|

Brass Mill

A brass mill is a mill which processes brass. Brass mills are common in England; many date from long before the Industrial Revolution. ;Examples of brass mills include: *Brassmill (Ross on Wye) *Saltford Brass Mill See also * Calamine brass * Latten Historically, the term "latten" referred loosely to the copper alloys such as brass or bronze that appeared in the Middle Ages and through to the late-18th and early-19th centuries. Such alloys were used for monumental brasses, in decorative effect ... * William Champion Further reading * Metallurgical facilities {{manufacturing-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brass

Brass is an alloy of copper (Cu) and zinc (Zn), in proportions which can be varied to achieve different mechanical, electrical, and chemical properties. It is a substitutional alloy: atoms of the two constituents may replace each other within the same crystal structure. Brass is similar to bronze, another copper alloy, that uses tin instead of zinc. Both bronze and brass may include small proportions of a range of other elements including arsenic (As), lead (Pb), phosphorus (P), aluminium (Al), manganese (Mn), and silicon (Si). Historically, the distinction between the two alloys has been less consistent and clear, and modern practice in museums and archaeology increasingly avoids both terms for historical objects in favor of the more general "copper alloy". Brass has long been a popular material for decoration due to its bright, gold-like appearance; being used for drawer pulls and doorknobs. It has also been widely used to make utensils because of its low melting ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going from hand production methods to machines, new chemical manufacturing and iron production processes, the increasing use of steam power and water power, the development of machine tools and the rise of the mechanized factory system. Output greatly increased, and a result was an unprecedented rise in population and in the rate of population growth. Textiles were the dominant industry of the Industrial Revolution in terms of employment, value of output and capital invested. The textile industry was also the first to use modern production methods. The Industrial Revolution began in Great Britain, and many of the technological and architectural innovations were of British origin. By the mid-18th century, Britain was the world's leadi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brassmill (Ross On Wye)

A brass mill is a mill which processes brass. Brass mills are common in England; many date from long before the Industrial Revolution. ;Examples of brass mills include: *Brassmill (Ross on Wye) *Saltford Brass Mill See also * Calamine brass * Latten Historically, the term "latten" referred loosely to the copper alloys such as brass or bronze that appeared in the Middle Ages and through to the late-18th and early-19th centuries. Such alloys were used for monumental brasses, in decorative effect ... * William Champion Further reading * Metallurgical facilities {{manufacturing-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Saltford Brass Mill

Saltford Brass Mill is a brass mill on the River Avon at Saltford, Somerset, England. It dates from the 1720s is listed as Grade II* and is also a Scheduled Ancient Monument. There was a watermill on the site at the time of the Domesday Book and it is the last surviving of over 30 mills which were once on this stretch of the Avon. Local brass making was initiated in Bristol around 1700 by the family of Abraham Darby who later moved upstream because of the better water supply at Saltford and Keynsham. The brass was made from Cornish ores refined at Crew's Hole and then transported via the river. These were mixed with calamine from the Mendip Hills to make calamine brass. This changed as processes improved and local copper smelting was replaced by supplies from Swansea. By the 1850s zinc metal was used instead of calamine, using a process introduced by William Champion, who lived nearby. The site includes a battery mill which was used for hollowing out brass sheet to make pan ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Calamine Brass

Calamine brass is brass produced by a particular alloying technique using the zinc ore calamine directly, rather than first refining it to metallic zinc. Direct zinc smelting appears to have been unknown in Europe until the mid-18th century, even though the alloyed calamine brass was in use for centuries, and metallic zinc was produced directly via reducing-atmosphere smelting in India and China from the 12th century CE onwards. Brass is an alloy of copper and zinc and, when it was first developed, methods for producing metallic zinc were unknown. Metallurgists wishing to produce brass thus used calamine (actually a mixture of the virtually indistinguishable zinc ores smithsonite and hemimorphite) as the zinc component of brass. The resulting brasses, produced by heating a mixture of copper and calamine to a high temperature for several hours (allowing zinc vapor to distill from the ores and permeate the metallic copper), contained a significant amount of slag material resulting f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Latten

Historically, the term "latten" referred loosely to the copper alloys such as brass or bronze that appeared in the Middle Ages and through to the late-18th and early-19th centuries. Such alloys were used for monumental brasses, in decorative effects on borders, rivets or other details of metalwork (particularly armour), in livery and pilgrim badges or funerary effigies. Latten commonly contained varying amounts of copper, tin, zinc and lead, giving it characteristics of both brass and bronze. Metalworkers commonly formed latten in thin sheets and used it to make church utensils. Brass of this period is made through the calamine brass process, from copper and zinc ore. (Later brass was made with zinc metal from Champion's smelting process and is not generally referred to as "latten".) This calamine brass was generally manufactured as hammered sheet or "battery brass" (hammered by a "battery" of water-powered trip hammer A trip hammer, also known as a tilt hammer or helve hammer, i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

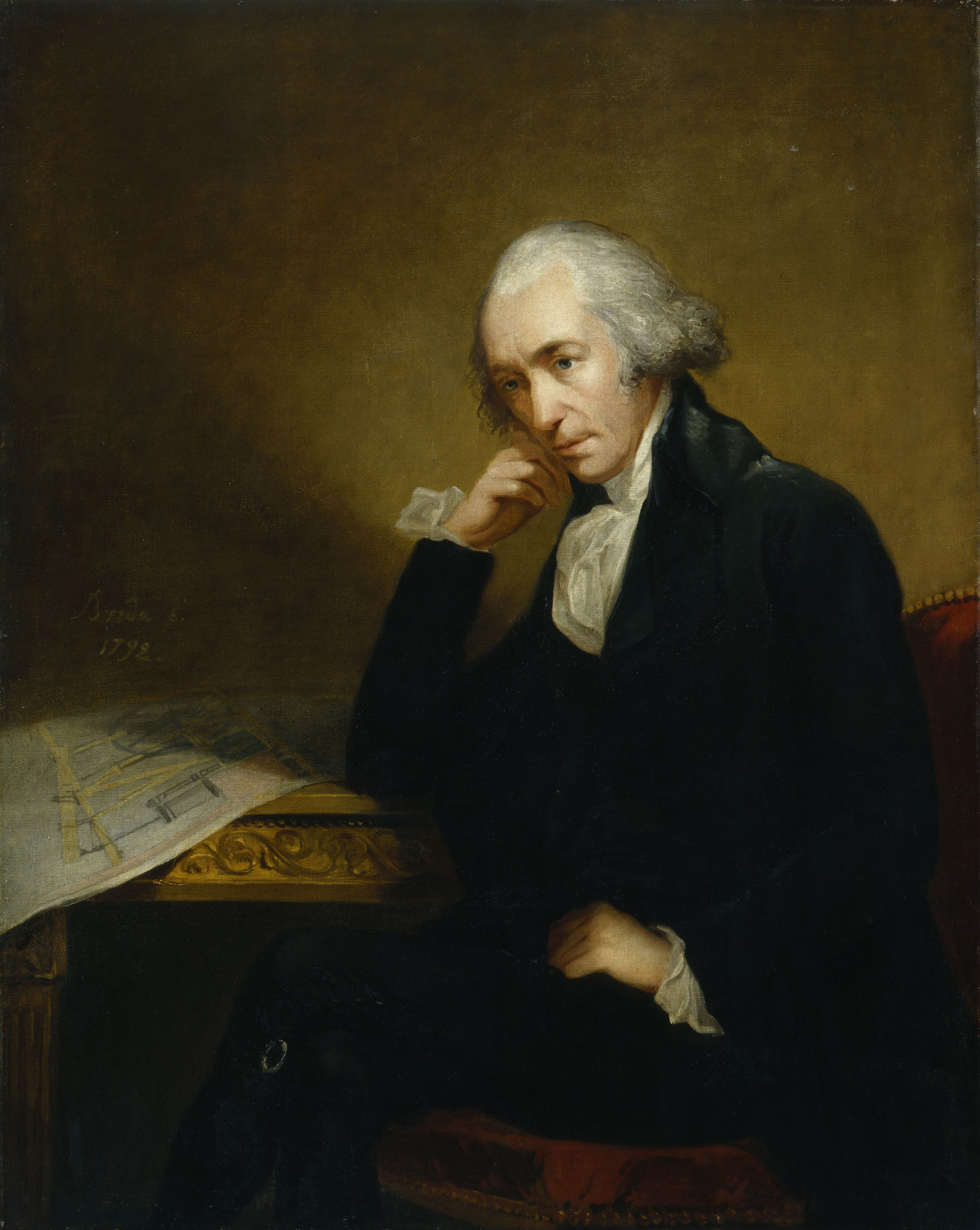

William Champion (metallurgist)

William Champion (1709–1789) is credited with patenting a process in Great Britain to distill zinc metal from calamine using charcoal in a smelter. Background After Abraham Darby I had left the Bristol Brass Company to form his own new copper works at Coalbrookdale, fellow Quaker Nehemiah Champion took over leadership. Nehemiah had three sons: John (1705–1794); Nehemiah (1709–1782); and the youngest William (1710–1789). Early life and patent As a young man, William Champion toured Europe to learn the art of brass making, returning to become a junior partner in the Bristol Brass Company in 1730. He then experimented for six years to develop a process to create zinc – then known as spelter. Using a scaled-up process similar to that used at the Zawar mines in India where this process was available centuries before William Champion rediscovered it, since the 12th century AD,p. 46, Ancient mining and metallurgy in Rajasthan, S. M. Gandhi, chapter 2 in ''Crustal Evolution an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |