|

Composite Propeller

Marine composite propellers are ship propellers, usually made from fiber composites like glass or carbon fibers infused with a high-strength resin like epoxy or polyimide. These kinds of composites are made from strong, light, and high-tech materials. Such composite propellers can be produced in several ways, including vacuum infused molding and injection molding processes, depending on size and resin viscosity. Advantages The composite propellers can be made with Lay-Up process which causes anisotropic properties. This can be designed to create a passive adaptation of the propeller blades passive self-twisting propeller. Self-twisting blades are much more energy-efficient compared to rigid propeller blades. Passive adaptation in form might also be affected by propeller geometry. Lower unit production cost and production without heat are the main advantages of composite material. While the initial cost of a composite propeller is usually comparable to aluminum, it is signifi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Propeller

A propeller (colloquially often called a screw if on a ship or an airscrew if on an aircraft) is a device with a rotating hub and radiating blades that are set at a pitch to form a helical spiral which, when rotated, exerts linear thrust upon a working fluid such as water or air. Propellers are used to pump fluid through a pipe or duct, or to create thrust to propel a boat through water or an aircraft through air. The blades are specially shaped so that their rotational motion through the fluid causes a pressure difference between the two surfaces of the blade by Bernoulli's principle which exerts force on the fluid. Most marine propellers are screw propellers with helical blades rotating on a propeller shaft (ship), propeller shaft with an approximately horizontal axis. History Early developments The principle employed in using a screw propeller is derived from sculling. In sculling, a single blade is moved through an arc, from side to side taking care to keep presenting the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glass Fiber

Glass fiber ( or glass fibre) is a material consisting of numerous extremely fine fibers of glass. Glassmakers throughout history have experimented with glass fibers, but mass manufacture of glass fiber was only made possible with the invention of finer machine tooling. In 1893, Edward Drummond Libbey exhibited a dress at the World's Columbian Exposition incorporating glass fibers with the diameter and texture of silk fibers. Glass fibers can also occur naturally, as Pele's hair. Glass wool, which is one product called "fiberglass" today, was invented some time between 1932 to 1933 by Games Slayter of Owens-Illinois, as a material to be used as thermal building insulation. It is marketed under the trade name Fiberglas, which has become a genericized trademark. Glass fiber when used as a thermal insulating material is specially manufactured with a bonding agent to trap many small air cells, resulting in the characteristically air-filled low-density "glass wool" family of pro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

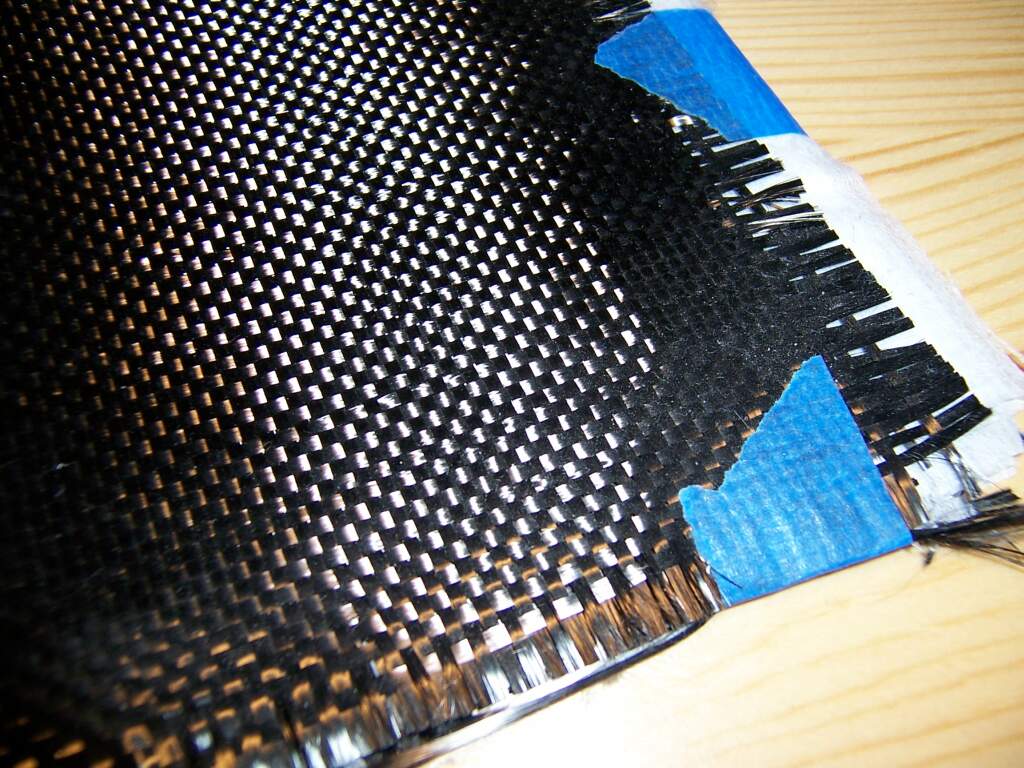

Carbon Fibers

Carbon fibers or carbon fibres (alternatively CF, graphite fiber or graphite fibre) are fibers about in diameter and composed mostly of carbon atoms. Carbon fibers have several advantages: high stiffness, high tensile strength, high strength to weight ratio, high chemical resistance, high-temperature tolerance, and low thermal expansion. These properties have made carbon fiber very popular in aerospace, civil engineering, military, motorsports, and other competition sports. However, they are relatively expensive compared to similar fibers, such as glass fiber, basalt fibers, or plastic fibers. To produce a carbon fiber, the carbon atoms are bonded together in crystals that are more or less aligned parallel to the fiber's long axis as the crystal alignment gives the fiber a high strength-to-volume ratio (in other words, it is strong for its size). Several thousand carbon fibers are bundled together to form a tow, which may be used by itself or woven into a fabric. Carbon f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Epoxy

Epoxy is the family of basic components or cured end products of epoxy resins. Epoxy resins, also known as polyepoxides, are a class of reactive prepolymers and polymers which contain epoxide groups. The epoxide functional group is also collectively called ''epoxy''. The IUPAC name for an epoxide group is an oxirane. Epoxy resins may be reacted (cross-linked) either with themselves through catalytic homopolymerisation, or with a wide range of co-reactants including polyfunctional amines, acids (and acid anhydrides), phenols, alcohols and thiols (usually called mercaptans). These co-reactants are often referred to as hardeners or curatives, and the cross-linking reaction is commonly referred to as curing. Reaction of polyepoxides with themselves or with polyfunctional hardeners forms a thermosetting polymer, often with favorable mechanical properties and high thermal and chemical resistance. Epoxy has a wide range of applications, including metal coatings, composites, use in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyimide

Polyimide (sometimes abbreviated PI) is a polymer containing imide groups belonging to the class of high-performance plastics. With their high heat-resistance, polyimides enjoy diverse applications in roles demanding rugged organic materials, e.g. high temperature fuel cells, displays, and various military roles. A classic polyimide is Kapton, which is produced by condensation of pyromellitic dianhydride and 4,4'-oxydianiline.Wright, Walter W. and Hallden-Abberton, Michael (2002) "Polyimides" in ''Ullmann's Encyclopedia of Industrial Chemistry'', Wiley-VCH, Weinheim. History The first polyimide was discovered in 1908 by Bogart and Renshaw. They found that 4-amino phthalic anhydride does not melt when heated but does release water upon the formation of a high molecular weight polyimide. The first semialiphatic polyimide was prepared by Edward and Robinson by melt fusion of diamines and tetra acids or diamines and diacids / diester. However, the first polyimide of significant ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

High-tech

High technology (high tech), also known as advanced technology (advanced tech) or exotechnology, is technology that is at the cutting edge: the highest form of technology available. It can be defined as either the most complex or the newest technology on the market. The opposite of high tech is '' low technology'', referring to simple, often traditional or mechanical technology; for example, a slide rule is a low-tech calculating device. When high tech becomes old, it becomes low tech, for example vacuum tube electronics. The phrase was used in a 1958 ''The New York Times'' story advocating "atomic energy" for Europe: "... Western Europe, with its dense population and its high technology ...." Robert Metz used the term in a financial column in 1969, saying Arthur H. Collins of Collins Radio "controls a score of high technology patents in a variety of fields." and in a 1971 article used the abbreviated form, "high tech." A widely used classification of high-technological manuf ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Injection Molding

Injection moulding (U.S. spelling: injection molding) is a manufacturing process for producing parts by injecting molten material into a mould, or mold. Injection moulding can be performed with a host of materials mainly including metals (for which the process is called die-casting), glasses, elastomers, confections, and most commonly thermoplastic and thermosetting polymers. Material for the part is fed into a heated barrel, mixed (using a helical screw), and injected into a mould cavity, where it cools and hardens to the configuration of the cavity. After a product is designed, usually by an industrial designer or an engineer, moulds are made by a mould-maker (or toolmaker) from metal, usually either steel or aluminium, and precision-machined to form the features of the desired part. Injection moulding is widely used for manufacturing a variety of parts, from the smallest components to entire body panels of cars. Advances in 3D printing technology, using photopolymers that ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lay-Up Process

A Lay-Up process is a moulding process for composite materials, in which the final product is obtained by overlapping a specific number of different layers, usually made of continuous polymeric or ceramic fibres and a thermoset polymeric liquid matrix. It can be divided into Dry Lay-up and Wet Lay-Up, depending on whether the layers are pre-impregnated or not. Dry Lay-up is a common process in the aerospace industry, due to the possibility of obtaining complex shapes with good mechanical properties, characteristics required in this field. On the contrary, as Wet Lay-Up does not allow uni-directional fabrics, which have better mechanical properties, it is mainly adopted for all other areas, which in general have lower requirements in terms of performance. The main stages of the Lay-Up process are cutting, lamination and polymerization. Even though some of the production steps can be automated, this process is mainly manual (hence often referred to as the Hand Lay-Up process), leadin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminum

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It has a great affinity towards oxygen, and forms a protective layer of oxide on the surface when exposed to air. Aluminium visually resembles silver, both in its color and in its great ability to reflect light. It is soft, non-magnetic and ductile. It has one stable isotope, 27Al; this isotope is very common, making aluminium the twelfth most common element in the Universe. The radioactivity of 26Al is used in radiodating. Chemically, aluminium is a post-transition metal in the boron group; as is common for the group, aluminium forms compounds primarily in the +3 oxidation state. The aluminium cation Al3+ is small and highly charged; as such, it is polarizing, and bonds aluminium forms tend towards covalency. The strong affinity towards ox ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stainless Steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's corrosion resistance, resistance to corrosion results from the chromium, which forms a Passivation (chemistry), passive film that can protect the material and self-healing material, self-heal in the presence of oxygen. The alloy's properties, such as luster and resistance to corrosion, are useful in many applications. Stainless steel can be rolled into Sheet metal, sheets, plates, bars, wire, and tubing. These can be used in cookware, cutlery, surgical instruments, major appliances, vehicles, construction material in large buildings, industrial equipment (e.g., in paper mills, chemical plants, water treatment), and storage tanks and tankers for chemicals and food products. The biological cleanability of stainless steel is superior to both alumi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engineering is the field dedicated to controlling and preventing corrosion. In the most common use of the word, this means electrochemical oxidation of metal in reaction with an oxidant such as oxygen, hydrogen or hydroxide. Rusting, the formation of iron oxides, is a well-known example of electrochemical corrosion. This type of damage typically produces oxide(s) or salt(s) of the original metal and results in a distinctive orange colouration. Corrosion can also occur in materials other than metals, such as ceramics or polymers, although in this context, the term "degradation" is more common. Corrosion degrades the useful properties of materials and structures including strength, appearance and permeability to liquids and gases. Many structural ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Saline Water

Saline water (more commonly known as salt water) is water that contains a high concentration of dissolved salts (mainly sodium chloride). On the United States Geological Survey (USGS) salinity scale, saline water is saltier than brackish water, but less salty than brine. The salt concentration is usually expressed in parts per thousand (permille, ‰) and parts per million (ppm). The USGS salinity scale defines three levels of saline water. The salt concentration in slightly saline water is 1,000 to 3,000 ppm (0.1–0.3%); in moderately saline water is 3,000 to 10,000 ppm (0.3–1%); and in highly saline water is 10,000 to 35,000 ppm (1–3.5%). Seawater has a salinity of roughly 35,000 ppm, equivalent to 35 grams of salt per one liter (or kilogram) of water. The saturation level is only nominally dependent on the temperature of the water. At one liter of water can dissolve about 357 grams of salt, a concentration of 26.3% w/w. At boiling () the amount that can be dissolved in o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |