Turbojet on:

[Wikipedia]

[Google]

[Amazon]

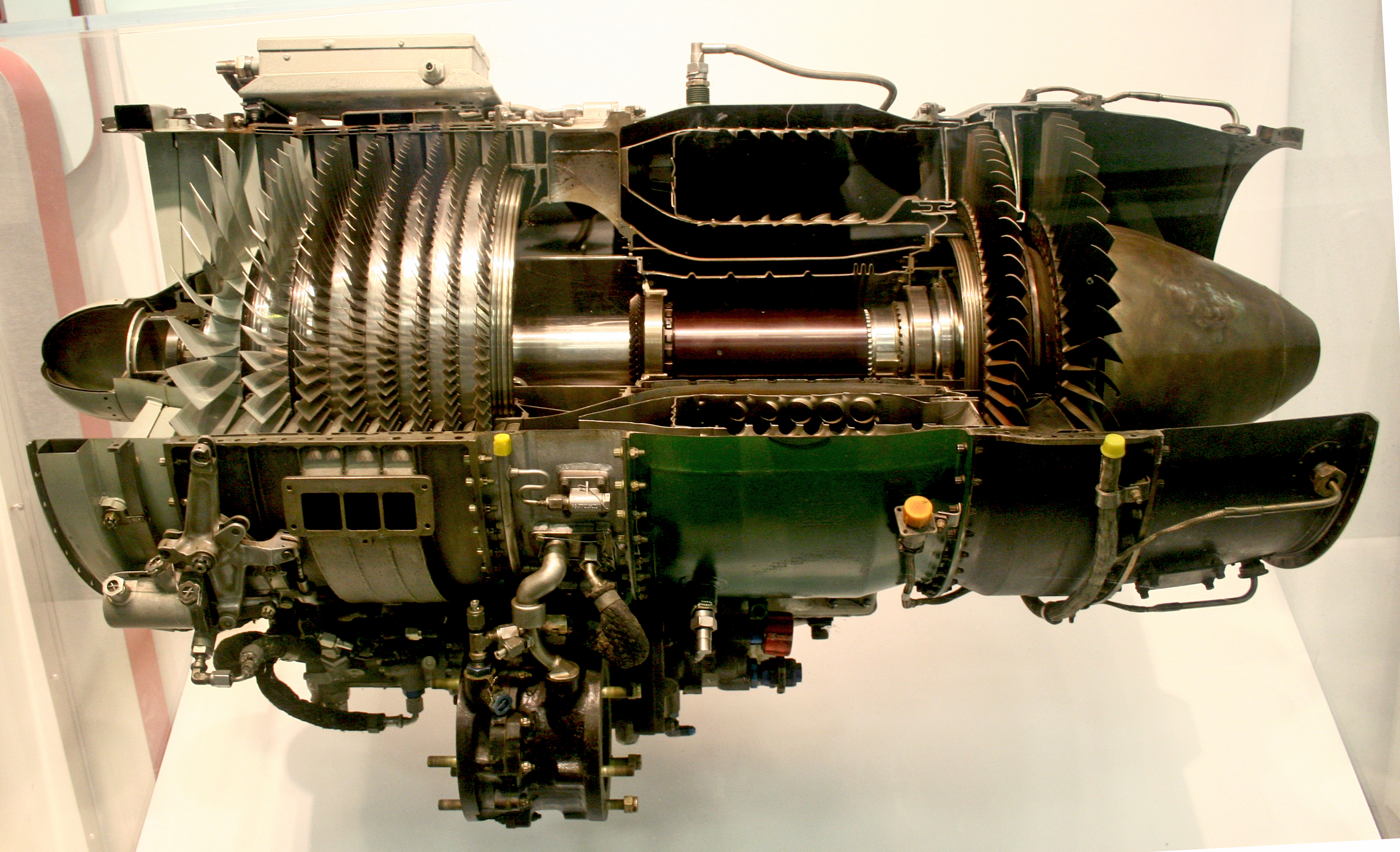

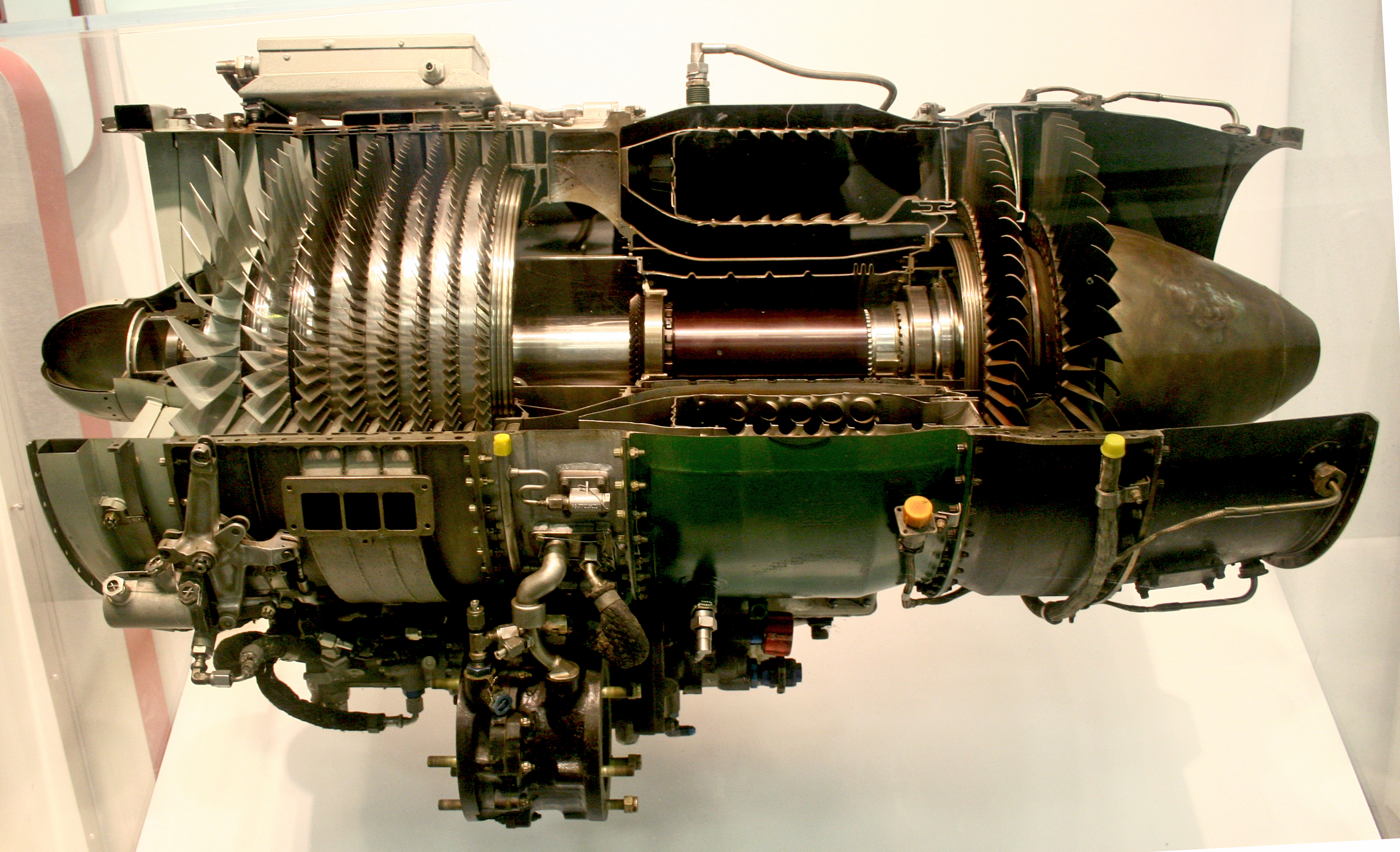

The turbojet is an airbreathing jet engine which is typically used in aircraft. It consists of a gas turbine with a propelling nozzle. The gas turbine has an air inlet which includes inlet guide vanes, a compressor, a combustion chamber, and a turbine (that drives the compressor). The compressed air from the compressor is heated by burning fuel in the combustion chamber and then allowed to expand through the turbine. The turbine exhaust is then expanded in the propelling nozzle where it is accelerated to high speed to provide thrust. Two engineers, Frank Whittle in the

The turbojet is an airbreathing jet engine which is typically used in aircraft. It consists of a gas turbine with a propelling nozzle. The gas turbine has an air inlet which includes inlet guide vanes, a compressor, a combustion chamber, and a turbine (that drives the compressor). The compressed air from the compressor is heated by burning fuel in the combustion chamber and then allowed to expand through the turbine. The turbine exhaust is then expanded in the propelling nozzle where it is accelerated to high speed to provide thrust. Two engineers, Frank Whittle in the

The first patent for using a gas turbine to power an aircraft was filed in 1921 by Frenchman Maxime Guillaume.Maxime Guillaume,"Propulseur par réaction sur l'air," French patent (filed: 3 May 1921; issued: 13 January 1922) His engine was to be an axial-flow turbojet, but was never constructed, as it would have required considerable advances over the state of the art in compressors.

The first patent for using a gas turbine to power an aircraft was filed in 1921 by Frenchman Maxime Guillaume.Maxime Guillaume,"Propulseur par réaction sur l'air," French patent (filed: 3 May 1921; issued: 13 January 1922) His engine was to be an axial-flow turbojet, but was never constructed, as it would have required considerable advances over the state of the art in compressors.

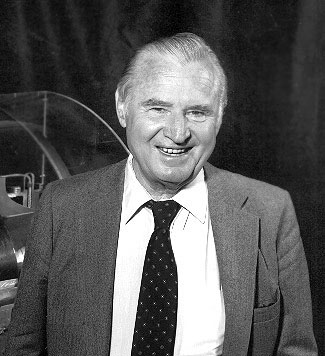

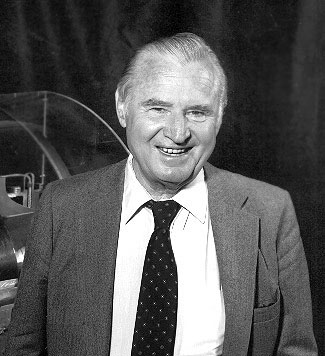

In 1928, British RAF College Cranwell cadet Frank Whittle formally submitted his ideas for a turbojet to his superiors. In October 1929 he developed his ideas further. On 16 January 1930 in England, Whittle submitted his first patent (granted in 1932). The patent showed a two-stage axial compressor feeding a single-sided centrifugal compressor. Practical axial compressors were made possible by ideas from A.A. Griffith in a seminal paper in 1926 ("An Aerodynamic Theory of Turbine Design"). Whittle later concentrated on the simpler centrifugal compressor only, for a variety of practical reasons. A Whittle engine was the first turbojet to run, the Power Jets WU, on 12 April 1937. It was liquid-fuelled. Whittle's team experienced near-panic during the first start attempts when the engine accelerated out of control to a relatively high speed despite the fuel supply being cut off. It was subsequently found that fuel had leaked into the combustion chamber during pre-start motoring checks and accumulated in pools, so the engine would not stop accelerating until all the leaked fuel had burned off. Whittle was unable to interest the government in his invention, and development continued at a slow pace.

In Germany, Hans von Ohain patented a similar engine in 1935. His design, an axial-flow engine, as opposed to Whittle's centrifugal flow engine, was eventually adopted by most manufacturers by the 1950's.

On 27 August 1939 the Heinkel He 178, powered by von Ohain´s design, became the world's first aircraft to fly using the thrust from a turbojet engine. It was flown by test pilot Erich Warsitz. The Gloster E.28/39, (also referred to as the "Gloster Whittle", "Gloster Pioneer", or "Gloster G.40") made the first British jet-engined flight in 1941. It was designed to test the Whittle jet engine in flight, and led to the development of the Gloster Meteor.

The first two operational turbojet aircraft, the Messerschmitt Me 262 and then the Gloster Meteor, entered service in 1944, towards the end of

In 1928, British RAF College Cranwell cadet Frank Whittle formally submitted his ideas for a turbojet to his superiors. In October 1929 he developed his ideas further. On 16 January 1930 in England, Whittle submitted his first patent (granted in 1932). The patent showed a two-stage axial compressor feeding a single-sided centrifugal compressor. Practical axial compressors were made possible by ideas from A.A. Griffith in a seminal paper in 1926 ("An Aerodynamic Theory of Turbine Design"). Whittle later concentrated on the simpler centrifugal compressor only, for a variety of practical reasons. A Whittle engine was the first turbojet to run, the Power Jets WU, on 12 April 1937. It was liquid-fuelled. Whittle's team experienced near-panic during the first start attempts when the engine accelerated out of control to a relatively high speed despite the fuel supply being cut off. It was subsequently found that fuel had leaked into the combustion chamber during pre-start motoring checks and accumulated in pools, so the engine would not stop accelerating until all the leaked fuel had burned off. Whittle was unable to interest the government in his invention, and development continued at a slow pace.

In Germany, Hans von Ohain patented a similar engine in 1935. His design, an axial-flow engine, as opposed to Whittle's centrifugal flow engine, was eventually adopted by most manufacturers by the 1950's.

On 27 August 1939 the Heinkel He 178, powered by von Ohain´s design, became the world's first aircraft to fly using the thrust from a turbojet engine. It was flown by test pilot Erich Warsitz. The Gloster E.28/39, (also referred to as the "Gloster Whittle", "Gloster Pioneer", or "Gloster G.40") made the first British jet-engined flight in 1941. It was designed to test the Whittle jet engine in flight, and led to the development of the Gloster Meteor.

The first two operational turbojet aircraft, the Messerschmitt Me 262 and then the Gloster Meteor, entered service in 1944, towards the end of

The turbojet is an airbreathing jet engine which is typically used in aircraft. It consists of a gas turbine with a propelling nozzle. The gas turbine has an air inlet which includes inlet guide vanes, a compressor, a combustion chamber, and a turbine (that drives the compressor). The compressed air from the compressor is heated by burning fuel in the combustion chamber and then allowed to expand through the turbine. The turbine exhaust is then expanded in the propelling nozzle where it is accelerated to high speed to provide thrust. Two engineers, Frank Whittle in the

The turbojet is an airbreathing jet engine which is typically used in aircraft. It consists of a gas turbine with a propelling nozzle. The gas turbine has an air inlet which includes inlet guide vanes, a compressor, a combustion chamber, and a turbine (that drives the compressor). The compressed air from the compressor is heated by burning fuel in the combustion chamber and then allowed to expand through the turbine. The turbine exhaust is then expanded in the propelling nozzle where it is accelerated to high speed to provide thrust. Two engineers, Frank Whittle in the United Kingdom

The United Kingdom of Great Britain and Northern Ireland, commonly known as the United Kingdom (UK) or Britain, is a country in Europe, off the north-western coast of the European mainland, continental mainland. It comprises England, Scotlan ...

and Hans von Ohain in Germany

Germany, officially the Federal Republic of Germany (FRG),, is a country in Central Europe. It is the most populous member state of the European Union. Germany lies between the Baltic and North Sea to the north and the Alps to the sou ...

, developed the concept independently into practical engines during the late 1930s.

Turbojets have poor efficiency at low vehicle speeds, which limits their usefulness in vehicles other than aircraft. Turbojet engines have been used in isolated cases to power vehicles other than aircraft, typically for attempts on land speed records. Where vehicles are "turbine-powered", this is more commonly by use of a turboshaft engine, a development of the gas turbine engine where an additional turbine is used to drive a rotating output shaft. These are common in helicopters and hovercraft. Turbojets were used on Concorde and the longer-range versions of the TU-144 which were required to spend a long period travelling supersonically. Turbojets are still common in medium range cruise missiles, due to their high exhaust speed, small frontal area, and relative simplicity. They are also still used on some supersonic fighters such as the MiG-25, but most spend little time travelling supersonically, and so employ turbofans and use afterburners to raise exhaust speed for supersonic sprints.

History

The first patent for using a gas turbine to power an aircraft was filed in 1921 by Frenchman Maxime Guillaume.Maxime Guillaume,"Propulseur par réaction sur l'air," French patent (filed: 3 May 1921; issued: 13 January 1922) His engine was to be an axial-flow turbojet, but was never constructed, as it would have required considerable advances over the state of the art in compressors.

The first patent for using a gas turbine to power an aircraft was filed in 1921 by Frenchman Maxime Guillaume.Maxime Guillaume,"Propulseur par réaction sur l'air," French patent (filed: 3 May 1921; issued: 13 January 1922) His engine was to be an axial-flow turbojet, but was never constructed, as it would have required considerable advances over the state of the art in compressors.

World War II

World War II or the Second World War, often abbreviated as WWII or WW2, was a world war that lasted from 1939 to 1945. It involved the World War II by country, vast majority of the world's countries—including all of the great power ...

. The Me 262 in April and the Gloster Meteor in July, so the Meteor only saw around 15 aircraft enter WW2 action , while up to 1400 Me 262 were produced, with 300 entering combat, delivering the first ground attacks and air combat victories of jet planes.

Air is drawn into the rotating compressor via the intake and is compressed to a higher pressure before entering the combustion chamber. Fuel

A fuel is any material that can be made to react with other substances so that it releases energy as thermal energy or to be used for work. The concept was originally applied solely to those materials capable of releasing chemical energy but ...

is mixed with the compressed air and burns in the combustor. The combustion products leave the combustor and expand through the turbine where power is extracted to drive the compressor. The turbine exit gases still contain considerable energy that is converted in the propelling nozzle to a high speed jet.

The first turbojets, used either a centrifugal compressor (as in the Heinkel HeS 3), or an axial compressor (as in the Junkers Jumo 004

The Junkers Jumo 004 was the world's first production turbojet engine in operational use, and the first successful axial compressor turbojet engine. Some 8,000 units were manufactured by Junkers in Germany late in World War II, powering the Mess ...

) which gave a smaller diameter, although longer, engine. By replacing the propeller used on piston engines with a high speed jet of exhaust, higher aircraft speeds were attainable.

One of the last applications for a turbojet engine was Concorde

The Aérospatiale/BAC Concorde () is a retired Franco-British supersonic airliner jointly developed and manufactured by Sud Aviation (later Aérospatiale) and the British Aircraft Corporation (BAC).

Studies started in 1954, and France and t ...

which used the Olympus 593

The Rolls-Royce/Snecma Olympus 593 was an Anglo-French turbojet with reheat (afterburners), which powered the supersonic airliner Concorde. It was initially a joint project between Bristol Siddeley Engines Limited (BSEL) and Snecma, derived f ...

engine. However, joint studies by Rolls-Royce and Snecma for a second generation SST engine using the 593 core were done more than three years before Concorde entered service. They evaluated bypass engines with bypass ratios between 0.1 and 1.0 to give improved take-off and cruising performance. Nevertheless, the 593 met all the requirements of the Concorde programme.Estimates made in 1964 for the Concorde design at Mach 2.2 showed the penalty in range for the supersonic airliner, in terms of miles per gallon, compared to subsonic airliners at Mach 0.85 (Boeing 707, DC-8) was relatively small. This is because the large increase in drag is largely compensated by an increase in powerplant efficiency (the engine efficiency is increased by the ram pressure rise which adds to the compressor pressure rise, the higher aircraft speed approaches the exhaust jet speed increasing propulsive efficiency).

Turbojet engines had a significant impact on commercial aviation. Aside from giving faster flight speeds turbojets had greater reliability than piston engines, with some models demonstrating dispatch reliability rating in excess of 99.9%. Pre-jet commercial aircraft were designed with as many as four engines in part because of concerns over in-flight failures. Overseas flight paths were plotted to keep planes within an hour of a landing field, lengthening flights. The increase in reliability that came with the turbojet enabled three- and two-engine designs, and more direct long-distance flights.

High-temperature alloys were a reverse salient

A reverse salient refers to a component of a technological system that, due to its insufficient development, prevents the system in its entirety from achieving its development goals. The term was coined by Thomas P. Hughes,Hughes, T. P. (1983). Ne ...

, a key technology that dragged progress on jet engines. Non-UK jet engines built in the 1930s and 1940s had to be overhauled every 10 or 20 hours due to creep failure

In materials science, creep (sometimes called cold flow) is the tendency of a solid material to move slowly or deform permanently under the influence of persistent mechanical stresses. It can occur as a result of long-term exposure to high leve ...

and other types of damage to blades. British engines, however, utilised Nimonic alloys which allowed extended use without overhaul, engines such as the Rolls-Royce Welland and Rolls-Royce Derwent, and by 1949 the de Havilland Goblin, being type tested for 500 hours without maintenance. It was not until the 1950s that superalloy

A superalloy, or high-performance alloy, is an alloy with the ability to operate at a high fraction of its melting point. Several key characteristics of a superalloy are excellent mechanical strength, resistance to thermal creep deformation, g ...

technology allowed other countries to produce economically practical engines.

Early designs

Early German turbojets had severe limitations on the amount of running they could do due to the lack of suitable high temperature materials for the turbines. British engines such as the Rolls-Royce Welland used better materials giving improved durability. The Welland was type-certified for 80 hours initially, later extended to 150 hours between overhauls, as a result of an extended 500-hour run being achieved in tests.

General Electric

General Electric Company (GE) is an American multinational conglomerate founded in 1892, and incorporated in New York state and headquartered in Boston. The company operated in sectors including healthcare, aviation, power, renewable energ ...

in the United States was in a good position to enter the jet engine business due to its experience with the high-temperature materials used in their turbosuperchargers during World War II.

Water injection was a common method used to increase thrust, usually during takeoff, in early turbojets that were thrust-limited by their allowable turbine entry temperature. The water increased thrust at the temperature limit, but prevented complete combustion, often leaving a very visible smoke trail.

Allowable turbine entry temperatures have increased steadily over time both with the introduction of superior alloys and coatings, and with the introduction and progressive effectiveness of blade cooling designs. On early engines, the turbine temperature limit had to be monitored, and avoided, by the pilot, typically during starting and at maximum thrust settings. Automatic temperature limiting was introduced to reduce pilot workload and reduce the likelihood of turbine damage due to over-temperature.

Components

Air intake

An intake, or tube, is needed in front of the compressor to help direct the incoming air smoothly into the rotating compressor blades. Older engines had stationary vanes in front of the moving blades. These vanes also helped to direct the air onto the blades. The air flowing into a turbojet engine is always subsonic, regardless of the speed of the aircraft itself. The intake has to supply air to the engine with an acceptably small variation in pressure (known as distortion) and having lost as little energy as possible on the way (known as pressure recovery). The ram pressure rise in the intake is the inlet's contribution to the propulsion system's overall pressure ratio and thermal efficiency. The intake gains prominence at high speeds when it generates more compression than the compressor stage. Well-known examples are the Concorde andLockheed SR-71 Blackbird

The Lockheed SR-71 "Blackbird" is a long-range, high-al