|

Failure (material)

Structural integrity and failure is an aspect of engineering that deals with the ability of a structure to support a designed structural load (weight, force, etc.) without breaking and includes the study of past structural failures in order to prevent failures in future designs. Structural integrity is the ability of an item—either a structural component or a structure consisting of many components—to hold together under a load, including its own weight, without breaking or deforming excessively. It assures that the construction will perform its designed function during reasonable use, for as long as its intended life span. Items are constructed with structural integrity to prevent catastrophic failure, which can result in injuries, severe damage, death, and/or monetary losses. ''Structural failure'' refers to the loss of structural integrity, or the loss of load-carrying capacity in either a structural component or the structure itself. Structural failure is initiated wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cascading Failure

A cascading failure is a failure in a system of interconnected parts in which the failure of one or few parts leads to the failure of other parts, growing progressively as a result of positive feedback. This can occur when a single part fails, increasing the probability that other portions of the system fail. Such a failure may happen in many types of systems, including power transmission, computer networking, finance, transportation systems, organisms, the human body, and ecosystems. Cascading failures may occur when one part of the system fails. When this happens, other parts must then compensate for the failed component. This in turn overloads these nodes, causing them to fail as well, prompting additional nodes to fail one after another. In power transmission Cascading failure is common in power grids when one of the elements fails (completely or partially) and shifts its load to nearby elements in the system. Those nearby elements are then pushed beyond their capacity s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tay Rail Bridge

The Tay Bridge ( gd, Drochaid-rèile na Tatha) carries the railway across the Firth of Tay in Scotland between Dundee and the suburb of Wormit in Fife. Its span is . It is the second bridge to occupy the site. Plans for a bridge over the Tay to replace the train ferry service emerged in 1854, but the first Tay Bridge did not open until 1878. It was a lightweight lattice design of relatively low cost with a single track. On 28 December 1879, the bridge suddenly collapsed in high winds. The incident is one of the greatest bridge-related engineering disasters to have occurred. An enquiry determined that the bridge was insufficiently engineered to cope with high winds. It was replaced by a second bridge constructed of iron and steel, with a double-track, parallel to the remains of the first bridge. Work commenced on 6 July 1883 and the bridge opened in 1887. The new bridge was subject to extensive testing by the Board of Trade, which resulted in a favourable report. In 2003, t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wrought Iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it a wood-like "grain" that is visible when it is etched, rusted, or bent to failure. Wrought iron is tough, malleable, ductile, corrosion resistant, and easily forge welded, but is more difficult to weld electrically. Before the development of effective methods of steelmaking and the availability of large quantities of steel, wrought iron was the most common form of malleable iron. It was given the name ''wrought'' because it was hammered, rolled, or otherwise worked while hot enough to expel molten slag. The modern functional equivalent of wrought iron is mild steel, also called low-carbon steel. Neither wrought iron nor mild steel contain enough carbon to be hardenable by heating and quenching. Wrought iron is highly refined, with a small amount of silic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cast Iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impurities which allow cracks to pass straight through, grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing. Carbon (C), ranging from 1.8 to 4 wt%, and silicon (Si), 1–3 wt%, are the main alloying elements of cast iron. Iron alloys with lower carbon content are known as steel. Cast iron tends to be brittle, except for malleable cast irons. With its relatively low melting point, good fluidity, castability, excellent machinability, resistance to deformation and wear resistance, cast irons have become an engineering material with a wide range of applicatio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Robert Stephenson

Robert Stephenson FRS HFRSE FRSA DCL (16 October 1803 – 12 October 1859) was an English civil engineer and designer of locomotives. The only son of George Stephenson, the "Father of Railways", he built on the achievements of his father. Robert has been called the greatest engineer of the 19th century. Life Robert was born in Willington Quay near Wallsend, Northumberland, the son of George Stephenson and his wife, Frances Henderson. The family moved to Killingworth, where Robert was taught at the local village school. Robert attended the middle-class Percy Street Academy in Newcastle and at the age of fifteen was apprenticed to the mining engineer Nicholas Wood. He left before he had completed his three years to help his father survey the Stockton and Darlington Railway. Robert spent six months at Edinburgh University before working for three years as a mining engineer in Colombia. When he returned his father was building the Liverpool and Manchester Railway, and Robe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Treating

Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. Although the term ''heat treatment'' applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding. Physical processes Metallic materials consist of a microstructure of small crystals called ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Negaunee Bus Barn Collapse

Negaunee ( or ) is a city in Marquette County in the U.S. state of Michigan. The population was 4,568 at the 2010 census. The city is located at the southwest corner of Negaunee Township, which is administratively separate, in the Upper Peninsula. The city is home to a luge track. The name ''Negaunee'' comes from an Anishinabemowin (Ojibwa) word ', meaning "foremost, in advance, leading," which was determined to be the closest Ojibwa translation for "pioneer". Within the city limits is Teal Lake. History The city was built after the discovery of the Marquette Iron Range during the early 19th century. The Jackson Mine was established in 1845 to mine the ore for shipment to iron forges; the first such forge to operate in the Lake Superior basin was set up in Negaunee during this period. In 1858, the community was given a post office. In 1865, Negaunee was incorporated as a village and reincorporated as a city in 1873. As mining operations expanded, many immigrants helped sett ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boiler Explosion

A boiler explosion is a catastrophic failure of a boiler. There are two types of boiler explosions. One type is a failure of the pressure parts of the steam and water sides. There can be many different causes, such as failure of the safety valve, corrosion of critical parts of the boiler, or low water level. Corrosion along the edges of lap joints was a common cause of early boiler explosions. The second kind is a fuel/air explosion in the furnace, which would more properly be termed a firebox explosion. Firebox explosions in solid-fuel-fired boilers are rare, but firebox explosions in gas or oil-fired boilers are still a potential hazard. Causes There are many causes for boiler explosions such as poor water treatment causing scaling and over heating of the plates, low water level, a stuck safety valve, or even a furnace explosion that in turn, if severe enough, can cause a boiler explosion. Poor operator training resulting in neglect or other mishandling of the boiler h ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

De Havilland Comet

The de Havilland DH.106 Comet was the world's first commercial jet airliner. Developed and manufactured by de Havilland in the United Kingdom, the Comet 1 prototype first flew in 1949. It featured an aerodynamically clean design with four de Havilland Ghost turbojet engines buried in the wing roots, a pressurised cabin, and large square windows. For the era, it offered a relatively quiet, comfortable passenger cabin and was commercially promising at its debut in 1952. Within a year of entering airline service, problems started to emerge, three Comets being lost within twelve months in highly publicised accidents, after suffering catastrophic in-flight break-ups. Two of these were found to be caused by structural failure resulting from metal fatigue in the airframe, a phenomenon not fully understood at the time; the other was due to overstressing of the airframe during flight through severe weather. The Comet was withdrawn from service and extensively tested. Design and co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stress Concentration

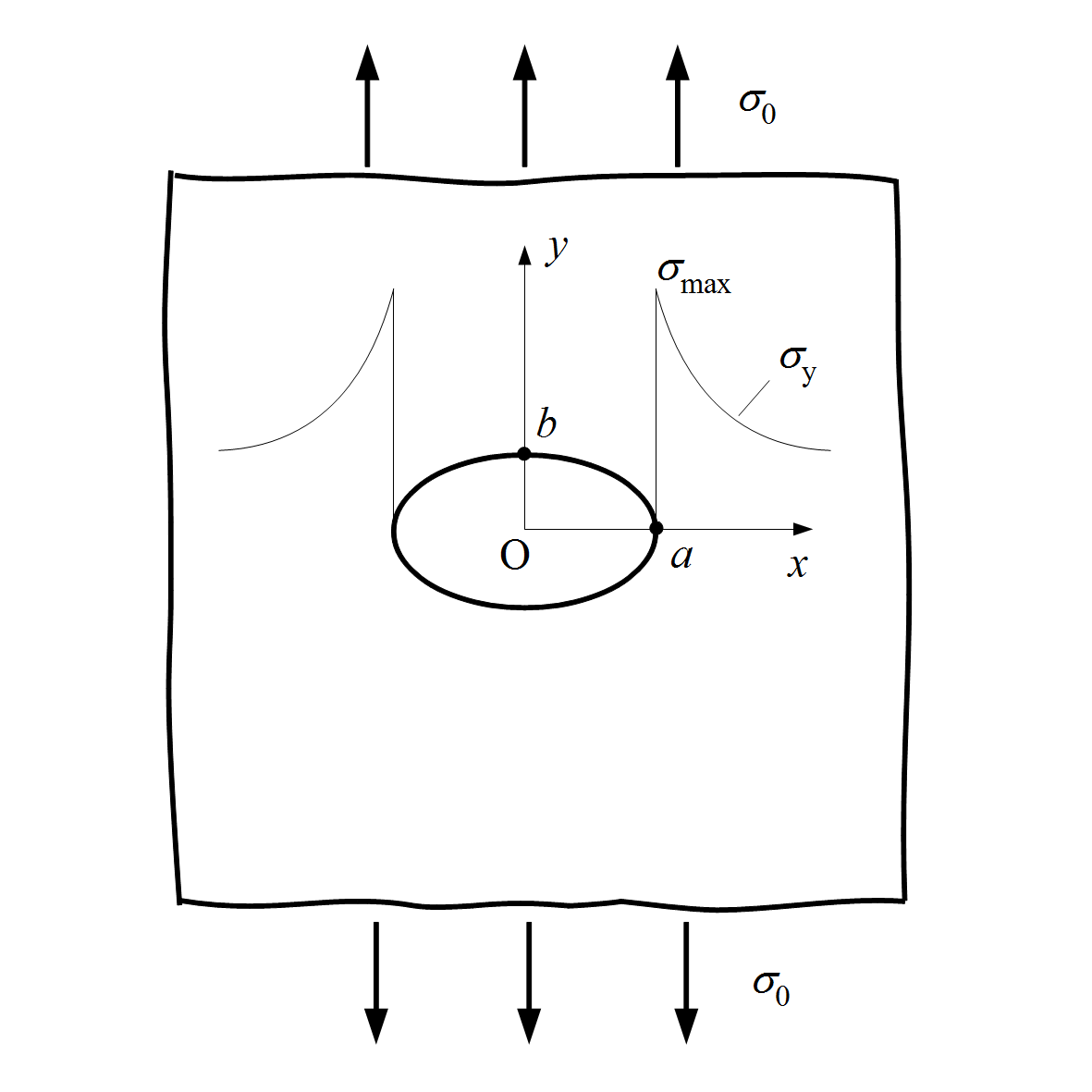

In solid mechanics, a stress concentration (also called a stress raiser or a stress riser) is a location in an object where the stress is significantly greater than the surrounding region. Stress concentrations occur when there are irregularities in the geometry or material of a structural component that cause an interruption to the flow of stress. This arises from such details as holes, grooves, notches and fillets. Stress concentrations may also occur from accidental damage such as nicks and scratches. The degree of concentration of a discontinuity under typically tensile loads can be expressed as a non-dimensional stress concentration factor K_t, which is the ratio of the highest stress to the nominal far field stress. For a circular hole in an infinite plate, K_t = 3. The stress concentration factor should not be confused with the stress intensity factor, which is used to define the effect of a crack on the stresses in the region around a crack tip. For ductile mate ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |