|

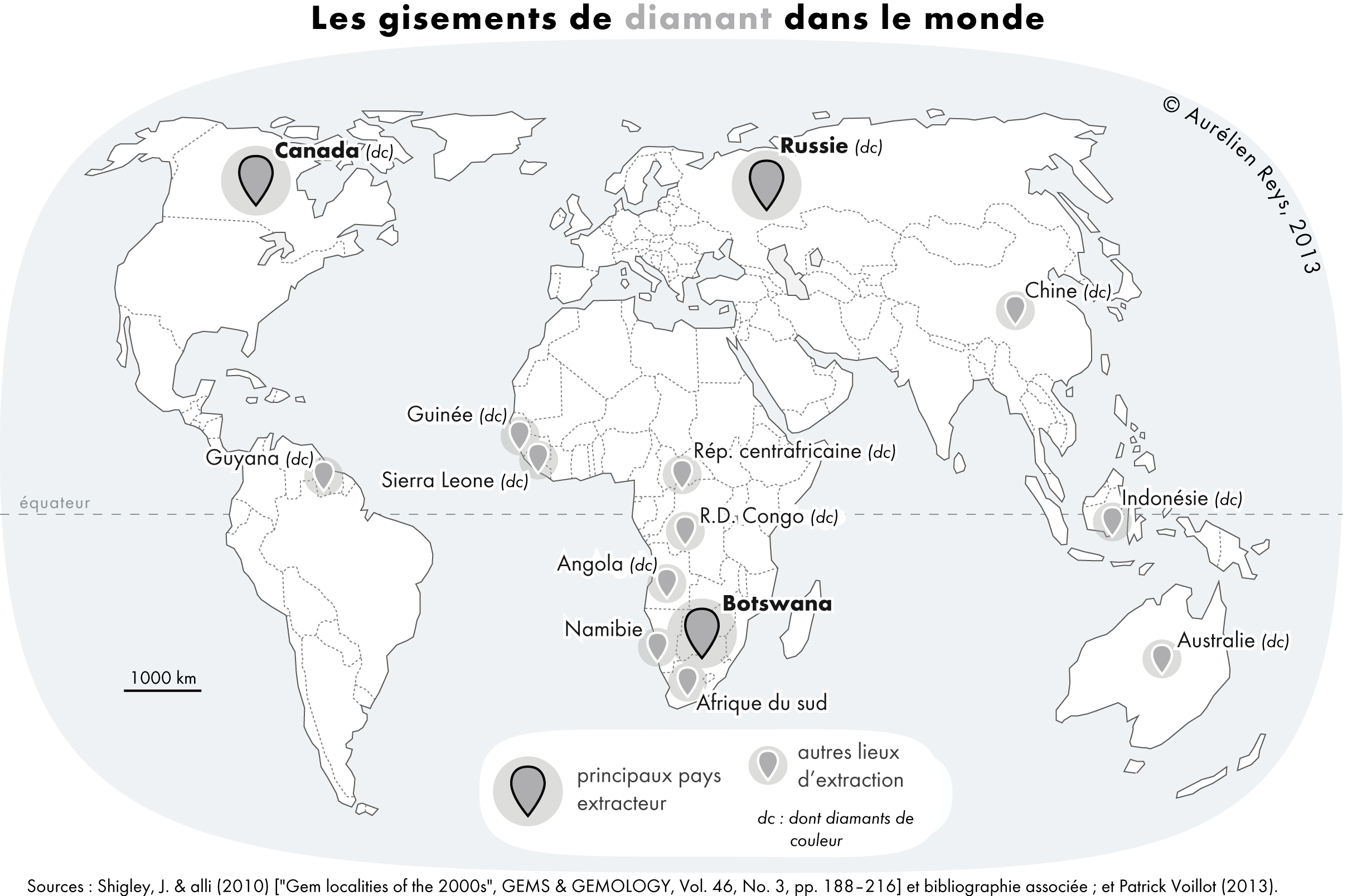

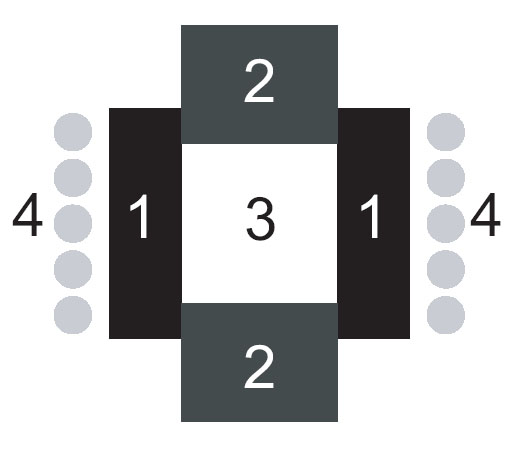

Diamond Segment

Diamond segment are the functional parts of a metal-bonded diamond tool. The metal-bonded diamond tool can be a metal-bonded diamond blade, a diamond grinding cup wheel, a diamond core drill bit, a diamond gang saw blade, etc. The diamonds of a metal-bonded diamond tool are all in the tool's diamond segments to play their role of cutting or grinding. Structure Diamond segments consist of small-size diamonds and metal bond materials. The metal bond materials may include the powders of Cu, Sn, Fe, Ag, Co, Ni, WC, Mo, graphite, etc. The diamonds are mixed with the bond materials, and the mixture is loaded into molds. After hot pressing Hot pressing is a high-pressure, low-strain-rate powder metallurgy process for forming of a powder or powder compact at a temperature high enough to induce sintering and creep processes. This is achieved by the simultaneous application of heat ... or cold pressing, sintering, and arc grinding, diamond segments are formed. The metal bond has two b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diamond Tool

A diamond tool is a cutting tool with diamond grains fixed on the functional parts of the tool via a bonding material or another method. As diamond is a superhard material, diamond tools have many advantages as compared with tools made with common abrasives such as corundum and silicon carbide. History In '' Natural History'', Pliny wrote "When an ''adamas'' is successfully broken it disintegrates into splinters so small as to be scarcely visible. These are much sought after by engravers of gems and are inserted by them into iron tools because they make hollows in the hardest materials without difficulty." Advantages Diamond is one of the hardest natural materials on earth; much harder than corundum and silicon carbide. Diamond also has high strength, good wear resistance, and a low friction coefficient. So when used as an abrasive, it has many obvious advantages over many other common abrasives. Advantages of diamond grinding tools Diamond can be used to make grinding tools ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diamond Blade

A diamond blade is a saw blade which has diamonds fixed on its edge for cutting hard or abrasive materials. There are many types of diamond blade, and they have many uses, including cutting stone, concrete, asphalt, bricks, coal balls, glass, and ceramics in the construction industry; cutting semiconductor materials in the semiconductor industry; and cutting gemstones, including diamonds, in the gem industry. Types Diamond blades are available in different shapes: * '' Circular diamond saw blades'' are the most widely used type of diamond blade. * A ''diamond gang saw blade'' is a long steel plate with diamond segments welded onto it. Normally, tens or hundreds of diamond gang saw blades are used together to saw raw stone blocks. * A ''diamond band saw blade'' is a flexible closed steel band with diamonds fixed (often by electroplating) on one edge of the band. Diamond blades designed for specific uses include marble, granite, concrete, asphalt, masonry, and gem-cutting bla ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diamond Grinding Cup Wheel

A diamond grinding cup wheel is a metal-bonded diamond tool with diamond segments welded or cold-pressed on a steel (or other metal, such as aluminum) wheel body, which usually looks like a cup. Diamond grinding cup wheels are usually mounted on concrete grinders to grind abrasive building materials like concrete, granite and marble. Use There are various styles and specifications of diamond grinding cup wheels to fit various application requirements. The ones with many big diamond segments can undertake heavy workloads, for example, grinding concrete and stone, while those with small or sparse diamond segments are normally used for fast removal of paints, wallpapers, glues, epoxy and other surface coatings. Just like other metal-bonded diamond tools, the diamond segments on diamond grinding cup wheels can have different bonds, different diamond grits, different diamond quality and different diamond concentrations to fit different uses. For example, if the material to be ground ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diamond Core Drill Bit

A hole saw (also styled holesaw), also known as a hole cutter, is a saw blade of annular (ring) shape, whose annular kerf creates a hole in the workpiece without having to cut up the core material. It is used in a drill. Hole saws typically have a pilot drill bit (arbor) at their center to keep the saw teeth from walking. The fact that a hole saw creates the hole without needing to cut up the core often makes it preferable to twist drills or spade drills for relatively large holes (especially those larger than ). The same hole can be made faster and using less power. The depth to which a hole saw can cut is limited by the depth of its cup-like shape. Most hole saws have a fairly short aspect ratio of diameter to depth, and they are used to cut through relatively thin workpieces. However, longer aspect ratios are available for applications that warrant them. Cutting with a hole saw is analogous to some machining operations, called ''trepanning'' in the trade, that swing a c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diamond

Diamond is a solid form of the element carbon with its atoms arranged in a crystal structure called diamond cubic. Another solid form of carbon known as graphite is the chemically stable form of carbon at room temperature and pressure, but diamond is metastable and converts to it at a negligible rate under those conditions. Diamond has the highest hardness and thermal conductivity of any natural material, properties that are used in major industrial applications such as cutting and polishing tools. They are also the reason that diamond anvil cells can subject materials to pressures found deep in the Earth. Because the arrangement of atoms in diamond is extremely rigid, few types of impurity can contaminate it (two exceptions are boron and nitrogen). Small numbers of defects or impurities (about one per million of lattice atoms) color diamond blue (boron), yellow (nitrogen), brown (defects), green (radiation exposure), purple, pink, orange, or red. Diamond also has a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hot Pressing

Hot pressing is a high-pressure, low-strain-rate powder metallurgy process for forming of a powder or powder compact at a temperature high enough to induce sintering and creep processes. This is achieved by the simultaneous application of heat and pressure. Hot pressing is mainly used to fabricate hard and brittle materials. One large use is in the consolidation of diamond-metal composite cutting tools and technical ceramics. The densification works through particle rearrangement and plastic flow at the particle contacts. The loose powder or the pre-compacted part is in most of the cases filled to a graphite mould that allows induction or resistance heating up to temperatures of typically . Pressures of up to can be applied. Other great use is in the pressing of different types of polymers. Within hot pressing technology, three distinctly different types of heating can be found in use: induction heating, indirect resistance heating and field assisted sintering technique ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalworking Cutting Tools

Metalworking is the process of shaping and reshaping metals to create useful objects, parts, assemblies, and large scale structures. As a term it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, and bridges down to precise engine parts and delicate jewelry. The historical roots of metalworking predate recorded history; its use spans cultures, civilizations and millennia. It has evolved from shaping soft, native metals like gold with simple hand tools, through the smelting of ores and hot forging of harder metals like iron, up to highly technical modern processes such as machining and welding. It has been used as an industry, a driver of trade, individual hobbies, and in the creation of art; it can be regarded as both a science and a craft. Modern metalworking processes, though diverse and specialized, can be categorized into one of three broad areas known as forming, cutting, or joining processes. Mo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |