|

Bending Machine (flat Metal Bending)

A bending machine is a forming machine tool (DIN 8586). Its purpose is to assemble a bend on a workpiece. A bend is manufactured by using a bending tool during a linear or rotating move. The detailed classification can be done with the help of the kinematics.M. Weck, p. 112 CNC bending CNC bending machines are developed for high flexibility and low setup times. Those machines are able to bend single pieces as well as small batches with the same precision and efficiency as series-produced parts in an economical way. Universal bending machines – modular construction Universal bending machines consists of a basic machine that can be adjusted with little effort and used for a variety of bends. A simple plug-in system supports quick and easy exchange of tools. The basic machine consists of a CNC-operated side stop, a work bench, and software for programming and operating. Its modular construction offers an affordable entry into the bending technology, because after an initial ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool (which is called the toolpath) is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or " freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material. The precise definition of the term ''machine tool'' varies among users, as discussed below. While all machine tools are "machines that help people to make things", not all factory machines are machine tools. Today machine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Numerical Control

Numerical control (also computer numerical control, and commonly called CNC) is the automated control of machining tools (such as drills, lathes, mills, grinders, routers and 3D printers) by means of a computer. A CNC machine processes a piece of material (metal, plastic, wood, ceramic, or composite) to meet specifications by following coded programmed instructions and without a manual operator directly controlling the machining operation. A CNC machine is a motorized maneuverable tool and often a motorized maneuverable platform, which are both controlled by a computer, according to specific input instructions. Instructions are delivered to a CNC machine in the form of a sequential program of machine control instructions such as G-code and M-code, and then executed. The program can be written by a person or, far more often, generated by graphical computer-aided design (CAD) or computer-aided manufacturing (CAM) software. In the case of 3D printers, the part to be printed is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

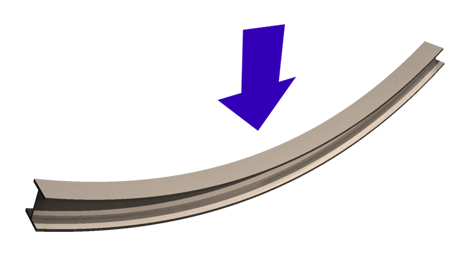

Bending Tool For Standard Bending EHRT

In applied mechanics, bending (also known as flexure) characterizes the behavior of a slender structural element subjected to an external load applied perpendicularly to a longitudinal axis of the element. The structural element is assumed to be such that at least one of its dimensions is a small fraction, typically 1/10 or less, of the other two.Boresi, A. P. and Schmidt, R. J. and Sidebottom, O. M., 1993, Advanced mechanics of materials, John Wiley and Sons, New York. When the length is considerably longer than the width and the thickness, the element is called a beam. For example, a closet rod sagging under the weight of clothes on clothes hangers is an example of a beam experiencing bending. On the other hand, a shell is a structure of any geometric form where the length and the width are of the same order of magnitude but the thickness of the structure (known as the 'wall') is considerably smaller. A large diameter, but thin-walled, short tube supported at its ends and loa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Standard Bending EHRT

Standard may refer to: Symbols * Colours, standards and guidons, kinds of military signs * Standard (emblem), a type of a large symbol or emblem used for identification Norms, conventions or requirements * Standard (metrology), an object that bears a defined relationship to a unit of measure used for calibration of measuring devices * Standard (timber unit), an obsolete measure of timber used in trade * Breed standard (also called bench standard), in animal fancy and animal husbandry * BioCompute Standard, a standard for next generation sequencing * ''De facto'' standard, product or system with market dominance * Gold standard, a monetary system based on gold; also used metaphorically for the best of several options, against which the others are measured * Internet Standard, a specification ratified as an open standard by the Internet Engineering Task Force * Learning standards, standards applied to education content * Standard displacement, a naval term describing the weig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shared Database EHRT

Shared may refer to: * Sharing * Shared ancestry or Common descent * Shared care * Shared-cost service * Shared decision-making in medicine * Shared delusion, various meanings * Shared government * Shared intelligence or collective intelligence * Shared library * Shared morality * Shared ownership * Shared parenting or shared custody * Shared property * Shared reading * Shared secret * Shared services * Shared universe, in fiction * Shared vision planning, in irrigation * Shared workspace Science and technology * Shared medium, in telecommunication * Shared neutral, in electric circuitry * Shared pair, in chemistry *Shared vertex (or shared corner or common corner), point of contact between polygons, polyhedra, etc. *Shared edge, line of contact between polygons, polyhedra, etc. Computing * Shared agenda, in groupware * Shared computing * Shared desktop * Shared data structure * Shared IP address * Shared memory architecture * Shared memory (interprocess communication) * Sha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Punching Machine

A punching machine is a machine tool for punching and embossing flat sheet-materials to produce form-features needed as mechanical element and/or to extend static stability of a sheet section. CNC punching Punch presses are developed for high flexibility and efficient processing of metal stampings. The main areas of application are for small and medium runs. Those machines are typically equipped with a linear die carrier (tool carrier) and quick change tools. Today the method is used where the application of lasers are inefficient or technically impractical. CNC is the abbreviation of Computer Numerically Controlled. Principle of operation After programming the work pieces and entering length of bars the control automatically calculates the maximum number of pieces to be punched (for example, 18 pieces of a bar of 6000 mm). Once the desired number of work pieces is entered, the bar is pushed toward the stop. The machine is fully automated once the production process is l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bending

In applied mechanics, bending (also known as flexure) characterizes the behavior of a slender structural element subjected to an external load applied perpendicularly to a longitudinal axis of the element. The structural element is assumed to be such that at least one of its dimensions is a small fraction, typically 1/10 or less, of the other two.Boresi, A. P. and Schmidt, R. J. and Sidebottom, O. M., 1993, Advanced mechanics of materials, John Wiley and Sons, New York. When the length is considerably longer than the width and the thickness, the element is called a beam. For example, a closet rod sagging under the weight of clothes on clothes hangers is an example of a beam experiencing bending. On the other hand, a shell is a structure of any geometric form where the length and the width are of the same order of magnitude but the thickness of the structure (known as the 'wall') is considerably smaller. A large diameter, but thin-walled, short tube supported at its ends and loa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metal Forming

Forming, metal forming, is the metalworking process of fashioning metal parts and objects through mechanical deformation; the workpiece is reshaped without adding or removing material, and its mass remains unchanged. Forming operates on the materials science principle of plastic deformation, where the physical shape of a material is permanently deformed. Characteristics Metal forming tends to have more uniform characteristics across its subprocesses than its contemporary processes, cutting and joining. On the industrial scale, forming is characterized by: * Very high loads and stresses required, between 50 and () * Large, heavy, and expensive machinery in order to accommodate such high stresses and loads * Production runs with many parts, to maximize the economy of production and compensate for the expense of the machine tools Forming processes Forming processes tend to be categorised by differences in effective stresses. These categories and descriptions are highly simplifie ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fabrication (metal)

Metal fabrication is the creation of metal structures by cutting, bending and assembling processes. It is a value-added process involving the creation of machines, parts, and structures from various raw materials. Typically, a fabrication shop bids on a job, usually based on engineering drawings, and if awarded the contract, builds the product. Large fab shops employ a multitude of value-added processes, including welding, cutting, forming and machining. As with other manufacturing processes, both human labor and automation are commonly used. A fabricated product may be called a ''fabrication'', and shops specializing in this type of work are called ''fab shops''. The end products of other common types of metalworking, such as machining, metal stamping, forging, and casting, may be similar in shape and function, but those processes are not classified as fabrication. Processes *''Cutting'' is done by sawing, shearing, or chiselling (all with manual and powered variants); ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |