|

Chanters Colliery

Chanters Colliery was a coal mine which was part of the Fletcher, Burrows and Company's collieries at Hindsford in Atherton, Greater Manchester, then in the historic county of Lancashire, England. Geology Chanters Colliery exploited the Middle Coal Measures which were laid down in the Carboniferous period and where coal is mined from more than a dozen coal seams. Chanters accessed 12 seams between the Crumbouke and Arley mines. The seams generally dip towards the south and west and are affected by small faults. The Upper Coal Measures are not worked in this part of the Manchester Coalfield. History Chanters Colliery in Hindsford was sunk in 1854 by John Fletcher in an area where coal had been mined for centuries from small shallow pits. One of these pits, the ''Gold Pit'', so named from 17th-century coins and the plates they were stamped from found at the bottom of the shaft, was working before 1800. In 1854 John Musgrave & Sons supplied a twin cylinder horizontal winding eng ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coal Mine

Coal mining is the process of extracting coal from the ground. Coal is valued for its energy content and since the 1880s has been widely used to generate electricity. Steel and cement industries use coal as a fuel for extraction of iron from iron ore and for cement production. In the United Kingdom and South Africa, a coal mine and its structures are a colliery, a coal mine is called a 'pit', and the above-ground structures are a 'pit head'. In Australia, "colliery" generally refers to an underground coal mine. Coal mining has had many developments in recent years, from the early days of men tunneling, digging and manually extracting the coal on carts to large open-cut and longwall mines. Mining at this scale requires the use of draglines, trucks, conveyors, hydraulic jacks and shearers. The coal mining industry has a long history of significant negative environmental impacts on local ecosystems, health impacts on local communities and workers, and contributes heavily to th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Winding Engine

A winding engine is a stationary engine used to control a cable, for example to power a mining hoist at a pit head. Electric hoist controllers have replaced proper winding engines in modern mining, but use electric motors that are also traditionally referred to as ''winding engines''. Early winding engines were hand, or more usually horse powered. The first powered winding engines were stationary steam engines. The demand for winding engines was one factor that drove James Watt to develop his rotative beam engine, with its ability continuously to turn a winding drum, rather than the early reciprocating beam engines that were only useful for working pumps. They differ from most other stationary steam engines in that, like a steam locomotive, they need to be able to stop frequently and also reverse. This requires more complex valve gear and other controls than are needed on engines used in mills or to drive pump A pump is a device that moves fluids (liquids or gases), or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mining In Lancashire

Mining is the extraction of valuable minerals or other geological materials from the Earth, usually from an ore body, lode, vein, seam, reef, or placer deposit. The exploitation of these deposits for raw material is based on the economic viability of investing in the equipment, labor, and energy required to extract, refine and transport the materials found at the mine to manufacturers who can use the material. Ores recovered by mining include metals, coal, oil shale, gemstones, limestone, chalk, dimension stone, rock salt, potash, gravel, and clay. Mining is required to obtain most materials that cannot be grown through agricultural processes, or feasibly created artificially in a laboratory or factory. Mining in a wider sense includes extraction of any non-renewable resource such as petroleum, natural gas, or even water. Modern mining processes involve prospecting for ore bodies, analysis of the profit potential of a proposed mine, extraction of the desired materials ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coal Mines In Lancashire

Coal is a combustible black or brownish-black sedimentary rock, formed as rock strata called coal seams. Coal is mostly carbon with variable amounts of other elements, chiefly hydrogen, sulfur, oxygen, and nitrogen. Coal is formed when dead plant matter decays into peat and is converted into coal by the heat and pressure of deep burial over millions of years. Vast deposits of coal originate in former wetlands called coal forests that covered much of the Earth's tropical land areas during the late Carboniferous ( Pennsylvanian) and Permian times. Many significant coal deposits are younger than this and originate from the Mesozoic and Cenozoic eras. Coal is used primarily as a fuel. While coal has been known and used for thousands of years, its usage was limited until the Industrial Revolution. With the invention of the steam engine, coal consumption increased. In 2020, coal supplied about a quarter of the world's primary energy and over a third of its electricity. Some iron a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glossary Of Coal Mining Terminology

This is a partial glossary of coal mining terminology commonly used in the coalfields of the United Kingdom. Some words were in use throughout the coalfields, some are historic and some are local to the different British coalfields. A Adit :An adit is an underground level or tunnel to the surface for access or drainage purposes. Afterdamp :Afterdamp is a mixture of carbon monoxide and chokedamp which replaces atmospheric air after an explosion. Agent :The agent was the senior colliery manager: the term "viewer", "captain" or "steward" also appeared in older regional terminology. Where the mine owner provided the capital and sank the shafts, the agent organised the development of the colliery, determined mining methods, advised the owner on the mine's commercial management and labour policy, and in later years was generally a trained mining engineer. In the management hierarchy the agent was superior to the colliery manager and under-manager, who had day to day operational resp ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

World War II

World War II or the Second World War, often abbreviated as WWII or WW2, was a world war that lasted from 1939 to 1945. It involved the vast majority of the world's countries—including all of the great powers—forming two opposing military alliances: the Allies and the Axis powers. World War II was a total war that directly involved more than 100 million personnel from more than 30 countries. The major participants in the war threw their entire economic, industrial, and scientific capabilities behind the war effort, blurring the distinction between civilian and military resources. Aircraft played a major role in the conflict, enabling the strategic bombing of population centres and deploying the only two nuclear weapons ever used in war. World War II was by far the deadliest conflict in human history; it resulted in 70 to 85 million fatalities, mostly among civilians. Tens of millions died due to genocides (including the Holocaust), starvation, ma ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bevin Boy

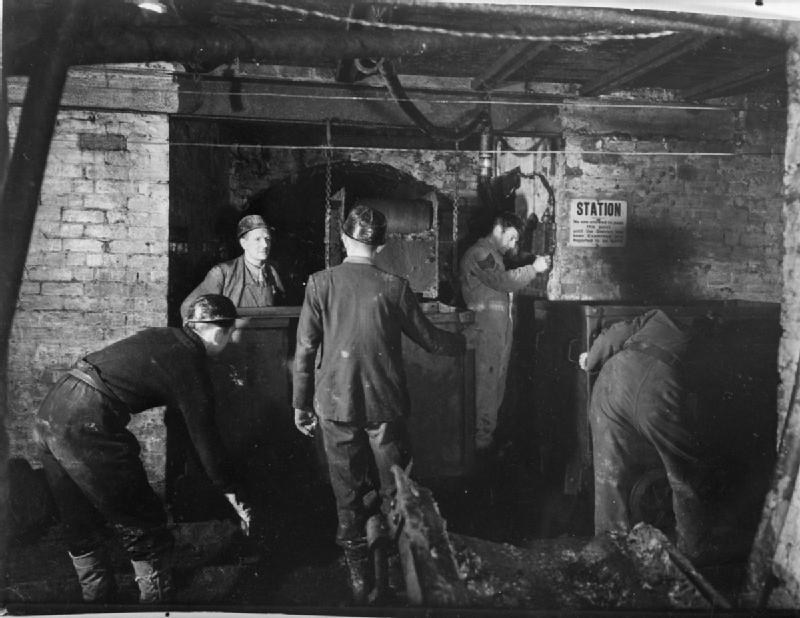

Bevin Boys were young British men Conscription in the United Kingdom, conscripted to work in coal mines between December 1943 and March 1948, to increase the rate of coal production, which had declined through the early years of World War II. The programme was named after Ernest Bevin, the Labour Party (UK), Labour Party politician who was Minister of Labour and National Service in the wartime coalition government. Chosen by lot as ten per cent of all male conscripts aged 18–25, plus some volunteering as an alternative to military conscription, nearly 48,000 Bevin Boys performed vital and dangerous civil conscription service in coal mines. Although the last ballot took place in May 1945 (shortly before Victory in Europe Day, VE Day), the final conscripts were not released from service until March 1948. Few chose to remain working in the Coal mining in the United Kingdom, mining industry after demobilisation; most left for further education or for employment in other se ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manchester Collieries

Manchester Collieries was a coal mining company with headquarters in Walkden formed from a group of independent companies operating on the Manchester Coalfield in 1929. The Mining Industry Act of 1926 attempted to stem the post-war decline in coal mining and encourage independent companies to merge in order to modernise and better survive the economic conditions of the day. Robert Burrows of the Atherton company Fletcher Burrows proposed a merger of several independent companies operating to the west of Manchester. The merger was agreed and took place in March 1929. Constituent companies The constituent companies of Manchester Collieries in 1929 were Fletcher, Burrows and Company who owned the Howe Bridge, Gibfield and Chanters Collieries in Atherton, Andrew Knowles and Sons, the Clifton and Kersley Coal Company, John Speakman and Sons owners of Bedford Colliery in Leigh, Bridgewater Collieries who operated pits in Little Hulton, Walkden and Mosley Common and the Astley and Tylde ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Trencherbone Mine

The Manchester Coalfield is part of the South Lancashire Coalfield, the coal seams of which were laid down in the Carboniferous Period. Some easily accessible seams were worked on a small scale from the Middle Ages, and extensively from the beginning of the Industrial Revolution in the early 19th century until the last quarter of the 20th century. The Coal Measures lie above a bed of Millstone Grit and are interspersed with sandstones, mudstones, shales, and fireclays. The Lower Coal Measures occupy the high ground of the West Pennine Moors above Bolton and are not worked in the Manchester Coalfield. The most productive of the coal measures are the lower two thirds of the Middle Coal Measures where coal is mined from seams between the Worsley Four Foot and Arley mines. The deepest and most productive collieries were to the south of the coalfield. The coalfield is affected by the northwest to southeast aligned Pendleton Fault along the Irwell Valley and the Rossendale Valley anticl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lancashire Boiler

A shell or flued boiler is an early and relatively simple form of boiler used to make steam, usually for the purpose of driving a steam engine. The design marked a transitional stage in boiler development, between the early haystack boilers and the later multi-tube fire-tube boilers. A flued boiler is characterized by a large cylindrical boiler shell forming a tank of water, traversed by one or more large flues containing the furnace. These boilers appeared around the start of the 19th century and some forms remain in service today. Although mostly used for static steam plants, some were used in early steam vehicles, railway locomotives and ships. Flued boilers were developed in an attempt to raise steam pressures and improve engine efficiency. Early haystack designs of Watt's day were mechanically weak and often presented an unsupported flat surface to the fire. Boiler explosions, usually beginning with failure of this firebox plate, were common. It was known that an arched stru ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

John Musgrave & Sons

John Musgrave & Sons was a company that manufactured stationary steam engines. It was founded in 1839 by John Musgrave and his son, Joseph, at the Globe Ironworks, in Bolton, historically in Lancashire, England. In 1854 the company supplied a twin cylinder horizontal winding engine, and in 1861 a single cylinder pumping engine to Chanters Colliery in Hindsford. Musgraves supplied winding engines to Wheatsheaf Colliery in 1868, Mosley Common Colliery in 1870, Brackley Colliery in 1879, Gin Pit Colliery in 1884, and Nook Colliery in 1913. The company produced steam engines during the 19th century and between 1899 and 1908 produced 504 large steam-driven engines. The company produced engines and equipment for the coal mining industry and built a boilerworks in Westhoughton in 1900 to produce Lancashire boilers. The Westhoughton works were subject to a chancery court judgement and sold in 1912 leading to the formation of John Musgrave and Sons (1913) Ltd. which kept the Globe Iron ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fletcher, Burrows And Company

Fletcher, Burrows and Company was a coal mining company that owned collieries and cotton mills in Atherton, Greater Manchester, England. Gibfield, Howe Bridge and Chanters collieries exploited the coal mines (seams) of the middle coal measures in the Manchester Coalfield. The Fletchers built company housing at Hindsford and a model village at Howe Bridge which included pithead baths and a social club for its workers. The company became part of Manchester Collieries in 1929. The collieries were nationalised in 1947 becoming part of the National Coal Board. History Fletcher Burrows In 1776 Robert Vernon Atherton of Atherton Hall leased the Atherton coal rights to Thomas Guest from Bedford and John Fletcher of Tonge with Haulgh, Bolton forbidding them to mine under the hall. The Fletchers had mining interests in Bolton and Clifton in the Irwell Valley from Elizabethan times. Matthew Fletcher's family owned most of Clifton in 1750 including the Ladyshore and Wet Earth collierie ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |