|

American System Of Manufacturing

The American system of manufacturing was a set of manufacturing methods that evolved in the 19th century. The two notable features were the extensive use of interchangeable parts and mechanization for production, which resulted in more efficient use of labor compared to hand methods. The system was also known as armory practice because it was first fully developed in armories, namely, the United States Armories at Springfield in Massachusetts and Harpers Ferry in Virginia (later West Virginia), inside contractors to supply the United States Armed Forces, and various private armories. The name "American system" came not from any aspect of the system that is unique to the American national character, but simply from the fact that for a time in the 19th century it was strongly associated with the American companies who first successfully implemented it, and how their methods contrasted (at that time) with those of British and continental European companies. In the 1850s, the "Americ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of secondary sector of the economy. The term may refer to a range of human activity, from handicraft to high-tech, but it is most commonly applied to industrial design, in which raw materials from the primary sector are transformed into finished goods on a large scale. Such goods may be sold to other manufacturers for the production of other more complex products (such as aircraft, household appliances, furniture, sports equipment or automobiles), or distributed via the tertiary industry to end users and consumers (usually through wholesalers, who in turn sell to retailers, who then sell them to individual customers). Manufacturing engineering is the field of engineering that designs and optimizes the manufacturing process, or the steps through which raw materials are transformed into a final p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Tools

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine. Thus, the relative movement between the workpiece and the cutting tool (which is called the toolpath) is controlled or constrained by the machine to at least some extent, rather than being entirely "offhand" or " freehand". It is a power-driven metal cutting machine which assists in managing the needed relative motion between cutting tool and the job that changes the size and shape of the job material. The precise definition of the term ''machine tool'' varies among users, as discussed below. While all machine tools are "machines that help people to make things", not all factory machines are machine tools. Today machine ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

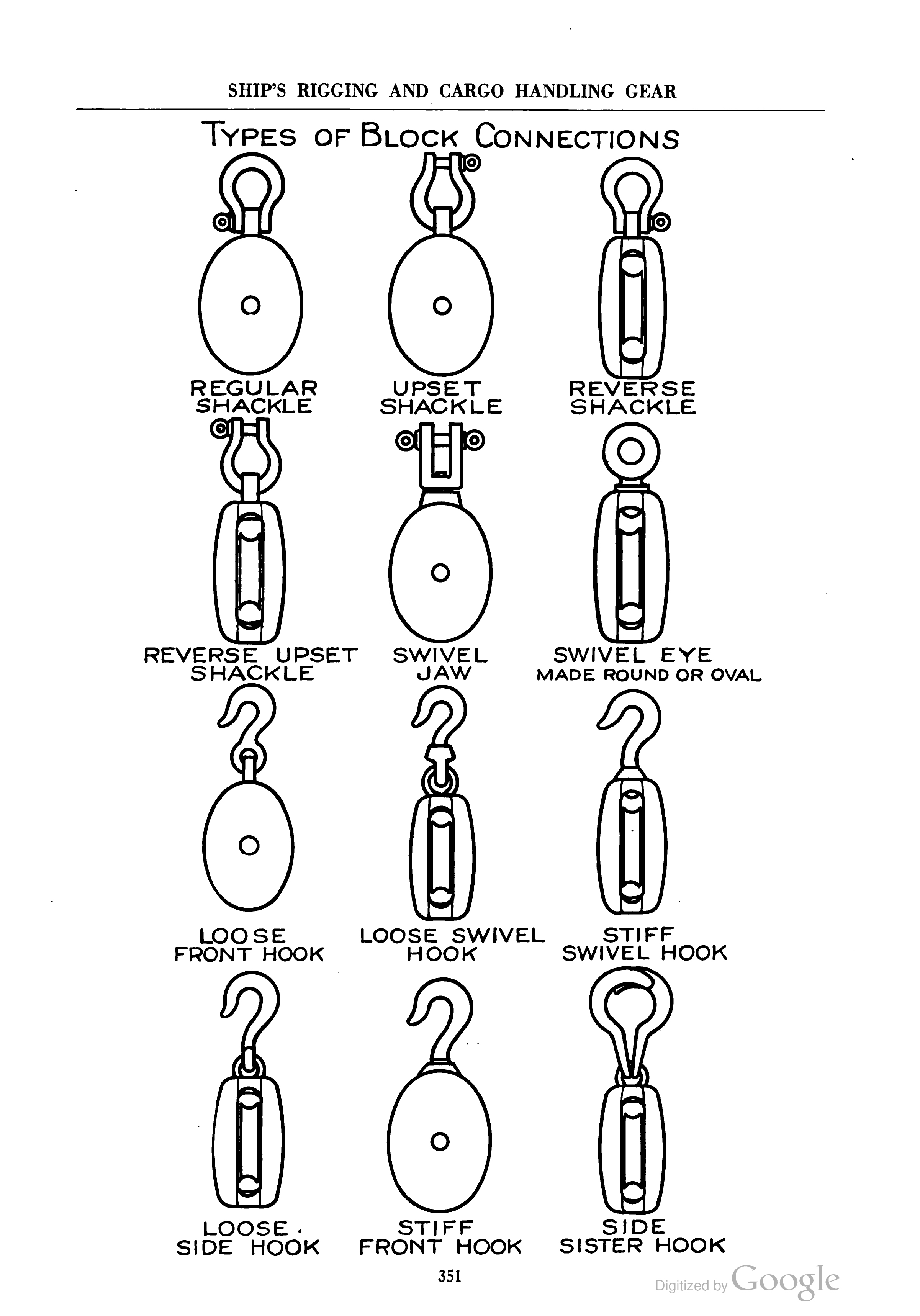

Block (sailing)

In sailing, a block is a single or multiple pulley. One or a number of ''sheaves'' are enclosed in an assembly between ''cheeks'' or ''chocks''. In use, a block is fixed to the end of a line, to a spar (sailing), spar, or to a surface. A line (rope) is ''reeved'' through the sheaves, and maybe through one or more matching blocks at some far end, to make up a Block and tackle, tackle. The ''purchase'' of a tackle refers to its mechanical advantage. In general the more sheaves in the blocks that make up a tackle, the higher its mechanical advantage. The matter is slightly complicated by the fact that every tackle has a ''working end'' where the final run of rope leaves the last sheave. More mechanical advantage can be obtained if this end is attached to the moving load rather than the fixed end of the tackle. There are various types of blocks that are used in sailing. Some blocks are used to increase mechanical advantage and others are used simply to change the direction of a li ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Portsmouth Dockyard

His Majesty's Naval Base, Portsmouth (HMNB Portsmouth) is one of three operating bases in the United Kingdom for the Royal Navy (the others being HMNB Clyde and HMNB Devonport). Portsmouth Naval Base is part of the city of Portsmouth; it is located on the eastern shore of Portsmouth Harbour, north of the Solent and the Isle of Wight. Until the early 1970s, it was officially known as Portsmouth Royal Dockyard (or HM Dockyard, Portsmouth); thereafter the term 'Naval Base' gained currency, acknowledging a greater focus on personnel and support elements alongside the traditional emphasis on building, repairing and maintaining ships. In 1984 Portsmouth's Royal Dockyard function was downgraded and it was formally renamed the 'Fleet Maintenance and Repair Organisation' (FMRO). The FMRO was privatized in 1998, and for a time (from 2002 to 2014), shipbuilding, in the form of block construction, returned. Around 2000, the designation HMS ''Nelson'' (which until then had been specific to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Portsmouth Block Mills

The Portsmouth Block Mills form part of the Portsmouth Dockyard at Portsmouth, Hampshire, England, and were built during the Napoleonic Wars to supply the British Royal Navy with pulley blocks. They started the age of mass-production using all-metal machine tools and are regarded as one of the seminal buildings of the British Industrial Revolution. They are also the site of the first stationary steam engines used by the Admiralty. Since 2003 English Heritage has been undertaking a detailed survey of the buildings and the records relating to the machines. Development of Portsmouth Dockyard The Royal Navy had evolved with Britain's development by the middle of the eighteenth century into what has been described as the greatest industrial power in the western world. The Admiralty and Navy Board began a programme of modernisation of dockyards at Portsmouth and Plymouth such that by the start of the war with Revolutionary France they possessed the most up-to-date fleet facilities i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Samuel Bentham

Sir Samuel Bentham (11 January 1757 – 31 May 1831) was a noted English mechanical engineer and naval architect credited with numerous innovations, particularly related to naval architecture, including weapons. He was the only surviving sibling of philosopher Jeremy Bentham, with whom he had a close bond. Early life Samuel Bentham was one of two surviving children of Jeremiah Bentham. His father was an attorney, and his older brother was the philosopher Jeremy Bentham, five other siblings having died in infancy or early childhood, and their mother dying in 1766. At the age of 14, Bentham was apprenticed to a shipwright at Woolwich Dockyard, serving there and at Chatham Dockyard, before completing his 7-year training at the Naval Academy in Portsmouth. Career Russia In 1780 he moved to Russia, where he was employed in the service of Prince Potemkin, who had an establishment designed to promote the introduction of various arts of civilization. Initially hired as a shipbuilder, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Henry Maudslay

Henry Maudslay ( pronunciation and spelling) (22 August 1771 – 14 February 1831) was an English machine tool innovator, tool and die maker, and inventor. He is considered a founding father of machine tool technology. His inventions were an important foundation for the Industrial Revolution. Maudslay's invention of a metal lathe to cut metal, circa 1800, enabled the manufacture of standard screw thread sizes. Standard screw thread sizes allowed interchangeable parts and the development of mass production. Early life Maudslay was the fifth of seven children of Henry Maudslay, a wheelwright in the Royal Engineers, and Margaret (''nee'' Whitaker), the young widow of Joseph Laundy. His father was wounded in action and so in 1756 became an 'artificer' at the Royal Arsenal, Woolwich (then in Kent), where he remained until 1776 and died in 1780. The family lived in an alley that no longer exists, off Beresford Square, between Powis Street and Beresford Street. Career Maudslay be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Marc Isambard Brunel

Sir Marc Isambard Brunel (, ; 25 April 1769 – 12 December 1849) was a French-British engineer who is most famous for the work he did in Britain. He constructed the Thames Tunnel and was the father of Isambard Kingdom Brunel. Born in France, Brunel fled to the United States during the French Revolution. In 1796, he was appointed Chief Engineer of New York City. He moved to London in 1799, where he married Sophia Kingdom. In addition to the construction of the Thames Tunnel, his work as a mechanical engineer included the design of machinery to automate the production of pulley blocks for the Royal Navy. Brunel preferred the given name Isambard, but is generally known to history as Marc to avoid confusion with his more famous son. Early life in France Brunel was the second son of Jean Charles Brunel and Marie-Victoire Lefebvre. Jean Charles was a prosperous farmer in Hacqueville, Normandy, and Marc was born on the family farm. It was customary for the first son to inher ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gribeauval System

The Gribeauval system (French: ''système Gribeauval'') was an artillery system introduced by Lieutenant General Jean Baptiste Vaquette de Gribeauval during the 18th century. This system revolutionized French cannons, with a new production system that allowed lighter, more uniform guns without sacrificing range. The Gribeauval system superseded the Vallière system beginning in 1765. The new guns contributed to French military victories during the French Revolutionary Wars and Napoleonic Wars. The system included improvements to cannons, howitzers, and mortars. The Year XI system partly replaced the field guns in 1803 and the Valée system completely superseded the Gribeauval system in 1829. Development The mid-18th Century saw the development of mobile field artillery. Ballistics engineers and metallurgy technicians introduced reforms that lowered the weight of gun tubes while other experts built lighter gun carriages. Gun calibers were standardized, easing the logistical headach ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Honoré Blanc

Honoré Blanc (1736–1801) was a French gunsmith and a pioneer of the use of interchangeable parts.. He was born in Avignon in 1736 and apprenticed to the gun-making trade at the age of twelve. His career spanned the decades from circa 1750 to 1801, a time period that included the reigns of Louis XV and Louis XVI, the American Revolution (which received military aid from Louis XVI), the French Revolution, and the French First Republic. Mass production innovation In the middle of the eighteenth century, Honoré Blanc was inspired by the work of French artillerists led by Jean-Baptiste Vaquette de Gribeauval, who had begun pursuing interchangeability in artillery. Their Gribeauval system involved standardization of cannons and shells. Blanc applied these concepts to muskets, and used gauges and filing jigs to bring duplicate parts to interchangeability. The uniformity of the parts was achieved via cut-and-try methods, using jigs, gauges, and master models to guide hand filing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Musket

A musket is a muzzle-loaded long gun that appeared as a smoothbore weapon in the early 16th century, at first as a heavier variant of the arquebus, capable of penetrating plate armour. By the mid-16th century, this type of musket gradually disappeared as the use of heavy armour declined, but ''musket'' continued as the generic term for smoothbore long guns until the mid-19th century. In turn, this style of musket was retired in the 19th century when rifled muskets (simply called rifles in modern terminology) using the Minié ball (invented by Claude-Étienne Minié in 1849) became common. The development of breech-loading firearms using self-contained cartridges (introduced by Casimir Lefaucheux in 1835) and the first reliable repeating rifles produced by Winchester Repeating Arms Company in 1860 also led to their demise. By the time that repeating rifles became common, they were known as simply "rifles", ending the era of the musket. Etymology According to the Online Et ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jean Baptiste Vaquette De Gribeauval

Lieutenant General Jean-Baptiste Vaquette de Gribeauval (15 September 1715 – 9 May 1789) was a French artillery officer and engineer who revolutionised the French cannon, creating a new production system that allowed for lighter, more uniform guns without sacrificing range. His Gribeauval system superseded the de Vallière system. These guns proved essential to French military victories during the Napoleonic Wars. Gribeauval is credited as the earliest known advocate for the interchangeability of gun parts. He is thus one of the principal influences on the later development (over many decades by many people) of interchangeable manufacture. Early life Jean-Baptiste was born in Amiens, the son of a magistrate. He entered the French royal artillery in 1732 as a volunteer, and became an officer in 1735. For nearly twenty years regimental duty and scientific work occupied him, and in 1752 he became captain of a company of miners.Summerfield (2011) ''SOJ-2'', p. 20 In 1755, he was e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |