|

Alfa Romeo Matta

The Alfa Romeo 1900 M (better known by its nickname Alfa Romeo Matta, meaning "mad") is a four-wheel drive utility vehicle produced by Italian car manufacturer Alfa Romeo from 1951 to 1954. Developed on request of the Italian Ministry of Defence, it was made in both military (AR 51) and civilian (AR 52) versions. History The AR 51 (''Autovettura da Ricognizione'', "Reconnaissance Car") was the result of the request of a light reconnaissance vehicle for use on paved, unpaved and mountain roads. A civilian version, the AR 52, was later developed from the military AR 51; several variants were made, adapted for use in agriculture, firefighting, and road maintenance. The Matta was built from 1952 to 1954, with 2,007 military AR 51s for the Italian Army and 154 civilian AR 52 units produced. In 1954, the Italian army abandoned the AR 51 and switched to the Fiat Campagnola, which was mechanically simpler. Specifications The Matta was powered by a 1884 cc t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alfa Romeo

Alfa Romeo Automobiles S.p.A. () is an Italian luxury car manufacturer and a subsidiary of Stellantis. The company was founded on 24 June 1910, in Milan, Italy. "Alfa" is an acronym of its founding name, "Anonima Lombarda Fabbrica Automobili." "Anonima" means "anonymous", which was a legal form of company at the time ( Società anonima). In the initial set-up phase, in order to have a building to produce cars, the company bought the Portello factory building of Darracq in Milan, which was closing up and selling all its assets. The brand is known for sport-oriented vehicles and has been involved in car racing since 1911. Alfa Romeo was owned by Fiat Chrysler Automobiles, the company that was responsible for the production of Alfa Romeo cars until its operations were fully merged with those of the PSA Group to form Stellantis on 16 January 2021. The first car produced by the company was the 1910 24 HP, designed by Giuseppe Merosi. A.L.F.A. ventured into motor racing, with driv ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dry Sump

A dry-sump system is a method to manage the lubricating motor oil in four-stroke and large two-stroke piston driven internal combustion engines. The dry-sump system uses two or more oil pumps and a separate oil reservoir, as opposed to a conventional wet-sump system, which uses only the main sump (U.S.: oil pan) below the engine and a single pump. A dry-sump engine requires a pressure relief valve to regulate negative pressure inside the engine, so internal seals are not inverted. Dry-sumps are common on larger diesel engines such as those used in ships, as well as gasoline engines used in racing cars, aerobatic aircraft, high-performance personal watercraft and motorcycles. Dry sump lubrication may be chosen for these applications due to increased reliability, oil capacity, reduction of oil starvation under high g-loads and/or other technical or performance reasons. Dry sump systems may not be suitable for all applications due to increased cost, complexity, and/or bulk, am ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Driveshaft

A drive shaft, driveshaft, driving shaft, tailshaft (Australian English), propeller shaft (prop shaft), or Cardan shaft (after Girolamo Cardano) is a component for transmitting mechanical power and torque and rotation, usually used to connect other components of a drivetrain that cannot be connected directly because of distance or the need to allow for relative movement between them. As torque carriers, drive shafts are subject to torsion and shear stress, equivalent to the difference between the input torque and the load. They must therefore be strong enough to bear the stress, while avoiding too much additional weight as that would in turn increase their inertia. To allow for variations in the alignment and distance between the driving and driven components, drive shafts frequently incorporate one or more universal joints, jaw couplings, or rag joints, and sometimes a splined joint or prismatic joint. History The term ''driveshaft'' first appeared during the mid-19th centu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drum Brakes

A drum brake is a brake that uses friction caused by a set of shoes or pads that press outward against a rotating cylinder-shaped part called a brake drum. The term ''drum brake'' usually means a brake in which shoes press on the inner surface of the drum. When shoes press on the outside of the drum, it is usually called a '' clasp brake''. Where the drum is pinched between two shoes, similar to a conventional disc brake, it is sometimes called a ''pinch drum brake'', though such brakes are relatively rare. A related type called a band brake uses a flexible belt or "band" wrapping around the outside of a drum. History The modern automobile drum brake was first used in a car made by Maybach in 1900, although the principle was only later patented in 1902 by Louis Renault. He used woven asbestos lining for the drum brake lining, as no alternative dissipated heat like the asbestos lining, though Maybach had used a less sophisticated drum brake. In the first drum brakes, levers a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Live Axle

A beam axle, rigid axle or solid axle is a dependent suspension design in which a set of wheels is connected laterally by a single beam or shaft. Beam axles were once commonly used at the rear wheels of a vehicle, but historically they have also been used as front axles in four-wheel-drive vehicles. In most automobiles, beam axles have been replaced with front and rear independent suspensions. Implementation With a beam axle the camber angle between the wheels is the same no matter where it is in the travel of the suspension. A beam axle's fore & aft location is constrained by either: trailing arms, semi-trailing arms, radius rods, or leaf springs. The lateral location can be constrained by a Panhard rod, a Scott Russell linkage or a Watt's linkage, or some other arrangement, most commonly by the leaf springs. Shock absorbers and either leaf springs, coil springs, or air bags are used to control vertical movement. The Twist-beam rear suspension is a similar suspension desig ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Double Wishbone Suspension

A double wishbone suspension is an independent suspension design for automobiles using two (occasionally parallel) wishbone-shaped arms to locate the wheel. Each wishbone or arm has two mounting points to the chassis and one joint at the knuckle. The shock absorber and coil spring mount to the wishbones to control vertical movement. Double wishbone designs allow the engineer to carefully control the motion of the wheel throughout suspension travel, controlling such parameters as camber angle, caster angle, toe pattern, roll center height, scrub radius, scuff and more. Implementation The double-wishbone suspension can also be referred to as "double A-arms", though the arms themselves can be A-shaped, L-shaped, or even a single bar linkage. A single wishbone or A-arm can also be used in various other suspension types, such as variations of the MacPherson strut. The upper arm is usually shorter to induce negative camber as the suspension jounces (rises), and often this arrangement ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

DOHC

An overhead camshaft (OHC) engine is a piston engine where the camshaft is located in the cylinder head above the combustion chamber. This contrasts with earlier overhead valve engines (OHV), where the camshaft is located below the combustion chamber in the engine block. ''Single overhead camshaft'' (SOHC) engines have one camshaft per bank of cylinders. ''Dual overhead camshaft'' (DOHC, also known as "twin-cam".) engines have two camshafts per bank. The first production car to use a DOHC engine was built in 1910. Use of DOHC engines slowly increased from the 1940s, leading to many automobiles by the early 2000s using DOHC engines. Design In an OHC engine, the camshaft is located at the top of the engine, above the combustion chamber. This contrasts the earlier overhead valve engine (OHV) and flathead engine configurations, where the camshaft is located down in the engine block. The valves in both OHC and OHV engines are located above the combustion chamber; however an OHV ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

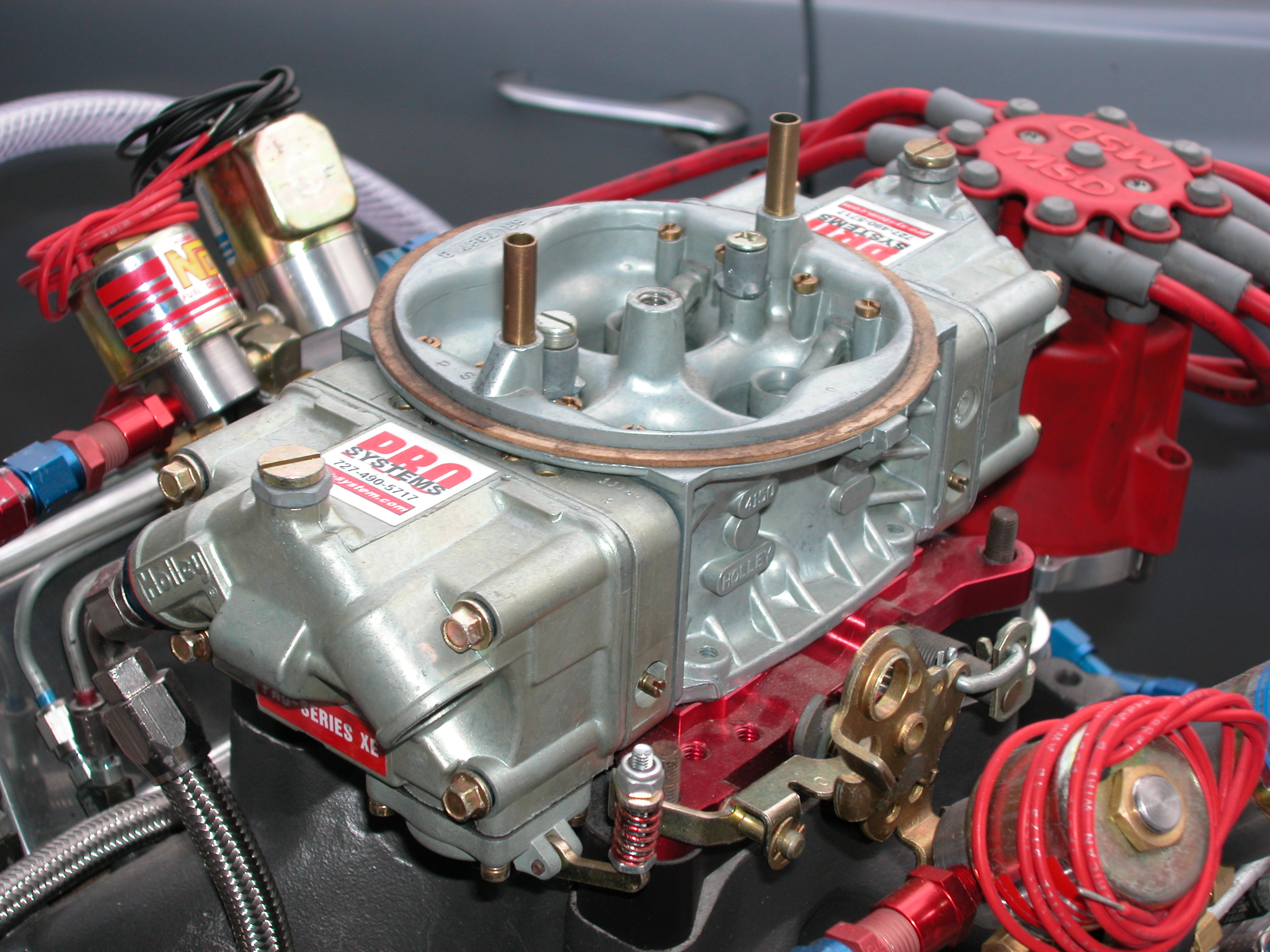

Carburetor

A carburetor (also spelled carburettor) is a device used by an internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the venturi tube in the main metering circuit, however various other components are also used to provide extra fuel or air in specific circumstances. Since the 1990s, carburetors have been largely replaced by fuel injection for cars and trucks, however carburetors are still used by some small engines (e.g. lawnmowers, generators and concrete mixers) and motorcycles. Diesel engines have always used fuel injection instead of carburetors. Etymology The name "carburetor" is derived from the verb ''carburet'', which means "to combine with carbon," or in particular, "to enrich a gas by combining it with carbon or hydrocarbons." Thus a carburetor mixes intake air with hydrocarbon-based fuel, such as petrol or autogas (LPG). The name is spelled "carburetor" in American English ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solex Carburetor

Solex is a French manufacturer of carburetors and the powered bicycle VéloSoleX. Solex carburetors were used by many European automobile companies and were licensed to Japanese maker Mikuni. History The Solex company was founded by Marcel Mennesson and Maurice Goudard to manufacture vehicle radiators. These were fitted to several makes of early cars including Delaunay-Belleville and buses of the Paris General Omnibus company. After World War I, the radiator business went into decline and the company bought the rights to the carburetor patents of Jouffret and Renée and named them Solex after their business. The Solex brand is now owned by Magneti Marelli. The original Solex company changed its name in 1994 to Magneti Marelli France and on May 31, 2001, Magneti Marelli France partially bought its assets (including the trademark SOLEX) from Magneti Marelli Motopropulsion France S.A.S. Carburetors Solex carburetors were widely used by many European makers and under license to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cast Iron

Cast iron is a class of iron–carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impurities which allow cracks to pass straight through, grey cast iron has graphite flakes which deflect a passing crack and initiate countless new cracks as the material breaks, and ductile cast iron has spherical graphite "nodules" which stop the crack from further progressing. Carbon (C), ranging from 1.8 to 4 wt%, and silicon (Si), 1–3 wt%, are the main alloying elements of cast iron. Iron alloys with lower carbon content are known as steel. Cast iron tends to be brittle, except for malleable cast irons. With its relatively low melting point, good fluidity, castability, excellent machinability, resistance to deformation and wear resistance, cast irons have become an engineering material with a wide range of applications and are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engine Block

In an internal combustion engine, the engine block is the structure which contains the cylinders and other components. In an early automotive engine, the engine block consisted of just the cylinder block, to which a separate crankcase was attached. Modern engine blocks typically have the crankcase integrated with the cylinder block as a single component. Engine blocks often also include elements such as coolant passages and oil galleries. The term "cylinder block" is often used interchangeably with "engine block", although technically, the block of a modern engine (i.e. multiple cylinders integrated with another component) would be classified as a monobloc. __TOC__ Construction The main structure of an engine typically consists of the cylinders, coolant passages, oil galleries, crankcase, and cylinder head(s). The first production engines of the 1880s to 1920s usually used separate components for each of these elements, which were bolted together during engine assembly. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |