|

Crankcase Compression Two-stroke Engine

In a piston engine, the crankcase is the housing that surrounds the crankshaft. In most modern engines, the crankcase is integrated into the engine block. Two-stroke engines typically use a crankcase-compression design, resulting in the fuel/air mixture passing through the crankcase before entering the cylinder(s). This design of the engine does not include an oil sump in the crankcase. Four-stroke engines typically have an oil sump at the bottom of the crankcase and the majority of the engine's oil is held within the crankcase. The fuel/air mixture does not pass through the crankcase in a four-stroke engine, however a small amount of exhaust gasses often enter as "blow-by" from the combustion chamber. The crankcase often forms the lower half of the main bearing journals (with the bearing caps forming the other half), although in some engines the crankcase completely surrounds the main bearing journals. An ''open-crank'' engine has no crankcase. This design was used in earl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scavenge Blower

The diesel engine, named after Rudolf Diesel, is an internal combustion engine in which ignition of the fuel is caused by the elevated temperature of the air in the cylinder due to mechanical compression; thus, the diesel engine is a so-called compression-ignition engine (CI engine). This contrasts with engines using spark plug-ignition of the air-fuel mixture, such as a petrol engine (gasoline engine) or a gas engine (using a gaseous fuel like natural gas or liquefied petroleum gas). Diesel engines work by compressing only air, or air plus residual combustion gases from the exhaust (known as exhaust gas recirculation (EGR)). Air is inducted into the chamber during the intake stroke, and compressed during the compression stroke. This increases the air temperature inside the cylinder to such a high degree that atomised diesel fuel injected into the combustion chamber ignites. With the fuel being injected into the air just before combustion, the dispersion of the fuel is uneven; ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tunnel Crankcase

A tunnel crankcase, tunnel crankshaft or disc-webbed crankshaft engine is a design feature of a diesel engine or petrol engine where the crankshaft is designed so that the main bearings (the bearings that support the crankshaft within the crankcase) are enlarged in diameter, such that they are now larger than the crank webs (the radial arms that link the big end bearings to the main bearings). They thus form the largest diameter of any part of the crankshaft. Rather than a conventional crankcase that has webs across it to support the narrow bearings of a conventional crankcase, the crankcase now has a large tunnel through it, hence the name. Tunnel crankcases appeared in the 1930s with the first high-speed diesel engines. They were favoured by some makers more than others, notably Saurer in Switzerland and Maybach-Motorenbau GmbH (now MTU) Friedrichshafen. They are described as both 'tunnel crankcases' and 'roller bearing cranks'; the two aspects are related and it is unclear as t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piston

A piston is a component of reciprocating engines, reciprocating pumps, gas compressors, hydraulic cylinders and pneumatic cylinders, among other similar mechanisms. It is the moving component that is contained by a cylinder and is made gas-tight by piston rings. In an engine, its purpose is to transfer force from expanding gas in the cylinder to the crankshaft via a piston rod and/or connecting rod. In a pump, the function is reversed and force is transferred from the crankshaft to the piston for the purpose of compressing or ejecting the fluid in the cylinder. In some engines, the piston also acts as a valve by covering and uncovering ports in the cylinder. __TOC__ Piston engines Internal combustion engines An internal combustion engine is acted upon by the pressure of the expanding combustion gases in the combustion chamber space at the top of the cylinder. This force then acts downwards through the connecting rod and onto the crankshaft. The connecting rod is att ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gardner 0 Engine, Abergavenny Steam Rally, 2015

Gardner may refer to: Name *Gardner (given name) *Gardner (surname) Places United States *Gardner, Colorado *Gardner, Illinois *Gardner, Kansas *Gardner, Massachusetts * Gardner, North Dakota *Gardner, Tennessee *Gardner, Wisconsin *Glen Gardner, New Jersey Geographical features *Gardner (crater) on the Moon *Gardner Canal in British Columbia, Canada *Gardner Inlet in Antarctica *Gardner Pinnacles in Hawaii, United States *Gardner River in Yellowstone National Park, United States *Gardner Island or Nikumaroro, part of the Phoenix Islands, Kiribati Institutions *Gardner–Webb University in North Carolina *Isabella Stewart Gardner Museum in Boston, Massachusetts *L. Gardner and Sons Ltd., Patricroft, Manchester, England - a builder of diesel engines *Gardner (automobile), a car maker based in St. Louis, Missouri, between 1920 and 1931 Animals *Gardner snake, any species of North American snake within the genus ''Thamnophis'', more properly called garter snakes Weapons *Gardner ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piston Ring

A piston ring is a metallic split ring that is attached to the outer diameter of a piston in an internal combustion engine or steam engine. The main functions of piston rings in engines are: # Sealing the combustion chamber so that there is minimal loss of gases to the crank case. # Improving heat transfer from the piston to the cylinder wall. # Maintaining the proper quantity of the oil between the piston and the cylinder wall # Regulating engine oil consumption by scraping oil from the cylinder walls back to the sump. Most piston rings are made from cast iron or steel. Design Piston rings are designed to seal the gap between the piston and the cylinder wall. If this gap were too small, thermal expansion of the piston could mean the piston seizes in the cylinder, causing serious damage to the engine. On the other hand, a large gap would cause insufficient sealing of the piston rings against the cylinder walls, resulting in excessive blow-by (combustion gases entering the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Windage

Windage is a term used in aerodynamics, firearms ballistics, and automobiles. Usage Aerodynamics Windage is a force created on an object by friction when there is relative movement between air and the object. Windage loss is the reduction in efficiency due to windage forces. For example, electric motors are affected by friction between the rotor and air. Large alternators have significant losses due to windage. To reduce losses, hydrogen gas may be used, since it is less dense. There are two causes of windage: # The object is moving and being slowed by resistance from the air. # A wind is blowing, producing a force on the object. The term can refer to: * The effect of the force, for example the deflection of a missile or an aircraft by a cross wind. * The area and shape of the object that make it susceptible to friction, for example those parts of a boat that are exposed to the wind. Aerodynamic streamlining can be used to reduce windage. There is a hydrodynamic effect si ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

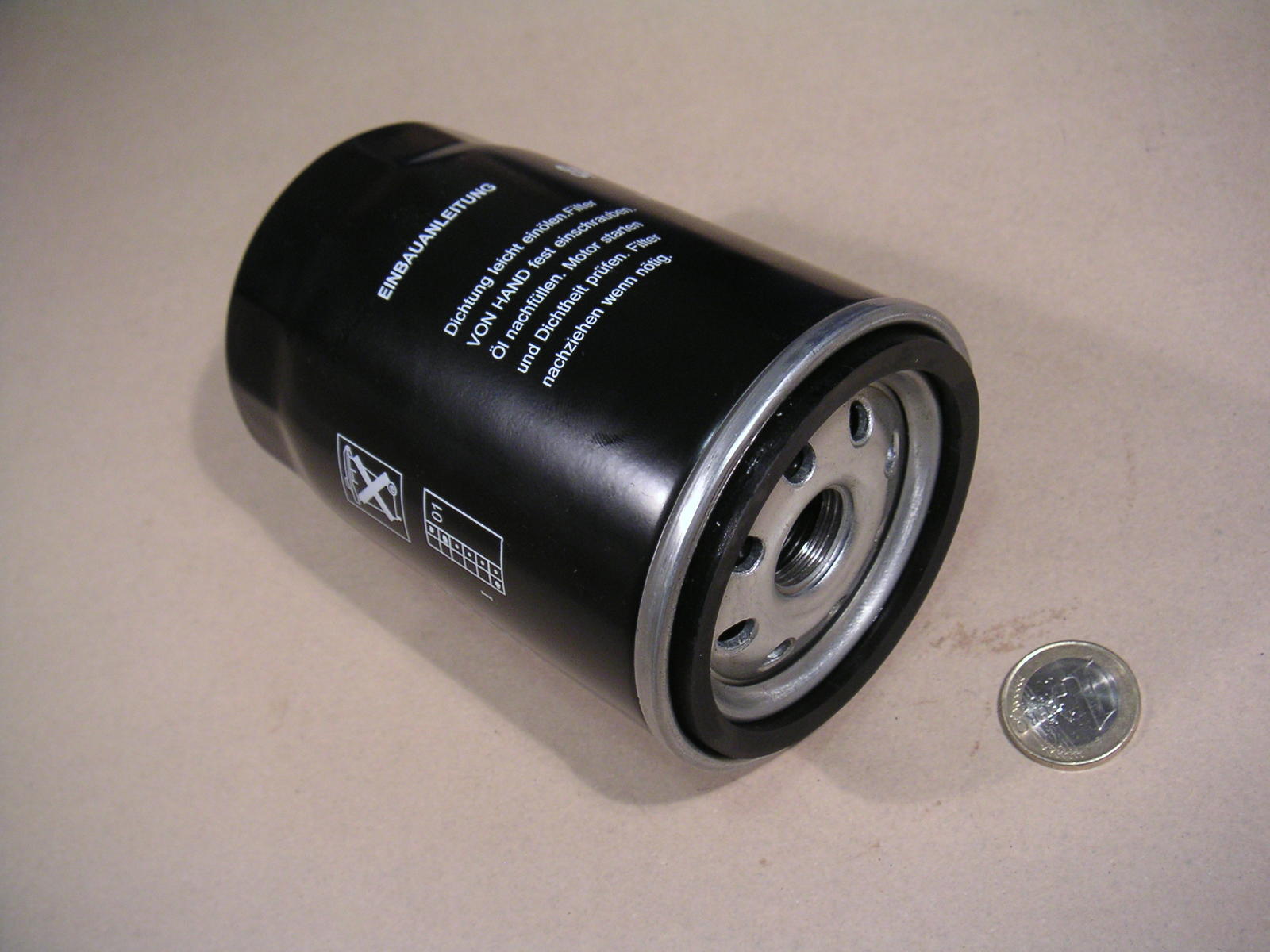

Oil Filter

An oil filter is a filter designed to remove contaminants from engine oil, transmission oil, lubricating oil, or hydraulic oil. Their chief use is in internal-combustion engines for motor vehicles (both on- and off-road ), powered aircraft, railway locomotives, ships and boats, and static engines such as generators and pumps. Other vehicle hydraulic systems, such as those in automatic transmissions and power steering, are often equipped with an oil filter. Gas turbine engines, such as those on jet aircraft, also require the use of oil filters. Oil filters are used in many different types of hydraulic machinery. The oil industry itself employs filters for oil production, oil pumping, and oil recycling. Modern engine oil filters tend to be "full-flow" (inline) or "bypass". History Early automobile engines did not have oil filters, having only a rudimentary mesh sieve placed at the oil pump intake. Consequently, along with the generally low quality of oil available, very freque ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oil Pump (internal Combustion Engine)

The oil pump is an internal combustion engine part that circulates engine oil under pressure to the rotating bearings, the sliding pistons and the camshaft of the engine. This lubricates the bearings, allows the use of higher-capacity fluid bearings and also assists in cooling the engine. As well as its primary purpose for lubrication, pressurized oil is increasingly used as a hydraulic fluid to power small actuators. One of the first notable uses in this way was for hydraulic tappets in camshaft and valve actuation. Increasingly common recent uses may include the tensioner for a timing belt or variators for variable valve timing systems. Pumps The type of pump used varies. Gear pumps trochoid pumps and vane pumps are all commonly used. Plunger pumps have been used in the past, but these are now only used rarely, for small engines. To avoid the need for priming, the pump is always mounted low-down, either submerged or around the level of the oil in the sump. A short pick-up ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dry Sump

A dry-sump system is a method to manage the lubricating motor oil in four-stroke and large two-stroke piston driven internal combustion engines. The dry-sump system uses two or more oil pumps and a separate oil reservoir, as opposed to a conventional wet-sump system, which uses only the main sump (U.S.: oil pan) below the engine and a single pump. A dry-sump engine requires a pressure relief valve to regulate negative pressure inside the engine, so internal seals are not inverted. Dry-sumps are common on larger diesel engines such as those used in ships, as well as gasoline engines used in racing cars, aerobatic aircraft, high-performance personal watercraft and motorcycles. Dry sump lubrication may be chosen for these applications due to increased reliability, oil capacity, reduction of oil starvation under high g-loads and/or other technical or performance reasons. Dry sump systems may not be suitable for all applications due to increased cost, complexity, and/or bulk, am ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wet Sump

Within piston engines, a wet sump is part of a lubrication system whereby the crankcase sump is used as an integral oil reservoir. An alternative system is the dry sump, whereby oil is pumped from a shallow sump into an external reservoir.Wet sump and dry sump compared - https://www.knowyourparts.com/technical-resources/engine/oil-system-differences/#:~:text=Dry%20Oil%20Systems%20Wet%20sump%20systems%20store%20the,is%20used%20to%20pump%20oil%20from%20the%20motor. Piston engines are lubricated by oil which is pumped into various bearings, and thereafter allowed to drain to the base of the engine under gravity. In most production automobiles and motorcycles, which use a wet sump system, the oil is collected in a capacity pan at the base of the engine, known as the sump or oil pan, where it is pumped back up to the bearings by the internal oil pump. A wet sump offers the advantage of a simple design, using a single pump and no external reservoir. Since the sump is internal, th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Four-stroke Engine

A four-stroke (also four-cycle) engine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either direction. The four separate strokes are termed: #Intake: Also known as induction or suction. This stroke of the piston begins at top dead center (T.D.C.) and ends at bottom dead center (B.D.C.). In this stroke the intake valve must be in the open position while the piston pulls an air-fuel mixture into the cylinder by producing vacuum pressure into the cylinder through its downward motion. The piston is moving down as air is being sucked in by the downward motion against the piston. #Compression: This stroke begins at B.D.C, or just at the end of the suction stroke, and ends at T.D.C. In this stroke the piston compresses the air-fuel mixture in preparation for ignition during the power stroke (below). Both the intake and exhaust valves are close ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)

.jpg)