|

Closed Loop Manufacturing

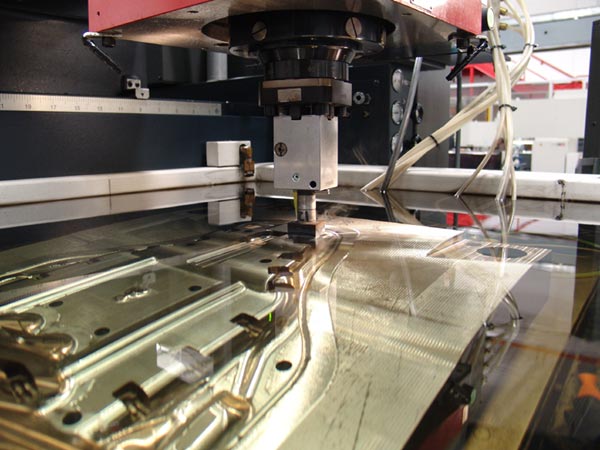

{{unreferenced, date=April 2014 Closed-loop manufacturing (abbreviated CLM) is a closed-loop process of manufacturing and measuring (checking) in the manufacturing machine. The pre-stage to this is inspection in manufacturing. The idea is to reduce costs and improve the quality and accuracy of the produced parts. General procedure Closed-loop manufacturing can be done in different ways dependent on the manufacturing technique and on the accuracy requirements. # Planning the sequence (iterations) # Producing nearly the target value on the part # Measuring the real value # Calculating the residual (stop if residual is smaller than needed accuracy) # Manufacturing the residual # Repeat from Step 3 Suitable manufacturing techniques CLM is very suitable for electrical discharge machining. Milling or turning is also suitable for CLM. Suitable measuring techniques In machining measurement techniques have to fulfill special needs. In particular optical techniques have the advantage ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of secondary sector of the economy. The term may refer to a range of human activity, from handicraft to high-tech, but it is most commonly applied to industrial design, in which raw materials from the primary sector are transformed into finished goods on a large scale. Such goods may be sold to other manufacturers for the production of other more complex products (such as aircraft, household appliances, furniture, sports equipment or automobiles), or distributed via the tertiary industry to end users and consumers (usually through wholesalers, who in turn sell to retailers, who then sell them to individual customers). Manufacturing engineering is the field of engineering that designs and optimizes the manufacturing process, or the steps through which raw materials are transformed into a final p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Measuring

Measurement is the quantification of attributes of an object or event, which can be used to compare with other objects or events. In other words, measurement is a process of determining how large or small a physical quantity is as compared to a basic reference quantity of the same kind. The scope and application of measurement are dependent on the context and discipline. In natural sciences and engineering, measurements do not apply to nominal properties of objects or events, which is consistent with the guidelines of the ''International vocabulary of metrology'' published by the International Bureau of Weights and Measures. However, in other fields such as statistics as well as the social and behavioural sciences, measurements can have multiple levels, which would include nominal, ordinal, interval and ratio scales. Measurement is a cornerstone of trade, science, technology and quantitative research in many disciplines. Historically, many measurement systems existed for t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inspection In Manufacturing

Inspection in manufacturing is conducting inspection during the production process. This approach of inspection helps to control the quality of products by helping to fix the sources of defects immediately after they are detected, and it is useful for any factory that wants to improve productivity, reduce Product defect, defect rates, and reduce re-work and waste. Positive impact *Reduces end-line defects *Saves time and efforts of final inspection *Helps to fix the problems at the outset, and prevents common mistakes being made repeatedly *Helps to ensure quality of the products of a production line See also * Quality control * Good manufacturing practice References Daizhong Su, Qingbin Zhang and Shifan Zhu. (2009). ''In-line inspection''. Industrial engineering ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Accuracy

Accuracy and precision are two measures of ''observational error''. ''Accuracy'' is how close a given set of measurements (observations or readings) are to their ''true value'', while ''precision'' is how close the measurements are to each other. In other words, ''precision'' is a description of ''random errors'', a measure of statistical variability. ''Accuracy'' has two definitions: # More commonly, it is a description of only '' systematic errors'', a measure of statistical bias of a given measure of central tendency; low accuracy causes a difference between a result and a true value; ISO calls this ''trueness''. # Alternatively, ISO defines accuracy as describing a combination of both types of observational error (random and systematic), so high accuracy requires both high precision and high trueness. In the first, more common definition of "accuracy" above, the concept is independent of "precision", so a particular set of data can be said to be accurate, precise, both, or n ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrical Discharge Machining

Electrical discharge machining (EDM), also known as spark machining, spark eroding, die sinking, wire burning or wire erosion, is a metal fabrication process whereby a desired shape is obtained by using electrical discharges (sparks). Material is removed from the work piece by a series of rapidly recurring current discharges between two electrodes, separated by a dielectric liquid and subject to an electric voltage. One of the electrodes is called the tool-electrode, or simply the or , while the other is called the workpiece-electrode, or . The process depends upon the tool and work piece not making physical contact. When the voltage between the two electrodes is increased, the intensity of the electric field in the volume between the electrodes becomes greater, causing dielectric break down of the liquid, and produces an electric arc. As a result, material is removed from the electrodes. Once the current stops (or is stopped, depending on the type of generator), new liquid di ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turning

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, describes a helix toolpath by moving more or less linearly while the workpiece rotates. Usually the term "turning" is reserved for the generation of ''external'' surfaces by this cutting action, whereas this same essential cutting action when applied to ''internal'' surfaces (holes, of one kind or another) is called " boring". Thus the phrase "turning and boring" categorizes the larger family of processes known as lathing. The cutting of faces on the workpiece, whether with a turning or boring tool, is called "facing", and may be lumped into either category as a subset. Turning can be done manually, in a traditional form of lathe, which frequently requires continuous supervision by the operator, or by using an automated lathe which does not. Today the most common type of such automation is computer numerical control, better known as CNC. (CNC is also commonly used with many other typ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Optical

Optics is the branch of physics that studies the behaviour and properties of light, including its interactions with matter and the construction of instruments that use or detect it. Optics usually describes the behaviour of visible, ultraviolet, and infrared light. Because light is an electromagnetic wave, other forms of electromagnetic radiation such as X-rays, microwaves, and radio waves exhibit similar properties. Most optical phenomena can be accounted for by using the classical electromagnetic description of light. Complete electromagnetic descriptions of light are, however, often difficult to apply in practice. Practical optics is usually done using simplified models. The most common of these, geometric optics, treats light as a collection of rays that travel in straight lines and bend when they pass through or reflect from surfaces. Physical optics is a more comprehensive model of light, which includes wave effects such as diffraction and interference that cannot be ac ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Focus Variation

Focus variation is a method used to sharpen images and to measure surface irregularities by means of optics with limited depth of field. Algorithm The algorithm work as follows: # at first images with difference focus are captured. This is done by moving the sample or the optics in relation to each other. # then for each position the focus over each plane is calculated # the plane with the best focus is used to get a sharp image. the corresponding depth gives the depth at this position- Optics Focus variation requires an optics with very little depth of field. This can be realized if a microscopy like optics and a microscope objective is used. These objectives have a high numerical aperture which gives a small depth of field. Usage The use of this method is for optical surface metrology and coordinate-measuring machine. This means measuring form, waviness and roughness on samples.{{cite web , last1=Burmudez , first1=Carlos , title=Active illumination focus variation , url=https:// ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Touch

In physiology, the somatosensory system is the network of neural structures in the brain and body that produce the perception of touch (haptic perception), as well as temperature (thermoception), body position (proprioception), and pain. It is a subset of the sensory nervous system, which also represents visual, auditory, olfactory, and gustatory stimuli. Somatosensation begins when mechano- and thermosensitive structures in the skin or internal organs sense physical stimuli such as pressure on the skin (see mechanotransduction, nociception). Activation of these structures, or receptors, leads to activation of peripheral sensory neurons that convey signals to the spinal cord as patterns of action potentials. Sensory information is then processed locally in the spinal cord to drive reflexes, and is also conveyed to the brain for conscious perception of touch and proprioception. Note, somatosensory information from the face and head enters the brain through peripheral senso ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quality Control

Quality control (QC) is a process by which entities review the quality of all factors involved in production. ISO 9000 defines quality control as "a part of quality management focused on fulfilling quality requirements". This approach places emphasis on three aspects (enshrined in standards such as ISO 9001): # Elements such as controls, job management, defined and well managed processes, performance and integrity criteria, and identification of records # Competence, such as knowledge, skills, experience, and qualifications # Soft elements, such as personnel, integrity, confidence, organizational culture, motivation, team spirit, and quality relationships. Inspection is a major component of quality control, where physical product is examined visually (or the end results of a service are analyzed). Product inspectors will be provided with lists and descriptions of unacceptable product defects such as cracks or surface blemishes for example. History and introduction Ea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Measuring

Measurement is the quantification of attributes of an object or event, which can be used to compare with other objects or events. In other words, measurement is a process of determining how large or small a physical quantity is as compared to a basic reference quantity of the same kind. The scope and application of measurement are dependent on the context and discipline. In natural sciences and engineering, measurements do not apply to nominal properties of objects or events, which is consistent with the guidelines of the ''International vocabulary of metrology'' published by the International Bureau of Weights and Measures. However, in other fields such as statistics as well as the social and behavioural sciences, measurements can have multiple levels, which would include nominal, ordinal, interval and ratio scales. Measurement is a cornerstone of trade, science, technology and quantitative research in many disciplines. Historically, many measurement systems existed for t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |