|

Adam Revo

The Adam Revo was a city car made by the now dead Adam Motor Company of Pakistan. It was the first car to be designed and assembled in Pakistan and was launched in 2005. The name "REVO" was derived from the word revolution, which it was supposed to make. However, production stopped by September 2006 due to unavailability of funds and lack of government support. Only 600 cars were sold. There were two variants available, equipped with two different Chinese made engines; the Revo 80 (0.8L) and Revo 105 (1.05L). The Revo was envisaged to be between 10% and 15% cheaper than other local competitors, mainly the Mehran 800, which dominates Pakistan's automobile industry. Specification Engine * Revo 80: 797 cc straight-4 OHC petrol engine with carburetor – at 5500 rpm, at 3000 rpm * Revo 105: 1051 cc straight-4 OHC petrol engine with Fuel injection – at 5500 rpm, at 3000 rpm Suspension *Front: Strut with Coil spring *Rear: Leaf spring with Shock absorber ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Adam Motor Company

Adam Motor Company, Ltd. is an automobile manufacturer and assembler based in Karachi, Pakistan. It produced Pakistan's first indigenous car ''Revo'', and currently produce rehabilitation products like walking sticks, walkers, stretchers and hospital beds. It is wholly owned subsidiary of Omar Jibran Engineering Industries Ltd. History Adam Motor Company Ltd. was notable for producing Pakistan's first indigenously designed car called Revo, whose production eventually got ceased in 2006 and assets were put up for sale. Initially Adam Motor was involved in assembling light trucks from Chinese components, followed by a four-wheel drive utility vehicle. Models * Revo (subcompact car) * Boltoro — 2x4 off-road vehicle * Zabardast Econo * Zabardast Super * Zabardast Rehabilitation Products GetOn... Motorized Wheelchair * GetOn... Motorized Wheelchair (foldable) * GetOn... Manual Wheelchairs * GetOn... Walking Sticks & Crutches * GetOn... Walkers * GetOn... Patients Carrying S ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

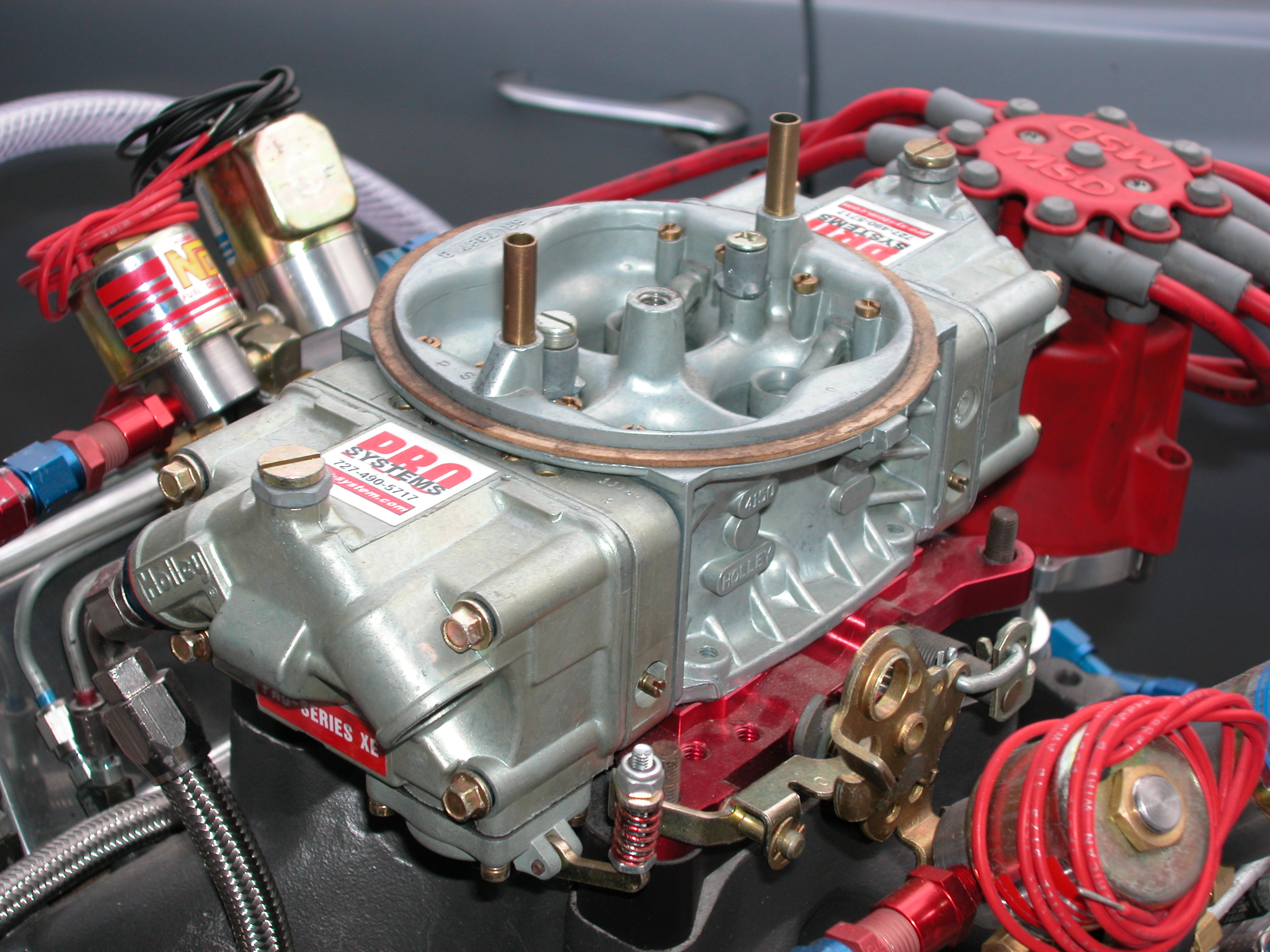

Carburetor

A carburetor (also spelled carburettor) is a device used by an internal combustion engine to control and mix air and fuel entering the engine. The primary method of adding fuel to the intake air is through the venturi tube in the main metering circuit, however various other components are also used to provide extra fuel or air in specific circumstances. Since the 1990s, carburetors have been largely replaced by fuel injection for cars and trucks, however carburetors are still used by some small engines (e.g. lawnmowers, generators and concrete mixers) and motorcycles. Diesel engines have always used fuel injection instead of carburetors. Etymology The name "carburetor" is derived from the verb ''carburet'', which means "to combine with carbon," or in particular, "to enrich a gas by combining it with carbon or hydrocarbons." Thus a carburetor mixes intake air with hydrocarbon-based fuel, such as petrol or autogas (LPG). The name is spelled "carburetor" in American English ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

City Cars

The A-segment is the 1st category in the passenger car classification system defined by the European Commission. It is used for city cars, the smallest category of passenger cars defined. A-segment sales represent approx. 7-8% of the market in 2010s. It is approximately equivalent to the kei car class in Japan. Definition As of 2021 A-segment category size span from approximately to (photo comparison of new city cars of all brands sorted by length): Characteristics Body styles for A-segment cars in Europe are always hatchbacks. But as crossovers gain popularity, new models may shift to resemble crossovers. Such examples are the Suzuki Ignis and the Toyota Aygo X. Other body styles such as sedans are not present in this segment because these shapes largely prove impractical at typical A-segment dimensions. History As of 2017, 2018, 2019 and 2020, A-segment sales account for 8.1%, 8%, 7.7% and 6.8% market share in Europe respectively. Current models In 2020 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Compressed Natural Gas

Compressed natural gas (CNG) is a fuel gas mainly composed of methane (CH4), compressed to less than 1% of the volume it occupies at standard atmospheric pressure. It is stored and distributed in hard containers at a pressure of , usually in cylindrical or spherical shapes. CNG is used in traditional petrol/internal combustion engine vehicles that have been modified, or in vehicles specifically manufactured for CNG use: either alone (dedicated), with a segregated liquid fuel system to extend range (dual fuel), or in conjunction with another fuel ( bi-fuel). It can be used in place of petrol (gasoline), diesel fuel, and liquefied petroleum gas (LPG). CNG combustion produces fewer undesirable gases than the aforementioned fuels. In comparison to other fuels, natural gas poses less of a threat in the event of a spill, because it is lighter than air and disperses quickly when released. Biomethane – refined biogas from anaerobic digestion or landfills – can be used. In ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drum Brake

A drum brake is a brake that uses friction caused by a set of shoes or pads that press outward against a rotating cylinder-shaped part called a brake drum. The term ''drum brake'' usually means a brake in which shoes press on the inner surface of the drum. When shoes press on the outside of the drum, it is usually called a '' clasp brake''. Where the drum is pinched between two shoes, similar to a conventional disc brake, it is sometimes called a ''pinch drum brake'', though such brakes are relatively rare. A related type called a band brake uses a flexible belt or "band" wrapping around the outside of a drum. History The modern automobile drum brake was first used in a car made by Maybach in 1900, although the principle was only later patented in 1902 by Louis Renault. He used woven asbestos lining for the drum brake lining, as no alternative dissipated heat like the asbestos lining, though Maybach had used a less sophisticated drum brake. In the first drum brakes, levers a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Disc Brake

A disc brake is a type of brake that uses the calipers to squeeze pairs of pads against a disc or a "rotor" to create friction. This action slows the rotation of a shaft, such as a vehicle axle, either to reduce its rotational speed or to hold it stationary. The energy of motion is converted into waste heat which must be dispersed. Hydraulically actuated disc brakes are the most commonly used form of brake for motor vehicles, but the principles of a disc brake are applicable to almost any rotating shaft. The components include the disc, master cylinder, and caliper (which contains a cylinder and two brake pads) on both sides of the disc. Design The development of disc-type brakes began in England in the 1890s. In 1902, the Lanchester Motor Company designed brakes that looked and operated in a similar way to a modern disc-brake system even though the disc was thin and a cable activated the brake pad. Other designs were not practical or widely available in cars for another 6 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shock Absorber

A shock absorber or damper is a mechanical or hydraulic device designed to absorb and damp shock impulses. It does this by converting the kinetic energy of the shock into another form of energy (typically heat) which is then dissipated. Most shock absorbers are a form of dashpot (a damper which resists motion via viscous friction). Description Pneumatic and hydraulic shock absorbers are used in conjunction with cushions and springs. An automobile shock absorber contains spring-loaded check valves and orifices to control the flow of oil through an internal piston (see below). One design consideration, when designing or choosing a shock absorber, is where that energy will go. In most shock absorbers, energy is converted to heat inside the viscous fluid. In hydraulic cylinders, the hydraulic fluid heats up, while in air cylinders, the hot air is usually exhausted to the atmosphere. In other types of shock absorbers, such as electromagnetic types, the dissipated energy can be ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Leaf Spring

A leaf spring is a simple form of spring commonly used for the suspension in wheeled vehicles. Originally called a ''laminated'' or ''carriage spring'', and sometimes referred to as a semi-elliptical spring, elliptical spring, or cart spring, it is one of the oldest forms of vehicle suspension. A leaf spring is one or more narrow, arc-shaped, thin plates which are attached to the axle and chassis in a way that allows the leaf spring to flex vertically in response to irregularities in the road surface. Lateral leaf springs are the most commonly used arrangement, running the length of the vehicle and mounted perpendicular to the wheel axle, but numerous examples of transverse leaf springs exist as well. Leaf springs can serve multiple suspension functions: location, springing, and to some extent damping as well, through interleaf friction. However, this friction is not well controlled, resulting in stiction and irregular suspension motions. For this reason, some manufacturers have ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Coil Spring

A selection of conical coil springs The most common type of spring is the coil spring, which is made out of a long piece of metal that is wound around itself. Coil springs were in use in Roman times, evidence of this can be found in bronze Fibulae - the clasps worn by Roman soldiers among others. These are quite commonly found in Roman archeological digs. Coil springs can be either compression springs, tension springs or torsion springs, depending on how they are wound. A coil spring is a mechanical device which is typically used to store energy and subsequently release it, to absorb shock, or to maintain a force between contacting surfaces. They are made of an elastic material formed into the shape of a helix which returns to its natural length when unloaded. They are commonly used in mattresses, automotive suspensions, and residential plumbing. Coil springs come in a variety of sizes and shapes and can be used for a variety of applications. Small coil springs are often us ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Strut

A strut is a structural component commonly found in engineering, aeronautics, architecture and anatomy. Struts generally work by resisting longitudinal compression, but they may also serve in tension. Human anatomy Part of the functionality of the clavicle is to serve as a strut between the scapula and sternum, resisting forces that would otherwise bring the upper limb close to the thorax. Keeping the upper limb away from the thorax is vital for its range of motion. Complete lack of clavicles may be seen in cleidocranial dysostosis, and the abnormal proximity of the shoulders to the median plane exemplifies the clavicle's importance as a strut. Architecture and construction Strut is a common name in timber framing for a support or brace of scantlings lighter than a post. Frequently struts are found in roof framing from either a tie beam or a king post to a principal rafter. Struts may be vertically plumb or leaning (then called canted, raking, or angled) and may be straight ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel Injection

Fuel injection is the introduction of fuel in an internal combustion engine, most commonly automotive engines, by the means of an injector. This article focuses on fuel injection in reciprocating piston and Wankel rotary engines. All compression-ignition engines (e.g. diesel engines), and many spark-ignition engines (i.e. petrol engines, such as Otto or Wankel), use fuel injection of one kind or another. Mass-produced diesel engines for passenger cars (such as the Mercedes-Benz OM 138) became available in the late 1930s and early 1940s, being the first fuel-injected engines for passenger car use. In passenger car petrol engines, fuel injection was introduced in the early 1950s and gradually gained prevalence until it had largely replaced carburettors by the early 1990s. The primary difference between carburetion and fuel injection is that fuel injection atomizes the fuel through a small nozzle under high pressure, while a carburettor relies on suction created by intake ai ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Petrol Engine

A petrol engine (gasoline engine in American English) is an internal combustion engine designed to run on petrol (gasoline). Petrol engines can often be adapted to also run on fuels such as liquefied petroleum gas and ethanol blends (such as ''E10'' and ''E85''). Most petrol engines use spark ignition, unlike diesel engines which typically use compression ignition. Another key difference to diesel engines is that petrol engines typically have a lower compression ratio. Design Thermodynamic cycle Most petrol engines use either the four-stroke Otto cycle or the two-stroke cycle. Petrol engines have also been produced using the Miller cycle and Atkinson cycle. Layout Most petrol-powered piston engines are straight engines or V engines. However, flat engines, W engines and other layouts are sometimes used. Wankel engines are classified by the number of rotors used. Compression ratio Cooling Petrol engines are either air-cooled or water-cooled. Ignition Petrol e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)