|

Buffered Oxide Etch

Buffered oxide etch (BOE), also known as buffered HF or BHF, is a wet etchant used in microfabrication. Its primary use is in etching thin films of silicon dioxide (SiO2) or silicon nitride (Si3N4). It is a mixture of a buffering agent, such as ammonium fluoride (NH4F), and hydrofluoric acid (HF). Concentrated HF (typically 49% HF in water) etches silicon dioxide too quickly for good process control and also peels photoresist used in lithographic Lithography () is a planographic method of printing originally based on the immiscibility of oil and water. The printing is from a stone (lithographic limestone) or a metal plate with a smooth surface. It was invented in 1796 by the German a ... patterning. Buffered oxide etch is commonly used for more controllable etching. Some oxides produce insoluble products in HF solutions. Thus, HCl is often added to BHF solutions in order to dissolve these insoluble products and produce a higher quality etch. A common buffered oxide etc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Etching (microfabrication)

Etching is used in microfabrication to chemically remove layers from the surface of a wafer during manufacturing. Etching is a critically important process module, and every wafer undergoes many etching steps before it is complete. For many etch steps, part of the wafer is protected from the etchant by a "masking" material which resists etching. In some cases, the masking material is a photoresist which has been patterned using photolithography. Other situations require a more durable mask, such as silicon nitride. Orientation-Dependent Etching * KOH pellets dissolved in water (self-heating) * Etch Rate > >> ** KOH has a slower etching orientation for the planes ** You cannot use this KOH photoresist as a etching mask, because the oxide attacks too slowly, so this resist will not survive * Photoresist can be used a etching mask, and the best photoresist for etching is nitride * For example, the etch rate of Si in KOH Depends on Crystallographic Plane * At low temperatur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Microfabrication

Microfabrication is the process of fabricating miniature structures of micrometre scales and smaller. Historically, the earliest microfabrication processes were used for integrated circuit fabrication, also known as "semiconductor manufacturing" or "semiconductor device fabrication". In the last two decades microelectromechanical systems (MEMS), microsystems (European usage), micromachines (Japanese terminology) and their subfields, microfluidics/lab-on-a-chip, optical MEMS (also called MOEMS), RF MEMS, PowerMEMS, BioMEMS and their extension into nanoscale (for example NEMS, for nano electro mechanical systems) have re-used, adapted or extended microfabrication methods. Flat-panel displays and solar cells are also using similar techniques. Miniaturization of various devices presents challenges in many areas of science and engineering: physics, chemistry, materials science, computer science, ultra-precision engineering, fabrication processes, and equipment design. It is also giving ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thin Film

A thin film is a layer of material ranging from fractions of a nanometer (monolayer) to several micrometers in thickness. The controlled synthesis of materials as thin films (a process referred to as deposition) is a fundamental step in many applications. A familiar example is the household mirror, which typically has a thin metal coating on the back of a sheet of glass to form a reflective interface. The process of silvering was once commonly used to produce mirrors, while more recently the metal layer is deposited using techniques such as sputtering. Advances in thin film deposition techniques during the 20th century have enabled a wide range of technological breakthroughs in areas such as magnetic recording media, electronic semiconductor devices, integrated passive devices, LEDs, optical coatings (such as antireflective coatings), hard coatings on cutting tools, and for both energy generation (e.g. thin-film solar cells) and storage ( thin-film batteries). It is also being ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicon Dioxide

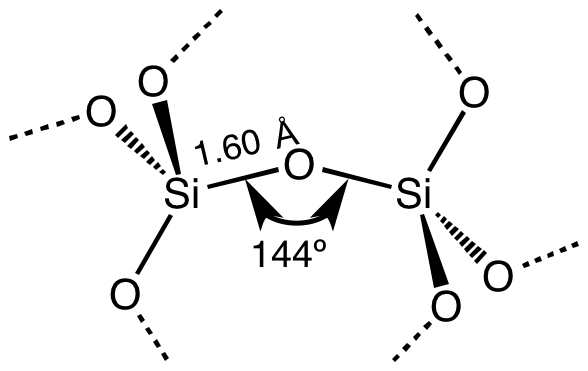

Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , most commonly found in nature as quartz and in various living organisms. In many parts of the world, silica is the major constituent of sand. Silica is one of the most complex and most abundant families of materials, existing as a compound of several minerals and as a synthetic product. Notable examples include fused quartz, fumed silica, silica gel, opal and aerogels. It is used in structural materials, microelectronics (as an electrical insulator), and as components in the food and pharmaceutical industries. Structure In the majority of silicates, the silicon atom shows tetrahedral coordination, with four oxygen atoms surrounding a central Si atomsee 3-D Unit Cell. Thus, SiO2 forms 3-dimensional network solids in which each silicon atom is covalently bonded in a tetrahedral manner to 4 oxygen atoms. In contrast, CO2 is a linear molecule. The starkly different structures of the dioxid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Silicon Nitride

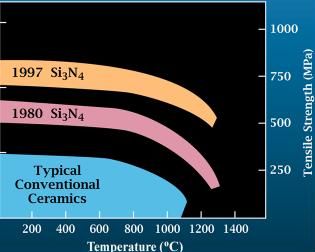

Silicon nitride is a chemical compound of the elements silicon and nitrogen. is the most thermodynamically stable and commercially important of the silicon nitrides, and the term "silicon nitride" commonly refers to this specific composition. It is a white, high-melting-point solid that is relatively chemically inert, being attacked by dilute HF and hot . It is very hard (8.5 on the mohs scale). It has a high thermal stability with strong optical nonlinearities for all-optical applications. Production Silicon nitride is prepared by heating powdered silicon between 1300 °C and 1400 °C in a nitrogen atmosphere: :3 Si + 2 → The silicon sample weight increases progressively due to the chemical combination of silicon and nitrogen. Without an iron catalyst, the reaction is complete after several hours (~7), when no further weight increase due to nitrogen absorption (per gram of silicon) is detected. In addition to , several other silicon nitride phases (with chemical ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Buffering Agent

A buffer solution (more precisely, pH buffer or hydrogen ion buffer) is an aqueous solution consisting of a mixture of a weak acid and its conjugate base, or vice versa. Its pH changes very little when a small amount of strong acid or base is added to it. Buffer solutions are used as a means of keeping pH at a nearly constant value in a wide variety of chemical applications. In nature, there are many living systems that use buffering for pH regulation. For example, the bicarbonate buffering system is used to regulate the pH of blood, and bicarbonate also acts as a buffer in the ocean. Principles of buffering Buffer solutions resist pH change because of a chemical equilibrium between the weak acid HA and its conjugate base A−: When some strong acid is added to an equilibrium mixture of the weak acid and its conjugate base, hydrogen ions (H+) are added, and the equilibrium is shifted to the left, in accordance with Le Chatelier's principle. Because of this, the hydrogen ion ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ammonium Fluoride

Ammonium fluoride is the inorganic compound with the formula NH4F. It crystallizes as small colourless prisms, having a sharp saline taste, and is highly soluble in water. Like all fluoride salts, it is moderately toxic in both acute and chronic overdose. Crystal structure Ammonium fluoride adopts the wurtzite crystal structure, in which both the ammonium cations and the fluoride anions are stacked in ABABAB... layers, each being tetrahedrally surrounded by four of the other. There are N−H···F hydrogen bonds between the anions and cations. This structure is very similar to ice, and ammonium fluoride is the only substance which can form mixed crystals with water. Reactions On passing hydrogen fluoride gas (in excess) through the salt, ammonium fluoride absorbs the gas to form the addition compound ammonium bifluoride. The reaction occurring is: :NH4F + HF → NH4HF2 It sublimes when heated—a property common among ammonium salts. In the sublimation, the salt decomposes to am ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrofluoric Acid

Hydrofluoric acid is a Solution (chemistry), solution of hydrogen fluoride (HF) in water. Solutions of HF are colourless, acidic and highly Corrosive substance, corrosive. It is used to make most fluorine-containing compounds; examples include the commonly used pharmaceutical antidepressant medication fluoxetine (Prozac) and the material polytetrafluoroethylene, PTFE (Teflon). Elemental fluorine is produced from it. It is commonly used to Etching (microfabrication), etch glass and silicon wafers. Uses Production of organofluorine compounds The principal use of hydrofluoric acid is in organofluorine chemistry. Many organofluorine compounds are prepared using HF as the fluorine source, including Polytetrafluoroethylene, Teflon, fluoropolymers, fluorocarbons, and refrigeration, refrigerants such as freon. Many pharmaceuticals contain fluorine. Production of inorganic fluorides Most high-volume inorganic fluoride compounds are prepared from hydrofluoric acid. Foremost are Na3AlF6 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Process Control

An industrial process control in continuous production processes is a discipline that uses industrial control systems to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control. It is implemented widely in industries such as automotive, mining, dredging, oil refining, pulp and paper manufacturing, chemical processing and power generating plants. There is a wide range of size, type and complexity, but it enables a small number of operators to manage complex processes to a high degree of consistency. The development of large industrial process control systems was instrumental in enabling the design of large high volume and complex processes, which could not be otherwise economically or safely operated. The applications can range from controlling the temperature and level of a single process vessel, to a complete chemical processing plant with several thousand control loops. History Early process control breakthrou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lithographic

Lithography () is a planographic method of printing originally based on the immiscibility of oil and water. The printing is from a stone (lithographic limestone) or a metal plate with a smooth surface. It was invented in 1796 by the German author and actor Alois Senefelder and was initially used mostly for musical scores and maps.Meggs, Philip B. A History of Graphic Design. (1998) John Wiley & Sons, Inc. p 146 Carter, Rob, Ben Day, Philip Meggs. Typographic Design: Form and Communication, Third Edition. (2002) John Wiley & Sons, Inc. p 11 Lithography can be used to print text or images onto paper or other suitable material. A lithograph is something printed by lithography, but this term is only used for fine art prints and some other, mostly older, types of printed matter, not for those made by modern commercial lithography. Originally, the image to be printed was drawn with a greasy substance, such as oil, fat, or wax onto the surface of a smooth and flat limestone plat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Oxidation

In microfabrication, thermal oxidation is a way to produce a thin layer of oxide (usually silicon dioxide) on the surface of a wafer. The technique forces an oxidizing agent to diffuse into the wafer at high temperature and react with it. The rate of oxide growth is often predicted by the Deal–Grove model. Thermal oxidation may be applied to different materials, but most commonly involves the oxidation of silicon substrates to produce silicon dioxide. The chemical reaction Thermal oxidation of silicon is usually performed at a temperature between 800 and 1200 °C, resulting in so called High Temperature Oxide layer (HTO). It may use either water vapor (usually UHP steam) or molecular oxygen as the oxidant; it is consequently called either ''wet'' or ''dry'' oxidation. The reaction is one of the following: :\rm Si + 2H_2O \rightarrow SiO_2 + 2H_ :\rm Si + O_2 \rightarrow SiO_2 \, The oxidizing ambient may also contain several percent of hydrochloric acid (HCl). The chlori ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

_250_nm_by_250_nm_image_of_one-atom-thick_silver_islands_grown_on_palladium_(111)_surface.png)

_0468.jpg)

.jpg)