|

Clinching Dies From Lambiase -

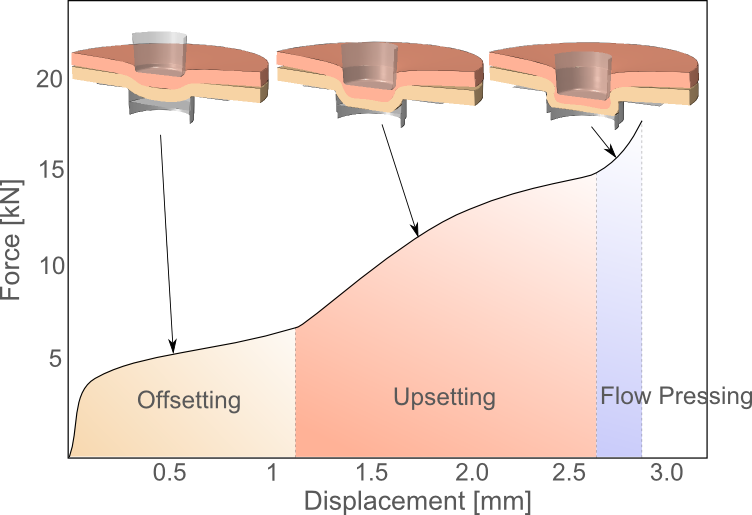

In metalworking, clinching or press-joining is a bulk sheet metal forming process aimed at joining thin metal sheets without additional components, using special tools to plastically form an interlock between two or more sheets. The process is generally performed at room temperature, but in some special cases the sheets can be pre-heated to improve the material ductility and thereby avoid the formation of cracks during the process. Clinching is characterized by a series of advantages over competitive technologies: * Reduced joining time (the joining time is less than a second) * Reduced cost and weight: the process does not involve additional elements such as screws, rivets or adhesives * Reduced cost of the machine * No pre-holes are required * Can be adopted to join different materials including metals, polymers, wood, and composite materials * Can be easily automated and does not require qualified workers * Eco-friendly: it does not require pretreatments with solvents, acid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Clinching Dies From Lambiase - "Mechanical Behaviour Of Polymer-metal Hybrid Joints Produced By Clinching With Different Types Of Dies"

In metalworking, clinching or press-joining is a bulk sheet metal forming process aimed at joining thin metal sheets without additional components, using special tools to Deformation (engineering), plastically form an interlock between two or more sheets. The process is generally performed at room temperature, but in some special cases the sheets can be pre-heated to improve the material ductility and thereby avoid the formation of cracks during the process. Clinching is characterized by a series of advantages over competitive technologies: * Reduced joining time (the joining time is less than a second) * Reduced cost and weight: the process does not involve additional elements such as screws, rivets or adhesives * Reduced cost of the machine * No Pilot hole, pre-holes are required * Can be adopted to join different materials including metals, polymers, wood, and composite materials * Can be easily automated and does not require qualified workers * Eco-friendly: it does not requi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

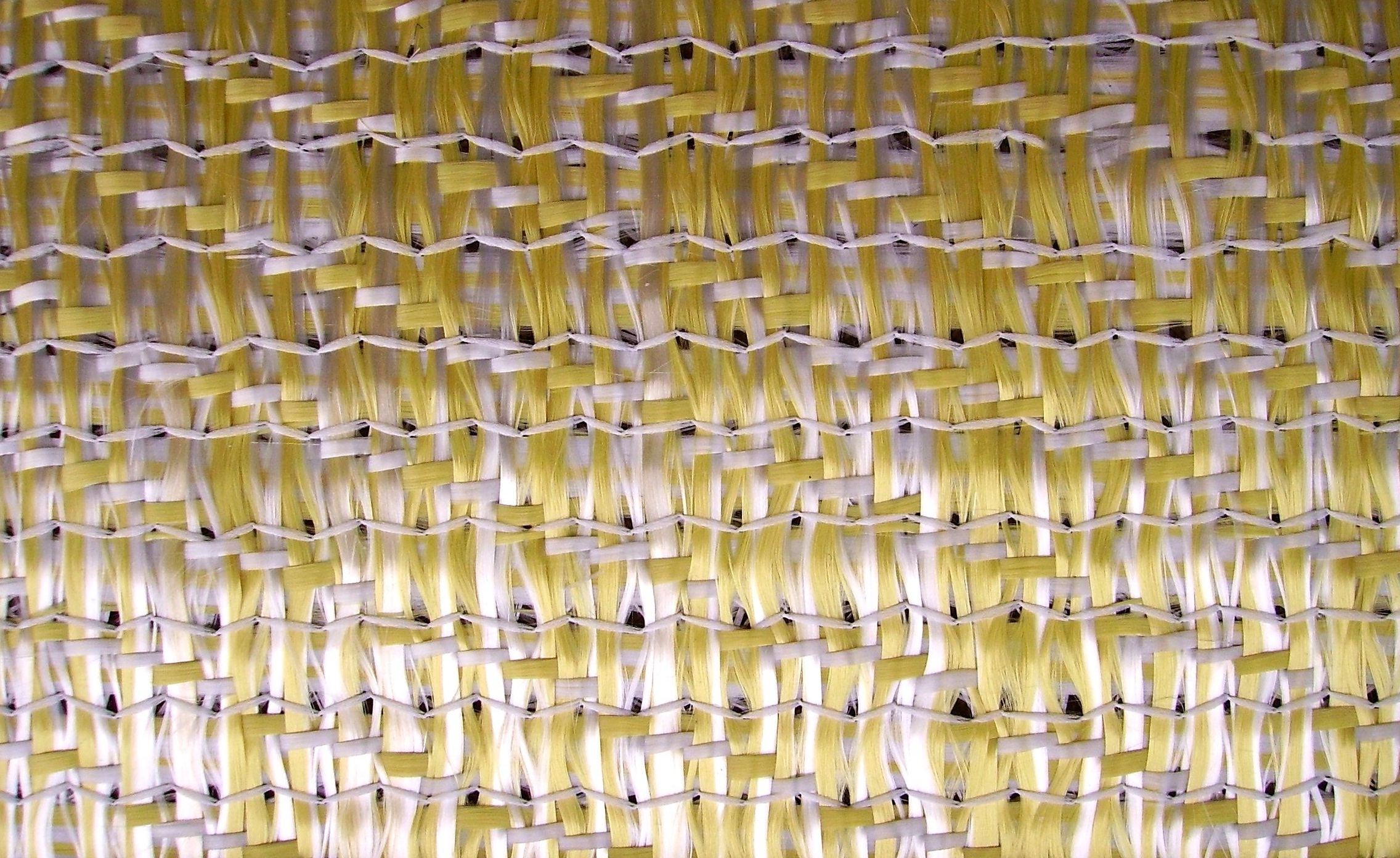

Fibre-reinforced Plastic

Fibre-reinforced plastic (FRP; also called fibre-reinforced polymer, or in American English ''fiber'') is a composite material made of a polymer matrix reinforced with fibres. The fibres are usually glass fibre, glass (in fibreglass), Carbon fibers, carbon (in carbon-fibre-reinforced polymer), aramid, or Basalt fibre, basalt. Rarely, other fibres such as paper, wood, or asbestos have been used. The polymer is usually an epoxy, vinyl ester resin, vinyl ester, or polyester thermosetting plastic, though phenol formaldehyde resins are still in use. FRPs are commonly used in the aerospace, automotive, marine, and construction industries. They are commonly found in ballistic armour and cylinders for self-contained breathing apparatuses. Process definition A polymer is generally manufactured by step-growth polymerization or addition polymerization. When combined with various agents to enhance or in any way alter the material properties of polymers, the result is referred to as a plasti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Titanium Alloy

Titanium alloys are alloys that contain a mixture of titanium and other chemical elements. Such alloys have very high tensile strength and toughness (even at extreme temperatures). They are light in weight, have extraordinary corrosion resistance and the ability to withstand extreme temperatures. However, the high cost of both raw materials and processing limit their use to military applications, aircraft, spacecraft, bicycles, medical devices, jewelry, highly stressed components such as connecting rods on expensive sports cars and some premium sports equipment and consumer electronics. Although "commercially pure" titanium has acceptable mechanical properties and has been used for orthopedic and dental implants, for most applications titanium is alloyed with small amounts of aluminium and vanadium, typically 6% and 4% respectively, by weight. This mixture has a solid solubility which varies dramatically with temperature, allowing it to undergo precipitation strengthening. This ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

High-strength Low-alloy Steel

High-strength low-alloy steel (HSLA) is a type of alloy steel that provides better mechanical properties or greater resistance to corrosion than carbon steel. HSLA steels vary from other steels in that they are not made to meet a specific chemical composition but rather specific mechanical properties. They have a carbon content between 0.05 and 0.25% to retain formability and weldability. Other alloying elements include up to 2.0% manganese and small quantities of copper, nickel, niobium, nitrogen, vanadium, chromium, molybdenum, titanium, calcium, rare-earth elements, or zirconium. Copper, titanium, vanadium, and niobium are added for strengthening purposes. These elements are intended to alter the microstructure of carbon steels, which is usually a ferrite-pearlite aggregate, to produce a very fine dispersion of alloy carbides in an almost pure ferrite matrix. This eliminates the toughness-reducing effect of a pearlitic volume fraction yet maintains and increases the material's ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

List Of Copper Alloys

Copper alloys are metal alloys that have copper as their principal component. They have high resistance against corrosion. The best known traditional types are bronze, where tin is a significant addition, and brass, using zinc instead. Both of these are imprecise terms, having both been commonly referred to as lattens in the past. Today the term ''copper alloy'' tends to be substituted, especially by museums. Composition The similarity in external appearance of the various alloys, along with the different combinations of elements used when making each alloy, can lead to confusion when categorizing the different compositions. There are as many as 400 different copper and copper alloy compositions loosely grouped into the categories: copper, high copper alloy, brasses, bronzes, copper nickels, copper–nickel–zinc (nickel silver), leaded copper, and special alloys. The following table lists the principal alloying element for four of the more common types used ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Steel

Carbon steel is a steel with carbon content from about 0.05 up to 2.1 percent by weight. The definition of carbon steel from the American Iron and Steel Institute (AISI) states: * no minimum content is specified or required for chromium, cobalt, molybdenum, nickel, niobium, titanium, tungsten, vanadium, zirconium, or any other element to be added to obtain a desired alloying effect; * the specified minimum for copper does not exceed 0.40%; * or the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65%; silicon 0.60%; copper 0.60%. The term ''carbon steel'' may also be used in reference to steel which is not stainless steel; in this use carbon steel may include alloy steels. High carbon steel has many different uses such as milling machines, cutting tools (such as chisels) and high strength wires. These applications require a much finer microstructure, which improves the toughness. Carbon steel is a popular met ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

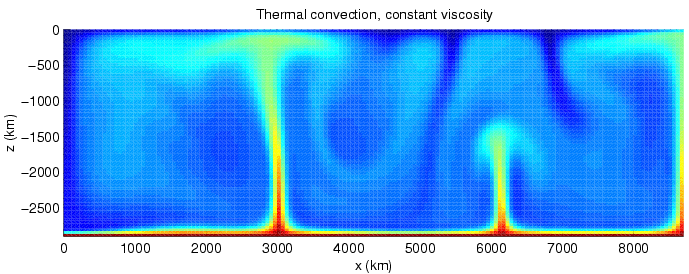

Convection Heating From Lambiase - "Joinability Of Different Thermoplastic Polymers With Aluminium AA6082 Sheets By Mechanical Clinching"

Convection is single or multiphase fluid flow that occurs spontaneously due to the combined effects of material property heterogeneity and body forces on a fluid, most commonly density and gravity (see buoyancy). When the cause of the convection is unspecified, convection due to the effects of thermal expansion and buoyancy can be assumed. Convection may also take place in soft solids or mixtures where particles can flow. Convective flow may be transient (such as when a multiphase mixture of oil and water separates) or steady state (see Convection cell). The convection may be due to gravitational, electromagnetic or fictitious body forces. Heat transfer by natural convection plays a role in the structure of Earth's atmosphere, its oceans, and its mantle. Discrete convective cells in the atmosphere can be identified by clouds, with stronger convection resulting in thunderstorms. Natural convection also plays a role in stellar physics. Convection is often categorised or desc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Magnesium Alloy

Magnesium alloys are mixtures of magnesium (the lightest structural metal) with other metals (called an alloy), often aluminium, zinc, manganese, silicon, copper, rare earths and zirconium. Magnesium alloys have a hexagonal lattice structure, which affects the fundamental properties of these alloys. Plastic deformation of the hexagonal lattice is more complicated than in cubic latticed metals like aluminium, copper and steel; therefore, magnesium alloys are typically used as cast alloys, but research of wrought alloys has been more extensive since 2003. Cast magnesium alloys are used for many components of modern automobiles and have been used in some high-performance vehicles; die-cast magnesium is also used for camera bodies and components in lenses. Practically, all the commercial magnesium alloys manufactured in the United States contain aluminium (3 to 13 percent) and manganese (0.1 to 0.4 percent). Many also contain zinc (0.5 to 3 percent) and some are hardenable by ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spot Welding

A spot welder Spot welding (or resistance spot welding) is a type of electric resistance welding used to weld various sheet metal products, through a process in which contacting metal surface points are joined by the heat obtained from resistance to electric current. The process uses two shaped copper alloy electrodes to concentrate welding current into a small "spot" and to simultaneously clamp the sheets together. Work-pieces are held together under pressure exerted by electrodes. Typically the sheets are in the thickness range. Forcing a large current through the spot will melt the metal and form the weld. The attractive feature of spot welding is that a large amount of energy can be delivered to the spot in a very short time (approximately 10–100 milliseconds). This permits the welding to occur without excessive heating of the remainder of the sheet. The amount of heat (energy) delivered to the spot is determined by the resistance between the electrodes and the magnitude ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electronics

The field of electronics is a branch of physics and electrical engineering that deals with the emission, behaviour and effects of electrons using electronic devices. Electronics uses active devices to control electron flow by amplification and rectification, which distinguishes it from classical electrical engineering, which only uses passive effects such as resistance, capacitance and inductance to control electric current flow. Electronics has hugely influenced the development of modern society. The central driving force behind the entire electronics industry is the semiconductor industry sector, which has annual sales of over $481 billion as of 2018. The largest industry sector is e-commerce, which generated over $29 trillion in 2017. History and development Electronics has hugely influenced the development of modern society. The identification of the electron in 1897, along with the subsequent invention of the vacuum tube which could amplify and rectify small ele ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Home Appliance

A home appliance, also referred to as a domestic appliance, an electric appliance or a household appliance, is a machine which assists in household functions such as cooking, cleaning and food preservation. Appliances are divided into three types: small appliances, major appliances (also known as white goods) and consumer electronics (brown goods). Definition Given a broad usage, the domestic application attached to home appliance is tied to the definition of appliance as "an instrument or device designed for a particular use or function". More specifically, Collins English Dictionary defines "home appliance" as: "devices or machines, usually electrical, that are in your home and which you use to do jobs such as cleaning or cooking". The broad usage, afforded to the definition allows for nearly any device intended for domestic use to be a home appliance, including consumer electronics as well as stoves, refrigerators, toasters and air conditioners. History While man ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |