|

Cross-flow Filtration

In chemical engineering, biochemical engineering and protein purification, crossflow filtration (also known as tangential flow filtration) is a type of filtration (a particular unit operation). Crossflow filtration is different from dead-end filtration in which the feed is passed through a membrane or bed, the solids being trapped in the filter and the filtrate being released at the other end. Cross-flow filtration gets its name because the majority of the feed flow travels tangentially ''across'' the surface of the filter, rather than into the filter. The principal advantage of this is that the filter cake (which can blind the filter) is substantially washed away during the filtration process, increasing the length of time that a filter unit can be operational. It can be a continuous process, unlike batch-wise dead-end filtration. This type of filtration is typically selected for feeds containing a high proportion of small particle size solids (where the permeate is of most val ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cross-flow

Crossflow may refer to: * Ford Crossflow, the 1967 version of the Ford Kent engine * Crossflow cylinder head * Cross-flow fan, a type of mechanical fan * Cross-flow filtration, a filtration technique * Cross-flow turbine A cross-flow turbine, Bánki-Michell turbine, or Ossberger turbine''E.F. Lindsley,'' Water power for your homePopular Science, May 1977, Vol. 210, No. 5 87-93. is a water turbine developed by the Australian Anthony Michell, the Hungarian Donát B ..., a type of water (or air) turbine {{disambig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tangent

In geometry, the tangent line (or simply tangent) to a plane curve at a given point is the straight line that "just touches" the curve at that point. Leibniz defined it as the line through a pair of infinitely close points on the curve. More precisely, a straight line is said to be a tangent of a curve at a point if the line passes through the point on the curve and has slope , where ''f'' is the derivative of ''f''. A similar definition applies to space curves and curves in ''n''-dimensional Euclidean space. As it passes through the point where the tangent line and the curve meet, called the point of tangency, the tangent line is "going in the same direction" as the curve, and is thus the best straight-line approximation to the curve at that point. The tangent line to a point on a differentiable curve can also be thought of as a '' tangent line approximation'', the graph of the affine function that best approximates the original function at the given point. Similarly, t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Citric Acid

Citric acid is an organic compound with the chemical formula HOC(CO2H)(CH2CO2H)2. It is a colorless weak organic acid. It occurs naturally in citrus fruits. In biochemistry, it is an intermediate in the citric acid cycle, which occurs in the metabolism of all aerobic organisms. More than two million tons of citric acid are manufactured every year. It is used widely as an acidifier, as a flavoring, and a chelating agent. A citrate is a derivative of citric acid; that is, the salts, esters, and the polyatomic anion found in solution. An example of the former, a salt is trisodium citrate; an ester is triethyl citrate. When part of a salt, the formula of the citrate anion is written as or . Natural occurrence and industrial production Citric acid occurs in a variety of fruits and vegetables, most notably citrus fruits. Lemons and limes have particularly high concentrations of the acid; it can constitute as much as 8% of the dry weight of these fruits (about 47 g/L in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sodium Hypochlorite

Sodium hypochlorite (commonly known in a dilute solution as bleach) is an Inorganic chemistry, inorganic chemical compound with the chemical formula, formula NaOCl (or NaClO), comprising a sodium cation () and a hypochlorite anion (or ). It may also be viewed as the sodium salt (chemistry), salt of hypochlorous acid. The anhydrous Chemical compound, compound is unstable and may decompose explosively. It can be crystallized as a hydrate, pentahydrate ·5, a pale greenish-yellow solid which is not explosive and is stable if kept refrigerated. Sodium hypochlorite is most often encountered as a pale greenish-yellow dilute solution referred to as liquid bleach, which is a household chemical widely used (since the 18th century) as a disinfectant or a bleaching agent. In solution, the compound is unstable and easily decomposes, liberating chlorine, which is the active principle of such products. Sodium hypochlorite is the oldest and still most important chlorine-releasing compounds, chl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Clean-in-place

Clean-in-place (CIP) is an automated method of cleaning the interior surfaces of pipes, vessels, equipment, filters and associated fittings, without major disassembly. CIP is commonly used for equipment such as piping, tanks, and fillers. CIP employs turbulent flow through piping, and/or spray balls for large surfaces. In some cases, CIP can also be accomplished with fill, soak and agitate. Up to the 1950s, closed systems were disassembled and cleaned manually. The advent of CIP was a boon to industries that needed frequent internal cleaning of their processes. Industries that rely heavily on CIP are those requiring high levels of hygiene, and include: dairy, beverage, brewing, processed foods, pharmaceutical, and cosmetics. The benefit to industries that use CIP is that the cleaning is faster, less labor-intensive and more repeatable, and poses less of a chemical exposure risk. CIP started as a manual practice involving a balance tank, centrifugal pump, and connection to the syst ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Repligen

Repligen is an American company devoted to the development and production of materials used in the manufacture of biological drugs. The company is based in Waltham, Massachusetts, and incorporated in Delaware in 1981. A public company, Repligen is listed on the NASDAQ exchange under the symbol RGEN. , Repligen employed 116 people, about 50% of these based in Sweden. Business model Before 2012, Repligen maintained dual capabilities in developing pharmaceutical therapeutics (drug discovery and development) and the development of materials supporting biological drug manufacture (bioprocessing business). A decision was made in 2012 to focus on the bioprocessing business and reduce research and development expenditures. In the period of 2010 to 2013, the majority of sales by the company were concentrated in the single Protein A product line. Sales and revenue Repligen employs a direct sales model to users of its products in the United States, with some sales through interm ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diaphragm Pump

A diaphragm pump (also known as a Membrane pump) is a positive displacement pump that uses a combination of the reciprocating action of a rubber, thermoplastic or teflon diaphragm and suitable valves on either side of the diaphragm ( check valve, butterfly valves, flap valves, or any other form of shut-off valves) to pump a fluid. There are three main types of diaphragm pumps: * Those in which the diaphragm is sealed with one side in the fluid to be pumped, and the other in air or hydraulic fluid. The diaphragm is flexed, causing the volume of the pump chamber to increase and decrease. A pair of non-return check valves prevent reverse flow of the fluid. * Those employing volumetric positive displacement where the prime mover of the diaphragm is electro-mechanical, working through a crank or geared motor drive, or purely mechanical, such as with a lever or handle. This method flexes the diaphragm through simple mechanical action, and one side of the diaphragm is open to air. * T ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Clean-in-place (CIP)

Clean-in-place (CIP) is an automated method of cleaning the interior surfaces of pipes, vessels, equipment, filters and associated fittings, without major disassembly. CIP is commonly used for equipment such as piping, tanks, and fillers. CIP employs turbulent flow through piping, and/or spray balls for large surfaces. In some cases, CIP can also be accomplished with fill, soak and agitate. Up to the 1950s, closed systems were disassembled and cleaned manually. The advent of CIP was a boon to industries that needed frequent internal cleaning of their processes. Industries that rely heavily on CIP are those requiring high levels of hygiene, and include: dairy, beverage, brewing, processed foods, pharmaceutical, and cosmetics. The benefit to industries that use CIP is that the cleaning is faster, less labor-intensive and more repeatable, and poses less of a chemical exposure risk. CIP started as a manual practice involving a balance tank, centrifugal pump, and connection to the syst ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microfiltration

Microfiltration is a type of physical filtration process where a contaminated fluid is passed through a special pore-sized membrane filter to separate microorganisms and suspended particles from process liquid. It is commonly used in conjunction with various other separation processes such as ultrafiltration and reverse osmosis to provide a product stream which is free of undesired contaminants. General principles Microfiltration usually serves as a pre-treatment for other separation processes such as ultrafiltration, and a post-treatment for granular media filtration. The typical particle size used for microfiltration ranges from about 0.1 to 10 μm.Baker, R 2012, ''Microfiltration, in Membrane Technology and Applications'', 3rd edn, John Wiley & Sons Ltd, California. p. 303 In terms of approximate molecular weight these membranes can separate macromolecules of molecular weights generally less than 100,000 g/mol.Microfiltration/Ultrafiltration, 2008, Hyflux Membranes, accesse ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ultrafiltration

Ultrafiltration (UF) is a variety of membrane filtration in which forces such as pressure or concentration gradients lead to a separation through a semipermeable membrane. Suspended solids and solutes of high molecular weight are retained in the so-called retentate, while water and low molecular weight solutes pass through the membrane in the permeate (filtrate). This separation process is used in industry and research for purifying and concentrating macromolecular (103–106 Da) solutions, especially protein solutions. Ultrafiltration is not fundamentally different from microfiltration. Both of these separate based on size exclusion or particle capture. It is fundamentally different from membrane gas separation, which separate based on different amounts of absorption and different rates of diffusion. Ultrafiltration membranes are defined by the molecular weight cut-off (MWCO) of the membrane used. Ultrafiltration is applied in cross-flow or dead-end mode. Applications Ind ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanofiltration

Nanofiltration is a membrane filtration process used most often to soften and disinfect water. Overview Nanofiltration is a Membrane technology, membrane filtration-based method that uses nanometer sized pores through which particles smaller than 10 nanometers pass through the membrane. Nanofiltration membranes have pore sizes from 1-10 nanometers, smaller than that used in microfiltration and ultrafiltration, but a little bit bigger than that in reverse osmosis. Membranes used are predominantly created from polymer thin films. Materials that are commonly used include polyethylene terephthalate or metals such as aluminum. Pore dimensions are controlled by pH, temperature and time during development with pore densities ranging from 1 to 106 pores per cm2. Membranes made from polyethylene terephthalate and other similar materials, are referred to as "track-etch" membranes, named after the way the pores on the membranes are made. "Tracking" involves bombarding the polymer thin fi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reverse Osmosis

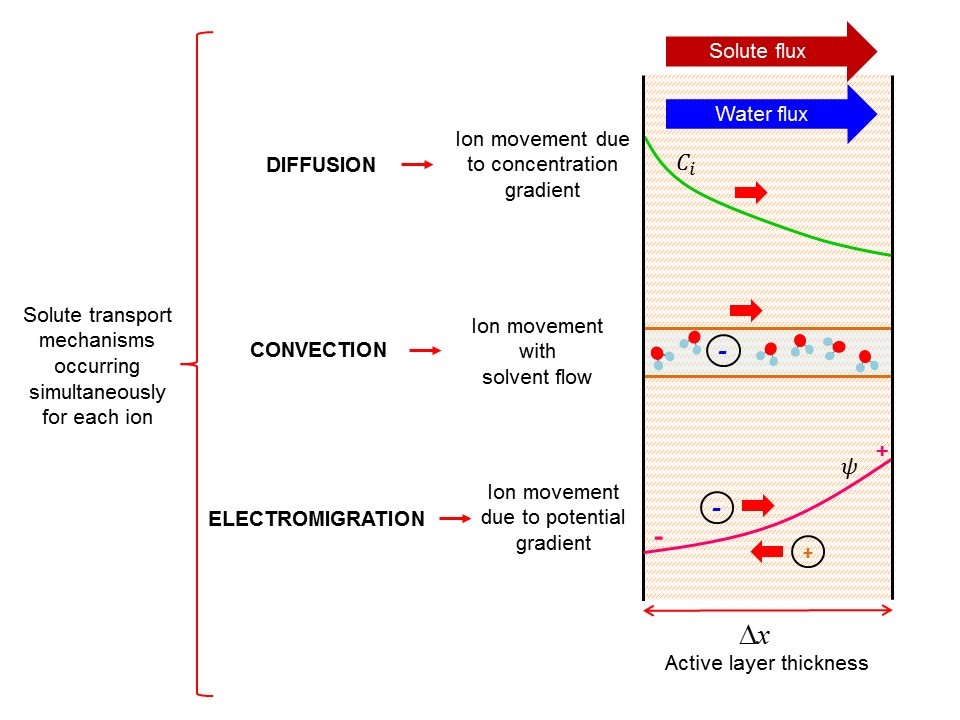

Reverse osmosis (RO) is a water purification process that uses a partially permeable membrane to separate ions, unwanted molecules and larger particles from drinking water. In reverse osmosis, an applied pressure is used to overcome osmotic pressure, a colligative property that is driven by chemical potential differences of the solvent, a thermodynamic parameter. Reverse osmosis can remove many types of dissolved and suspended chemical species as well as biological ones (principally bacteria) from water, and is used in both industrial processes and the production of potable water. The result is that the solute is retained on the pressurized side of the membrane and the pure solvent is allowed to pass to the other side. To be "selective", this membrane should not allow large molecules or ions through the wiktionary:pore, pores (holes), but should allow smaller components of the solution (such as solvent molecules, e.g., water, H2O) to pass freely. In the normal osmosis process, t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |