|

Body In White

Body in white (BIW) is the stage in automobile manufacturing in which a car body's frame has been joined together, that is before painting and before the motor, chassis sub-assemblies, or trim (glass, door locks/handles, seats, upholstery, electronics, etc.) have been integrated into the structure. Assembly involves different techniques such as welding (spot, MIG/MAG), riveting, clinching, bonding and laser brazing. The term derives from manufacturing practices before steel unibody monocoques — when automobile bodies were made by outside firms on a separate chassis with an engine, suspension, and bumpers attached. The manufacturers built or purchased wooden bodies (with thin, non-structural metal sheets on the outside) to bolt onto the frame. The bodies were painted white prior to the final color. A folk etymology for "body in white" is the appearance of a car body after it is dipped into a white bath of primer (undercoat paint)— despite the primer's actual gray col ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Suzuki Alto (GF) Hatchback, Body In White (2010-10-16) 04

The is a kei car produced by Suzuki since 1979. The model, currently in its ninth generation, was first introduced in 1979 and has been built in many countries worldwide. The Alto originated as a commercial vehicle derivative of the Fronte, but over time the Alto nameplate gained in popularity and by 1988 it replaced the Fronte name completely. The Alto badge has often been used on different cars in Japan and in export markets, where it is considered a city car. Nameplate history In Japan, the Alto badge was originally meant to be for the commercial use version of the Fronte passenger car. The word "alto" is a musical term. When introduced, the Alto was only available as a three-door "light van" and with bare-bones equipment. However, Suzuki generally did not use the "Fronte" badge in export, usually calling all versions "Alto" abroad. Most early export Altos were thus technically speaking rebadged Suzuki Frontes. These were exported with changes such as enlarged engines, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Automotive Industry

The automotive industry comprises a wide range of company, companies and organizations involved in the design, Business development, development, manufacturing, marketing, and selling of motor vehicles. It is one of the world's largest industry (economics), industries by revenue (from 16 % such as in France up to 40 % to countries like Slovakia). It is also the industry with the highest spending on research & development per firm. The word ''automotive'' comes from the Greek language, Greek ''autos'' (self), and Latin ''motivus'' (of motion), referring to any form of self-powered vehicle. This term, as proposed by Elmer Ambrose Sperry, Elmer Sperry (1860-1930), first came into use with reference to automobiles in 1898. History The automotive industry began in the 1860s with hundreds of manufacturers that pioneered the Brass Era car, horseless carriage. For many decades, the United States led the world in total automobile production. In 1929, before the Great Depression, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing Fusion welding, fusion. Welding is distinct from lower temperature techniques such as brazing and soldering, which do not melting, melt the base metal (parent metal). In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that, based on weld configuration (butt, full penetration, fillet, etc.), can be stronger than the base material. Pressure may also be used in conjunction with heat or by itself to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from being contaminated or Oxidation, oxidized. Many different energy sources can be used for welding, including a gas flame (chemical), an electric arc (electrical), a laser, an electron ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rivet

A rivet is a permanent mechanical fastener. Before being installed, a rivet consists of a smooth cylindrical shaft with a head on one end. The end opposite to the head is called the ''tail''. On installation, the rivet is placed in a punched or drilled hole, and the tail is ''upset'', or ''bucked'' (i.e., deformed), so that it expands to about 1.5 times the original shaft diameter, holding the rivet in place. In other words, the pounding or pulling creates a new "head" on the tail end by smashing the "tail" material flatter, resulting in a rivet that is roughly a dumbbell shape. To distinguish between the two ends of the rivet, the original head is called the ''factory head'' and the deformed end is called the ''shop head'' or buck-tail. Because there is effectively a head on each end of an installed rivet, it can support tension loads. However, it is much more capable of supporting shear loads (loads perpendicular to the axis of the shaft). Fastenings used in traditional w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

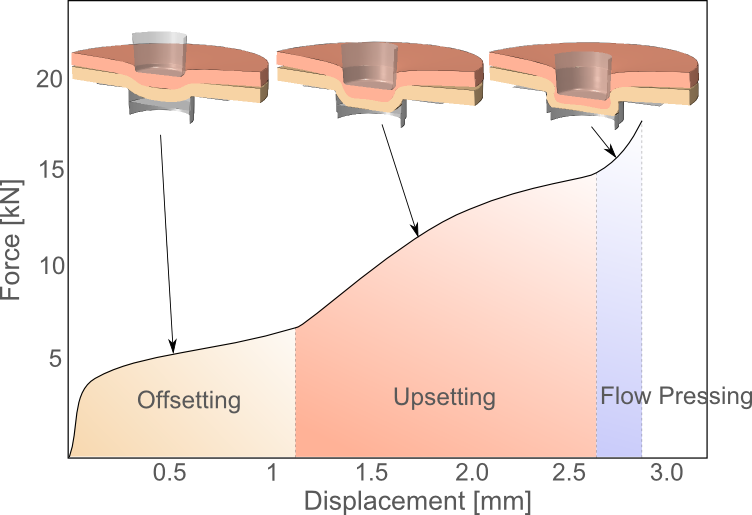

Clinching

In metalworking, clinching or press-joining is a bulk sheet metal forming process aimed at joining thin metal sheets without additional components, using special tools to plastically form an interlock between two or more sheets. The process is generally performed at room temperature, but in some special cases the sheets can be pre-heated to improve the material ductility and thereby avoid the formation of cracks during the process. Clinching is characterized by a series of advantages over competitive technologies: * Reduced joining time (the joining time is less than a second) * Reduced cost and weight: the process does not involve additional elements such as screws, rivets or adhesives * Reduced cost of the machine * No pre-holes are required * Can be adopted to join different materials including metals, polymers, wood, and composite materials * Can be easily automated and does not require qualified workers * Eco-friendly: it does not require pretreatments with solvents, acid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metallic Bonding

Metallic bonding is a type of chemical bonding that arises from the electrostatic attractive force between conduction electrons (in the form of an electron cloud of delocalized electrons) and positively charged metal ions. It may be described as the sharing of ''free'' electrons among a structure of positively charged ions ( cations). Metallic bonding accounts for many physical properties of metals, such as strength, ductility, thermal and electrical resistivity and conductivity, opacity, and luster. Metallic bonding is not the only type of chemical bonding a metal can exhibit, even as a pure substance. For example, elemental gallium consists of covalently-bound pairs of atoms in both liquid and solid-state—these pairs form a crystal structure with metallic bonding between them. Another example of a metal–metal covalent bond is the mercurous ion (). History As chemistry developed into a science, it became clear that metals formed the majority of the periodic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brazing

Brazing is a metal-joining process in which two or more metal items are joined together by melting and flowing a filler metal into the joint, with the filler metal having a lower melting point than the adjoining metal. Brazing differs from welding in that it does not involve melting the work pieces. Brazing differs from soldering through the use of a higher temperature and much more closely fitted parts than when soldering. During the brazing process, the filler metal flows into the gap between close-fitting parts by capillary action. The filler metal is brought slightly above its melting ( liquidus) temperature while protected by a suitable atmosphere, usually a flux. It then flows over the base metal (in a process known as wetting) and is then cooled to join the work pieces together. A major advantage of brazing is the ability to join the same or different metals with considerable strength. Basics High-quality brazed joints require that parts be closely fitted with base m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Monocoque

Monocoque ( ), also called structural skin, is a structural system in which loads are supported by an object's external skin, in a manner similar to an egg shell. The word ''monocoque'' is a French term for "single shell". First used for boats, a true monocoque carries both tensile and compressive forces within the skin and can be recognised by the absence of a load-carrying internal frame. Few metal aircraft other than those with milled skins can strictly be regarded as pure monocoques, as they use a metal shell or sheeting reinforced with frames riveted to the skin, but most wooden aircraft are described as monocoques, even though they also incorporate frames. By contrast, a semi-monocoque is a hybrid combining a tensile stressed skin and a compressive structure made up of longerons and ribs or frames. Other semi-monocoques, not to be confused with true monocoques, include vehicle unibodies, which tend to be composites, and inflatable shells or balloon tanks, both of which ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Folk Etymology

Folk etymology (also known as popular etymology, analogical reformation, reanalysis, morphological reanalysis or etymological reinterpretation) is a change in a word or phrase resulting from the replacement of an unfamiliar form by a more familiar one. The form or the meaning of an archaic, foreign, or otherwise unfamiliar word is reinterpreted as resembling more familiar words or morphemes. The term ''folk etymology'' is a loan translation from German language, German ''Volksetymologie'', coined by Ernst Förstemann in 1852. Folk etymology is a Productivity (linguistics), productive process in historical linguistics, language change, and social relation, social interaction. Reanalysis of a word's history or original form can affect its spelling, pronunciation, or meaning. This is frequently seen in relation to loanwords or words that have become archaic or obsolete. Examples of words created or changed through folk etymology include the English dialectal form wikt:sparrowgrass ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Primer (paint)

A primer () or undercoat is a preparatory coating put on materials before painting. Priming ensures better adhesion of paint to the surface, increases paint durability, and provides additional protection for the material being painted. Composition A primer consists of synthetic resin, solvent and additive agent while some primers contain polyethylene (plastic), for better durability. Use Primer is a paint product that allows finishing paint to adhere much better than if it were used alone. It is designed to adhere to surfaces and to form a binding layer that is better prepared to receive the paint. Compared to paint, a primer is not intended to be used as the outermost durable finish and can instead be engineered to have improved filling and binding properties with the material underneath. Sometimes this is achieved by chemistry, as in the case of aluminum primer, but more often this is achieved through controlling the primer's physical properties such as its porosity, tackiness ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Die (manufacturing)

A die is a specialized machine tool used in manufacturing industries to cut and/or form material to a desired shape or profile. Stamping dies are used with a press, as opposed to drawing dies (used in the manufacture of wire) and casting dies (used in molding) which are not. Like molds, dies are generally customized to the item they are used to create. Products made with dies range from simple paper clips to complex pieces used in advanced technology. Continuous-feed laser cutting may displace the analogous die-based process in the automotive industry, among others. Die stamping Blanking and piercing are two die cutting operations, and bending is an example of a die forming operation. Die forming Forming operations work by deforming materials like sheet metal or plastic using force (compression, tension, or both) and rely on the material's mechanical properties. Forming dies are typically made by tool and die makers and put into production after mounting into a press. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crashworthiness

Crashworthiness is the ability of a structure to protect its occupants during an impact. This is commonly tested when investigating the safety of aircraft and vehicles. Depending on the nature of the impact and the vehicle involved, different criteria are used to determine the crashworthiness of the structure. Crashworthiness may be assessed either prospectively, using computer models (e.g., LS-DYNA, PAM-CRASH, MSC Dytran, MADYMO) or experiments, or retrospectively by analyzing crash outcomes. Several criteria are used to assess crashworthiness prospectively, including the deformation patterns of the vehicle structure, the acceleration experienced by the vehicle during an impact, and the probability of injury predicted by human body models. Injury probability is defined using criteria, which are mechanical parameters (e.g., force, acceleration, or deformation) that correlate with injury risk. A common injury criterion is the head impact criterion (HIC). Crashworthiness is asse ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)