|

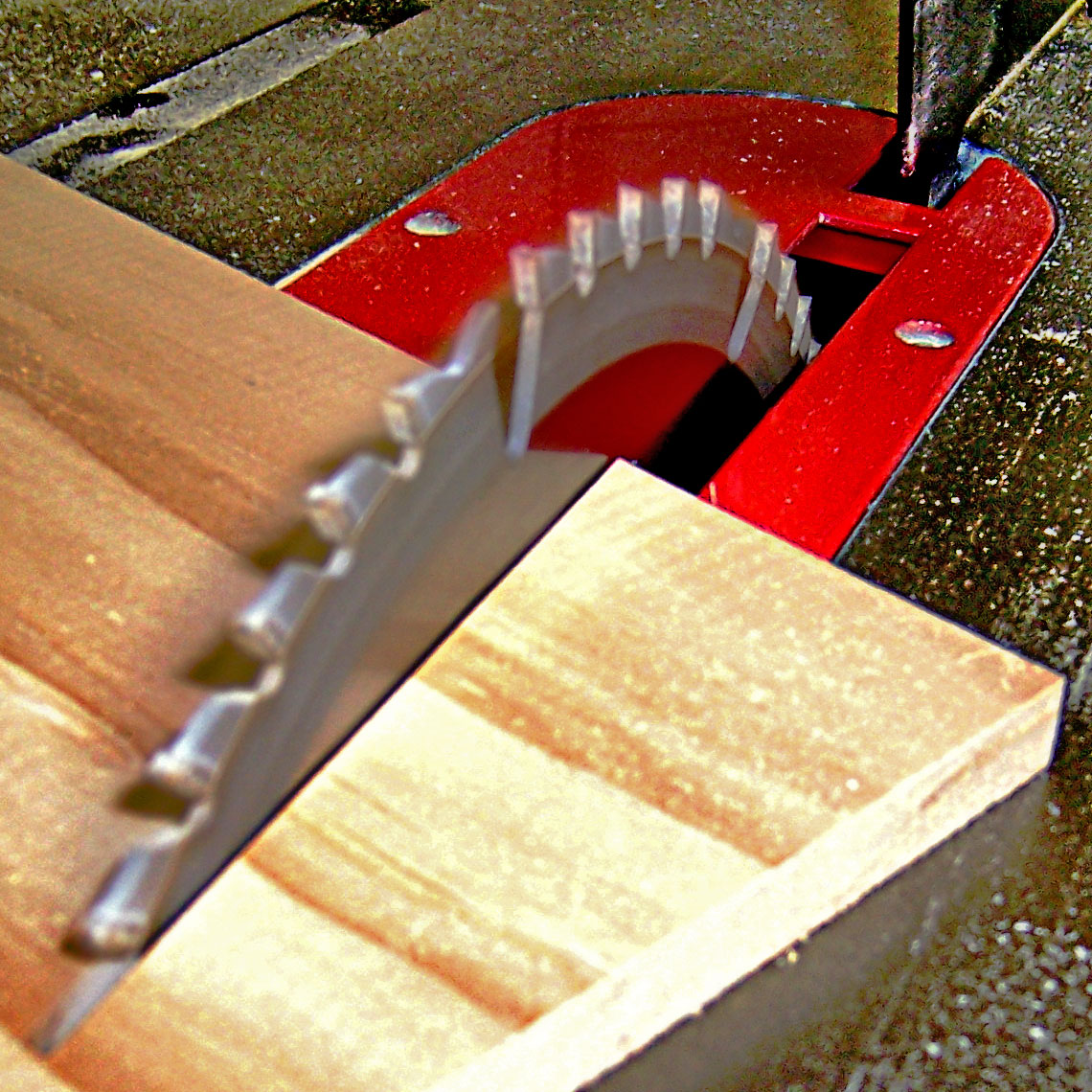

Box Joint

A box joint is a woodworking joint made by cutting a set of complementary, interlocking profiles in two pieces of wood, which are then joined (usually) at right angles, usually glued. The glued box joint has a high glued surface area resulting in a strong bond, on a similar principle to a finger joint. Box joints are used for corners of boxes or box-like constructions, hence the name. The joint does not have the same interlocking properties as a dovetail joint, but is much simpler to make, and can be mass-produced fairly easily. Creation Box joints are generally created by using the same profile but displaced for both halves. In modern workshops these are often made on table saws, sometimes using a dado set. Custom machinery can cut the entire joint in one pass, using a suitable jig multiple pieces, even of opposing senses, can be cut at once. They were traditionally produced manually using a tenon saw and chisel, and fine cabinet makers still use these methods. Jigs can ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woodworking Joint

Joinery is a part of woodworking that involves joining pieces of wood, engineered lumber, or synthetic substitutes (such as laminate), to produce more complex items. Some woodworking joints employ mechanical fasteners, bindings, or adhesives, while others use only wood elements (such as dowels or plain mortise and tenon fittings). The characteristics of wooden joints - strength, flexibility, toughness, appearance, etc. - derive from the properties of the materials involved and the purpose of the joint. Therefore, different joinery techniques are used to meet differing requirements. For example, the joinery used to construct a house can be different from that used to make cabinetry or furniture, although some concepts overlap. While a form of carpentry elsewhere, in British English usage it is distinguished from it, which is considered to be a form of structural timber work. History Many traditional wood joinery techniques use the distinctive material properties of wood, oft ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Wood

Wood is a porous and fibrous structural tissue found in the stems and roots of trees and other woody plants. It is an organic materiala natural composite of cellulose fibers that are strong in tension and embedded in a matrix of lignin that resists compression. Wood is sometimes defined as only the secondary xylem in the stems of trees, or it is defined more broadly to include the same type of tissue elsewhere such as in the roots of trees or shrubs. In a living tree it performs a support function, enabling woody plants to grow large or to stand up by themselves. It also conveys water and nutrients between the leaves, other growing tissues, and the roots. Wood may also refer to other plant materials with comparable properties, and to material engineered from wood, or woodchips or fiber. Wood has been used for thousands of years for fuel, as a construction material, for making tools and weapons, furniture and paper. More recently it emerged as a feedstock for the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Finger Joint

A finger joint, also known as a comb joint, is a woodworking joint made by cutting a set of complementary, interlocking profiles in two pieces of wood, which are then glued. The cross-section of the joint resembles the interlocking of fingers between two hands, hence the name "finger joint". The sides of each profile increases the surface area for gluing, resulting in a strong bond, stronger than a butt joint but not very visually appealing. Finger joints are regularly confused with box joints, which are used for corners of boxes or box-like constructions. Creation Finger joints are generally created by using identical profiles for both pieces. They are made complementary by rotation or translation of the tool with respect to the workpiece. Typically a finger router bit is used, but spindle moulders can also be used. Manual cutting of finger joints is time-consuming and error prone hence rarely done except in craft pieces. Applications A tapered or scarfed finger joint ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Table Saw

A table saw (also known as a sawbench or bench saw in England) is a woodworking tool, consisting of a circular saw blade, mounted on an arbor, that is driven by an electric motor (either directly, by belt, or by gears). The blade protrudes through the top of a table, which provides support for the material, usually wood, being cut. In most modern table saws, the depth of the cut is varied by moving the blade up and down: the higher the blade protrudes above the table, the deeper the cut that is made in the material. In some early table saws, the blade and arbor were fixed, and the table was moved up and down to expose more or less of the blade. The angle of cut is controlled by adjusting the angle of blade. Some earlier saws angled the table to control the cut angle. Types The general types of table saws are compact, benchtop, jobsite, contractor, hybrid, cabinet, and sliding table saws. Benchtop Benchtop table saws are lightweight and are designed to be placed on a table or ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dado Set

A dado set or dado blade is a type of circular saw blade, usually used with a table saw or radial arm saw, which is used to cut dadoes or grooves in woodworking. There are two common kinds of dado sets, stacked dado set and wobble blade. Stacked dado set consists of two circular saw blades fixed on either side of a set of removable chippers. As the dado set spins, the two outside blades cut the dado walls and the chippers remove the waste material in between and smooth the bottom of the dado. The chippers are added or removed to the set as required to make a dado of the desired width. Chippers can also be interspersed with spacers to finely adjust the dado width. Consequently, changing the dado width requires the complete removal of the dado blade set from the arbor Arbor(s) or Arbour(s) may refer to: Arts and entertainment * ''Arbor'' (installation), a 2013 public artwork in Indianapolis, Indiana, US * Arbor, a counterweight-carrying device found in theater fly systems * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tenon Saw

A backsaw is any hand saw which has a stiffening rib on the edge opposite the cutting edge, enabling better control and more precise cutting than with other types of saws. Backsaws are normally used in woodworking for precise work, such as cutting dovetails, mitres, or tenons in cabinetry and joinery. Because of the stiffening rib, backsaws are limited in the depth to which they can cut. Backsaws usually have relatively closely spaced teeth, often with little or no set. Types of backsaws Backsaws include the tenon saw, the dovetail saw, and the (United Kingdom) sash saw 1. Tenon and dovetail saws usually have a pistol grip style handle which may be open or closed at the bottom. Different types of backsaw include: * Mitre saw – often referred to as a large backsaw (20–30 inches or 60–90 cm) used either in a wooden or metal mitre box or in a metal frame which allowed cutting mitres of any specified angle. Note that not all mitre saws are backsaws, and the electric ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Box Joint On Enigma Machine

A box (plural: boxes) is a container used for the storage or transportation of its contents. Most boxes have flat, parallel, rectangular sides. Boxes can be very small (like a matchbox) or very large (like a shipping box for furniture), and can be used for a variety of purposes from functional to decorative. Boxes may be made of a variety of materials, both durable, such as wood and metal; and non-durable, such as corrugated fiberboard and paperboard. Corrugated metal boxes are commonly used as shipping containers. Most commonly, boxes have flat, parallel, rectangular sides, making them rectangular prisms; but boxes may also have other shapes. Rectangular prisms are often referred to colloquially as "boxes." Boxes may be closed and shut with flaps, doors, or a separate lid. They can be secured shut with adhesives, tapes, or more decorative or elaborately functional mechanisms, such as a catch, clasp or lock. Types Packaging Several types of boxes are used in packaging and s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bridle Joint

A bridle joint is a woodworking joint, similar to a mortise and tenon, in that a tenon is cut on the end of one member and a mortise is cut into the other to accept it. The distinguishing feature is that the tenon and the mortise are cut to the full width of the tenon member. The corner bridle joint (also known as a slot mortise and tenon) joins two members at their respective ends, forming a corner. This form of the joint is commonly used to house a rail in uprights, such as legs. It provides good strength in compression and is fairly resistant to racking, although a mechanical fastener or pin is often required. The bridle joint is very popular in workbench construction. Corner bridles are often used to join frame components when the frame is to be shaped. Material can be removed from the joined members after assembly without sacrificing joint integrity. A variation of the bridle joint is the T-bridle, which joins the end of one member to the middle of another.Woodwork Joint ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dovetail Joint

A dovetail joint or simply dovetail is a joinery technique most commonly used in woodworking joinery (carpentry), including furniture, cabinets, log buildings, and traditional timber framing. Noted for its resistance to being pulled apart ( tensile strength), the dovetail joint is commonly used to join the sides of a drawer to the front. A series of 'pins' cut to extend from the end of one board interlock with a series of 'tails' cut into the end of another board. The pins and tails have a trapezoidal shape. Once glued, a wooden dovetail joint requires no mechanical fasteners. History The dovetail joint technique probably pre-dates written history. Some of the earliest known examples of the dovetail joint are in ancient Egyptian furniture entombed with mummies dating from First Dynasty, the tombs of Chinese emperors, and a stone pillar at the Vazhappally Maha Siva Temple in India. The dovetail design is an important method of distinguishing various periods of furniture. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Finger Joint

A finger joint, also known as a comb joint, is a woodworking joint made by cutting a set of complementary, interlocking profiles in two pieces of wood, which are then glued. The cross-section of the joint resembles the interlocking of fingers between two hands, hence the name "finger joint". The sides of each profile increases the surface area for gluing, resulting in a strong bond, stronger than a butt joint but not very visually appealing. Finger joints are regularly confused with box joints, which are used for corners of boxes or box-like constructions. Creation Finger joints are generally created by using identical profiles for both pieces. They are made complementary by rotation or translation of the tool with respect to the workpiece. Typically a finger router bit is used, but spindle moulders can also be used. Manual cutting of finger joints is time-consuming and error prone hence rarely done except in craft pieces. Applications A tapered or scarfed finger joint ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

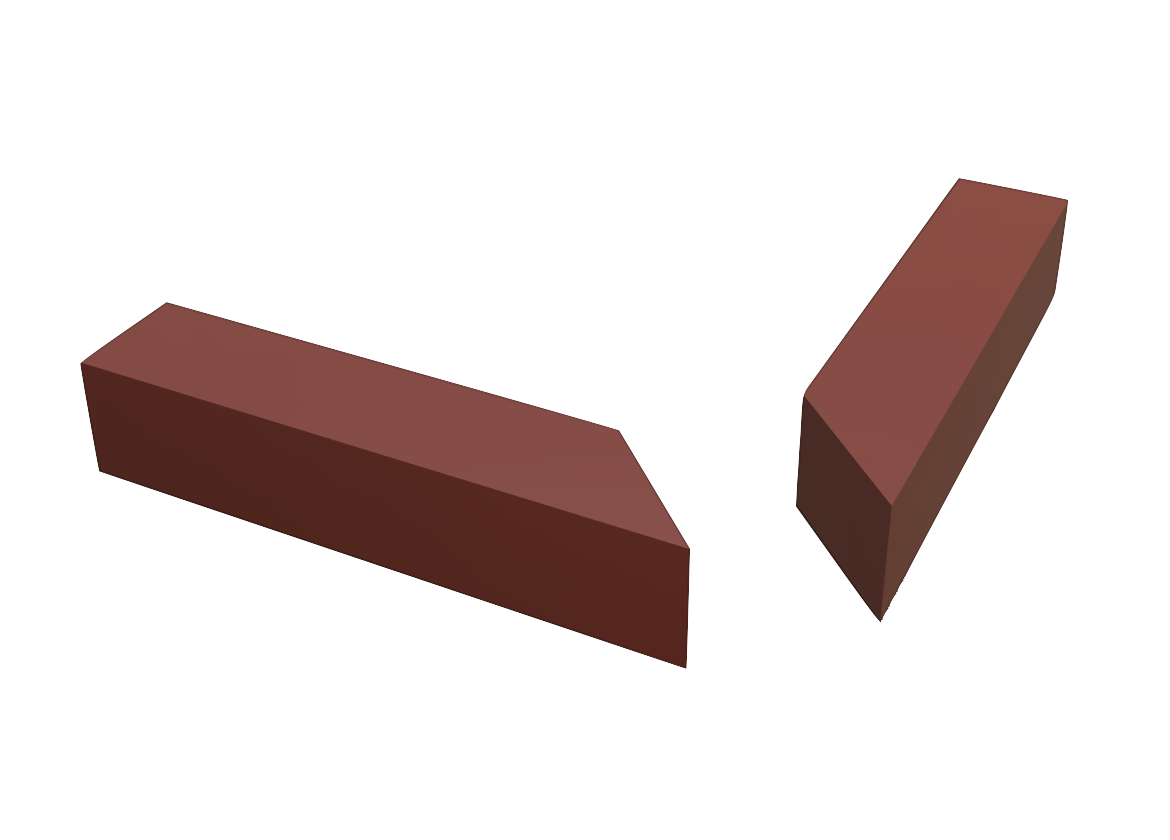

Miter Joint

A mitre joint (often miter in American English) is a joint made by cutting each of two parts to be joined, across the main surface, usually at a 45° angle, to form a corner, usually to form a 90° angle, though it can comprise any angle greater than 0 degrees. It is called beveling when the angled cut is done on the side, although the resulting joint is still a mitre joint. For woodworking, a disadvantage of a mitre joint is its weakness, but it can be strengthened with a spline (a thin wafer of wood inserted into a slot, usually arranged with the long grain of the spline across the short grain of the frame timber). There are two common variations of a splined mitre joint, one where the spline is long and runs the length of the mating surfaces and another where the spline is perpendicular to the joined edges. Common applications include picture frames, pipes, and molding. Non-perpendicular joints For mitre joints occurring at angles other than 90°, for materials of the s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |