|

Dado Blade

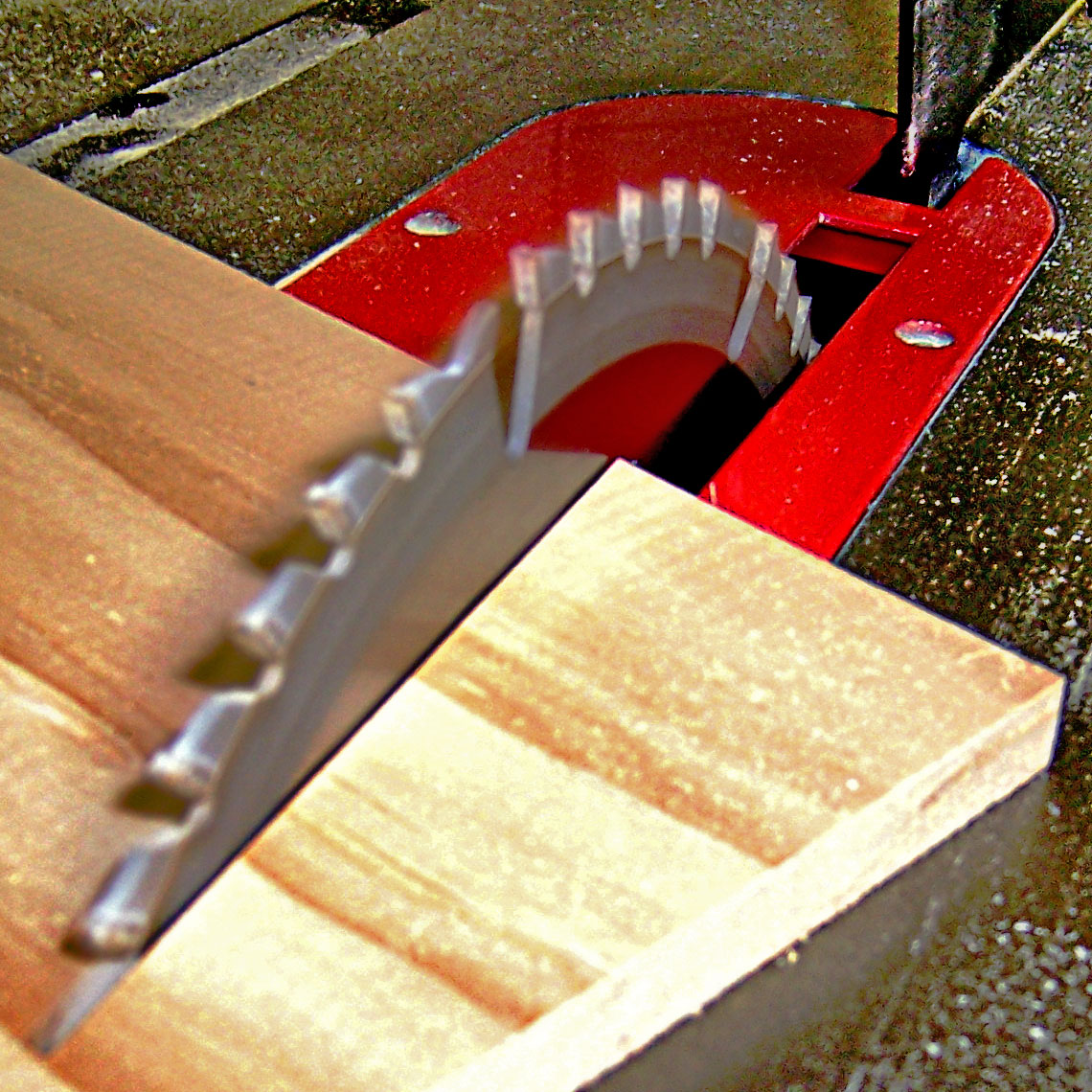

A dado set or dado blade is a type of circular saw blade, usually used with a table saw or radial arm saw, which is used to cut dadoes or grooves in woodworking Woodworking is the skill of making items from wood, and includes cabinet making (cabinetry and furniture), wood carving, woodworking joints, joinery, carpentry, and woodturning. History Along with Rock (geology), stone, clay and animal parts, .... There are two common kinds of dado sets, stacked dado set and wobble blade. Stacked dado set consists of two circular saw blades fixed on either side of a set of removable chippers. As the dado set spins, the two outside blades cut the dado walls and the chippers remove the waste material in between and smooth the bottom of the dado. The chippers are added or removed to the set as required to make a dado of the desired width. Chippers can also be interspersed with spacers to finely adjust the dado width. Consequently, changing the dado width requires the complete remova ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Circular Saw

A circular saw is a power-saw using a toothed or abrasive disc or blade to cut different materials using a rotary motion spinning around an arbor. A hole saw and ring saw also use a rotary motion but are different from a circular saw. ''Circular saws'' may also be loosely used for the blade itself. Circular saws were invented in the late 18th century and were in common use in sawmills in the United States by the middle of the 19th century. A circular saw is a tool for cutting many materials such as wood, masonry, plastic, or metal and may be hand-held or mounted to a machine. In woodworking the term "circular saw" refers specifically to the hand-held type and the table saw and chop saw are other common forms of circular saws. "Skilsaw" and "Skil saw" have become generic trademarks for conventional hand-held circular saws. Circular saw blades are specially designed for each particular material they are intended to cut and in cutting wood are specifically designed for making ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Table Saw

A table saw (also known as a sawbench or bench saw in England) is a woodworking tool, consisting of a circular saw blade, mounted on an arbor, that is driven by an electric motor (either directly, by belt, or by gears). The blade protrudes through the top of a table, which provides support for the material, usually wood, being cut. In most modern table saws, the depth of the cut is varied by moving the blade up and down: the higher the blade protrudes above the table, the deeper the cut that is made in the material. In some early table saws, the blade and arbor were fixed, and the table was moved up and down to expose more or less of the blade. The angle of cut is controlled by adjusting the angle of blade. Some earlier saws angled the table to control the cut angle. Types The general types of table saws are compact, benchtop, jobsite, contractor, hybrid, cabinet, and sliding table saws. Benchtop Benchtop table saws are lightweight and are designed to be placed on a table o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Radial Arm Saw

A radial arm saw is a cutting machine consisting of a circular saw mounted on a sliding horizontal arm. Invented by Raymond DeWalt in 1922, the radial arm saw was the primary tool used for cutting long pieces of stock to length until the introduction of the power miter saw in the 1970s. In addition to making length cuts, a radial arm saw may be configured with a dado blade to create cuts for dado, rabbet or half lap joints. In addition some radial arm saws allow the blade to be turned parallel to the back fence, allowing a rip cut to be performed. Origins Unlike most types of woodworking machinery, the radial arm saw has a clear genesis: it was invented by Raymond DeWalt of Leola, Pennsylvania. DeWalt applied for patents in 1923, which were issued in 1925 (US Patent 1,528,536). DeWalt and others subsequently patented many variations on the original, but DeWalt's original design (sold under the moniker Wonder Worker) remained the most successful: a circular saw blade directly ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dado (joinery)

A dado (US and Canada), housing (UK) or trench (Europe) is a slot or trench cut into the surface of a piece of machinable material, usually wood. When viewed in cross-section, a dado has three sides. A dado is cut across, or perpendicular to, the grain and is thus differentiated from a groove which is cut with, or parallel to the grain. Dados are often used to affix shelves to cabinetry bodies. Similar to the dado, see rabbet (rebate). Variations * A ''through'' dado involves cuts which run between both edges of the surface, leaving both ends open. * A ''stopped'' or ''blind'' dado ends before one (stopped) or both (blind) of the cuts meets the edge of the surface. * A ''half dado'' is formed with a narrow dado cut into one part, coupled with a rabbet of another piece. This joint tends to be used because of its ability to hide unattractive gaps due to varying material thicknesses. See also * Dado set * Woodworking joints Joinery is a part of woodworking that involves joi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Groove (joinery)

In joinery, a groove is a slot or trench cut into a member which runs parallel to the grain. A groove is thus differentiated from a dado, which runs across the grain. Grooves are used for a range of purposes in cabinet making and other woodworking fields. Typically, grooves are used to house the panels in frame and panel construction and the bottoms of drawers. For more structural construction, grooves are created along the sides and/or ends of panels, such as in tongue and groove construction. Applications include roofing, siding and flooring. A groove may be ''through'', meaning that it passes all the way through the surface and its ends are open, or ''stopped'', meaning that one or both of the ends finish before the groove meets edge of the surface. Methods A groove can be cut by the following methods: * electric router using a straight or rebate bit * circular saw with multiple passes (depending on width and depth) *dado set in a single pass *spindle moulder (wood shaper ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodworking

Woodworking is the skill of making items from wood, and includes cabinet making (cabinetry and furniture), wood carving, woodworking joints, joinery, carpentry, and woodturning. History Along with Rock (geology), stone, clay and animal parts, wood was one of the first materials worked by early humans. Lithic analysis, Microwear analysis of the Mousterian stone tools used by the Neanderthals show that many were used to work wood. The development of civilization was closely tied to the development of increasingly greater degrees of skill in working these materials. Among early finds of wooden tools are the worked sticks from Kalambo Falls, Clacton-on-Sea and Lehringen. The spears from Schöningen (Germany) provide some of the first examples of wooden hunting gear. Flint tools were used for carving. Since Neolithic, Neolithic times, carved wooden vessels are known, for example, from the Linear Pottery culture water well, wells at Kückhofen and Eythra. Examples of Bronze Age woo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mandrel

A mandrel, mandril, or arbor is a gently tapered cylinder against which material can be forged or shaped (e.g., a ring mandrel - also called a triblet - used by jewelers to increase the diameter of a wedding ring), or a flanged or tapered or threaded bar that grips a workpiece to be machined in a lathe. A flanged mandrel is a parallel bar of a specific diameter with an integral flange towards one end, and threaded at the opposite end. Work is gripped between the flange and a nut on the thread. A tapered mandrel (often called a plain mandrel) has a taper of approximately 0.005 inches per foot and is designed to hold work by being driven into an accurate hole on the work, gripping the work by friction. A threaded mandrel may have a male or female thread, and work which has an identical thread is screwed onto the mandrel. On a lathe, mandrels are commonly mounted between centres and driven by a lathe dog (typically the flanged or tapered mandrels), but may also be gripped in a ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Saws

A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge. It is used to cut through material, very often wood, though sometimes metal or stone. The cut is made by placing the toothed edge against the material and moving it forcefully forth and less vigorously back or continuously forward. This force may be applied by hand, or powered by steam, water, electricity or other power source. An abrasive saw has a powered circular blade designed to cut through metal or ceramic. Terminology * Abrasive saw: A saw that cuts with an abrasive disc or band, rather than a toothed blade. * Back: the edge opposite the toothed edge. * Fleam: The angle of the faces of the teeth relative to a line perpendicular to the face of the saw. * Gullet: The valley between the points of the teeth. * Heel: The end closest to the handle. * Kerf: The narrow channel left behind by the saw and (relatedly) the measure of its width. The kerf depends on several factors: the width of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |