|

Chemistry Of Pressure-sensitive Adhesives

The chemistry of pressure-sensitive adhesives describes the chemical science associated with pressure-sensitive adhesives (PSA). PSA tapes and labels have become an important part of everyday life. These rely on adhesive material affixed to a backing such as paper or plastic film. Because of the inherent tackiness of the adhesive material and low surface energy, these tapes can be placed onto a variety of substrates when light pressure is applied, including paper, wood, metals, and ceramics. The design of tapes requires a balance of the need for long service life and adaptation to a variety of environmental and human effects, including temperature, UV exposure, mechanical wear, contamination of the substrate surface, and adhesive degradation.Werner Karmann and Andreas B. Kummer "Tapes, Adhesive" in Ullmann's Encyclopedia of Industrial Chemistry, Wiley-VCH, Weinheim, 2000. Composition A typical PSA tape consists of a pressure-sensitive adhesive (the sticky part of the tape) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure-sensitive Adhesive

Pressure-sensitive adhesive (PSA, self-adhesive, self-stick adhesive) is a type of nonreactive adhesive which forms a bond when pressure is applied to bond the adhesive with a surface. No solvent, water, or heat is needed to activate the adhesive. It is used in pressure-sensitive tapes, labels, glue dots, stickers, sticky note pads, automobile trim, and a wide variety of other products. As the name "pressure-sensitive" indicates, the degree of bond is influenced by the amount of pressure which is used to apply the adhesive to the surface. Surface factors such as smoothness, surface energy, removal of contaminants, etc. are also important to proper bonding. PSAs are usually designed to form a bond and hold properly at room temperatures. PSAs typically reduce or lose their tack at low temperatures and reduce their shear holding ability at high temperatures; special adhesives are made to function at high or low temperatures. Structural and pressure-sensitive adhesives Adhesives ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glass Transition Temperature

The glass–liquid transition, or glass transition, is the gradual and reversible transition in amorphous materials (or in amorphous regions within semicrystalline materials) from a hard and relatively brittle "glassy" state into a viscous or rubbery state as the temperature is increased. ISO 11357-2: Plastics – Differential scanning calorimetry – Part 2: Determination of glass transition temperature (1999). An amorphous solid that exhibits a glass transition is called a glass. The reverse transition, achieved by supercooling a viscous liquid into the glass state, is called vitrification. The glass-transition temperature ''T''g of a material characterizes the range of temperatures over which this glass transition occurs (as an experimental definition, typically marked as 100 s of relaxation time). It is always lower than the melting temperature, ''T''m, of the crystalline state of the material, if one exists. Hard plastics like polystyrene and poly(methyl methacrylate) are u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Elasticity (physics)

In physics and materials science, elasticity is the ability of a body to resist a distorting influence and to return to its original size and shape when that influence or force is removed. Solid objects will deform when adequate loads are applied to them; if the material is elastic, the object will return to its initial shape and size after removal. This is in contrast to ''plasticity'', in which the object fails to do so and instead remains in its deformed state. The physical reasons for elastic behavior can be quite different for different materials. In metals, the atomic lattice changes size and shape when forces are applied (energy is added to the system). When forces are removed, the lattice goes back to the original lower energy state. For rubbers and other polymers, elasticity is caused by the stretching of polymer chains when forces are applied. Hooke's law states that the force required to deform elastic objects should be directly proportional to the distance of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Contact Area

When two objects touch, only a certain portion of their surface areas will be in contact with each other. This area of true contact, most often constitutes only a very small fraction of the apparent or ''nominal'' contact area. In relation to two contacting objects, the term Contact area refers to the fraction of the nominal area that consists of atoms of one object in true contact with the atoms of the other object. Because objects are never perfectly flat due to asperities, the actual contact area (on a microscopic scale) is usually much less than the contact area apparent on a macroscopic scale. Contact area may depend on the normal force between the two objects due to deformation. The contact area depends on the geometry of the contacting bodies, the load, and the material properties. The contact area between the two parallel cylinders is a narrow rectangle. Two, non-parallel cylinders have an elliptical contact area, unless the cylinders are crossed at 90 degrees, in which cas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stress (mechanics)

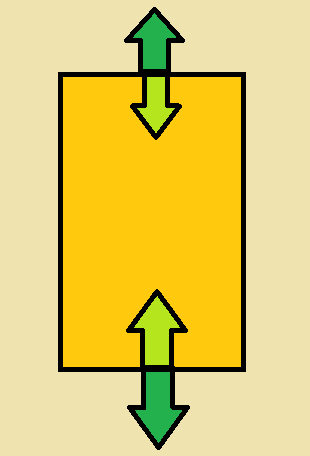

In continuum mechanics, stress is a physical quantity. It is a quantity that describes the magnitude of forces that cause deformation. Stress is defined as ''force per unit area''. When an object is pulled apart by a force it will cause elongation which is also known as deformation, like the stretching of an elastic band, it is called tensile stress. But, when the forces result in the compression of an object, it is called compressive stress. It results when forces like tension or compression act on a body. The greater this force and the smaller the cross-sectional area of the body on which it acts, the greater the stress. Therefore, stress is measured in newton per square meter (N/m2) or pascal (Pa). Stress expresses the internal forces that neighbouring particles of a continuous material exert on each other, while strain is the measure of the deformation of the material. For example, when a solid vertical bar is supporting an overhead weight, each particle in the bar pushe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wetting

Wetting is the ability of a liquid to maintain contact with a solid surface, resulting from intermolecular interactions when the two are brought together. This happens in presence of a gaseous phase or another liquid phase not miscible with the first one. The degree of wetting (wettability) is determined by a force balance between adhesive and cohesive forces. Wetting is important in the bonding or adherence of two materials. Wetting and the surface forces that control wetting are also responsible for other related effects, including capillary effects. There are two types of wetting: non-reactive wetting and reactive wetting. Wetting deals with three phases of matter: gas, liquid, and solid. It is now a center of attention in nanotechnology and nanoscience studies due to the advent of many nanomaterials in the past two decades (e.g. graphene, Carbon nano tube, carbon nanotube, boron nitride nanomesh). Explanation Adhesive forces between a liquid and solid cause a liquid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Adhesive

Adhesive, also known as glue, cement, mucilage, or paste, is any non-metallic substance applied to one or both surfaces of two separate items that binds them together and resists their separation. The use of adhesives offers certain advantages over other binding techniques such as sewing, mechanical fastenings, or welding. These include the ability to bind different materials together, the more efficient distribution of stress across a joint, the cost-effectiveness of an easily mechanized process, and greater flexibility in design. Disadvantages of adhesive use include decreased stability at high temperatures, relative weakness in bonding large objects with a small bonding surface area, and greater difficulty in separating objects during testing. Adhesives are typically organized by the method of adhesion followed by ''reactive'' or ''non-reactive'', a term which refers to whether the adhesive chemically reacts in order to harden. Alternatively, they can be organized eithe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and even by industry. Further, both spellings are often used ''within'' a particular industry or country. Industries in British English-speaking countries typically use the "gauge" spelling. is the pressure relative to the ambient pressure. Various units are used to express pressure. Some of these derive from a unit of force divided by a unit of area; the SI unit of pressure, the pascal (Pa), for example, is one newton per square metre (N/m2); similarly, the pound-force per square inch (psi) is the traditional unit of pressure in the imperial and U.S. customary systems. Pressure may also be expressed in terms of standard atmospheric pressure; the atmosphere (atm) is equal to this pressure, and the torr is defined as of this. Manometric u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plasma Processing

Plasma processing is a plasma-based material processing technology that aims at modifying the chemical and physical properties of a surface. Plasma processing techniques include: *Plasma activation *Plasma ashing *Plasma cleaning *Plasma electrolytic oxidation *Plasma etching *Plasma functionalization *Plasma polymerization *Corona treatment *Plasma modification Related topics are plasma chemistry, chemical vapor deposition, and physical vapor deposition processes like sputter deposition, plasma iondoping, vacuum plasmaspraying, and reactive ion etching. See also *List of plasma (physics) applications articles This is a list of plasma physics topics. A * Ablation * Abradable coating * Abraham–Lorentz force * Absorption band * Accretion disk * Active galactic nucleus * Adiabatic invariant * ADITYA (tokamak) * Aeronomy * Afterglow plasma * A ... References {{reflist ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corona Treatment

Corona treatment (sometimes referred to as air plasma) is a surface modification technique that uses a low temperature corona discharge plasma to impart changes in the properties of a surface. The corona plasma is generated by the application of high voltage to an electrode that has a sharp tip. The plasma forms at the tip. A linear array of electrodes is often used to create a curtain of corona plasma. Materials such as plastics, cloth, or paper may be passed through the corona plasma curtain in order to change the surface energy of the material. All materials have an inherent surface energy. Surface treatment systems are available for virtually any surface format including dimensional objects, sheets and roll goods that are handled in a web format. Corona treatment is a widely used surface treatment method in the plastic film, extrusion, and converting industries. History The corona treatment was invented by the Danish engineer Verner Eisby in 1951. Eisby had been asked by ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Biaxially Oriented Polypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene. Polypropylene belongs to the group of polyolefins and is partially crystalline and non-polar. Its properties are similar to polyethylene, but it is slightly harder and more heat-resistant. It is a white, mechanically rugged material and has a high chemical resistance. Bio-PP is the bio-based counterpart of polypropylene (PP). Polypropylene is the second-most widely produced commodity plastic (after polyethylene). In 2019, the global market for polypropylene was worth $126.03 billion. Revenues are expected to exceed US$145 billion by 2019. The sales of this material are forecast to grow at a rate of 5.8% per year until 2021. History Phillips Petroleum chemists J. Paul Hogan and Robert Banks first demonstrated the polymerization of propylene in 1951. The stereoselective polymerization to th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |