|

Backflush Accounting

Backflush accounting is a subset of management accounting focused on types of "postproduction issuing;" It is a product costing approach, used in a Just-In-Time (JIT) operating environment, in which costing is delayed until goods are finished. Backflush accounting delays the recording of costs until after the events have taken place, then standard costs are used to work backwards to 'flush' out the manufacturing costs. The result is that detailed tracking of costs is eliminated. Journal entries to inventory accounts may be delayed until the time of product completion or even the time of sale, and standard costs are used to assign costs to units when journal entries are made. Backflushing transaction has two steps: one step of the transaction reports the produced part which serves to increase the quantity on-hand of the produced part and a second step which relieves the inventory of all the component parts. Component part numbers and quantities-per are taken from the standard bill ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Management Accounting

In management accounting or managerial accounting, managers use accounting information in decision-making and to assist in the management and performance of their control functions. Definition One simple definition of management accounting is the provision of financial and non-financial decision-making information to managers. In other words, management accounting helps the directors inside an organization to make decisions. This can also be known as Cost Accounting. This is the way toward distinguishing, examining, deciphering and imparting data to supervisors to help accomplish business goals. The information gathered includes all fields of accounting that educates the administration regarding business tasks identifying with the financial expenses and decisions made by the organization. Accountants use plans to measure the overall strategy of operations within the organization. According to the Institute of Management Accountants (IMA), "Management accounting is a profession t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing Resource Planning

Manufacturing resource planning (MRP II) is defined as a method for the effective planning of all resources of a manufacturing company. Ideally, it addresses operational planning in units, financial planning, and has a simulation capability to answer " what-if" questions and is an extension of closed-loop MRP (Material Requirements Planning). This is not exclusively a software function, but the management of people skills, requiring a dedication to database accuracy, and sufficient computer resources. It is a total company management concept for using human and company resources more productively. Key functions and features MRP II is not a proprietary software system and can thus take many forms. It is almost impossible to visualize an MRP II system that does not use a computer, but an MRP II system can be based on either purchased–licensed or in-house software. Almost every MRP II system is modular in construction. Characteristic basic modules in an MRP II system are: * ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

SAP EWM

SAP EWM is part of SAP AG's Supply Chain Management Suite of solutions. The Extended Warehouse Management product is an integrated software platform for inflexible, automated support for processing goods movements and for managing inventory in the warehouse. Overview "SAP EWM firms the ability to control warehouse processes and manage movements in the warehouse, mitigate problems and issues with enhanced warehouse efficiency, and transform operations into an adaptive fulfillment supply chain that can share its resources". SAP EWM is similar to SAP WM functionality, but with more flexibility in building objects like Warehouse structure, picking, put away, HU (handling unit), RF, and more. Also, Activity Areas, Work Centers, and Resources are elements incorporated into SAP EWM that are new additions since SAP WM. SAP WM was the company's first foray into a specific Warehouse Management Solution. By 2025 SAP WM will no longer be supported and completely replaced by SAP EWM. Like S ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heuristic

A heuristic (; ), or heuristic technique, is any approach to problem solving or self-discovery that employs a practical method that is not guaranteed to be optimal, perfect, or rational, but is nevertheless sufficient for reaching an immediate, short-term goal or approximation. Where finding an optimal solution is impossible or impractical, heuristic methods can be used to speed up the process of finding a satisfactory solution. Heuristics can be mental shortcuts that ease the cognitive load of making a decision. Examples that employ heuristics include using trial and error, a rule of thumb or an educated guess. Heuristics are the strategies derived from previous experiences with similar problems. These strategies depend on using readily accessible, though loosely applicable, information to control problem solving in human beings, machines and abstract issues. When an individual applies a heuristic in practice, it generally performs as expected. However it can alternati ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brute-force Search

In computer science, brute-force search or exhaustive search, also known as generate and test, is a very general problem-solving technique and algorithmic paradigm that consists of systematically enumerating all possible candidates for the solution and checking whether each candidate satisfies the problem's statement. A brute-force algorithm that finds the divisors of a natural number ''n'' would enumerate all integers from 1 to n, and check whether each of them divides ''n'' without remainder. A brute-force approach for the eight queens puzzle would examine all possible arrangements of 8 pieces on the 64-square chessboard and for each arrangement, check whether each (queen) piece can attack any other. While a brute-force search is simple to implement and will always find a solution if it exists, implementation costs are proportional to the number of candidate solutionswhich in many practical problems tends to grow very quickly as the size of the problem increases ( §Combinator ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Travelling Salesman Problem

The travelling salesman problem (also called the travelling salesperson problem or TSP) asks the following question: "Given a list of cities and the distances between each pair of cities, what is the shortest possible route that visits each city exactly once and returns to the origin city?" It is an NP-hard problem in combinatorial optimization, important in theoretical computer science and operations research. The travelling purchaser problem and the vehicle routing problem are both generalizations of TSP. In the theory of computational complexity, the decision version of the TSP (where given a length ''L'', the task is to decide whether the graph has a tour of at most ''L'') belongs to the class of NP-complete problems. Thus, it is possible that the worst-case running time for any algorithm for the TSP increases superpolynomially (but no more than exponentially) with the number of cities. The problem was first formulated in 1930 and is one of the most intensively studi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flow Shop Scheduling

Flow-shop scheduling is an optimization problem in computer science and operations research. It is a variant of optimal job scheduling. In a general job-scheduling problem, we are given ''n'' jobs ''J''1, ''J''2, ..., ''Jn'' of varying processing times, which need to be scheduled on ''m'' machines with varying processing power, while trying to minimize the makespan – the total length of the schedule (that is, when all the jobs have finished processing). In the specific variant known as ''flow-shop scheduling'', each job contains exactly ''m'' operations. The ''i''-th operation of the job must be executed on the ''i''-th machine. No machine can perform more than one operation simultaneously. For each operation of each job, execution time is specified. Flow-shop scheduling is a special case of job-shop scheduling where there is strict order of all operations to be performed on all jobs. Flow-shop scheduling may apply as well to production facilities as to computing d ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Job Shop Scheduling

Job-shop scheduling, the job-shop problem (JSP) or job-shop scheduling problem (JSSP) is an optimization problem in computer science and operations research. It is a variant of optimal job scheduling. In a general job scheduling problem, we are given ''n'' jobs ''J''1, ''J''2, ..., ''Jn'' of varying processing times, which need to be scheduled on ''m'' machines with varying processing power, while trying to minimize the makespan – the total length of the schedule (that is, when all the jobs have finished processing). In the specific variant known as ''job-shop scheduling'', each job consists of a set of ''operations'' ''O''1, ''O''2, ..., ''On'' which need to be processed in a specific order (known as ''precedence constraints''). Each operation has a ''specific machine'' that it needs to be processed on and only one operation in a job can be processed at a given time. A common relaxation is the flexible job shop, where each operation can be processed ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kanban

Kanban ( Japanese: カンバン and Chinese: 看板, meaning signboard or billboard) is a scheduling system for lean manufacturing (also called just-in-time manufacturing, abbreviated JIT). Taiichi Ohno, an industrial engineer at Toyota, developed kanban to improve manufacturing efficiency. The system takes its name from the cards that track production within a factory. Kanban is also known as the ''Toyota nameplate system'' in the automotive industry. Kanban became an effective tool to support running a production system as a whole, and an excellent way to promote improvement. Problem areas are highlighted by measuring lead time and cycle time of the full process and process steps. One of the main benefits of kanban is to establish an upper limit to work in process (commonly referred as "WIP") inventory to avoid overcapacity. Other systems with similar effect exist, for example CONWIP. A systematic study of various configurations of kanban systems, such as Generalized Kanba ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Value Stream Mapping

Value-stream mapping, also known as "material- and information-flow mapping", is a lean-management method for analyzing the current state and designing a future state for the series of events that take a product or service from the beginning of the specific process until it reaches the customer. A value stream map is a visual tool that displays all critical steps in a specific process and easily quantifies the time and volume taken at each stage. Value stream maps show the flow of both materials and information as they progress through the process. Whereas a value stream map represents a core business process that adds value to a material product, a value chain diagram shows an overview of all activities within a company. Other business activities may be represented in "value stream diagrams" and/or other kinds of diagram that represent business processes that create and use business data. Purpose The purpose of value-stream mapping is to identify and remove or reduce "waste ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lean Production

Lean manufacturing is a production method aimed primarily at reducing times within the production system as well as response times from suppliers and to customers. It is closely related to another concept called just-in-time manufacturing (JIT manufacturing in short). Just-in-time manufacturing tries to match production to demand by only supplying goods which have been ordered and focuses on efficiency, productivity (with a commitment to continuous improvement) and reduction of "wastes" for the producer and supplier of goods. Lean manufacturing adopts the just-in-time approach and additionally focuses on reducing cycle, flow and throughput times by further eliminating activities which do not add any value for the customer. Lean manufacturing also involves people who work outside of the manufacturing process, such as in marketing and customer service. Lean manufacturing is particularly related to the operational model implemented in the post-war 1950s and 1960s by the J ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

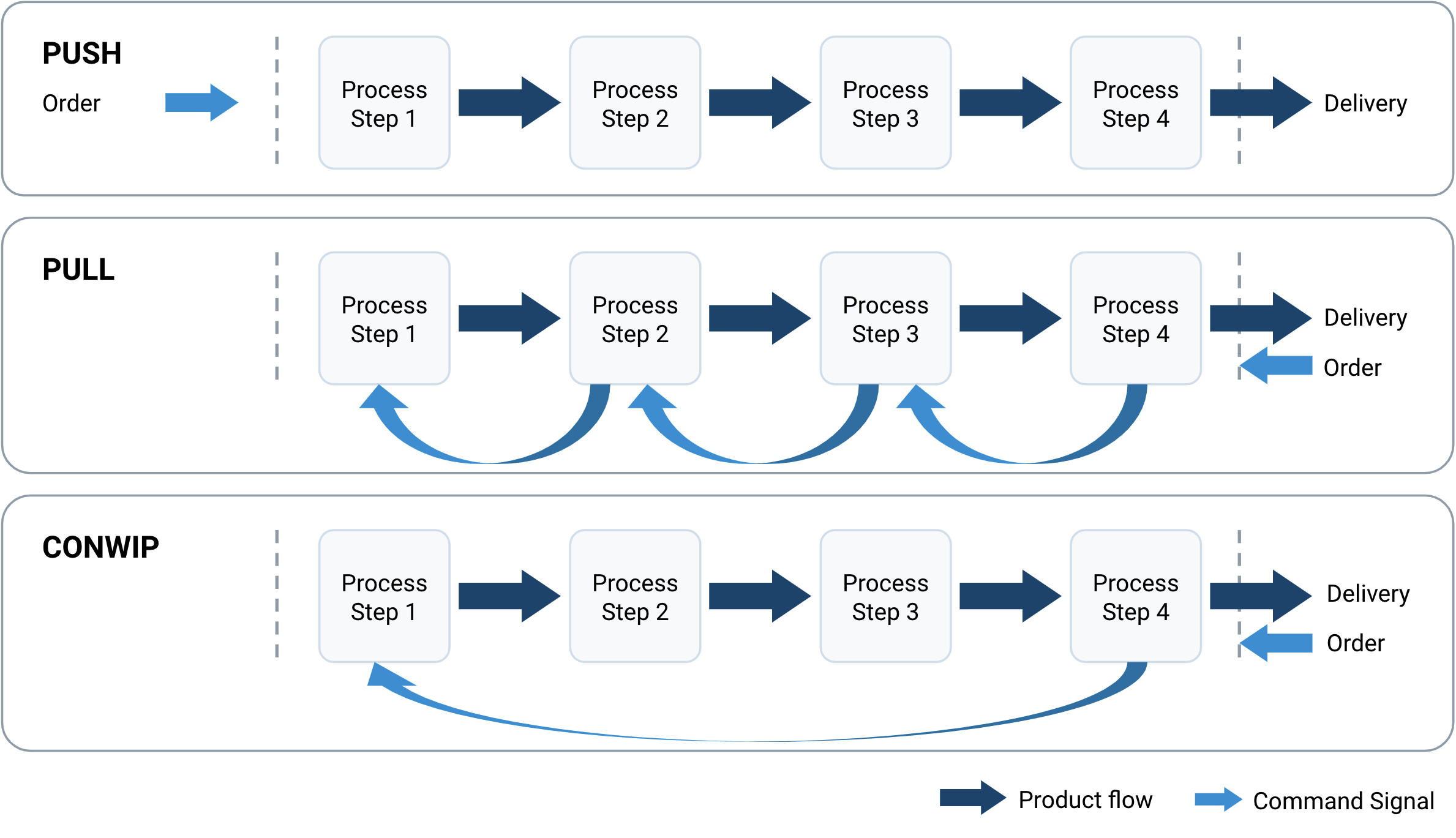

Push–pull Strategy

The business terms ''push'' and ''pull'' originated in logistics and supply chain management, but are also widely used in marketing and in the hotel distribution business. Walmart is an example of a company that uses the push vs. pull strategy. Supply-chain management Complete definition There are several definitions on the distinction between push and pull strategies. Liberopoulos (2013) identifies three such definitions: # A pull system initiates production as a reaction to present demand, while a push system initiates production in anticipation of future demand. # In a pull system, production is triggered by actual demands for finished products, while in a push system, production is initiated independently of demands. # A pull system is one that explicitly limits the amount of WIP that can be in the system, while a push system has no explicit limit on the amount of WIP that can be in the system. Other definitions are: * ''Push'': As stated by Bonney et al. (1999) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |