Strain energy release rate on:

[Wikipedia]

[Google]

[Amazon]

In

The energy release rate is defined as the instantaneous loss of total potential energy per unit crack growth area ,

:

where the total potential energy is written in terms of the total strain energy , surface traction , displacement , and body force by

:

The first integral is over the surface of the material, and the second over its volume .

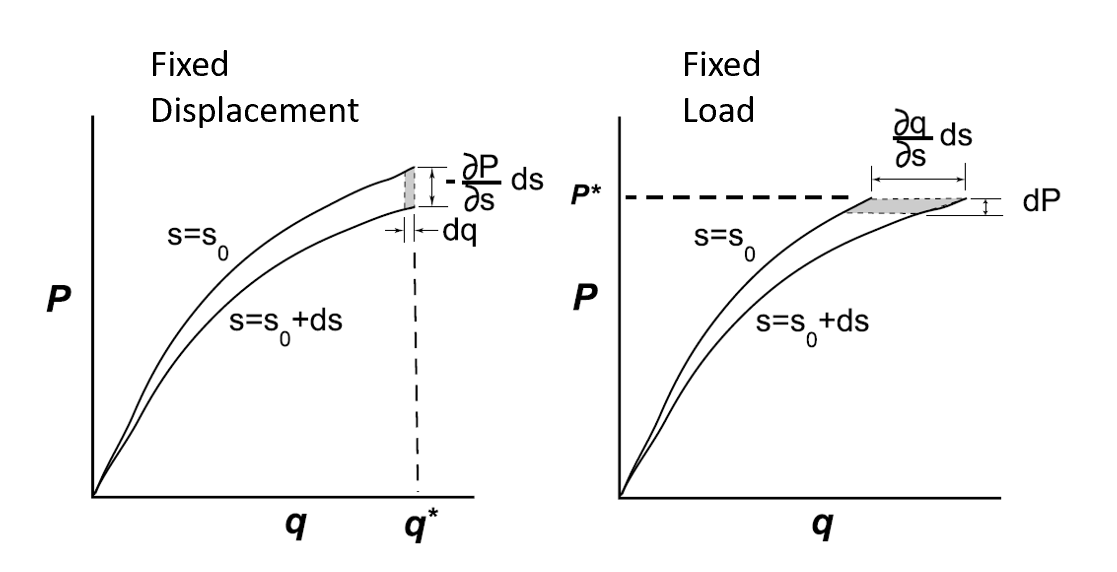

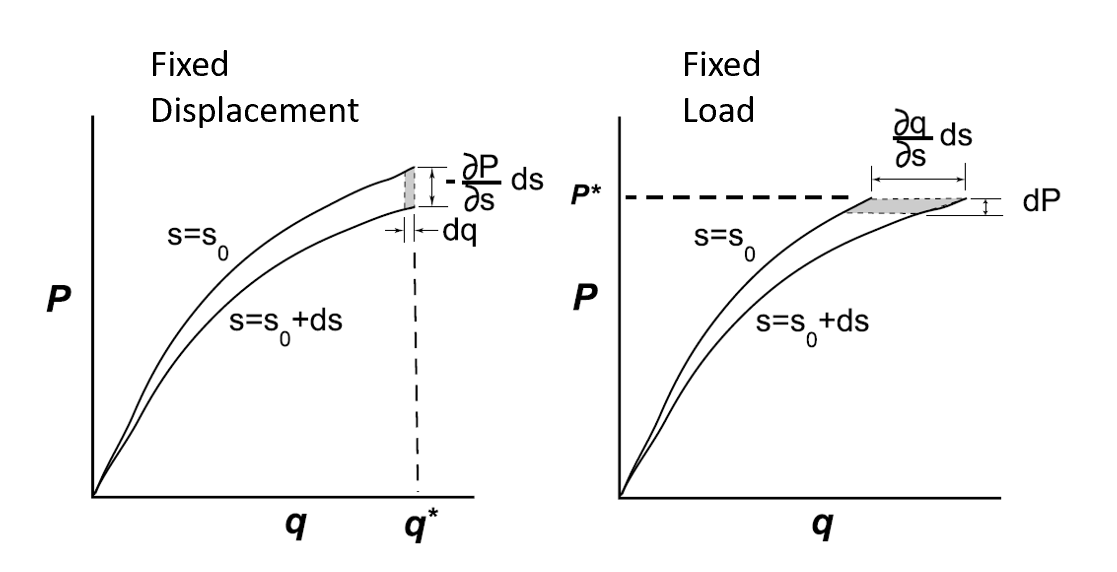

The figure on the right shows the plot of an external force vs. the load-point displacement , in which the area under the curve is the strain energy. The white area between the curve and the -axis is referred to as the complementary energy. In the case of a linearly-elastic material, is a straight line and the strain energy is equal to the complementary energy.

The energy release rate is defined as the instantaneous loss of total potential energy per unit crack growth area ,

:

where the total potential energy is written in terms of the total strain energy , surface traction , displacement , and body force by

:

The first integral is over the surface of the material, and the second over its volume .

The figure on the right shows the plot of an external force vs. the load-point displacement , in which the area under the curve is the strain energy. The white area between the curve and the -axis is referred to as the complementary energy. In the case of a linearly-elastic material, is a straight line and the strain energy is equal to the complementary energy.

In the case of prescribed displacement, holding the crack length fixed, the energy release rate can be computed by

:

while in the case of prescribed load,

:

As one can see that, in both cases, the energy release rate times the change in surface returns the area between curves, which indicates the energy dissipated for the new surface area as illustrated in the right figure

:

In the case of prescribed displacement, holding the crack length fixed, the energy release rate can be computed by

:

while in the case of prescribed load,

:

As one can see that, in both cases, the energy release rate times the change in surface returns the area between curves, which indicates the energy dissipated for the new surface area as illustrated in the right figure

:

Where is the width of the element bounding the crack tip. The accuracy of the method highly depends on the mesh refinement, both because the displacement and forces depend on it, and because . Note that the equations above are derived using the crack closure integral.

If the energy release rate exceed a critical value, the crack will grow. In this case, a new FEA simulation is performed (for the next time step) where the node at the crack tip is released. For a bounded substrate, we may simply stop enforcing fixed Dirichlet boundary conditions at the crack tip node of the previous time step (i.e. displacements are no longer restrained) . For a symmetric crack, we would need to update the geometry of the domain with a longer crack opening (and therefore generate a new mesh).

Where is the width of the element bounding the crack tip. The accuracy of the method highly depends on the mesh refinement, both because the displacement and forces depend on it, and because . Note that the equations above are derived using the crack closure integral.

If the energy release rate exceed a critical value, the crack will grow. In this case, a new FEA simulation is performed (for the next time step) where the node at the crack tip is released. For a bounded substrate, we may simply stop enforcing fixed Dirichlet boundary conditions at the crack tip node of the previous time step (i.e. displacements are no longer restrained) . For a symmetric crack, we would need to update the geometry of the domain with a longer crack opening (and therefore generate a new mesh).

The 4-node square linear elements seen in Figure 2 have a distance between nodes and equal to Consider a crack with its tip located at node Similar to the nodal release method, if the crack were to propagate one element length along the line of symmetry (parallel to the -axis) the crack opening displacement would be the displacement at the previous crack tip, i.e. and the force at the new crack tip would be Since the crack growth is assumed to be self-similar the displacement at node after the crack propagates is equal to the displacement at node before the crack propagates. This same concept can be applied to the forces at node and Utilizing the same method shown in the nodal release section we recover the following equations for energy release rate:

The 4-node square linear elements seen in Figure 2 have a distance between nodes and equal to Consider a crack with its tip located at node Similar to the nodal release method, if the crack were to propagate one element length along the line of symmetry (parallel to the -axis) the crack opening displacement would be the displacement at the previous crack tip, i.e. and the force at the new crack tip would be Since the crack growth is assumed to be self-similar the displacement at node after the crack propagates is equal to the displacement at node before the crack propagates. This same concept can be applied to the forces at node and Utilizing the same method shown in the nodal release section we recover the following equations for energy release rate:

The 8-node rectangular elements seen in Figure 3 have quadratic basis functions. The process for calculating G is the same as the 4-node elements with the exception that (the crack growth over one element) is now the distance from node to Once again, making the assumption of self-similar straight crack growth the energy release rate can be calculated utilizing with the following equations:

The 8-node rectangular elements seen in Figure 3 have quadratic basis functions. The process for calculating G is the same as the 4-node elements with the exception that (the crack growth over one element) is now the distance from node to Once again, making the assumption of self-similar straight crack growth the energy release rate can be calculated utilizing with the following equations:

The J-integral may be calculated directly using the finite element mesh and shape functions. We consider a domain countour as shown in figure 4 and choose an arbitrary smooth function such that on and on .

For linear elastic cracks growing straight ahead, . The energy release rate can then be calculated over the area bounded by the contour using an updated formulation:

The formula above may be applied to any annular area surrounding the crack tip (in particular, a set of neighboring elements can be used). This method is very accurate, even with a coarse mesh around the crack tip (one may choose an integration domain located far away, with stresses and displacement less sensitive to mesh refinement)

:

The J-integral may be calculated directly using the finite element mesh and shape functions. We consider a domain countour as shown in figure 4 and choose an arbitrary smooth function such that on and on .

For linear elastic cracks growing straight ahead, . The energy release rate can then be calculated over the area bounded by the contour using an updated formulation:

The formula above may be applied to any annular area surrounding the crack tip (in particular, a set of neighboring elements can be used). This method is very accurate, even with a coarse mesh around the crack tip (one may choose an integration domain located far away, with stresses and displacement less sensitive to mesh refinement)

:

The 8-node quadratic element are described by Figure 5 in both parent space with local coordinates and and by the mapped element in physical/global space by and The parent element is mapped from the local space to the physical space by the shape functions and the degree of freedom coordinates The crack tip is located at or In a similar way, displacements (defined as ) can also be mapped.A property of shape functions in the finite element method is

The 8-node quadratic element are described by Figure 5 in both parent space with local coordinates and and by the mapped element in physical/global space by and The parent element is mapped from the local space to the physical space by the shape functions and the degree of freedom coordinates The crack tip is located at or In a similar way, displacements (defined as ) can also be mapped.A property of shape functions in the finite element method is  If the nodes are spaced evenly on the rectangular element then the strain will not contain the singularity. By moving nodes 5 and 8 position to a quarter of the length of the element closer to the crack tip as seen in figure 5, the mapping from becomes:Solving for and taking the derivative results in:Plugging this result into the equation for strain the final result is obtained:By moving the mid-nodes to a quarter position results in the correct crack tip singularity.

If the nodes are spaced evenly on the rectangular element then the strain will not contain the singularity. By moving nodes 5 and 8 position to a quarter of the length of the element closer to the crack tip as seen in figure 5, the mapping from becomes:Solving for and taking the derivative results in:Plugging this result into the equation for strain the final result is obtained:By moving the mid-nodes to a quarter position results in the correct crack tip singularity.

The rectangular element method does not allow for singular elements to be easily meshed around the crack tip. This impedes the ability to capture the angular dependence of the stress fields which is critical in determining the crack path. Also, except along the element edges the singularity exists in a very small region near the crack tip. Figure 6 shows another quarter-point method for modeling this singularity. The 8-node rectangular element can be mapped into a triangle. This is done by collapsing the nodes on the line to the mid-node location and shifting the mid-nodes on to the quarter-point location. The collapsed rectangle can more easily surround the crack tip but requires that the element edges be straight or the accuracy of calculating the stress intensity factor will be reduced.

A better candidate for the quarter-point method is the natural triangle as seen in Figure 7. The element's geometry allows for the crack tip to be easily surrounded and meshing is simplified. Following the same procedure described above, the displacement and strain field for the triangular elements are:This method reproduces the first two terms of the Williams solutions with a constant and singular term.

An advantage of quarter-point method is that it can be easily generalized to 3-dimensional models. This can greatly reduce computation when compared to other 3-dimensional methods but can lead to error if that crack tip propagates with a large degree of curvature.{{Cite journal, last1=Peano, first1=A., last2=Pasini, first2=A., date=February 1982, title=A warning against misuse of quarter-point elements, journal=International Journal for Numerical Methods in Engineering, volume=18, issue=2, pages=314–320, doi=10.1002/nme.1620180212, issn=0029-5981, bibcode=1982IJNME..18..314P

The rectangular element method does not allow for singular elements to be easily meshed around the crack tip. This impedes the ability to capture the angular dependence of the stress fields which is critical in determining the crack path. Also, except along the element edges the singularity exists in a very small region near the crack tip. Figure 6 shows another quarter-point method for modeling this singularity. The 8-node rectangular element can be mapped into a triangle. This is done by collapsing the nodes on the line to the mid-node location and shifting the mid-nodes on to the quarter-point location. The collapsed rectangle can more easily surround the crack tip but requires that the element edges be straight or the accuracy of calculating the stress intensity factor will be reduced.

A better candidate for the quarter-point method is the natural triangle as seen in Figure 7. The element's geometry allows for the crack tip to be easily surrounded and meshing is simplified. Following the same procedure described above, the displacement and strain field for the triangular elements are:This method reproduces the first two terms of the Williams solutions with a constant and singular term.

An advantage of quarter-point method is that it can be easily generalized to 3-dimensional models. This can greatly reduce computation when compared to other 3-dimensional methods but can lead to error if that crack tip propagates with a large degree of curvature.{{Cite journal, last1=Peano, first1=A., last2=Pasini, first2=A., date=February 1982, title=A warning against misuse of quarter-point elements, journal=International Journal for Numerical Methods in Engineering, volume=18, issue=2, pages=314–320, doi=10.1002/nme.1620180212, issn=0029-5981, bibcode=1982IJNME..18..314P

Nonlinear Fracture Mechanics Notes

by Prof. John Hutchinson (from Harvard University)

o

www.fracturemechanics.org

Fracture mechanics Solid mechanics Mechanics

fracture mechanics

Fracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics t ...

, the energy release rate, , is the rate at which energy

In physics, energy (from Ancient Greek: ἐνέργεια, ''enérgeia'', “activity”) is the quantitative property that is transferred to a body or to a physical system, recognizable in the performance of work and in the form of heat a ...

is transformed as a material

Material is a substance or mixture of substances that constitutes an object. Materials can be pure or impure, living or non-living matter. Materials can be classified on the basis of their physical and chemical properties, or on their geologi ...

undergoes fracture

Fracture is the separation of an object or material into two or more pieces under the action of stress. The fracture of a solid usually occurs due to the development of certain displacement discontinuity surfaces within the solid. If a displa ...

. Mathematically, the energy release rate is expressed as the decrease in total potential energy

In physics, potential energy is the energy held by an object because of its position relative to other objects, stresses within itself, its electric charge, or other factors.

Common types of potential energy include the gravitational potentia ...

per increase in fracture surface area, and is thus expressed in terms of energy per unit area. Various energy balances can be constructed relating the energy released during fracture to the energy of the resulting new surface, as well as other dissipative

In thermodynamics, dissipation is the result of an irreversible process that takes place in homogeneous thermodynamic systems. In a dissipative process, energy (internal, bulk flow kinetic, or system potential) transforms from an initial form to a ...

processes such as plasticity

Plasticity may refer to:

Science

* Plasticity (physics), in engineering and physics, the propensity of a solid material to undergo permanent deformation under load

* Neuroplasticity, in neuroscience, how entire brain structures, and the brain it ...

and heat generation. The energy release rate is central to the field of fracture mechanics when solving problems and estimating material properties related to fracture and fatigue

Fatigue describes a state of tiredness that does not resolve with rest or sleep. In general usage, fatigue is synonymous with extreme tiredness or exhaustion that normally follows prolonged physical or mental activity. When it does not resolve ...

.

Definition

The energy release rate is defined as the instantaneous loss of total potential energy per unit crack growth area ,

:

where the total potential energy is written in terms of the total strain energy , surface traction , displacement , and body force by

:

The first integral is over the surface of the material, and the second over its volume .

The figure on the right shows the plot of an external force vs. the load-point displacement , in which the area under the curve is the strain energy. The white area between the curve and the -axis is referred to as the complementary energy. In the case of a linearly-elastic material, is a straight line and the strain energy is equal to the complementary energy.

The energy release rate is defined as the instantaneous loss of total potential energy per unit crack growth area ,

:

where the total potential energy is written in terms of the total strain energy , surface traction , displacement , and body force by

:

The first integral is over the surface of the material, and the second over its volume .

The figure on the right shows the plot of an external force vs. the load-point displacement , in which the area under the curve is the strain energy. The white area between the curve and the -axis is referred to as the complementary energy. In the case of a linearly-elastic material, is a straight line and the strain energy is equal to the complementary energy.

Prescribed displacement

In the case of prescribed displacement, the strain energy can be expressed in terms of the specified displacement and the crack surface , and the change in this strain energy is only affected by the change in fracture surface area: . Correspondingly, the energy release rate in this case is expressed as : Here is where one can accurately refer to as the strain energy release rate.Prescribed loads

When the load is prescribed instead of the displacement, the strain energy needs to be modified as . The energy release rate is then computed as : If the material is linearly-elastic, then and one may instead write :G in two-dimensional cases

In the cases of two-dimensional problems, the change in crack growth area is simply the change in crack length times the thickness of the specimen. Namely, . Therefore, the equation for computing can be modified for the 2D case: * Prescribed Displacement: * Prescribed Load: * Prescribed Load, Linear Elastic: One can refer to the example calculations embedded in the next section for further information. Sometimes, the strain energy is written using , an energy-per-unit thickness. This gives * Prescribed Displacement: * Prescribed Load: * Prescribed Load, Linear Elastic:Relation to stress intensity factors

The energy release rate is directly related to thestress intensity factor

In fracture mechanics, the stress intensity factor () is used to predict the stress state ("stress intensity") near the tip of a crack or notch caused by a remote load or residual stresses. It is a theoretical construct usually applied to a h ...

associated with a given two-dimensional loading mode ( Mode-I, Mode-II, or Mode-III) when the crack grows straight ahead. This is applicable to cracks under plane stress

In continuum mechanics, a material is said to be under plane stress if the stress vector is zero across a particular plane. When that situation occurs over an entire element of a structure, as is often the case for thin plates, the stress analys ...

, plane strain

In continuum mechanics, the infinitesimal strain theory is a mathematical approach to the description of the deformation of a solid body in which the displacements of the material particles are assumed to be much smaller (indeed, infinitesimally ...

, and antiplane shear

Antiplane shear or antiplane strainW. S. Slaughter, 2002, ''The Linearized Theory of Elasticity'', Birkhauser is a special state of strain in a body. This state of strain is achieved when the displacements in the body are zero in the plane of inte ...

.

For Mode-I, the energy release rate rate is related

''Related'' is an American comedy-drama television series that aired on The WB from October 5, 2005, to March 20, 2006. It revolves around the lives of four close-knit sisters of Italian descent, raised in Brooklyn and living in Manhattan.

The ...

to the Mode-I stress intensity factor for a linearly-elastic material by

:

where is related to Young's modulus

Young's modulus E, the Young modulus, or the modulus of elasticity in tension or compression (i.e., negative tension), is a mechanical property that measures the tensile or compressive stiffness of a solid material when the force is applied leng ...

and Poisson's ratio

In materials science and solid mechanics, Poisson's ratio \nu ( nu) is a measure of the Poisson effect, the deformation (expansion or contraction) of a material in directions perpendicular to the specific direction of loading. The value of Pois ...

depending on whether the material is under plane stress or plane strain:

:

For Mode-II, the energy release rate is similarly written as

:

For Mode-III (antiplane shear), the energy release rate now is a function of the shear modulus

In materials science, shear modulus or modulus of rigidity, denoted by ''G'', or sometimes ''S'' or ''μ'', is a measure of the elastic shear stiffness of a material and is defined as the ratio of shear stress to the shear strain:

:G \ \stackrel ...

,

:

For an arbitrary combination of all loading modes, these linear elastic solutions may be superposed as

:

Relation to fracture toughness

Crack growth is initiated when the energy release rate over comes a critical value , which is a material property, : Under Mode-I loading, the critical energy release rate is then related to the Mode-Ifracture toughness

In materials science, fracture toughness is the critical stress intensity factor of a sharp crack where propagation of the crack suddenly becomes rapid and unlimited. A component's thickness affects the constraint conditions at the tip of a c ...

, another material property, by

:

Calculating ''G''

There are a variety of methods available for calculating the energy release rate given material properties, specimen geometry, and loading conditions. Some are dependent on certain criteria being satisfied, such as the material being entirely elastic or even linearly-elastic, and/or that the crack must grow straight ahead. The only method presented that works arbitrarily is that using the total potential energy. If two methods are both applicable, they should yield identical energy release rates.Total potential energy

The only method to calculate for arbitrary conditions is to calculate the total potential energy and differentiate it with respect to the crack surface area. This is typically done by: * calculating the stress field resulting from the loading, * calculating the strain energy in the material resulting from the stress field, * calculating the work done by the external loads, all in terms of the crack surface area.Compliance method

If the material is linearly-elastic, the computation of its energy release rate can be much simplified. In this case, the Load vs. Load-point Displacement curve is linear with a positive slope, and the displacement per unit force applied is defined as the compliance, : The corresponding strain energy (area under the curve) is equal to : Using the compliance method, one can show that the energy release rate for both cases of prescribed load and displacement come out to be :Multiple specimen methods for nonlinear materials

In the case of prescribed displacement, holding the crack length fixed, the energy release rate can be computed by

:

while in the case of prescribed load,

:

As one can see that, in both cases, the energy release rate times the change in surface returns the area between curves, which indicates the energy dissipated for the new surface area as illustrated in the right figure

:

In the case of prescribed displacement, holding the crack length fixed, the energy release rate can be computed by

:

while in the case of prescribed load,

:

As one can see that, in both cases, the energy release rate times the change in surface returns the area between curves, which indicates the energy dissipated for the new surface area as illustrated in the right figure

:

Crack closure integral

Since the energy release rate is defined as the negative derivative of the total potential energy with respect to crack surface growth, the energy release rate may be written as the difference between the potential energy before and after the crack grows. After some careful derivation, this leads one to the crack closure integral : where is the new fracture surface area, are the components of the traction released on the top fracture surface as the crack grows, are the components of the crack opening displacement (the difference in displacement increments between the top and bottom crack surfaces), and the integral is over the surface of the material . The crack closure integral is valid only for elastic materials, but is still valid for cracks that grow in any direction. Nevertheless, for a two-dimensional crack that does indeed grow straight ahead, the crack closure integral simplifies to : where is the new crack length, and the displacement components are written as a function of the polar coordinates and .J''-''integral

In certain situations, the energy release rate can be calculated using theJ-integral

The J-integral represents a way to calculate the strain energy release rate, or work ( energy) per unit fracture surface area, in a material. The theoretical concept of J-integral was developed in 1967 by G. P. Cherepanov and independently in 1968 ...

, i.e. , using

:

where is the elastic strain energy density, is the component of the unit vector normal to , the curve used for the line integral, are the components of the traction vector , where is the stress tensor, and are the components of the displacement vector.

This integral is zero over a simple closed path and is path independent, allowing any simple path starting and ending on the crack faces to be used to calculate .

In order to equate the energy release rate to the J-integral, , the following conditions must be met:

* the crack must be growing straight ahead, and

* the deformation near the crack (enclosed by ) must be elastic (not plastic).

The J-integral may be calculated with these conditions violated, but then . When they are not violated, one can then relate the energy release rate and the J-integral to the elastic moduli and the stress intensity factors using

:

Computational methods in fracture mechanics

A handful of methods exist for calculating with finite elements. Although a direct calculation of theJ-integral

The J-integral represents a way to calculate the strain energy release rate, or work ( energy) per unit fracture surface area, in a material. The theoretical concept of J-integral was developed in 1967 by G. P. Cherepanov and independently in 1968 ...

is possible (using the strains and stresses outputted by FEA), approximate approaches for some type of crack growth exist and provide reasonable accuracy with straightforward calculations. This section will elaborate on some relatively simple methods for fracture analysis utilizing numerical simulations.

Nodal release method

If the crack is growing straight, the energy release rate can be decomposed as a sum of 3 terms associated with the energy in each 3 modes. As a result, the Nodal Release method (NR) can be used to determine from FEA results. The energy release rate is calculated at the nodes of the finite element mesh for the crack at an initial length and extended by a small distance . First, we calculate the displacement variation at the node of interest (before and after the crack tip node is released). Secondly, we keep track of the nodal force outputted by FEA. Finally, we can find each components of using the following formulas: Where is the width of the element bounding the crack tip. The accuracy of the method highly depends on the mesh refinement, both because the displacement and forces depend on it, and because . Note that the equations above are derived using the crack closure integral.

If the energy release rate exceed a critical value, the crack will grow. In this case, a new FEA simulation is performed (for the next time step) where the node at the crack tip is released. For a bounded substrate, we may simply stop enforcing fixed Dirichlet boundary conditions at the crack tip node of the previous time step (i.e. displacements are no longer restrained) . For a symmetric crack, we would need to update the geometry of the domain with a longer crack opening (and therefore generate a new mesh).

Where is the width of the element bounding the crack tip. The accuracy of the method highly depends on the mesh refinement, both because the displacement and forces depend on it, and because . Note that the equations above are derived using the crack closure integral.

If the energy release rate exceed a critical value, the crack will grow. In this case, a new FEA simulation is performed (for the next time step) where the node at the crack tip is released. For a bounded substrate, we may simply stop enforcing fixed Dirichlet boundary conditions at the crack tip node of the previous time step (i.e. displacements are no longer restrained) . For a symmetric crack, we would need to update the geometry of the domain with a longer crack opening (and therefore generate a new mesh).

Modified crack closure integral

Similar to the Nodal Release Method, the Modified Crack Closure Integral (MCCI) is a method for calculating theenergy release rate In fracture mechanics, the energy release rate, G, is the rate at which energy is transformed as a material undergoes fracture. Mathematically, the energy release rate is expressed as the decrease in total potential energy per increase in fractu ...

utilizing FEA nodal displacements and forces . Where represents the direction corresponding to the Cartesian basis vectors with origin at the crack tip, and represents the nodal index. MCCI is more computationally efficient than the nodal release method because it only requires one analysis for each increment of crack growth.

A necessary condition for the MCCI method is uniform element length along the crack face in the direction. Additionally, this method requires sufficient discretization such that over the length of one element stress fields are self-similar. This implies that as the crack propagates. Below are examples of the MCCI method with two types of common finite elements.

4-node elements

The 4-node square linear elements seen in Figure 2 have a distance between nodes and equal to Consider a crack with its tip located at node Similar to the nodal release method, if the crack were to propagate one element length along the line of symmetry (parallel to the -axis) the crack opening displacement would be the displacement at the previous crack tip, i.e. and the force at the new crack tip would be Since the crack growth is assumed to be self-similar the displacement at node after the crack propagates is equal to the displacement at node before the crack propagates. This same concept can be applied to the forces at node and Utilizing the same method shown in the nodal release section we recover the following equations for energy release rate:

The 4-node square linear elements seen in Figure 2 have a distance between nodes and equal to Consider a crack with its tip located at node Similar to the nodal release method, if the crack were to propagate one element length along the line of symmetry (parallel to the -axis) the crack opening displacement would be the displacement at the previous crack tip, i.e. and the force at the new crack tip would be Since the crack growth is assumed to be self-similar the displacement at node after the crack propagates is equal to the displacement at node before the crack propagates. This same concept can be applied to the forces at node and Utilizing the same method shown in the nodal release section we recover the following equations for energy release rate:Where (displacement above and below the crack face respectively). Because we have a line of symmetry parallel to the crack, we can assume Thus,

8-node elements

The 8-node rectangular elements seen in Figure 3 have quadratic basis functions. The process for calculating G is the same as the 4-node elements with the exception that (the crack growth over one element) is now the distance from node to Once again, making the assumption of self-similar straight crack growth the energy release rate can be calculated utilizing with the following equations:

The 8-node rectangular elements seen in Figure 3 have quadratic basis functions. The process for calculating G is the same as the 4-node elements with the exception that (the crack growth over one element) is now the distance from node to Once again, making the assumption of self-similar straight crack growth the energy release rate can be calculated utilizing with the following equations:Like with the nodal release method the accuracy of MCCI is highly dependent on the level of discretization along the crack tip, i.e. Accuracy also depends on element choice. A mesh of 8-node quadratic elements can produce more accurate results than a mesh of 4-node linear elements with the same number of degrees of freedom in the mesh.

Domain integral approach for J

The J-integral may be calculated directly using the finite element mesh and shape functions. We consider a domain countour as shown in figure 4 and choose an arbitrary smooth function such that on and on .

For linear elastic cracks growing straight ahead, . The energy release rate can then be calculated over the area bounded by the contour using an updated formulation:

The formula above may be applied to any annular area surrounding the crack tip (in particular, a set of neighboring elements can be used). This method is very accurate, even with a coarse mesh around the crack tip (one may choose an integration domain located far away, with stresses and displacement less sensitive to mesh refinement)

:

The J-integral may be calculated directly using the finite element mesh and shape functions. We consider a domain countour as shown in figure 4 and choose an arbitrary smooth function such that on and on .

For linear elastic cracks growing straight ahead, . The energy release rate can then be calculated over the area bounded by the contour using an updated formulation:

The formula above may be applied to any annular area surrounding the crack tip (in particular, a set of neighboring elements can be used). This method is very accurate, even with a coarse mesh around the crack tip (one may choose an integration domain located far away, with stresses and displacement less sensitive to mesh refinement)

:

2-D crack tip singular elements

The above-mentioned methods for calculating energy release rate asymptotically approach the actual solution with increased discretization, but fail to fully capture the crack tip singularity. More accurate simulations can be preformed by utilizing quarter-point elements around the crack tip. These elements have a built in singularity which more accurately produces stress fields around the crack tip. The advantage of the quarter-point method is that it allows for coarser finite element meshes and greatly reduces computational cost. Furthermore, these elements are derived from small modifications to common finite elements without requiring special computational programs for analysis. For the purposes of this section elastic materials will be examined, although this method can be extended to elastic-plastic

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their plasticity makes it possible for plastics to be moulded, extruded or pressed into solid objects of various shapes. This adaptab ...

fracture mechanics. Assuming perfect elasticity the stress fields will experience a crack tip singularity.

8-node isoparametric element

The 8-node quadratic element are described by Figure 5 in both parent space with local coordinates and and by the mapped element in physical/global space by and The parent element is mapped from the local space to the physical space by the shape functions and the degree of freedom coordinates The crack tip is located at or In a similar way, displacements (defined as ) can also be mapped.A property of shape functions in the finite element method is

The 8-node quadratic element are described by Figure 5 in both parent space with local coordinates and and by the mapped element in physical/global space by and The parent element is mapped from the local space to the physical space by the shape functions and the degree of freedom coordinates The crack tip is located at or In a similar way, displacements (defined as ) can also be mapped.A property of shape functions in the finite element method is compact support

In mathematics, the support of a real-valued function f is the subset of the function domain containing the elements which are not mapped to zero. If the domain of f is a topological space, then the support of f is instead defined as the smallest ...

, specifically the Kronecker delta

In mathematics, the Kronecker delta (named after Leopold Kronecker) is a function of two variables, usually just non-negative integers. The function is 1 if the variables are equal, and 0 otherwise:

\delta_ = \begin

0 &\text i \neq j, \\

1 &\ ...

property (i.e. at node and zero at all other nodes). This results in the following shape functions for the 8-node quadratic elements:When considering a line in front of the crack that is co-linear with the - axis (i.e. ) all basis functions are zero except for

Calculating the normal strain involves using the

chain rule

In calculus, the chain rule is a formula that expresses the derivative of the composition of two differentiable functions and in terms of the derivatives of and . More precisely, if h=f\circ g is the function such that h(x)=f(g(x)) for every , ...

to take the derivative of displacement with respect to

If the nodes are spaced evenly on the rectangular element then the strain will not contain the singularity. By moving nodes 5 and 8 position to a quarter of the length of the element closer to the crack tip as seen in figure 5, the mapping from becomes:Solving for and taking the derivative results in:Plugging this result into the equation for strain the final result is obtained:By moving the mid-nodes to a quarter position results in the correct crack tip singularity.

If the nodes are spaced evenly on the rectangular element then the strain will not contain the singularity. By moving nodes 5 and 8 position to a quarter of the length of the element closer to the crack tip as seen in figure 5, the mapping from becomes:Solving for and taking the derivative results in:Plugging this result into the equation for strain the final result is obtained:By moving the mid-nodes to a quarter position results in the correct crack tip singularity.

Other element types

The rectangular element method does not allow for singular elements to be easily meshed around the crack tip. This impedes the ability to capture the angular dependence of the stress fields which is critical in determining the crack path. Also, except along the element edges the singularity exists in a very small region near the crack tip. Figure 6 shows another quarter-point method for modeling this singularity. The 8-node rectangular element can be mapped into a triangle. This is done by collapsing the nodes on the line to the mid-node location and shifting the mid-nodes on to the quarter-point location. The collapsed rectangle can more easily surround the crack tip but requires that the element edges be straight or the accuracy of calculating the stress intensity factor will be reduced.

A better candidate for the quarter-point method is the natural triangle as seen in Figure 7. The element's geometry allows for the crack tip to be easily surrounded and meshing is simplified. Following the same procedure described above, the displacement and strain field for the triangular elements are:This method reproduces the first two terms of the Williams solutions with a constant and singular term.

An advantage of quarter-point method is that it can be easily generalized to 3-dimensional models. This can greatly reduce computation when compared to other 3-dimensional methods but can lead to error if that crack tip propagates with a large degree of curvature.{{Cite journal, last1=Peano, first1=A., last2=Pasini, first2=A., date=February 1982, title=A warning against misuse of quarter-point elements, journal=International Journal for Numerical Methods in Engineering, volume=18, issue=2, pages=314–320, doi=10.1002/nme.1620180212, issn=0029-5981, bibcode=1982IJNME..18..314P

The rectangular element method does not allow for singular elements to be easily meshed around the crack tip. This impedes the ability to capture the angular dependence of the stress fields which is critical in determining the crack path. Also, except along the element edges the singularity exists in a very small region near the crack tip. Figure 6 shows another quarter-point method for modeling this singularity. The 8-node rectangular element can be mapped into a triangle. This is done by collapsing the nodes on the line to the mid-node location and shifting the mid-nodes on to the quarter-point location. The collapsed rectangle can more easily surround the crack tip but requires that the element edges be straight or the accuracy of calculating the stress intensity factor will be reduced.

A better candidate for the quarter-point method is the natural triangle as seen in Figure 7. The element's geometry allows for the crack tip to be easily surrounded and meshing is simplified. Following the same procedure described above, the displacement and strain field for the triangular elements are:This method reproduces the first two terms of the Williams solutions with a constant and singular term.

An advantage of quarter-point method is that it can be easily generalized to 3-dimensional models. This can greatly reduce computation when compared to other 3-dimensional methods but can lead to error if that crack tip propagates with a large degree of curvature.{{Cite journal, last1=Peano, first1=A., last2=Pasini, first2=A., date=February 1982, title=A warning against misuse of quarter-point elements, journal=International Journal for Numerical Methods in Engineering, volume=18, issue=2, pages=314–320, doi=10.1002/nme.1620180212, issn=0029-5981, bibcode=1982IJNME..18..314P

See also

*Fracture mechanics

Fracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics t ...

* Stress intensity factor

In fracture mechanics, the stress intensity factor () is used to predict the stress state ("stress intensity") near the tip of a crack or notch caused by a remote load or residual stresses. It is a theoretical construct usually applied to a h ...

* Fracture toughness

In materials science, fracture toughness is the critical stress intensity factor of a sharp crack where propagation of the crack suddenly becomes rapid and unlimited. A component's thickness affects the constraint conditions at the tip of a c ...

*J-integral

The J-integral represents a way to calculate the strain energy release rate, or work ( energy) per unit fracture surface area, in a material. The theoretical concept of J-integral was developed in 1967 by G. P. Cherepanov and independently in 1968 ...

References

External links

Nonlinear Fracture Mechanics Notes

by Prof. John Hutchinson (from Harvard University)

o

www.fracturemechanics.org

Fracture mechanics Solid mechanics Mechanics