|

Electromechanical Film

Electromechanical Film (EMFI, EMFIT, trademarks of Emfit Ltd) is a thin, flexible film that can function as a sensor or actuator. It is composed of a charged polymer coated with two conductive layers, making it an electret. It was invented and first made by Finnish inventor Kari Kirjavainen. It's voided internal structure and high resistivity allow it to hold a high electric charge and make the film very sensitive to force. Changes in the film's thickness create an electric charge and make it operate as a sensor, or when an electric voltage is applied, it can function as an actuator. This gives the film applications in different fields of technology, including, but not limited to, mechanical vibration and ultrasound sensors, microphones, loudspeaker panels, keyboards, and physiological touch sensors. Other than being cheap, its main advantage is its versatility; it can be cut, reshaped, and resized depending on its surface of application. Manufacturing and structure The base film i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electret

An electret (formed as a portmanteau of ''electr-'' from "electricity" and ''-et'' from "magnet") is a dielectric material that has a quasi-permanent electric charge or dipole polarisation. An electret generates internal and external electric fields, and is the electrostatic equivalent of a permanent magnet. Although Oliver Heaviside coined this term in 1885, materials with electret properties were already known to science and had been studied since the early 1700s. One particular example is the electrophorus, a device consisting of a slab with electret properties and a separate metal plate. The electrophorus was originally invented by Johan Carl Wilcke in Sweden and again by Alessandro Volta in Italy. The name derives from "electron" and "magnet"; drawing analogy to the formation of a magnet by alignment of magnetic domains in a piece of iron. Historically, electrets were made by first melting a suitable dielectric material such as a polymer or wax that contains polar molecules, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene. Polypropylene belongs to the group of polyolefins and is partially crystalline and non-polar. Its properties are similar to polyethylene, but it is slightly harder and more heat-resistant. It is a white, mechanically rugged material and has a high chemical resistance. Bio-PP is the bio-based counterpart of polypropylene (PP). Polypropylene is the second-most widely produced commodity plastic (after polyethylene). In 2019, the global market for polypropylene was worth $126.03 billion. Revenues are expected to exceed US$145 billion by 2019. The sales of this material are forecast to grow at a rate of 5.8% per year until 2021. History Phillips Petroleum chemists J. Paul Hogan and Robert Banks first demonstrated the polymerization of propylene in 1951. The stereoselective polymerization t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blow Molding

Blow molding (or moulding) is a manufacturing process for forming hollow plastic parts. It is also used for forming glass bottles or other hollow shapes. In general, there are three main types of blow molding: extrusion blow molding, injection blow molding, and injection stretch blow molding. The blow molding process begins with softening plastic by heating a preform or parison. The parison is a tube-like piece of plastic with a hole in one end through which compressed air can enter. The plastic workpiece is then clamped into a mold and air is blown into it. The air pressure inflates the plastic which conforms to the mold. Once the plastic has cooled and hardened the mold opens and the part is ejected. Water channels within the mold assist cooling. History The process principle comes from the idea of glassblowing. Enoch Ferngren and William Kopitke produced a blow molding machine and sold it to Hartford Empire Company in 1938. This was the beginning of the commercial blow mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

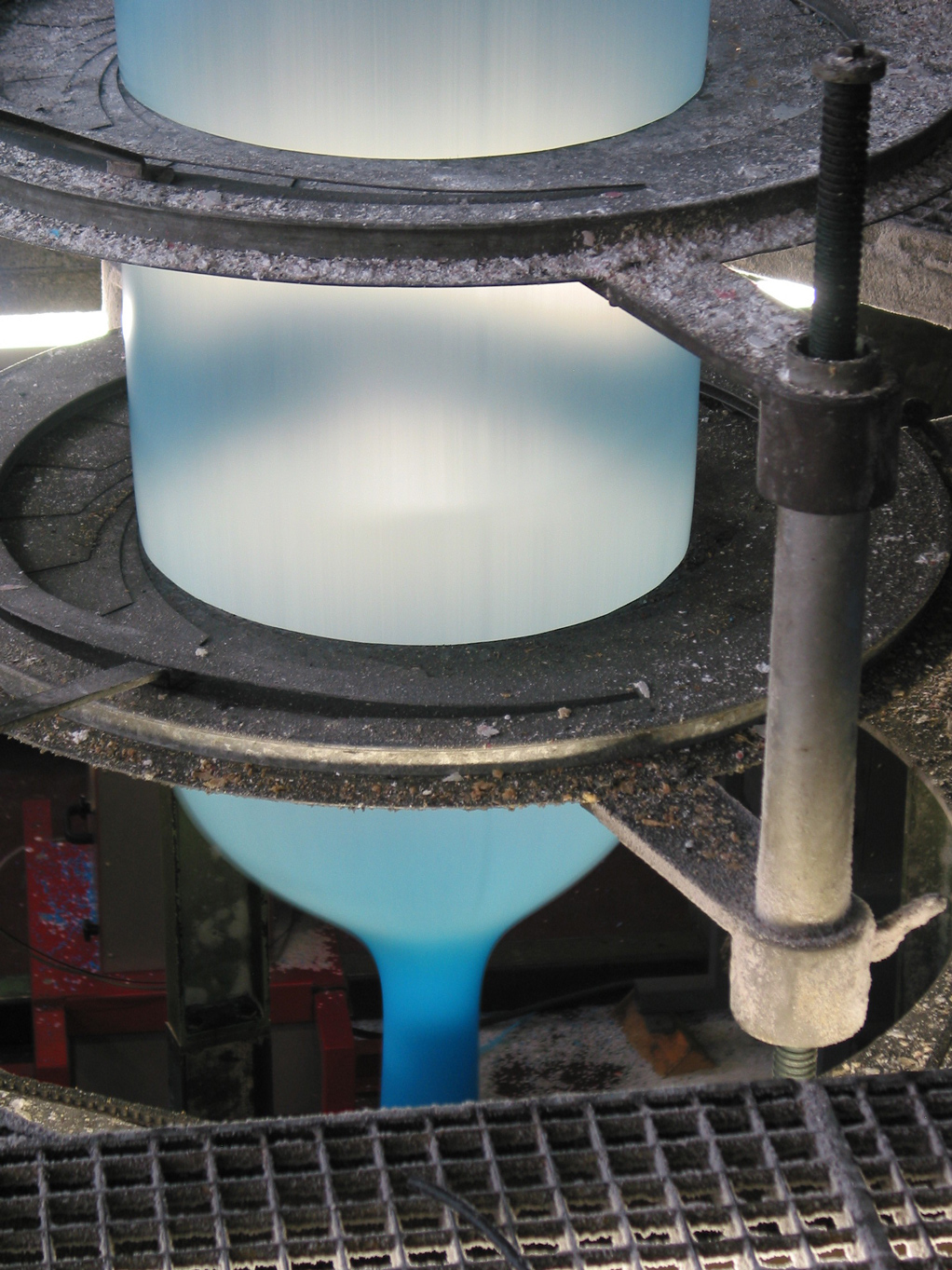

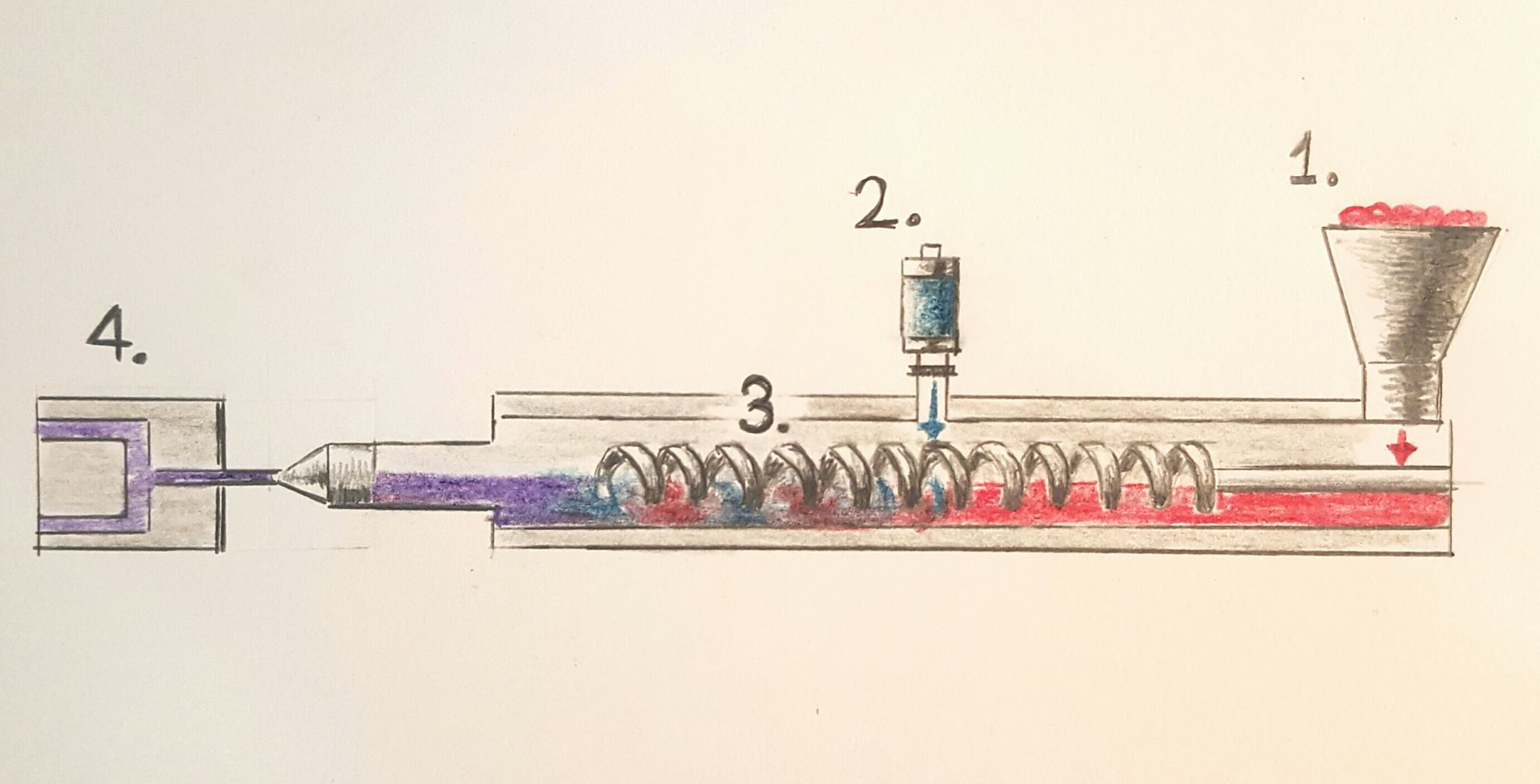

Film Blowing Machine

A film blowing machine involves one process used to make plastic film. Extruded tubular processing is most often used with polyethylene films but can be used with other polymers. The film may be Laminate, laminating film, shrink film, Agriculture, agricultural covering film, Plastic bag, bags or film for textiles and clothing, and other packaging materials. Technical information Parts include: screw and barrel, Electric motor, motor, Inverter (electrical), inverter, heaters, Die (manufacturing), die head, winder, and tower. The main motor may have Variable-frequency drive, frequency control of motor speed to improve speed regulation and save electricity. The screw and material barrel may be made from a Nitriding, nitrogen-treated chromium-molybdenum-aluminum alloy. Process At the beginning of the process, the polymer comes in the form of a pellet. it is heated and melted into a viscous liquid between rotating screws and barrels of the Extrusion, extruder. This allows for the po ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microcellular Plastic

Microcellular plastics, otherwise known as microcellular foam, is a form of manufactured plastic fabricated to contain billions of tiny bubbles less than 50 microns wide (typically 0.1–100 micrometers). It is formed by dissolving gas under high pressure into various polymers, relying on the phenomenon of thermodynamic instability to cause the uniform arrangement of the gas bubbles, otherwise known as nucleation. Its main purpose was to reduce material usage while maintaining valuable mechanical properties. the density of the finished product is determined by the gas used. Depending on the gas, the foam's density can be between 5% and 99% of the pre-processed plastic. Design parameters, focused on the foam's final form and the molding process afterward, include the type of die or mold to be used, as well as the dimensions of the bubbles, or cells, that classify the material as a foam. Since the cells' size is close to the wavelength of light, to the casual observer the foam retains ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corona Treatment

Corona treatment (sometimes referred to as air plasma) is a surface modification technique that uses a low temperature corona discharge plasma to impart changes in the properties of a surface. The corona plasma is generated by the application of high voltage to an electrode that has a sharp tip. The plasma forms at the tip. A linear array of electrodes is often used to create a curtain of corona plasma. Materials such as plastics, cloth, or paper may be passed through the corona plasma curtain in order to change the surface energy of the material. All materials have an inherent surface energy. Surface treatment systems are available for virtually any surface format including dimensional objects, sheets and roll goods that are handled in a web format. Corona treatment is a widely used surface treatment method in the plastic film, extrusion, and converting industries. History The corona treatment was invented by the Danish engineer Verner Eisby in 1951. Eisby had been asked by ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrode

An electrode is an electrical conductor used to make contact with a nonmetallic part of a circuit (e.g. a semiconductor, an electrolyte, a vacuum or air). Electrodes are essential parts of batteries that can consist of a variety of materials depending on the type of battery. The electrophore, invented by Johan Wilcke, was an early version of an electrode used to study static electricity. Anode and cathode in electrochemical cells Electrodes are an essential part of any battery. The first electrochemical battery made was devised by Alessandro Volta and was aptly named the Voltaic cell. This battery consisted of a stack of copper and zinc electrodes separated by brine-soaked paper disks. Due to fluctuation in the voltage provided by the voltaic cell it wasn't very practical. The first practical battery was invented in 1839 and named the Daniell cell after John Frederic Daniell. Still making use of the zinc–copper electrode combination. Since then many more batteries have be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sensor

A sensor is a device that produces an output signal for the purpose of sensing a physical phenomenon. In the broadest definition, a sensor is a device, module, machine, or subsystem that detects events or changes in its environment and sends the information to other electronics, frequently a computer processor. Sensors are always used with other electronics. Sensors are used in everyday objects such as touch-sensitive elevator buttons (tactile sensor) and lamps which dim or brighten by touching the base, and in innumerable applications of which most people are never aware. With advances in micromachinery and easy-to-use microcontroller platforms, the uses of sensors have expanded beyond the traditional fields of temperature, pressure and flow measurement, for example into Attitude and heading reference system, MARG sensors. Analog sensors such as potentiometers and force-sensing resistors are still widely used. Their applications include manufacturing and machinery, airplane ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Actuator

An actuator is a component of a machine that is responsible for moving and controlling a mechanism or system, for example by opening a valve. In simple terms, it is a "mover". An actuator requires a control device (controlled by control signal) and a source of energy. The control signal is relatively low energy and may be electric voltage or current, pneumatic, or hydraulic fluid pressure, or even human power. Its main energy source may be an electric current, hydraulic pressure, or pneumatic pressure. The Control device is usually a valve. When it receives a control signal, an actuator responds by converting the source's energy into mechanical motion. In the ''electric'', ''hydraulic'', and ''pneumatic'' sense, it is a form of automation or automatic control. History The history of the pneumatic actuation system and the hydraulic actuation system dates to around the time of World War II (1938). It was first created by Xhiter Anckeleman who used his knowledge of engines and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Active Noise Control

Active noise control (ANC), also known as noise cancellation (NC), or active noise reduction (ANR), is a method for reducing unwanted sound by the addition of a second sound specifically designed to cancel the first. The concept was first developed in the late 1930s; later developmental work that began in the 1950s eventually resulted in commercial airline headsets with the technology becoming available in the late 1980s. The technology is also used in road vehicles, mobile telephones, earbuds, and headphones Explanation Sound is a pressure wave, which consists of alternating periods of compression and rarefaction. A noise-cancellation speaker emits a sound wave with the same amplitude but with inverted phase (also known as antiphase) relative to the original sound. The waves combine to form a new wave, in a process called interference, and effectively cancel each other out – an effect which is called destructive interference. Modern active noise control is generally achiev ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ballistocardiography

The ballistocardiograph (BCG) is a measure of ballistic forces generated by the heart. The downward movement of blood through the descending aorta produces an upward recoil, moving the body upward with each heartbeat. As different parts of the aorta expand and contract, the body continues to move downward and upward in a repeating pattern. Ballistocardiography is a technique for producing a graphical representation of repetitive motions of the human body arising from the sudden ejection of blood into the great vessels with each heart beat. It is a vital sign in the 1–20 Hz frequency range which is caused by the mechanical movement of the heart and can be recorded by noninvasive methods from the surface of the body. It was shown for the first time, after an extensive research work by Dr. Isaac Starr, that the effect of main heart malfunctions can be identified by observing and analyzing the BCG signal. Recent work also validates BCG could be monitored using camera in a non-cont ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |