|

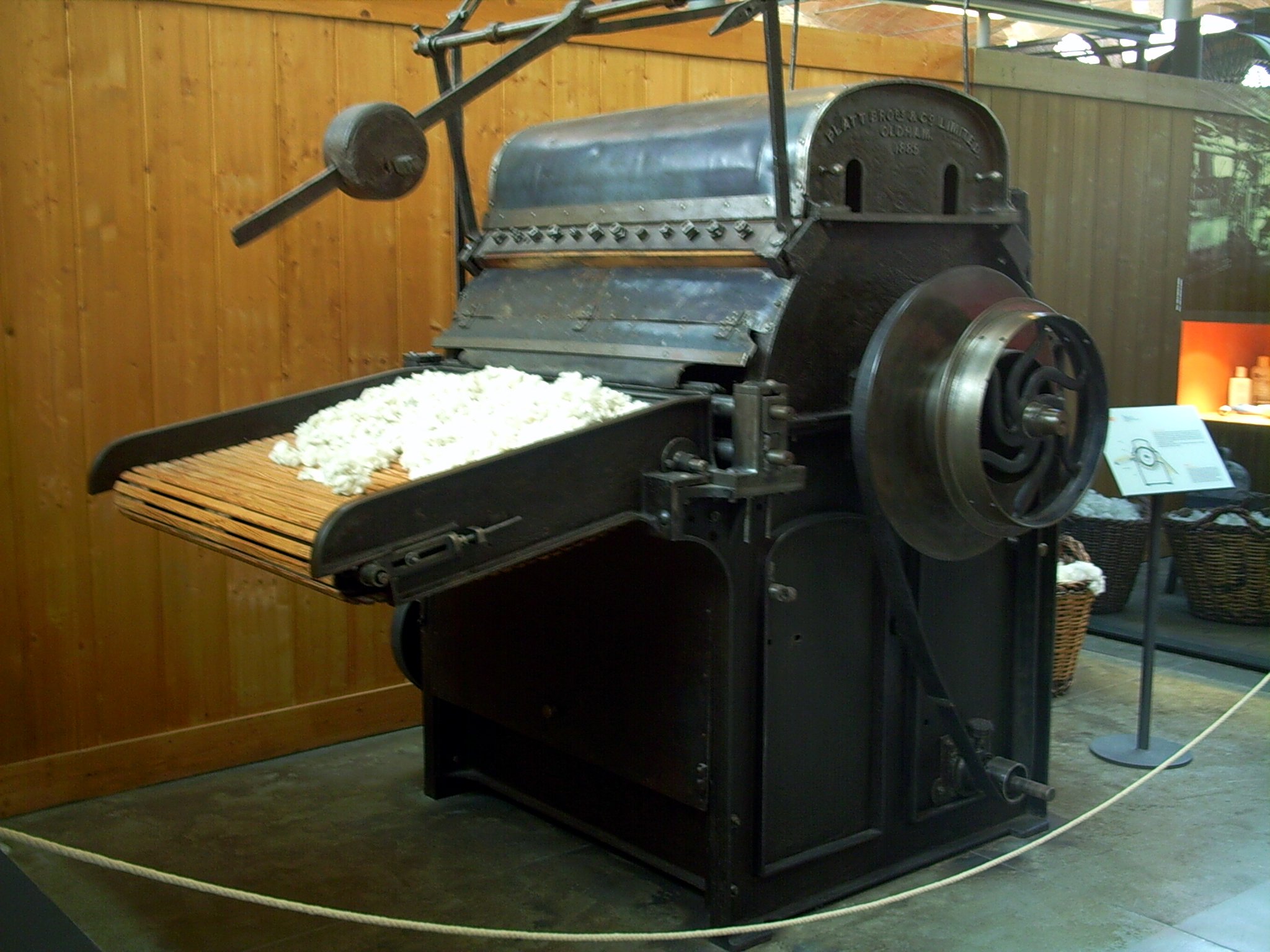

Barber-Colman Knotter

A Barber-Colman knotter is a piece of textile machinery used in a weaving shed A weaving shed is a distinctive type of mill developed in the early 1800s in Lancashire, :Derbyshire and Yorkshire to accommodate the new power looms weaving cotton, silk, woollen and worsted. A weaving shed can be a stand-alone mill, or a com .... When all the warp carried on the weavers beam has been used, a new beam replaces it. Each end has to pass through the eyes on the existing heddles, and through the existing reed. The knotter takes each new thread and knots it the existing end, which will pull it through the correct healds and reed, saving much time. A good man could do 32 or 33 warps a day. See also * Barber-Colman Company References * Textile machinery Weaving equipment {{Tool-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Textile

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, different fabric types, etc. At first, the word "textiles" only referred to woven fabrics. However, weaving is not the only manufacturing method, and many other methods were later developed to form textile structures based on their intended use. Knitting and non-woven are other popular types of fabric manufacturing. In the contemporary world, textiles satisfy the material needs for versatile applications, from simple daily clothing to bulletproof jackets, spacesuits, and doctor's gowns. Textiles are divided into two groups: Domestic purposes onsumer textilesand technical textiles. In consumer textiles, aesthetics and comfort are the most important factors, but in technical textiles, functional properties are the priority. Geotextiles, industrial textiles, medical textiles, and many other areas are examples of technical textiles, whereas clothing and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Weaving Shed

A weaving shed is a distinctive type of mill developed in the early 1800s in Lancashire, :Derbyshire and Yorkshire to accommodate the new power looms weaving cotton, silk, woollen and worsted. A weaving shed can be a stand-alone mill, or a component of a combined mill. Power looms cause severe vibrations requiring them to be located on a solid ground floor. In the case of cotton, the weaving shed needs to remain moist. Maximum daylight is achieved, by the sawtooth "north-facing roof lights". History The early textile trade relied on domestic outworking. Handloom weavers would take the yarn to their cottage loom shops, and return the completed fabric to the mill. Reliable power looms that could be worked from an overhead line shaft were not available before Kenworthy and Bulloughs weft stop motion, the roller temple and the loose reed which appeared in the 1840s. The first weaving floors were on the ground floor of the existing narrow mills, where the workpiece was lit by tal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heddle

A heddle is an integral part of a loom. Each thread in the warp passes through a heddle,"Weaving." ''The Encyclopædia Britannica''. 11th ed. 1911. which is used to separate the warp threads for the passage of the weft."Heddle." ''The Oxford English Dictionary''. 2nd ed. 1989. The typical heddle is made of cord or wire and is suspended on a shaft of a loom. Each heddle has an eye in the center where the warp is threaded through. As there is one heddle for each thread of the warp, there can be near a thousand heddles used for fine or wide warps. A handwoven tea-towel will generally have between 300 and 400 warp threads and thus use that many heddles. In weaving, the warp threads are moved up or down by the shaft. This is achieved because each thread of the warp goes through a heddle on a shaft. When the shaft is raised the heddles are too, and thus the warp threads threaded through the heddles are raised. Heddles can be either equally or unequally distributed on the shafts, dep ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reed (weaving)

A reed is part of a weaving loom, and resembles a comb. It is used to separate and space the warp threads, to guide the shuttle's motion across the loom, and to push the weft threads into place."Reed." ''The Oxford English Dictionary''. 2nd ed. 1989.1911 Encyclopædia Britannica The reed is securely held by the beater, and consists of a frame with many vertical slits. Floor looms and mechanized looms both use a beater with a reed, whereas Inkle weaving and tablet weaving do not use reeds. History Modern reeds are made by placing flattened strips of wire (made of carbon or stainless steel) between two half round ribs of wood, and binding the whole together with tarred string. Historically, reeds were made of reed or split cane. The split cane was then bound between ribs of wood in the same manner as wire is now. In 1738, John Kay replaced split cane with flattened iron or brass wire, and the change was quickly adopted. To make a reed, wire is flattened to a uniform thickn ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Textile Machinery

Textile Manufacturing or Textile Engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products. Different types of fibres are used to produce yarn. Cotton remains the most widely used and common natural fiber making up 90% of all-natural fibers used in the textile industry. People often use cotton clothing and accessories because of comfort, not limited to different weathers. There are many variable processes available at the spinning and fabric-forming stages coupled with the complexities of the finishing and colouration processes to the production of a wide range of products. History Textile manufacturing in the modern era is an evolved form of the art and craft industries. Until the 18th and 19th centuries, the textile industry was a household work. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |