|

Bottom Hole Assembly

A bottom hole assembly (BHA) is a component of a drilling rig. It is the lowest part of the drill string, extending from the bit to the drill pipe. The assembly can consist of drill collars, subs such as stabilisers, reamers, shocks, hole-openers, and the bit sub and bit. The BHA design is based upon the requirements of having enough weight transfer to the bit (WOB) to be able to drill and achieve a sufficient Rate of Penetration (ROP), giving the Driller or Directional Driller directional control to drill as per the planned trajectory and to also include whatever Logging While Drilling (LWD) / Measurement While Drilling (MWD) tools for formation evaluation. As such BHA design can vary greatly from simple vertical wells with little or no LWD requirements to complex directional wells which must run multi-combo LWD suites. Prior to running a BHA most oilfield service providers have software to model the BHA behaviour such as the maximum WOB achievable, the directional tendencies ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drilling Rig

A drilling rig is an integrated system that Drilling, drills wells, such as oil or water wells, or holes for piling and other construction purposes, into the earth's subsurface. Drilling rigs can be massive structures housing equipment used to drill water wells, oil wells, or natural gas extraction wells, or they can be small enough to be moved manually by one person and such are called auger (drill), augers. Drilling rigs can sample subsurface mineral deposits, test rock, soil and groundwater physical properties, and also can be used to install sub-surface fabrications, such as underground utilities, instrumentation, tunnels or wells. Drilling rigs can be mobile equipment mounted on trucks, tracks or trailers, or more permanent land or marine-based structures (such as oil platforms, commonly called 'offshore oil rigs' even if they don't contain a drilling rig). The term "rig" therefore generally refers to the complex equipment that is used to penetrate the surface of the Earth's ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill String

A drill string on a drilling rig is a column, or string, of drill pipe that transmits drilling fluid (via the mud pumps) and torque (via the kelly drive or top drive) to the drill bit. The term is loosely applied to the assembled collection of the smuggler pool, drill collars, tools and drill bit. The drill string is hollow so that drilling fluid can be pumped down through it and circulated back up the annulus (the void between the drill string and the casing/open hole). Drill string components The drill string is typically made up of three sections: * Bottom hole assembly (BHA) * Transition pipe, which is often heavyweight drill pipe (HWDP) * Drill pipe Bottom hole assembly (BHA) The Bottom Hole Assembly (BHA) is made up of: a drill bit, which is used to break up the rock formations; drill collars, which are heavy, thick-walled tubes used to apply weight to the drill bit; and drilling stabilizers, which keep the assembly centered in the hole. The BHA may al ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill Pipe

Drill pipe, is hollow, thin-walled, steel or aluminium alloy piping that is used on drilling rigs. It is hollow to allow drilling fluid to be pumped down the hole through the bit and back up the annulus. It comes in a variety of sizes, strengths, and wall thicknesses, but is typically 27 to 32 feet in length (Range 2). Longer lengths, up to 45 feet, exist (Range 3). Background Drill stems must be designed to transfer drilling torque for combined lengths that often exceed several miles down into the Earth's crust, and also must be able to resist pressure differentials between inside and outside (or vice versa), and have sufficient strength to suspend the total weight of deeper components. For deep wells this requires tempered steel tubes that are expensive, and owners spend considerable efforts to reuse them after finishing a well. A used drill stem is inspected on site, or off location. Ultrasonic testing and modified instruments similar to the spherometer are used at inspec ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rate Of Penetration

In the drilling industry, the rate of penetration (ROP), also known as penetration rate or drill rate, is the speed at which a drill bit breaks the rock under it to deepen the borehole. It is normally measured in feet per minute or meters per hour, but sometimes it is expressed in minutes per foot. Generally, ROP increases in fast drilling formation such as sandstone (positive drill break) and decreases in slow drilling formations such as shale (reverse break). ROP decreases in shale due to diagenesis and overburden stresses. Over pressured zones can give twice of ROP as expected which is an indicative of a ''well kick''. Drillers need to stop and do the bottoms up. See also *Drilling rig A drilling rig is an integrated system that Drilling, drills wells, such as oil or water wells, or holes for piling and other construction purposes, into the earth's subsurface. Drilling rigs can be massive structures housing equipment used to ...计划和扩建后 References External ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fulcrum (mechanics)

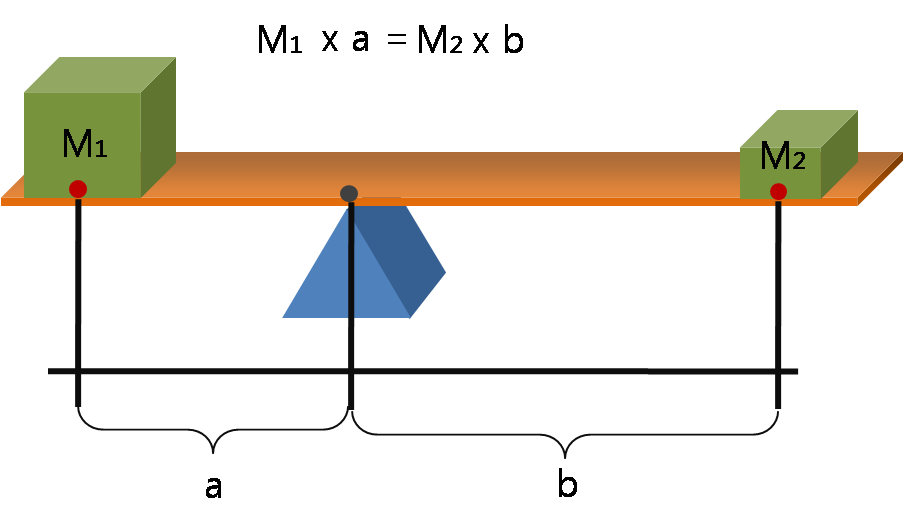

A lever is a simple machine consisting of a beam or rigid rod pivoted at a fixed hinge, or '' fulcrum''. A lever is a rigid body capable of rotating on a point on itself. On the basis of the locations of fulcrum, load and effort, the lever is divided into three types. Also, leverage is mechanical advantage gained in a system. It is one of the six simple machines identified by Renaissance scientists. A lever amplifies an input force to provide a greater output force, which is said to provide leverage. The ratio of the output force to the input force is the mechanical advantage of the lever. As such, the lever is a mechanical advantage device, trading off force against movement. Etymology The word "lever" entered English around 1300 from Old French, in which the word was ''levier''. This sprang from the stem of the verb ''lever'', meaning "to raise". The verb, in turn, goes back to the Latin ''levare'', itself from the adjective ''levis'', meaning "light" (as in "not heavy") ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Directional Drilling

Directional drilling (or slant drilling) is the practice of drilling non-vertical bores. It can be broken down into four main groups: oilfield directional drilling, utility installation directional drilling, directional boring (horizontal directional drilling - HDD), and surface in seam (SIS), which horizontally intersects a vertical bore target to extract coal bed methane. History Many prerequisites enabled this suite of technologies to become productive. Probably, the first requirement was the realization that oil wells, or water wells, do not necessarily need to be vertical. This realization was quite slow, and did not really grasp the attention of the oil industry until the late 1920s when there were several lawsuits alleging that wells drilled from a rig on one property had crossed the boundary and were penetrating a reservoir on an adjacent property. Initially, proxy evidence such as production changes in other wells was accepted, but such cases fueled the development of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Underreamer

An underreamer is a device used to enlarge the borehole below an existing casing or restriction, during a well drilling operation. It can be positioned either above the drill bit or above a pilot assembly run inside the existing borehole. Numerous designs exist, in sizes varying from a couple of inches to above 40". It is typically used in hydrocarbon drilling operations, but also geothermal or water wells drilling. This device is typically composed of a body connected to the drillstring, and of mobile parts ("arms" , "blocks" or "blades", typically 3 of them) retracted in the body during the descent and extended downhole for the reaming operation. Reaming itself can be conducted either in an existing borehole ("pilot reaming") or during the drilling operation ("reaming while drilling"). Underreaming is primarily used to allow a wider clearance for running and cementing the casing correctly, either due to restrictions (swelling shales, tortuosity) or to be able to run a larger ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |