|

Corrugated Iron

Corrugated galvanised iron or steel, colloquially corrugated iron (near universal), wriggly tin (taken from UK military slang), pailing (in Caribbean English), corrugated sheet metal (in North America) and occasionally abbreviated CGI is a building material composed of sheets of hot-dip galvanised mild steel, cold-rolled to produce a linear ridged pattern in them. Although it is still popularly called "iron" in the UK, the material used is actually steel (which is iron alloyed with carbon for strength, commonly 0.3% carbon), and only the surviving vintage sheets may actually be made up of 100% iron. The corrugations increase the bending strength of the sheet in the direction perpendicular to the corrugations, but not parallel to them, because the steel must be stretched to bend perpendicular to the corrugations. Normally each sheet is manufactured longer in its strong direction. CGI is lightweight and easily transported. It was and still is widely used especially in rural a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sheet Metal

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of shapes. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or coiled strips. The coils are formed by running a continuous sheet of metal through a roll slitter. In most of the world, sheet metal thickness is consistently specified in millimeters. In the U.S., the thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its gauge. The larger the gauge number, the thinner the metal. Commonly used steel sheet metal ranges from 30 gauge to about 7 gauge. Gauge differs between ferrous ( iron-based) metals and nonferrous metals such as aluminum or copper. Cop ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hot-dip Galvanization

Hot-dip galvanization is a form of galvanization. It is the process of coating iron and steel with zinc, which alloys with the surface of the base metal when immersing the metal in a bath of molten zinc at a temperature of around . When exposed to the atmosphere, the pure zinc (Zn) reacts with oxygen ( O2) to form zinc oxide ( ZnO), which further reacts with carbon dioxide ( CO2) to form zinc carbonate ( ZnCO3), a usually dull grey, fairly strong material that protects the steel underneath from further corrosion in many circumstances. Galvanized steel is widely used in applications where corrosion resistance is needed without the cost of stainless steel, and is considered superior in terms of cost and life-cycle. It can be identified by the crystallization patterning on the surface (often called a "spangle"). Galvanized steel can be welded; however, one must exercise caution around the resulting toxic zinc fumes. Galvanized fumes are released when the galvanized metal reach ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rust 1

Rust is an iron oxide, a usually reddish-brown oxide formed by the reaction of iron and oxygen in the catalytic presence of water or air moisture. Rust consists of hydrous iron(III) oxides (Fe2O3·nH2O) and iron(III) oxide-hydroxide (FeO(OH), Fe(OH)3), and is typically associated with the corrosion of refined iron. Given sufficient time, any iron mass, in the presence of water and oxygen, could eventually convert entirely to rust. Surface rust is commonly flaky and friable, and provides no passivational protection to the underlying iron, unlike the formation of patina on copper surfaces. ''Rusting'' is the common term for corrosion of elemental iron and its alloys such as steel. Many other metals undergo similar corrosion, but the resulting oxides are not commonly called "rust". Several forms of rust are distinguishable both visually and by spectroscopy, and form under different circumstances. Other forms of rust include the result of reactions between iron and chlorid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hückeswagen - Kölner Straße - Tennishalle 02 Ies

Hückeswagen ) is a town in the north of Oberbergischen Kreis, in North Rhine-Westphalia, Germany. It is part of the governmental district of Cologne. Geography Hückeswagen is situated on the river Wupper. Two dams, Bevertal dam and Wuppertal dam, are near the city. Hückeswagen's location in the narrow valley and well as the castle mountain are notable. It is located approximately 40 km away from Cologne. Nearby towns are Radevormwald, Wipperfürth, Wermelskirchen and Remscheid. The coat of arms of Hückeswagen The arms were granted on August 9, 1892. The arms show in the upper part the lion from the arms of the Counts of Berg, who bought the area in 1260 from the Counts of Hückeswagen. The lower part is a symbol for the textile industry, which has been important to the town since the late Middle Ages. The combination of lion and spindle appears first in a seal from 1555. History Hückeswagen was an ancestral seat of the counts of Hückeswagen and in 1085 became for t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Formwork

Formwork is Molding (process), molds into which concrete or similar materials are either precast concrete, precast or cast-in-place concrete, cast-in-place. In the context of concrete construction, the falsework supports the shuttering molds. In specialty applications formwork may be permanently incorporated into the final structure, adding insulation or helping reinforce the finished structure. Types Formwork may be made of wood, metal, plastic, or composite materials: #''Traditional timber formwork''. The formwork is built on site out of timber and plywood or moisture-resistant particleboard. It is easy to produce but time-consuming for larger structures, and the plywood facing has a relatively short lifespan. It is still used extensively where the labour costs are lower than the costs for procuring reusable formwork. It is also the most flexible type of formwork, so even where other systems are in use, complicated sections may use it. #''Engineered Formwork System''. Th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

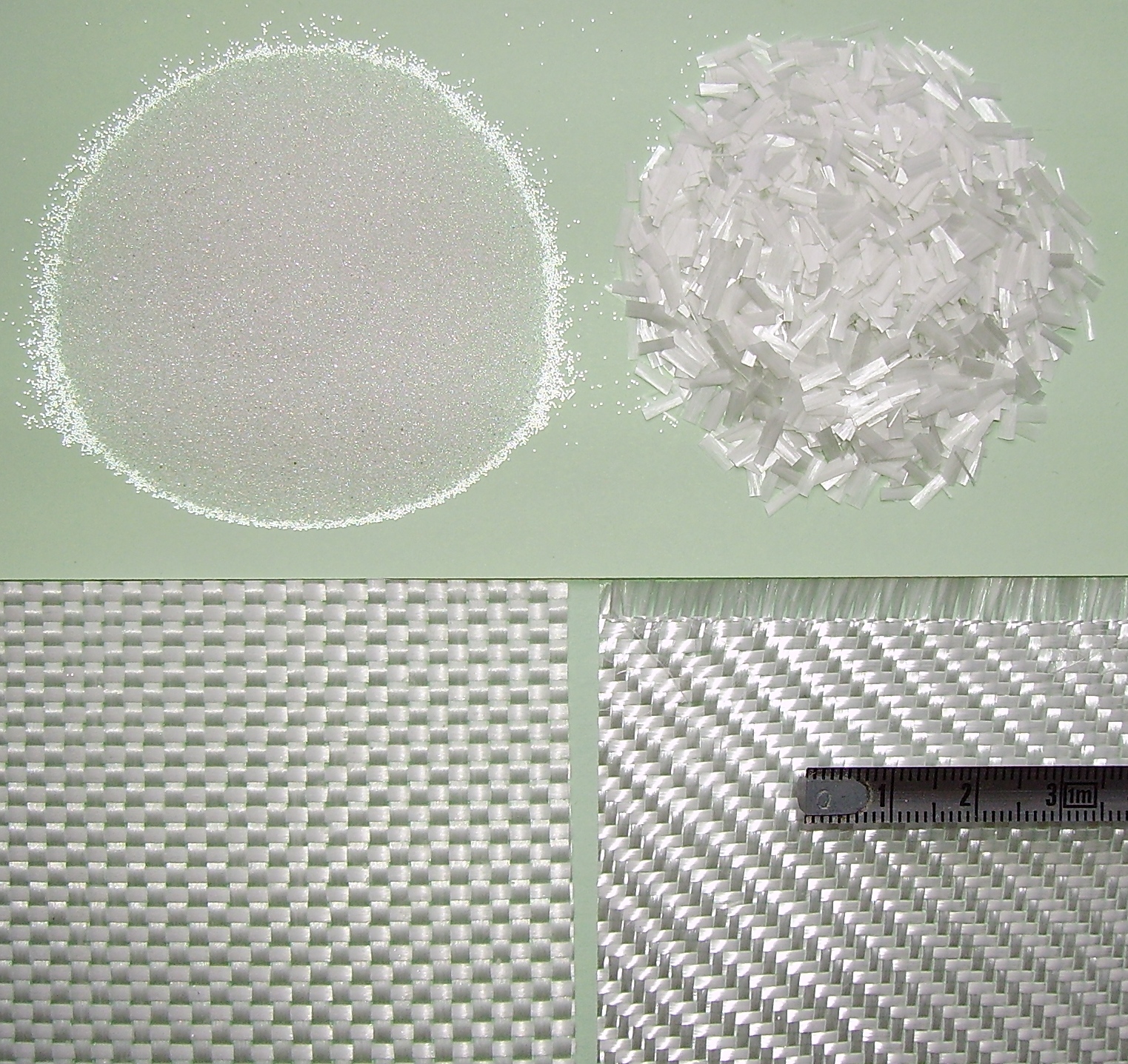

Fibreglass

Fiberglass (American English) or fibreglass (Commonwealth English) is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet called a chopped strand mat, or woven into glass cloth. The plastic matrix may be a thermoset polymer matrix—most often based on thermosetting polymers such as epoxy, polyester resin, or vinyl ester resin—or a thermoplastic. Cheaper and more flexible than carbon fiber, it is stronger than many metals by weight, non-magnetic, non-conductive, transparent to electromagnetic radiation, can be molded into complex shapes, and is chemically inert under many circumstances. Applications include aircraft, boats, automobiles, bath tubs and enclosures, swimming pools, hot tubs, septic tanks, water tanks, roofing, pipes, cladding, orthopedic casts, surfboards, and external door skins. Other common names for fiberglass are glass-reinforced plastic (GRP), glass-fiber reinforced plastic (GFRP) or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sheet Metal Gauge

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process. Sheet metal is one of the fundamental forms used in metalworking, and it can be cut and bent into a variety of shapes. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel. Sheet metal is available in flat pieces or coiled strips. The coils are formed by running a continuous sheet of metal through a roll slitter. In most of the world, sheet metal thickness is consistently specified in millimeters. In the U.S., the thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its gauge. The larger the gauge number, the thinner the metal. Commonly used steel sheet metal ranges from 30 gauge to about 7 gauge. Gauge differs between ferrous ( iron-based) metals and nonferrous metals such as aluminum or copper. Copp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stainless Steel

Stainless steel is an alloy of iron that is resistant to rusting and corrosion. It contains at least 11% chromium and may contain elements such as carbon, other nonmetals and metals to obtain other desired properties. Stainless steel's corrosion resistance, resistance to corrosion results from the chromium, which forms a Passivation (chemistry), passive film that can protect the material and self-healing material, self-heal in the presence of oxygen. The alloy's properties, such as luster and resistance to corrosion, are useful in many applications. Stainless steel can be rolled into Sheet metal, sheets, plates, bars, wire, and tubing. These can be used in cookware, cutlery, surgical instruments, major appliances, vehicles, construction material in large buildings, industrial equipment (e.g., in paper mills, chemical plants, water treatment), and storage tanks and tankers for chemicals and food products. The biological cleanability of stainless steel is superior to both alumi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alloys

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductility, opacity, and luster, but may have properties that differ from those of the pure metals, such as increased strength or hardness. In some cases, an alloy may reduce the overall cost of the material while preserving important properties. In other cases, the mixture imparts synergistic properties to the constituent metal elements such as corrosion resistance or mechanical strength. Alloys are defined by a metallic bonding character. The alloy constituents are usually measured by mass percentage for practical applications, and in atomic fraction for basic science studies. Alloys are usually classified as substitutional or interstitial alloys, depending on the atomic arrangement that forms the alloy. They can be further classified as homogene ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |