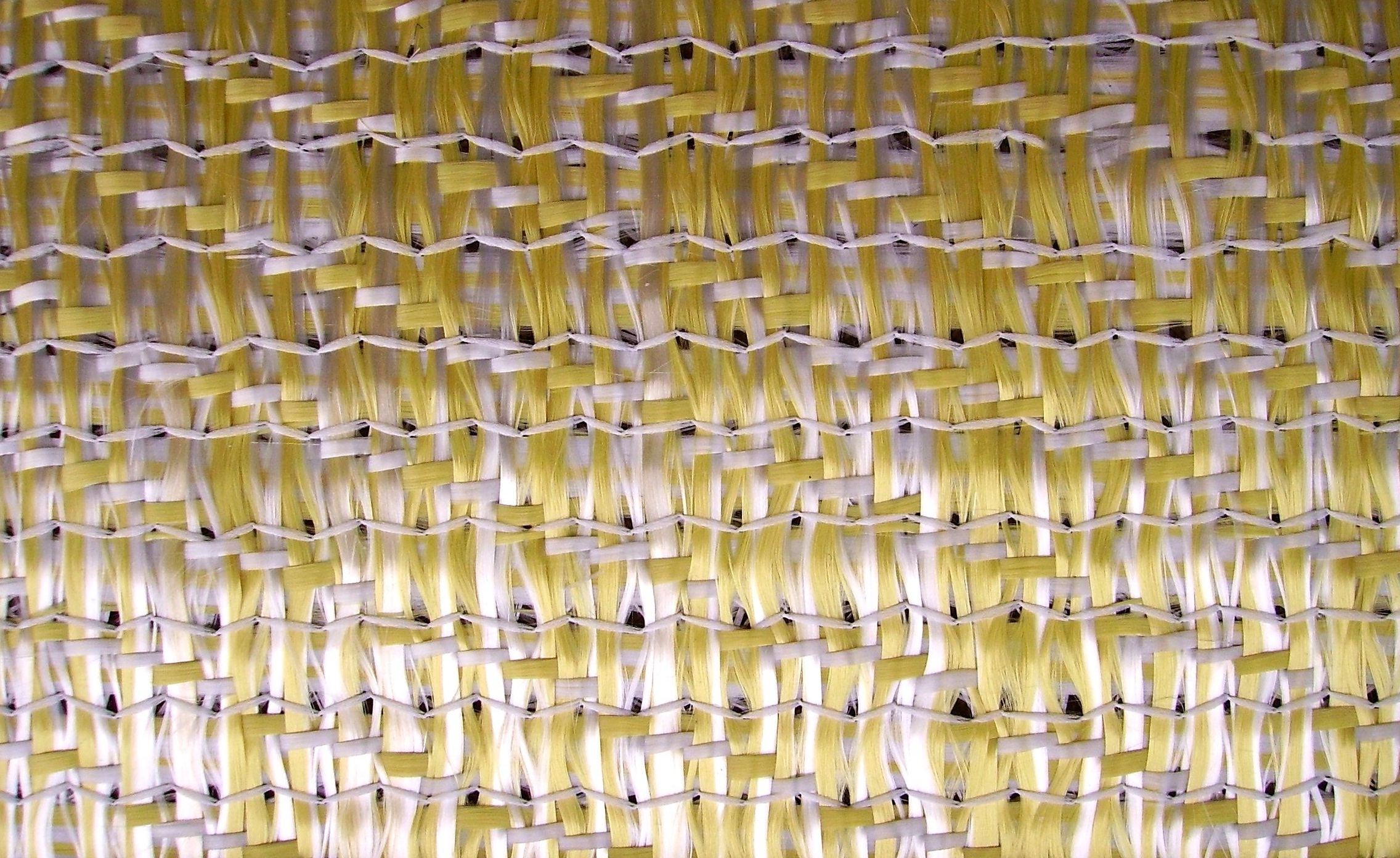

Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English ''fiber'') is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass fibre, glass (in fibreglass), Carbon fibers, carbon (in carbon-fibre-reinforced polymer), aramid, or Basalt fibre, basalt. Rarely, other fibres such as paper, wood, or asbestos have been used. The polymer is usually an epoxy, vinyl ester resin, vinyl ester, or polyester thermosetting plastic, though phenol formaldehyde resins are still in use. FRPs are commonly used in the aerospace, automotive, marine, and construction industries. They are commonly found in ballistic armour and cylinders for self-contained breathing apparatuses. Process definition A polymer is generally manufactured by step-growth polymerization or addition polymerization. When combined with various agents to enhance or in any way alter the material properties of polymers, the result is referred to as a plasti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glass-reinforced Plastic

Fiberglass (American English) or fibreglass (Commonwealth English) is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass cloth. The plastic matrix may be a thermoset polymer matrix—most often based on thermosetting polymers such as epoxy, polyester resin, or vinyl ester resin—or a thermoplastic. Cheaper and more flexible than carbon fiber, it is stronger than many metals by weight, non-magnetic, non-conductive, transparent to electromagnetic radiation, can be molded into complex shapes, and is chemically inert under many circumstances. Applications include aircraft, boats, automobiles, bath tubs and enclosures, swimming pools, hot tubs, septic tanks, water tanks, roofing, pipes, cladding, orthopedic casts, surfboards, and external door skins. Other common names for fiberglass are glass-reinforced plastic (GRP), glass-fiber reinforced plastic (GFRP) or GFK ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminium Trihydrate

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It has a great affinity towards oxygen, and forms a protective layer of oxide on the surface when exposed to air. Aluminium visually resembles silver, both in its color and in its great ability to reflect light. It is soft, non-magnetic and ductile. It has one stable isotope, 27Al; this isotope is very common, making aluminium the twelfth most common element in the Universe. The radioactivity of 26Al is used in radiodating. Chemically, aluminium is a post-transition metal in the boron group; as is common for the group, aluminium forms compounds primarily in the +3 oxidation state. The aluminium cation Al3+ is small and highly charged; as such, it is polarizing, and bonds aluminium forms tend towards covalency. The strong affinity toward ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vinyl Ester Resin

Vinyl ester resin, or often just vinyl ester, is a resin produced by the esterification of an epoxy resin with acrylic or methacrylic acids. The "vinyl" groups refer to these ester substituents, which are prone to polymerize and thus an inhibitor is usually added. The diester product is then dissolved in a reactive solvent, such as styrene, to approximately 35–45 percent content by weight. Polymerization is initiated by free radicals, which are generated by UV-irradiation or peroxides. 352px, Bis-GMA a typical "vinyl ester" derived from bisphenol A diglycidyl ether. This thermosetting polymer, thermoset material can be used as an alternative to polyester and epoxy materials as the thermoset polymer matrix in composite materials, where its characteristics, strengths, and bulk cost are intermediate between polyester and epoxy. Vinyl ester has lower resin viscosity (approx. 200 cps) than polyester (approx. 500cps) and epoxy (approx. 900cps). Uses In homebuilt airplanes, the Gla ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kevlar

Kevlar (para-aramid) is a strong, heat-resistant synthetic fiber, related to other aramids such as Nomex and Technora. Developed by Stephanie Kwolek at DuPont in 1965, the high-strength material was first used commercially in the early 1970s as a replacement for steel in racing tires. It is typically spun into ropes or fabric sheets that can be used as such, or as an ingredient in composite material components. Kevlar has many applications, ranging from bicycle tires and racing sails to bulletproof vests, all due to its high tensile strength-to-weight ratio; by this measure it is five times stronger than steel. It is also used to make modern marching drumheads that withstand high impact; and for mooring lines and other underwater applications. A similar fiber called Twaron with the same chemical structure was developed by Akzo in the 1970s; commercial production started in 1986, and Twaron is now manufactured by Teijin. History Poly-paraphenylene terephthalami ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pneumatic

Pneumatics (from Greek ‘wind, breath’) is a branch of engineering that makes use of gas or pressurized air. Pneumatic systems used in industry are commonly powered by compressed air or compressed inert gases. A centrally located and electrically-powered compressor powers cylinders, air motors, pneumatic actuators, and other pneumatic devices. A pneumatic system controlled through manual or automatic solenoid valves is selected when it provides a lower cost, more flexible, or safer alternative to electric motors, and hydraulic actuators. Pneumatics also has applications in dentistry, construction, mining, and other areas. Gases used in pneumatic systems Pneumatic systems in fixed installations, such as factories, use compressed air because a sustainable supply can be made by compressing atmospheric air. The air usually has moisture removed, and a small quantity of oil is added at the compressor to prevent corrosion and lubricate mechanical components. Factory-plumbed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Fibre

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers (Commonwealth English The use of the English language in current and former member countries of the Commonwealth of Nations was largely inherited from British colonisation, with some exceptions. English serves as the medium of inter-Commonwealth relations. Many ...), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon composite, or just carbon, are extremely strong and light fiber-reinforced plastics that contain carbon fibers. CFRPs can be expensive to produce, but are commonly used wherever high strength-to-weight ratio and stiffness (rigidity) are required, such as aerospace, superstructures of ships, automotive, civil engineering, sports equipment, and an increasing number of consumer and technical applications. The binding polymer is often a thermosetting polymer, thermoset resin such as epoxy, but oth ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roving

A roving is a long and narrow bundle of fiber. Rovings are produced during the process of making spun yarn from wool fleece, raw cotton, or other fibres. Their main use is as fibre prepared for spinning, but they may also be used for specialised kinds of knitting or other textile arts. After carding, the fibres lie roughly parallel in smooth bundles. These are drawn out, by hand or machine, and slightly twisted to form lengths suitable for spinning. These unspun strands of fibre are the rovings. Roving can also mean a roll of these strands, the strands in general (as a mass noun), or the process of creating them. Because it is carded, the fibres are less parallel than wool top (which is combed) and are not of uniform length. Carded rovings look fluffier than combed top, which looks smooth and has a high lustre. The fibres in combed top tend to be of a fairly uniform length due to the method of preparation. Though drawing it into strips may line the fibres up a bit. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |