|

Diffusion Bonding

Diffusion bonding or diffusion welding is a solid-state welding technique used in metalworking, capable of joining similar and dissimilar metals. It operates on the principle of solid-state diffusion, wherein the atoms of two solid, metallic surfaces intersperse themselves over time. This is typically accomplished at an elevated temperature, approximately 50-75% of the absolute melting temperature of the materials. Diffusion bonding is usually implemented by applying high pressure, in conjunction with necessarily high temperature, to the materials to be welded; the technique is most commonly used to weld "sandwiches" of alternating layers of thin metal foil, and metal wires or filaments. Currently, the diffusion bonding method is widely used in the joining of high-strength and refractory metals within the aerospace and nuclear industries. History The act of diffusion welding is centuries old. This can be found in the form of "gold-filled," a technique used to bond gold and copper ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diffusion Welding Animation

Diffusion is the net movement of anything (for example, atoms, ions, molecules, energy) generally from a region of higher concentration to a region of lower concentration. Diffusion is driven by a gradient in Gibbs free energy or chemical potential. It is possible to diffuse "uphill" from a region of lower concentration to a region of higher concentration, like in spinodal decomposition. The concept of diffusion is widely used in many fields, including physics ( particle diffusion), chemistry, biology, sociology, economics, and finance (diffusion of people, ideas, and price values). The central idea of diffusion, however, is common to all of these: a substance or collection undergoing diffusion spreads out from a point or location at which there is a higher concentration of that substance or collection. A gradient is the change in the value of a quantity, for example, concentration, pressure, or temperature with the change in another variable, usually distance. A change i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Asperity (materials Science)

In materials science, asperity, defined as "unevenness of surface, roughness, ruggedness" (from the Latin ''asper''—"rough"), has implications (for example) in physics and seismology. Smooth surfaces, even those polished to a mirror finish, are not truly smooth on a microscopic scale. They are rough, with sharp, rough or rugged projections, termed "asperities". Surface asperities exist across multiple scales, often in a self affine or fractal geometry. The fractal dimension of these structures has been correlated with the contact mechanics exhibited at an interface in terms of friction and contact stiffness. When two macroscopically smooth surfaces come into contact, initially they only touch at a few of these asperity points. These cover only a very small portion of the surface area. Friction and wear originate at these points, and thus understanding their behavior becomes important when studying materials in contact. When the surfaces are subjected to a compressive load, t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nacelle

A nacelle ( ) is a "streamlined body, sized according to what it contains", such as an engine, fuel, or equipment on an aircraft. When attached by a pylon entirely outside the airframe, it is sometimes called a pod, in which case it is attached with a pylon or strut and the engine is known as a podded engine. In some cases—for instance in the typical "Farman" type "pusher" aircraft, or the World War II-era P-38 Lightning—an aircraft cockpit may also be housed in a nacelle, rather than in a conventional fuselage. Etymology Like many aviation terms, the word comes from French, in this case from a word for a small boat. Development The development of the Arado Ar 234, merging the four nacelles into two The Arado Ar 234 was one of the first operational jet aircraft with engines mounted in nacelles. During its development, the four jet engines were merged from having four distinct nacelles, all of which contained their own landing gear wheel, to two nacelles with two engi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Landing Gear

Landing gear is the undercarriage of an aircraft or spacecraft that is used for takeoff or landing. For aircraft it is generally needed for both. It was also formerly called ''alighting gear'' by some manufacturers, such as the Glenn L. Martin Company. For aircraft, Stinton makes the terminology distinction ''undercarriage (British) = landing gear (US)''. For aircraft, the landing gear supports the craft when it is not flying, allowing it to take off, land, and taxi without damage. Wheeled landing gear is the most common, with skis or floats needed to operate from snow/ice/water and skids for vertical operation on land. Faster aircraft have retractable undercarriages, which fold away during flight to reduce drag. Some unusual landing gear have been evaluated experimentally. These include: no landing gear (to save weight), made possible by operating from a catapult cradle and flexible landing deck: air cushion (to enable operation over a wide range of ground obstacles and wat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuselage

The fuselage (; from the French ''fuselé'' "spindle-shaped") is an aircraft's main body section. It holds crew, passengers, or cargo. In single-engine aircraft, it will usually contain an engine as well, although in some amphibious aircraft the single engine is mounted on a pylon attached to the fuselage, which in turn is used as a floating hull. The fuselage also serves to position the control and stabilization surfaces in specific relationships to lifting surfaces, which is required for aircraft stability and maneuverability. Types of structures Truss structure This type of structure is still in use in many lightweight aircraft using welded steel tube trusses. A box truss fuselage structure can also be built out of wood—often covered with plywood. Simple box structures may be rounded by the addition of supported lightweight stringers, allowing the fabric covering to form a more aerodynamic shape, or one more pleasing to the eye. Geodesic construction Geo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strategic Material

Strategic material is any sort of raw material that is important to an individual's or organization's strategic plan and supply chain management. Lack of supply of strategic materials may leave an organization or government vulnerable to disruption of the manufacturing of products which require those materials. It can also refer to a group or department that manages these materials. In government terms, they are materials, usually raw materials that have a particular strategic significance to a government or nation, often in time of war. Their strategic need is because of their crucial importance for either economic or military purposes. Some materials are relatively simple, but are required in great quantities during wartime. Others are obscure and technically complex. Although not required in large quantities, their irreplaceability and critical need makes them especially valuable. Foodstuffs are not generally classed as strategic materials: although vital, they are treated ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Military Aircraft

A military aircraft is any fixed-wing or rotary-wing aircraft that is operated by a legal or insurrectionary armed service of any type. Military aircraft can be either combat or non-combat: * Combat aircraft are designed to destroy enemy equipment or personnel using their own aircraft ordnance. Combat aircraft are typically developed and procured only by military forces. * Non-combat aircraft are not designed for combat as their primary function, but may carry weapons for self-defense. These mainly operate in support roles, and may be developed by either military forces or civilian organizations. History Lighter-than-air In 1783, when the first practical aircraft (hot-air and hydrogen balloons) were established, they were quickly adopted for military duties. The first military balloon unit was the French Aerostatic Corps, who in 1794 flew an observation balloon during the Battle of Fleurus, the first major battle to feature aerial observation. Balloons continued to be use ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

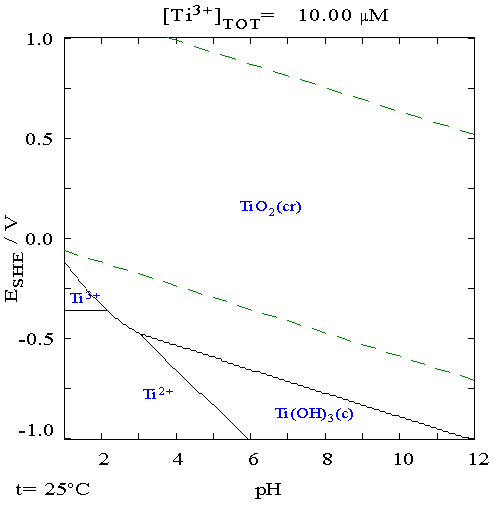

Titanium

Titanium is a chemical element with the symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in sea water, aqua regia, and chlorine. Titanium was discovered in Cornwall, Great Britain, by William Gregor in 1791 and was named by Martin Heinrich Klaproth after the Titans of Greek mythology. The element occurs within a number of minerals, principally rutile and ilmenite, which are widely distributed in the Earth's crust and lithosphere; it is found in almost all living things, as well as bodies of water, rocks, and soils. The metal is extracted from its principal mineral ores by the Kroll and Hunter processes. The most common compound, titanium dioxide, is a popular photocatalyst and is used in the manufacture of white pigments. Other compounds include titanium tetrachloride (TiCl4), a component of smoke screens and catalysts; and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Superplastic Forming

Superplastic forming is an industrial process used for creating precise and complex components out of superplastic materials. Process The material is first heated up to promote superplasticity. For titanium alloys e.g. Ti 6Al 4V and some stainless steels this is around and for aluminium alloys e.g. AA5083 it is between 450 and 520 °C. In this state the material becomes soft so processes that are usually used on plastics can be applied, such as: thermoforming, blow forming, and vacuum forming.E. Degarmo, J. Black, and R. Kohser, Materials and Processes in Manufacturing (9th ed.), 2003, Wiley, . Inert gas pressure is applied on the superplastic sheet forcing it into a female die. Advantages and disadvantages The major advantage of this process is that it can form large and complex workpieces in one operation. The finished product has excellent precision and a fine surface finish. It also does not suffer from springback or residual stresses. Products can also be made larger t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Explosion Welding

Explosion welding (EXW) is a solid state (solid-phase) process where welding is accomplished by accelerating one of the components at extremely high velocity through the use of chemical explosives. This process is often used to clad carbon steel or aluminium plate with a thin layer of a harder or more corrosion-resistant material (e.g., stainless steel, nickel alloy, titanium, or zirconium). Due to the nature of this process, producible geometries are very limited. Typical geometries produced include plates, tubing and tube sheets. Development Unlike other forms of welding such as arc welding (which was developed in the late 19th century), explosion welding was developed relatively recently, in the decades after World War II. Its origins, however, go back to World War I, when it was observed that pieces of shrapnel sticking to armor plating were not only embedding themselves, but were actually being welded to the metal. Since the extreme heat involved in other forms of welding ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Output 9GbY2F

Output may refer to: * The information produced by a computer, see Input/output * An output state of a system, see state (computer science) * Output (economics), the amount of goods and services produced ** Gross output in economics, the value of net output or GDP plus intermediate consumption ** Net output in economics, the gross revenue from production less the value of goods and services * Power (physics) or Work (physics) In physics, work is the energy transferred to or from an object via the application of force along a displacement. In its simplest form, for a constant force aligned with the direction of motion, the work equals the product of the force stre ... output of a machine * Dependent variable of a function, in mathematics * ''Output'' (album) {{disambiguation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tensile Testing

Tensile testing, also known as tension testing, is a fundamental materials science and engineering test in which a sample is subjected to a controlled tension until failure. Properties that are directly measured via a tensile test are ultimate tensile strength, breaking strength, maximum elongation and reduction in area. From these measurements the following properties can also be determined: Young's modulus, Poisson's ratio, yield strength, and strain-hardening characteristics. ''Uniaxial tensile testing'' is the most commonly used for obtaining the mechanical characteristics of isotropic materials. Some materials use biaxial tensile testing. The main difference between these testing machines being how load is applied on the materials. Purposes of tensile testing Tensile testing might have a variety of purposes, such as: *Select a material or item for an application *Predict how a material will perform in use: normal and extreme forces. * Determine if, or verify that, the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)