|

Competition Cams

Competition Cams, Inc., often styled as COMP Cams, is a specialty performance automotive aftermarket, motorcycle, and kart parts manufacturer. The company has five US locations including headquarters in Memphis, Tennessee. History Although founded in 1976, Competition Cams wasn't incorporated until 1977, when it began by selling valve train products through satellite distribution stores. The company has acquired manufacturers of transmissions, electronic fuel injection, and nitrous oxide systems through its holding group, COMP Performance Group, consisting of 13 companies. In the late 1980s, the company contributed to the Specialty Equipment Market Association (SEMA), and its annual trade show in the Las Vegas Convention Center. Competition Cams was started by John McWhirter, Ivars Smiltniks, Tom Woitesek, and Bob Woodard. Former owners, Ron Coleman and Paul Brothers were inducted into the SEMA Hall of Fame in 2000 and 2005, respectively. In January 2020, Competition Ca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Privately Held Company

A privately held company (or simply a private company) is a company whose shares and related rights or obligations are not offered for public subscription or publicly negotiated in the respective listed markets, but rather the company's stock is offered, owned, traded, exchanged privately, or Over-the-counter (finance), over-the-counter. In the case of a closed corporation, there are a relatively small number of shareholders or company members. Related terms are closely-held corporation, unquoted company, and unlisted company. Though less visible than their public company, publicly traded counterparts, private companies have major importance in the world's economy. In 2008, the 441 list of largest private non-governmental companies by revenue, largest private companies in the United States accounted for ($1.8 trillion) in revenues and employed 6.2 million people, according to ''Forbes''. In 2005, using a substantially smaller pool size (22.7%) for comparison, the 339 companies on ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dynamics (physics)

Dynamics is the branch of classical mechanics that is concerned with the study of forces and their effects on motion. Isaac Newton was the first to formulate the fundamental physical laws that govern dynamics in classical non-relativistic physics, especially his second law of motion. Principles Generally speaking, researchers involved in dynamics study how a physical system might develop or alter over time and study the causes of those changes. In addition, Newton established the fundamental physical laws which govern dynamics in physics. By studying his system of mechanics, dynamics can be understood. In particular, dynamics is mostly related to Newton's second law of motion. However, all three laws of motion are taken into account because these are interrelated in any given observation or experiment. Linear and rotational dynamics The study of dynamics falls under two categories: linear and rotational. Linear dynamics pertains to objects moving in a line and involves such ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sponsor (commercial)

Sponsoring something (or someone) is the act of supporting an event, activity, person, or organization financially or through the provision of products or services. The individual or group that provides the support, similar to a benefactor, is known as the sponsor. Definition Sponsorship is a cash and/or in-kind fee paid to a property (typically in sports, arts, entertainment or causes) in return for access to the exploitable commercial potential associated with that property. While the sponsoree (property being sponsored) may be nonprofit, unlike philanthropy, sponsorship is done with the expectation of a commercial return. While sponsorship can deliver increased awareness, brand building and propensity to purchase, it is different from advertising. Unlike advertising, sponsorship can not communicate specific product attributes. Nor can it stand alone, as sponsorship requires support elements. Theories A range of psychological and communications theories have been used to exp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Superfinishing

Superfinishing, also known as micromachining, microfinishing, and short-stroke honing, is a metalworking process that improves surface finish and workpiece geometry. This is achieved by removing just the thin amorphous surface layer left by the last process with an abrasive stone or tape; this layer is usually about 1 μm in magnitude. Superfinishing, unlike polishing which produces a mirror finish, creates a cross-hatch pattern on the workpiece.. The superfinishing process was developed by the Chrysler Corporation in 1934. Process After a metal piece is ground to an initial finish, it is superfinished with a finer grit solid abrasive. The abrasive is oscillated or rotated while the workpiece is rotated in the opposite direction; these motions are what causes the cross-hatching. The geometry of the abrasive depends on the geometry of the workpiece surface; a stone (rectangular shape) is for cylindrical surfaces and cups and wheels are used for flat and spherical surfaces. A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bearing Journal

A plain bearing, or more commonly sliding contact bearing and slide bearing (in railroading sometimes called a solid bearing, journal bearing, or friction bearing), is the simplest type of bearing, comprising just a bearing surface and no rolling elements. Therefore, the journal (i.e., the part of the shaft in contact with the bearing) slides over the bearing surface. The simplest example of a plain bearing is a shaft rotating in a hole. A simple linear bearing can be a pair of flat surfaces designed to allow motion; e.g., a drawer and the slides it rests on or the ways on the bed of a lathe. Plain bearings, in general, are the least expensive type of bearing. They are also compact and lightweight, and they have a high load-carrying capacity. Design The design of a plain bearing depends on the type of motion the bearing must provide. The three types of motions possible are: * ''Journal'' (''friction'', ''radial'' or ''rotary'') ''bearing'': This is the most common type of p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bearing Surface

A bearing surface in mechanical engineering is the area of contact between two objects. It usually is used in reference to bolted joints and bearings, but can be applied to a wide variety of engineering applications. On a screw the bearing area loosely refers to the underside of the head. Strictly speaking, the bearing area refers to the area of the screw head that directly bears on the part being fastened. For a cylindrical bearing it is the projected area perpendicular to the applied force. On a spring the bearing area refers to the amount of area on the top or bottom surface of the spring in contact with the constraining part.. The ways of machine tools, such as dovetail slides, box ways, prismatic ways, and other types of machine slides are also bearing surfaces. See also *Babbitt, an alloy that covers a bearing surface *Bridge bearing * Pillow block bearing * Plain bearing A plain bearing, or more commonly sliding contact bearing and slide bearing (in railroading so ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanoscopic Scale

The nanoscopic scale (or nanoscale) usually refers to structures with a length scale applicable to nanotechnology, usually cited as 1–100 nanometers (nm). A nanometer is a billionth of a meter. The nanoscopic scale is (roughly speaking) a lower bound to the mesoscopic scale for most solids. For technical purposes, the nanoscopic scale is the size at which fluctuations in the averaged properties (due to the motion and behavior of individual particles) begin to have a significant effect (often a few percent) on the behavior of a system, and must be taken into account in its analysis. The nanoscopic scale is sometimes marked as the point where the properties of a material change; above this point, the properties of a material are caused by 'bulk' or 'volume' effects, namely which atoms are present, how they are bonded, and in what ratios. Below this point, the properties of a material change, and while the type of atoms present and their relative orientations are still importan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface Finish

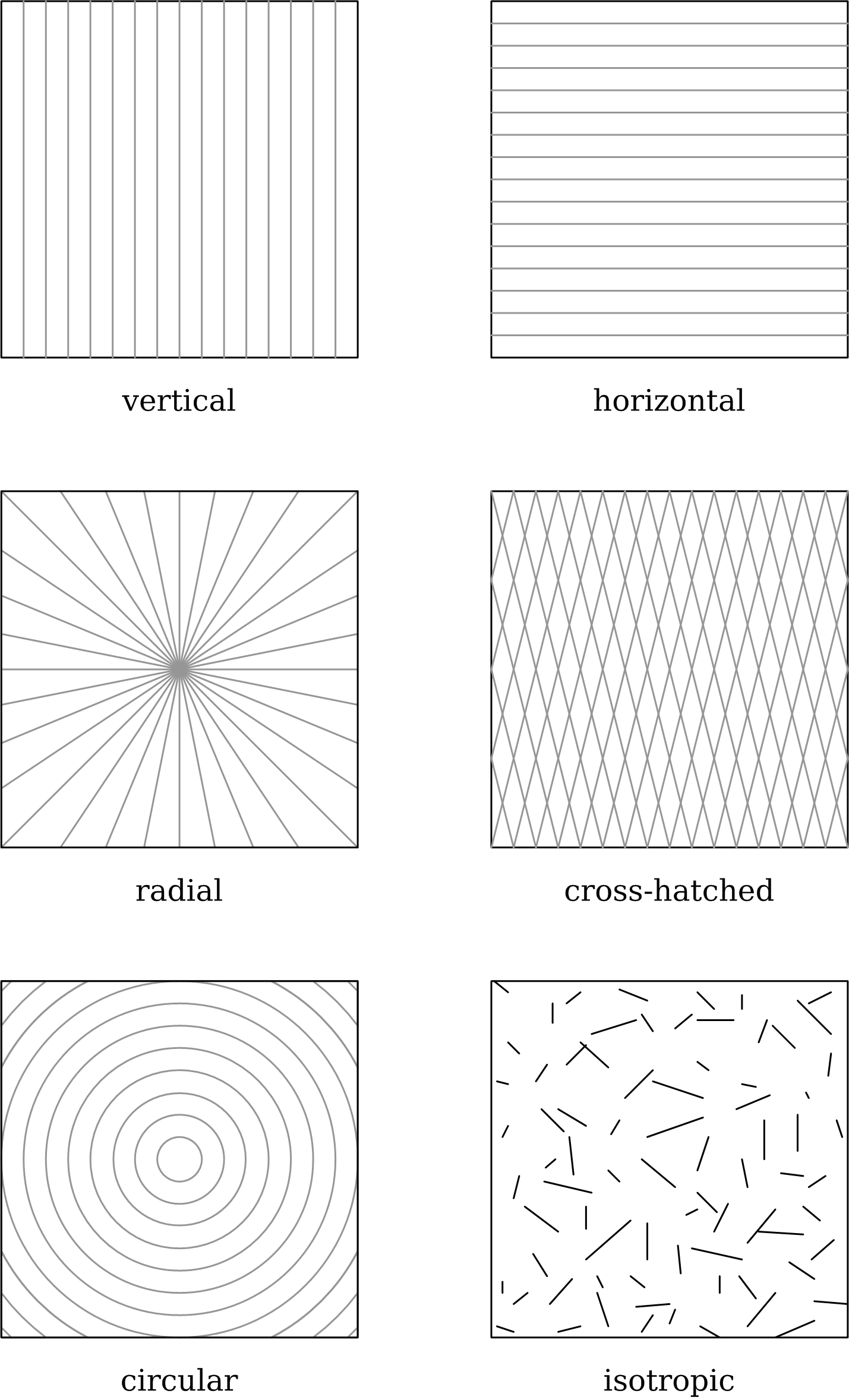

Surface finish, also known as surface texture or surface topography, is the nature of a surface as defined by the three characteristics of lay, surface roughness, and waviness.. It comprises the small, local deviations of a surface from the perfectly flat ideal (a true plane). Surface texture is one of the important factors that control friction and transfer layer formation during sliding. Considerable efforts have been made to study the influence of surface texture on friction and wear during sliding conditions. Surface textures can be isotropic or anisotropic. Sometimes, stick-slip friction phenomena can be observed during sliding, depending on surface texture. Each manufacturing process (such as the many kinds of machining) produces a surface texture. The process is usually optimized to ensure that the resulting texture is usable. If necessary, an additional process will be added to modify the initial texture. The latter process may be grinding (abrasive cutting), polishing, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Modern Machine Shop

''Modern Machine Shop'' (ISSN 0026-8003) is a media brand that reports on product technology and process technology being used in North America's CNC machining and metalworking industry. Modern Machine Shop's audience consists primarily of owners, managers, and engineers at OEMs, contract manufacturers, and job shops that machine for industries including automotive, aerospace, electronics, energy, medical/surgical, defense, and construction equipment. First published in 1928, ''Modern Machine Shop'' is the flagship publication of Gardner Business Media. ''Modern Machine Shops qualified, no-charge subscription base is BPA-audited. As of August 2017, monthly circulation was 85,500. The publisher is Bryce Ellis and the Editor-in-Chief is Pete Zelinski. Editorial offices are located in Cincinnati, Ohio, USA. ''Modern Machine Shop'' is published 12 times per year. ''Modern Machine Shops also maintains a complete suite of multi-media resources used for researching machining and met ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Case-hardening

Case-hardening or surface hardening is the process of hardening the surface of a metal object while allowing the metal deeper underneath to remain soft, thus forming a thin layer of harder metal at the surface. For iron or steel with low carbon content, which has poor to no hardenability of its own, the case-hardening process involves infusing additional carbon or nitrogen into the surface layer. Case-hardening is usually done after the part has been formed into its final shape, but can also be done to increase the hardening element content of bars to be used in a pattern welding or similar process. The term face hardening is also used to describe this technique, when discussing modern armour. Hardening is desirable for metal components that are subject to sliding contact with hard or abrasive materials, as the hardened metal is more resistant to surface wear. However, because hardened metal is usually more brittle than softer metal, through-hardening (that is, hardening the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nitriding

Nitriding is a heat treating process that diffuses nitrogen into the surface of a metal to create a case-hardened surface. These processes are most commonly used on low-alloy steels. They are also used on titanium, aluminium and molybdenum. Typical applications include gears, crankshafts, camshafts, cam followers, valve parts, extruder screws, die-casting tools, forging dies, extrusion dies, firearm components, injectors and plastic-mold tools. Processes The processes are named after the medium used to donate. The three main methods used are: ''gas nitriding'', ''salt bath nitriding'', and ''plasma nitriding''. Gas nitriding In gas nitriding the donor is a nitrogen-rich gas, usually ammonia (NH3), which is why it is sometimes known as ''ammonia nitriding''. When ammonia comes into contact with the heated work piece it dissociates into nitrogen and hydrogen. The nitrogen then diffuses onto the surface of the material creating a nitride layer. This process has existed for nearly ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylindrical Grinder

The cylindrical grinder is a type of grinding machine used to shape the outside of an object. The cylindrical grinder can work on a variety of shapes, however the object must have a central axis of rotation. This includes but is not limited to such shapes as a cylinder, an ellipse, a cam, or a crankshaft.Lewis, Kenneth. ''The Grinding Wheel''. 2nd. Cleveland: Judson Company, 1959. 104-141. Cylindrical grinding is defined as having four essential actions: #The work (object) must be constantly rotating #The grinding wheel must be constantly rotating #The grinding wheel is fed towards and away from the work #Either the work or the grinding wheel is transversed with respect to the other. While the majority of cylindrical grinders employ all four movements, there are grinders that only employ three of the four actions. History The origins of the cylindrical grinder, as with all other modern machine tools, stem from the experimentation and invention of John Wilkinson and later Henry ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)