|

Basic Sediment And Water

Basic sediment and water (BS&W) is a both a technical specification of certain impurities in crude oil and the method for measuring it. When extracted from an oil reservoir, the crude oil will contain some amount of water and suspended solids from the reservoir formation. The particulate matter is known as sediment or mud. The water content can vary greatly from field to field, and may be present in large quantities for older fields, or if oil extraction is enhanced using water injection technology. The bulk of the water and sediment is usually separated at the field to minimize the quantity that needs to be transported further. The residual content of these unwanted impurities is measured as BS&W. Oil refineries may either buy crude to a certain BS&W specification or may alternatively have initial crude oil dehydration and desalting process units that reduce the BS&W to acceptable limits, or a combination thereof. Testing ASTM method D4007 or API An application program ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crude Oil

Petroleum, also known as crude oil, or simply oil, is a naturally occurring yellowish-black liquid mixture of mainly hydrocarbons, and is found in geological formations. The name ''petroleum'' covers both naturally occurring unprocessed crude oil and petroleum products that consist of refined crude oil. A fossil fuel, petroleum is formed when large quantities of dead organisms, mostly zooplankton and algae, are buried underneath sedimentary rock and subjected to both prolonged heat and pressure. Petroleum is primarily recovered by oil drilling. Drilling is carried out after studies of structural geology, sedimentary basin analysis, and reservoir characterisation. Recent developments in technologies have also led to exploitation of other Unconventional (oil & gas) reservoir, unconventional reserves such as oil sands and oil shale. Once extracted, oil is refined and separated, most easily by Continuous distillation#Continuous distillation of crude oil, distillation, into innume ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oil Reservoir

A petroleum reservoir or oil and gas reservoir is a subsurface accumulation of hydrocarbons contained in porous or fractured rock formations. Such reservoirs form when kerogen (ancient plant matter) is created in surrounding rock by the presence of high heat and pressure in the Earth's crust. Petroleum reservoirs are broadly classified as ''conventional'' and '' unconventional'' reservoirs. In conventional reservoirs, the naturally occurring hydrocarbons, such as crude oil or natural gas, are trapped by overlying rock formations with lower permeability, while in unconventional reservoirs, the rocks have high porosity and low permeability, which keeps the hydrocarbons trapped in place, therefore not requiring a cap rock. Reservoirs are found using hydrocarbon exploration methods. Oil field An oil field is an area of accumulation of liquid oil underground in multiple (potentially linked) reservoirs, trapped as it rises by impermeable rock formations. In industrial terms, an o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Suspended Solids

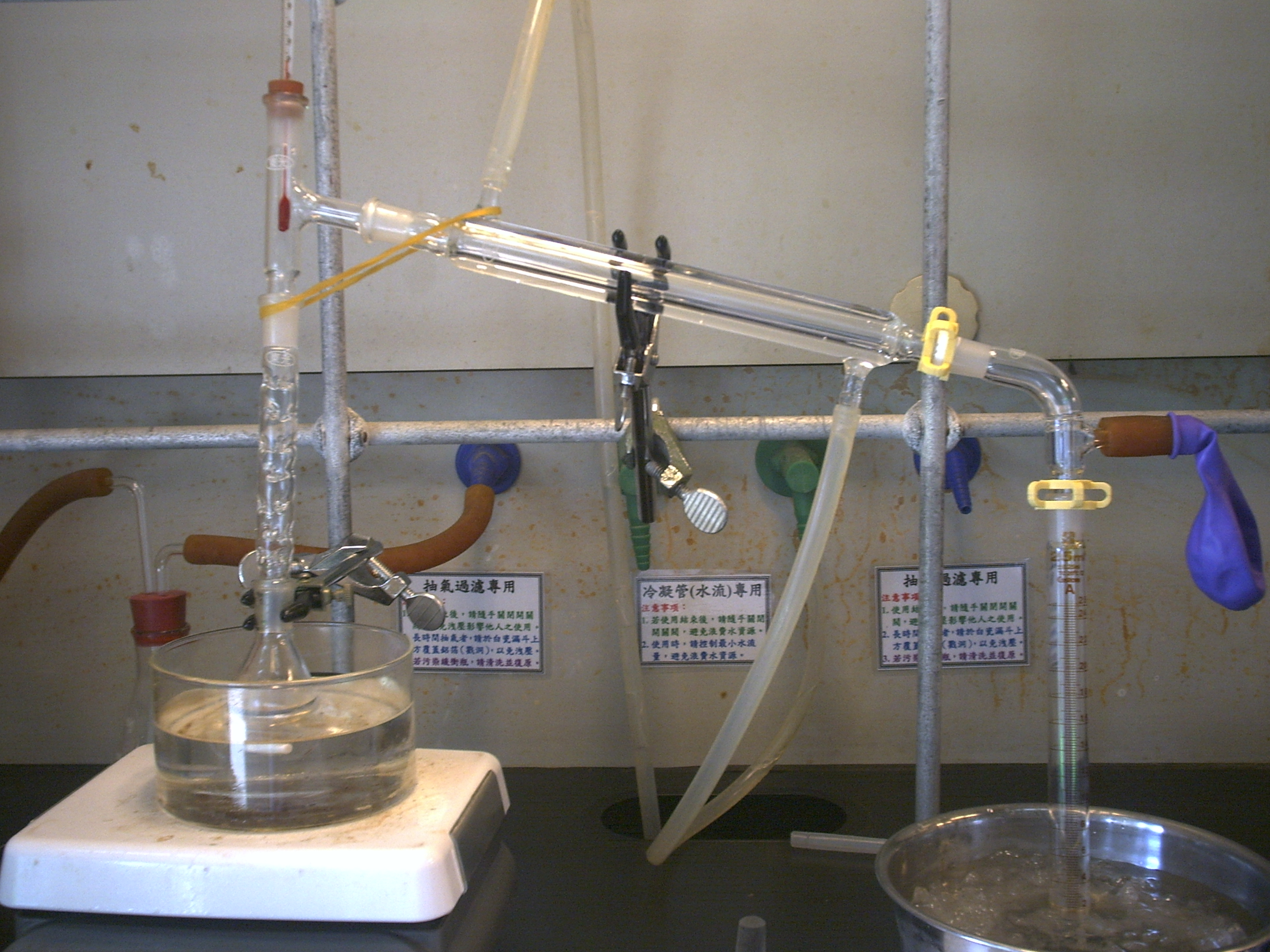

Suspended solids refers to small solid particles which remain in suspension in water as a colloid or due to motion of the water. Suspended solids can be removed by sedimentation if their size or density is comparatively large, or by filtration. It is used as one indicator of water quality and of the strength of sewage, or wastewater in general. It is an important design parameter for sewage treatment processes. It is sometimes abbreviated SS, but is not to be confused with settleable solids, also abbreviated SS, which contribute to the blocking of sewer pipes. Explanation Suspended solids are important as pollutants and pathogens are carried on the surface of particles. The smaller the particle size, the greater the total surface area per unit mass of particle in grams, and so the higher the pollutant load that is likely to be carried. Removal Removal of suspended solids is generally achieved through the use of sedimentation and/or water filters (usually at a municipal level) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Water Injection (oil Production)

In the oil industry, waterflooding or water injection is where water is injected into the oil reservoir, to maintain the pressure (also known as voidage replacement), or to drive oil towards the wells, and thereby increase production. Water injection wells may be located on- and offshore, to increase oil recovery from an existing reservoir. Normally only 30% of the oil in a reservoir can be extracted, but water injection increases the recovery (known as the recovery factor) and maintains the production rate of a reservoir over a longer period. Waterflooding began accidentally in Pithole, Pennsylvania by 1865. Waterflooding became common in Pennsylvania in the 1880s. Sources of injection water Most sources of bulk water can be used for injection. The following sources of water are used for recovery of oil: Produced water is often used as an injection fluid. This reduces the potential of causing formation damage due to incompatible fluids, although the risk of scaling or corr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Oil Refinery

An oil refinery or petroleum refinery is an industrial process plant where petroleum (crude oil) is transformed and refined into useful products such as gasoline (petrol), diesel fuel, asphalt base, fuel oils, heating oil, kerosene, liquefied petroleum gas and petroleum naphtha. Petrochemicals feedstock like ethylene and propylene can also be produced directly by cracking crude oil without the need of using refined products of crude oil such as naphtha. The crude oil feedstock has typically been processed by an oil production plant. There is usually an oil depot at or near an oil refinery for the storage of incoming crude oil feedstock as well as bulk liquid products. In 2020, the total capacity of global refineries for crude oil was about 101.2 million barrels per day. Oil refineries are typically large, sprawling industrial complexes with extensive piping running throughout, carrying streams of fluids between large chemical processing units, such as distillation colu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Desalter

A desalter is a process unit in an oil refinery that removes salt from the crude oil. The salt is dissolved in the water in the crude oil, not in the crude oil itself. The desalting is usually the first process in crude oil refining. The salt content after the desalter is usually measured in PTB – pounds of salt per thousand barrels of crude oil. Another specification is Basic sediment and water. The term desalter may also refer to a water desalination facility used to treat brackish water from agricultural runoff. This may be done either to produce potable water for human or animal consumption, or to reduce the salinity of river water prior to its crossing an international border, usually to comply with the terms of a treaty. Desalters are also used to treat groundwater reservoirs in areas impacted by cattle feedlots and dairies. Desalting crude oil The salts that are most frequently present in crude oil are calcium, sodium and magnesium chlorides. If these compoun ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ASTM

ASTM International, formerly known as American Society for Testing and Materials, is an international standards organization that develops and publishes voluntary consensus technical standards for a wide range of materials, products, systems, and services. Some 12,575 ASTM voluntary consensus standards operate globally. The organization's headquarters is in West Conshohocken, Pennsylvania, about northwest of Philadelphia. It is founded in 1902 as the American Section of the International Association for Testing Materials (see also International Organization for Standardization). History A group of scientists and engineers, led by Charles Dudley, formed ASTM in 1898 to address the frequent rail breaks affecting the fast-growing railroad industry. The group developed a standard for the steel used to fabricate rails. Originally called the "American Society for Testing Materials" in 1902, it became the "American Society for Testing And Materials" in 1961. In 2001, ASTM official ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

American Petroleum Institute

The American Petroleum Institute (API) is the largest U.S. trade association for the oil and natural gas industry. It claims to represent nearly 600 corporations involved in production, refinement, distribution, and many other aspects of the petroleum industry. Much of its work has been dedicated to the advancement of climate change denial and blocking of climate legislation to defend the interests of its constituent organizations. The association describes its mission as "to promote safety across the industry globally and influence public policy in support of a strong, viable U.S. oil and natural gas industry". API's chief functions on behalf of the industry include advocacy, negotiation and lobbying with governmental, legal, and regulatory agencies; research into economic, toxicological, and environmental effects; establishment and certification of industry standards; and education outreach. API both funds and conducts research related to many aspects of the petroleum indus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Processes

Industrial processes are procedures involving chemical, physical, electrical or mechanical steps to aid in the manufacturing of an item or items, usually carried out on a very large scale. Industrial processes are the key components of heavy industry. Chemical processes by main basic material Certain chemical process yield important basic materials for society, e.g., (cement, steel, aluminum, and fertilizer). However, these chemical reactions contribute to climate change by emitting carbon dioxide, a greenhouse gas, through chemical reactions, as well as through the combustion of fossil fuels to generate the high temperatures needed to reach the activation energies of the chemical reactions. Cement (the paste within concrete) * Calcination – Limestone, which is largely composed of fossilized calcium carbonate (CaCO3), breaks down at high temperatures into useable calcium oxide (CaO) and carbon dioxide gas (), which gets released as a by-product. This chemical reaction, call ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chemical Process Engineering

A chemical substance is a form of matter having constant chemical composition and characteristic properties. Some references add that chemical substance cannot be separated into its constituent elements by physical separation methods, i.e., without breaking chemical bonds. Chemical substances can be simple substances (substances consisting of a single chemical element), chemical compounds, or alloys. Chemical substances are often called 'pure' to set them apart from mixtures. A common example of a chemical substance is pure water; it has the same properties and the same ratio of hydrogen to oxygen whether it is isolated from a river or made in a laboratory. Other chemical substances commonly encountered in pure form are diamond (carbon), gold, table salt (sodium chloride) and refined sugar (sucrose). However, in practice, no substance is entirely pure, and chemical purity is specified according to the intended use of the chemical. Chemical substances exist as solids, liquids, g ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |