A resistor is a passive two-terminal

A resistor is a passive two-terminal Electronic symbols and notation

Two typical schematic diagram symbols are as follows:Theory of operation

Ohm's law

An ''ideal resistor'' (i.e. a resistance without reactance) obeysSeries and parallel resistors

The total resistance of resistors connected in series is the sum of their individual resistance values. The total resistance of resistors connected in parallel is the reciprocal of the sum of the reciprocals of the individual resistors. For example, a 10 ohm resistor connected in parallel with a 5 ohm resistor and a 15 ohm resistor produces ohms of resistance, or = 2.727 ohms. A resistor network that is a combination of parallel and series connections can be broken up into smaller parts that are either one or the other. Some complex networks of resistors cannot be resolved in this manner, requiring more sophisticated circuit analysis. Generally, the Y-Δ transform, or matrix methods can be used to solve such problems.Power dissipation

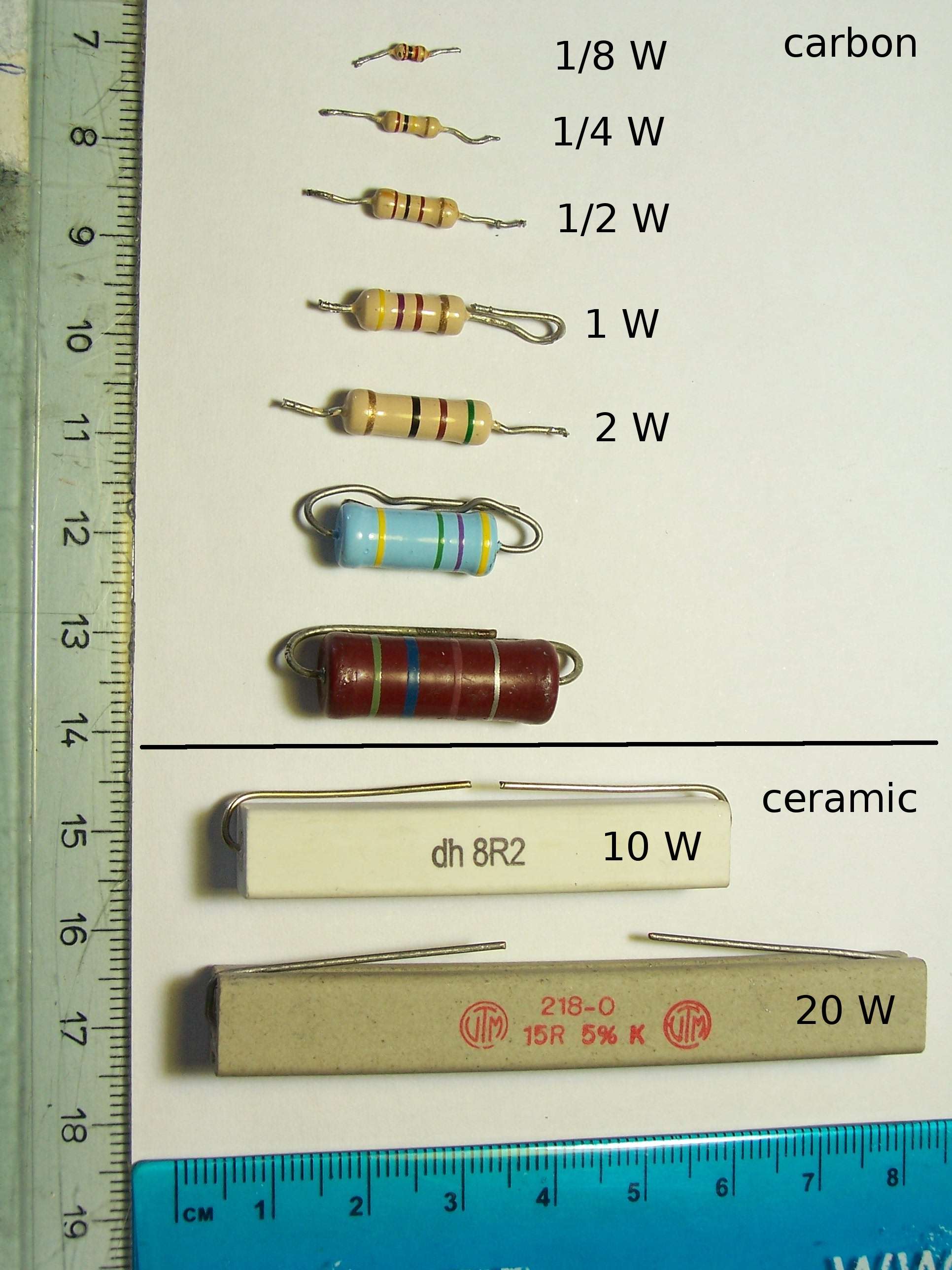

At any instant, the power ''P'' (watts) consumed by a resistor of resistance ''R'' (ohms) is calculated as: where ''V'' (volts) is the voltage across the resistor and ''I'' (amps) is the current flowing through it. Using Power resistors are required to dissipate substantial amounts of power and are typically used in power supplies, power conversion circuits, and power amplifiers; this designation is loosely applied to resistors with power ratings of 1 watt or greater. Power resistors are physically larger and may not use the preferred values, color codes, and external packages described below.

If the average power dissipated by a resistor is more than its power rating, damage to the resistor may occur, permanently altering its resistance; this is distinct from the reversible change in resistance due to its

Power resistors are required to dissipate substantial amounts of power and are typically used in power supplies, power conversion circuits, and power amplifiers; this designation is loosely applied to resistors with power ratings of 1 watt or greater. Power resistors are physically larger and may not use the preferred values, color codes, and external packages described below.

If the average power dissipated by a resistor is more than its power rating, damage to the resistor may occur, permanently altering its resistance; this is distinct from the reversible change in resistance due to its Nonideal properties

Practical resistors have a series inductance and a small parallelFixed resistors

Lead arrangements

Through-hole components typically have "leads" (pronounced ) leaving the body "axially", that is, on a line parallel with the part's longest axis. Others have leads coming off their body "radially" instead. Other components may be SMT (surface mount technology), while high power resistors may have one of their leads designed into theCarbon composition

Carbon composition resistors (CCR) consist of a solid cylindrical resistive element with embedded wire leads or metal end caps to which the lead wires are attached. The body of the resistor is protected with paint or plastic. Early 20th-century carbon composition resistors had uninsulated bodies; the lead wires were wrapped around the ends of the resistance element rod and soldered. The completed resistor was painted for color-coding of its value. The resistive element in carbon composition resistors is made from a mixture of finely powdered carbon and an insulating material, usually ceramic. A resin holds the mixture together. The resistance is determined by the ratio of the fill material (the powdered ceramic) to the carbon. Higher concentrations of carbon, which is a good conductor, result in lower resistances. Carbon composition resistors were commonly used in the 1960s and earlier, but are not popular for general use now as other types have better specifications, such as tolerance, voltage dependence, and stress. Carbon composition resistors change value when stressed with over-voltages. Moreover, if internal moisture content, such as from exposure for some length of time to a humid environment, is significant, soldering heat creates a non-reversible change in resistance value. Carbon composition resistors have poor stability with time and were consequently factory sorted to, at best, only 5% tolerance. These resistors are non-inductive, which provides benefits when used in voltage pulse reduction and surge protection applications.HVR International (ed.)"SR Series: Surge Resistors for PCB Mounting"

(PDF; 252 kB), 26 May 2005, retrieved 24 January 2017. Carbon composition resistors have higher capability to withstand overload relative to the component's size.Beyschlag, Vishay (2008)

"Basics of Linear Fixed Resistors Application Note"

Document Number 28771. Carbon composition resistors are still available, but relatively expensive. Values ranged from fractions of an ohm to 22 megohms. Due to their high price, these resistors are no longer used in most applications. However, they are used in power supplies and welding controls. They are also in demand for repair of vintage electronic equipment where authenticity is a factor.

Carbon pile

A carbon pile resistor is made of a stack of carbon disks compressed between two metal contact plates. Adjusting the clamping pressure changes the resistance between the plates. These resistors are used when an adjustable load is required, such as in testing automotive batteries or radio transmitters. A carbon pile resistor can also be used as a speed control for small motors in household appliances (sewing machines, hand-held mixers) with ratings up to a few hundred watts. A carbon pile resistor can be incorporated in automaticCarbon film

In manufacturing carbon film resistors, a carbon film is deposited on an insulating substrate, and a helix is cut in it to create a long, narrow resistive path. Varying shapes, coupled with the resistivity of

In manufacturing carbon film resistors, a carbon film is deposited on an insulating substrate, and a helix is cut in it to create a long, narrow resistive path. Varying shapes, coupled with the resistivity of Printed carbon resistors

Carbon composition resistors can be printed directly onto

Carbon composition resistors can be printed directly onto Thick and thin film

Metal film

A common type of axial-leaded resistor today is the metal-film resistor. Metal Electrode Leadless Face ( MELF) resistors often use the same technology. Metal film resistors are usually coated with nickel chromium (NiCr), but might be coated with any of the cermet materials listed above for thin film resistors. Unlike thin film resistors, the material may be applied using different techniques than sputtering (though this is one technique used). The resistance value is determined by cutting a helix through the coating rather than by etching, similar to the way carbon resistors are made. The result is a reasonable tolerance (0.5%, 1%, or 2%) and a temperature coefficient that is generally between 50 and 100 ppm/K. Metal film resistors possess good noise characteristics and low non-linearity due to a low voltage coefficient. They are also beneficial due to long-term stability.Metal oxide film

Metal-oxide film resistors are made of metal oxides which results in a higher operating temperature and greater stability and reliability than metal film. They are used in applications with high endurance demands.Wire wound

Wirewound resistors are commonly made by winding a metal wire, usually nichrome, around a ceramic, plastic, or fiberglass core. The ends of the wire are soldered or welded to two caps or rings, attached to the ends of the core. The assembly is protected with a layer of paint, molded plastic, or an enamel coating baked at high temperature. These resistors are designed to withstand unusually high temperatures of up to 450 °C. Wire leads in low power wirewound resistors are usually between 0.6 and 0.8 mm in diameter and tinned for ease of soldering. For higher power wirewound resistors, either a ceramic outer case or an aluminum outer case on top of an insulating layer is used. If the outer case is ceramic, such resistors are sometimes described as "cement" resistors, though they do not actually contain any traditional cement. The aluminum-cased types are designed to be attached to a heat sink to dissipate the heat; the rated power is dependent on being used with a suitable heat sink, e.g., a 50 W power rated resistor overheats at a fraction of the power dissipation if not used with a heat sink. Large wirewound resistors may be rated for 1,000 watts or more.

Because wirewound resistors are coils they have more undesirable inductance than other types of resistor. However, winding the wire in sections with alternately reversed direction can minimize inductance. Other techniques employ bifilar winding, or a flat thin former (to reduce cross-section area of the coil). For the most demanding circuits, resistors with Ayrton–Perry winding are used.

Applications of wirewound resistors are similar to those of composition resistors with the exception of high frequency applications. The high frequency response of wirewound resistors is substantially worse than that of a composition resistor.

Wirewound resistors are commonly made by winding a metal wire, usually nichrome, around a ceramic, plastic, or fiberglass core. The ends of the wire are soldered or welded to two caps or rings, attached to the ends of the core. The assembly is protected with a layer of paint, molded plastic, or an enamel coating baked at high temperature. These resistors are designed to withstand unusually high temperatures of up to 450 °C. Wire leads in low power wirewound resistors are usually between 0.6 and 0.8 mm in diameter and tinned for ease of soldering. For higher power wirewound resistors, either a ceramic outer case or an aluminum outer case on top of an insulating layer is used. If the outer case is ceramic, such resistors are sometimes described as "cement" resistors, though they do not actually contain any traditional cement. The aluminum-cased types are designed to be attached to a heat sink to dissipate the heat; the rated power is dependent on being used with a suitable heat sink, e.g., a 50 W power rated resistor overheats at a fraction of the power dissipation if not used with a heat sink. Large wirewound resistors may be rated for 1,000 watts or more.

Because wirewound resistors are coils they have more undesirable inductance than other types of resistor. However, winding the wire in sections with alternately reversed direction can minimize inductance. Other techniques employ bifilar winding, or a flat thin former (to reduce cross-section area of the coil). For the most demanding circuits, resistors with Ayrton–Perry winding are used.

Applications of wirewound resistors are similar to those of composition resistors with the exception of high frequency applications. The high frequency response of wirewound resistors is substantially worse than that of a composition resistor.

Metal foil resistor

In 1960, Felix Zandman and Sidney J. Stein presented a development of resistor film of very high stability.

The primary resistance element of a foil resistor is a chromium nickel alloy foil several micrometers thick. Chromium nickel alloys are characterized by having a large electrical resistance (about 58 times that of copper), a small temperature coefficient and high resistance to oxidation. Examples are Chromel A and Nichrome V, whose typical composition is 80 Ni and 20 Cr, with a melting point of 1420 °C. When iron is added, the chromium nickel alloy becomes more ductile. The Nichrome and Chromel C are examples of an alloy containing iron. The composition typical of Nichrome is 60 Ni, 12 Cr, 26 Fe, 2 Mn and Chromel C, 64 Ni, 11 Cr, Fe 25. The melting temperature of these alloys are 1350 °C and 1390 °C, respectively.

Since their introduction in the 1960s, foil resistors have had the best precision and stability of any resistor available. One of the important parameters of stability is the temperature coefficient of resistance (TCR). The TCR of foil resistors is extremely low, and has been further improved over the years. One range of ultra-precision foil resistors offers a TCR of 0.14 ppm/°C, tolerance ±0.005%, long-term stability (1 year) 25 ppm, (3 years) 50 ppm (further improved 5-fold by hermetic sealing), stability under load (2000 hours) 0.03%, thermal EMF 0.1 μV/°C, noise −42 dB, voltage coefficient 0.1 ppm/V, inductance 0.08 μH, capacitance 0.5 pF.

The thermal stability of this type of resistor also has to do with the opposing effects of the metal's electrical resistance increasing with temperature, and being reduced by thermal expansion leading to an increase in thickness of the foil, whose other dimensions are constrained by a ceramic substrate.

In 1960, Felix Zandman and Sidney J. Stein presented a development of resistor film of very high stability.

The primary resistance element of a foil resistor is a chromium nickel alloy foil several micrometers thick. Chromium nickel alloys are characterized by having a large electrical resistance (about 58 times that of copper), a small temperature coefficient and high resistance to oxidation. Examples are Chromel A and Nichrome V, whose typical composition is 80 Ni and 20 Cr, with a melting point of 1420 °C. When iron is added, the chromium nickel alloy becomes more ductile. The Nichrome and Chromel C are examples of an alloy containing iron. The composition typical of Nichrome is 60 Ni, 12 Cr, 26 Fe, 2 Mn and Chromel C, 64 Ni, 11 Cr, Fe 25. The melting temperature of these alloys are 1350 °C and 1390 °C, respectively.

Since their introduction in the 1960s, foil resistors have had the best precision and stability of any resistor available. One of the important parameters of stability is the temperature coefficient of resistance (TCR). The TCR of foil resistors is extremely low, and has been further improved over the years. One range of ultra-precision foil resistors offers a TCR of 0.14 ppm/°C, tolerance ±0.005%, long-term stability (1 year) 25 ppm, (3 years) 50 ppm (further improved 5-fold by hermetic sealing), stability under load (2000 hours) 0.03%, thermal EMF 0.1 μV/°C, noise −42 dB, voltage coefficient 0.1 ppm/V, inductance 0.08 μH, capacitance 0.5 pF.

The thermal stability of this type of resistor also has to do with the opposing effects of the metal's electrical resistance increasing with temperature, and being reduced by thermal expansion leading to an increase in thickness of the foil, whose other dimensions are constrained by a ceramic substrate.

Ammeter shunts

An ammeter shunt is a special type of current-sensing resistor, having four terminals and a value in milliohms or even micro-ohms. Current-measuring instruments, by themselves, can usually accept only limited currents. To measure high currents, the current passes through the shunt across which the voltage drop is measured and interpreted as current. A typical shunt consists of two solid metal blocks, sometimes brass, mounted on an insulating base. Between the blocks, and soldered or brazed to them, are one or more strips of low temperature coefficient of resistance (TCR) manganin alloy. Large bolts threaded into the blocks make the current connections, while much smaller screws provide volt meter connections. Shunts are rated by full-scale current, and often have a voltage drop of 50 mV at rated current. Such meters are adapted to the shunt full current rating by using an appropriately marked dial face; no change need to be made to the other parts of the meter.Grid resistor

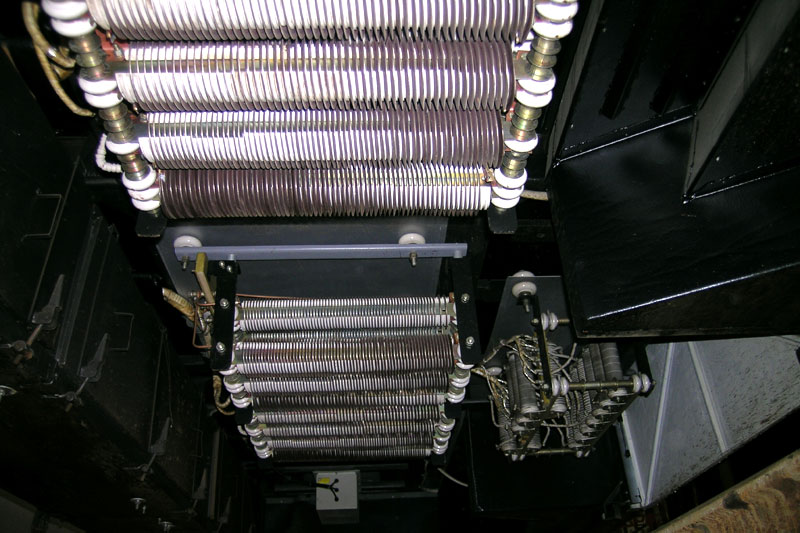

In heavy-duty industrial high-current applications, a grid resistor is a large convection-cooled lattice of stamped metal alloy strips connected in rows between two electrodes. Such industrial grade resistors can be as large as a refrigerator; some designs can handle over 500 amperes of current, with a range of resistances extending lower than 0.04 ohms. They are used in applications such as dynamic braking and load banking for locomotives and trams, neutral grounding for industrial AC distribution, control loads for cranes and heavy equipment, load testing of generators and harmonic filtering for electric substations. The term ''grid resistor'' is sometimes used to describe a resistor of any type connected to the control grid of aSpecial varieties

* Cermet * Phenolic *Variable resistors

Adjustable resistors

A resistor may have one or more fixed tapping points so that the resistance can be changed by moving the connecting wires to different terminals. Some wirewound power resistors have a tapping point that can slide along the resistance element, allowing a larger or smaller part of the resistance to be used. Where continuous adjustment of the resistance value during operation of equipment is required, the sliding resistance tap can be connected to a knob accessible to an operator. Such a device is called a rheostat and has two terminals.Potentiometers

A potentiometer (colloquially, ''pot'') is a three-terminal resistor with a continuously adjustable tapping point controlled by rotation of a shaft or knob or by a linear slider. The name ''potentiometer'' comes from its function as an adjustable voltage divider to provide a variable potential at the terminal connected to the tapping point. Volume control in an audio device is a common application of a potentiometer. A typical low power potentiometer ''(see drawing)'' is constructed of a flat resistance element ''(B)'' of carbon composition, metal film, or conductive plastic, with a springy

A potentiometer (colloquially, ''pot'') is a three-terminal resistor with a continuously adjustable tapping point controlled by rotation of a shaft or knob or by a linear slider. The name ''potentiometer'' comes from its function as an adjustable voltage divider to provide a variable potential at the terminal connected to the tapping point. Volume control in an audio device is a common application of a potentiometer. A typical low power potentiometer ''(see drawing)'' is constructed of a flat resistance element ''(B)'' of carbon composition, metal film, or conductive plastic, with a springy Resistance decade boxes

A resistance decade box or resistor substitution box is a unit containing resistors of many values, with one or more mechanical switches which allow any one of various discrete resistances offered by the box to be dialed in. Usually the resistance is accurate to high precision, ranging from laboratory/calibration grade accuracy of 20 parts per million, to field grade at 1%. Inexpensive boxes with lesser accuracy are also available. All types offer a convenient way of selecting and quickly changing a resistance in laboratory, experimental and development work without needing to attach resistors one by one, or even stock each value. The range of resistance provided, the maximum resolution, and the accuracy characterize the box. For example, one box offers resistances from 0 to 100 megohms, maximum resolution 0.1 ohm, accuracy 0.1%.Special devices

There are various devices whose resistance changes with various quantities. The resistance of NTC thermistors exhibit a strong negative temperature coefficient, making them useful for measuring temperatures. Since their resistance can be large until they are allowed to heat up due to the passage of current, they are also commonly used to prevent excessive current surges when equipment is powered on. Similarly, the resistance of a humistor varies with humidity. One sort of photodetector, the photoresistor, has a resistance which varies with illumination. The strain gauge, invented by Edward E. Simmons and Arthur C. Ruge in 1938, is a type of resistor that changes value with applied strain. A single resistor may be used, or a pair (half bridge), or four resistors connected in a Wheatstone bridge configuration. The strain resistor is bonded with adhesive to an object that is subjected to mechanical strain. With the strain gauge and a filter, amplifier, and analog/digital converter, the strain on an object can be measured. A related but more recent invention uses a Quantum Tunnelling Composite to sense mechanical stress. It passes a current whose magnitude can vary by a factor of 1012 in response to changes in applied pressure.Measurement

The value of a resistor can be measured with an ohmmeter, which may be one function of aStandards

Production resistors

Resistor characteristics are quantified and reported using various national standards. In the US, MIL-STD-202 contains the relevant test methods to which other standards refer. There are various standards specifying properties of resistors for use in equipment: * IEC 60062 (IEC 62) / DIN 40825 / BS 1852 / IS 8186 / JIS C 5062 etc. ( Resistor color code, RKM code, date code) * EIA RS-279 / DIN 41429 (Resistor color code) * IEC 60063 (IEC 63) / JIS C 5063 (Standard E series values) * MIL-PRF-26 * MIL-PRF-39007 (Fixed power, established reliability) * MIL-PRF-55342 (Surface-mount thick and thin film) * MIL-PRF-914 * MIL-R-11 Standard Canceled * MIL-R-39017 (Fixed, General Purpose, Established Reliability) * MIL-PRF-32159 (zero ohm jumpers) * UL 1412 (fusing and temperature limited resistors) There are other United States military procurement MIL-R- standards.Resistance standards

The primary standard for resistance, the "mercury ohm" was initially defined in 1884 in as a column of mercury 106.3 cm long and in cross-section, at . Difficulties in precisely measuring the physical constants to replicate this standard result in variations of as much as 30 ppm. From 1900 the mercury ohm was replaced with a precision machined plate of manganin. Since 1990 the international resistance standard has been based on the quantized Hall effect discovered by Klaus von Klitzing, for which he won the Nobel Prize in Physics in 1985. Resistors of extremely high precision are manufactured for calibration andResistor marking

Axial resistor cases are usually tan, brown, blue, or green (though other colors are occasionally found as well, such as dark red or dark gray), and display three to six colored stripes that indicate resistance (and by extension tolerance), and may include bands to indicate the temperature coefficient and reliability class. In four-striped resistors, the first two stripes represent the first two digits of the resistance in ohms, the third represents a multiplier, and the fourth the tolerance (which if absent, denotes ±20%). For five- and six- striped resistors the third band is the third digit, the fourth is the multiplier and the fifth is the tolerance; a sixth stripe represents the temperature coefficient. The power rating of the resistor is usually not marked and is deduced from its size.

Axial resistor cases are usually tan, brown, blue, or green (though other colors are occasionally found as well, such as dark red or dark gray), and display three to six colored stripes that indicate resistance (and by extension tolerance), and may include bands to indicate the temperature coefficient and reliability class. In four-striped resistors, the first two stripes represent the first two digits of the resistance in ohms, the third represents a multiplier, and the fourth the tolerance (which if absent, denotes ±20%). For five- and six- striped resistors the third band is the third digit, the fourth is the multiplier and the fifth is the tolerance; a sixth stripe represents the temperature coefficient. The power rating of the resistor is usually not marked and is deduced from its size.

Preferred values

Early resistors were made in more or less arbitrary round numbers; a series might have 100, 125, 150, 200, 300, etc. Early power wirewound resistors, such as brown vitreous-enameled types, were made with a system of preferred values like some of those mentioned here. Resistors as manufactured are subject to a certain percentage tolerance, and it makes sense to manufacture values that correlate with the tolerance, so that the actual value of a resistor overlaps slightly with its neighbors. Wider spacing leaves gaps; narrower spacing increases manufacturing and inventory costs to provide resistors that are more or less interchangeable. A logical scheme is to produce resistors in a range of values which increase in a geometric progression, so that each value is greater than its predecessor by a fixed multiplier or percentage, chosen to match the tolerance of the range. For example, for a tolerance of ±20% it makes sense to have each resistor about 1.5 times its predecessor, covering a decade in 6 values. More precisely, the factor used is 1.4678 ≈ , giving values of 1.47, 2.15, 3.16, 4.64, 6.81, 10 for the 1–10-decade (a decade is a range increasing by a factor of 10; 0.1–1 and 10–100 are other examples); these are rounded in practice to 1.5, 2.2, 3.3, 4.7, 6.8, 10; followed by 15, 22, 33, ... and preceded by ... 0.47, 0.68, 1. This scheme has been adopted as the E6 series of the IEC 60063 preferred number values. There are also E12, E24, E48, E96 and E192 series for components of progressively finer resolution, with 12, 24, 48, 96, and 192 different values within each decade. The actual values used are in the IEC 60063 lists of preferred numbers. A resistor of 100 ohms ±20% would be expected to have a value between 80 and 120 ohms; its E6 neighbors are 68 (54–82) and 150 (120–180) ohms. A sensible spacing, E6 is used for ±20% components; E12 for ±10%; E24 for ±5%; E48 for ±2%, E96 for ±1%; E192 for ±0.5% or better. Resistors are manufactured in values from a few milliohms to about a gigaohm in IEC60063 ranges appropriate for their tolerance. Manufacturers may sort resistors into tolerance-classes based on measurement. Accordingly, a selection of 100 ohms resistors with a tolerance of ±10%, might not lie just around 100 ohm (but no more than 10% off) as one would expect (a bell-curve), but rather be in two groups – either between 5 and 10% too high or 5 to 10% too low (but not closer to 100 ohm than that) because any resistors the factory had measured as being less than 5% off would have been marked and sold as resistors with only ±5% tolerance or better. When designing a circuit, this may become a consideration. This process of sorting parts based on post-production measurement is known as "binning", and can be applied to other components than resistors (such as speed grades for CPUs).SMT resistors

Surface mounted resistors of larger sizes (metric 1608 and above) are printed with numerical values in a code related to that used on axial resistors. Standard-tolerance surface-mount technology (SMT) resistors are marked with a three-digit code, in which the first two digits are the first two

Surface mounted resistors of larger sizes (metric 1608 and above) are printed with numerical values in a code related to that used on axial resistors. Standard-tolerance surface-mount technology (SMT) resistors are marked with a three-digit code, in which the first two digits are the first two Precision resistor markings

Many precision resistors, including surface mount and axial-lead types, are marked with a four-digit code. The first three digits are the significant figures and the fourth is the power of ten. For example: * 1001 = 100 × 101 Ω = 1.00 kΩ * 4992 = 499 × 102 Ω = 49.9 kΩ * 1000 = 100 × 100 Ω = 100 Ω Axial-lead precision resistors often use color code bands to represent this four-digit code.EIA-96 marking

The former EIA-96 marking system now included in IEC 60062:2016 is a more compact marking system intended for physically small high-precision resistors. It uses a two-digit code plus a letter (a total of three alphanumeric characters) to indicate 1% resistance values to three significant digits. The two digits (from "01" to "96") are a code that indicates one of the 96 "positions" in the standard E96 series of 1% resistor values. The uppercase letter is a code that indicates aIndustrial type designation

Steps to find out the resistance or capacitance values: # First two letters gives the power dissipation capacity. # Next three digits gives the resistance value. ## First two digits are the significant values ## Third digit is the multiplier. # Final digit gives the tolerance. If a resistor is coded: * EB1041: power dissipation capacity = 1/2 watts, resistance value = ±10% = between ohms and ohms. * CB3932: power dissipation capacity = 1/4 watts, resistance value = ±20% = between and ohms.Common usage patterns

There are several common usage patterns that resistors are commonly configured in.Current limiting

Resistors are commonly used to limit the amount of current flowing through a circuit. Many circuit components (such as LEDs) require the current flowing through them to be limited, but do not themselves limit the amount of current. Therefore, oftentimes resistors will be added to prevent overcurrent situations. Additionally, oftentimes circuits do not need the amount of current that would be otherwise flowing through them, so resistors can be added to limit the power consumption of such circuits.Voltage divider

Oftentimes circuits need to provide various reference voltages for other circuits (such as voltage comparators). A fixed voltage can be obtained by taking two resistors in series between two other fixed voltages (such as the source voltage and ground). The terminal between the two resistors will be at a voltage that is between the two voltages, at a linear distance based on the relative resistances of the two resistors. For instance, if a 200 ohm resistor and a 400 ohm resistor are placed in series between 6 V and 0 V, the terminal between them will be at 4 V.Pull-down and pull-up resistors

When a circuit is not connected to power, the voltage of that circuit is not zero but undefined (it can be influenced by previous voltages or the environment). A pull-up or pull-down resistor provides a voltage for a circuit when it is otherwise disconnected (such as when a button is not pushed down or a transistor is not active). A pull-up resistor connects the circuit to a high positive voltage (if the circuit requires a high positive default voltage) and a pull-down resistor connects the circuit to a low voltage or ground (if the circuit requires a low default voltage). The resistor value must be high enough so that, when the circuit is active, the voltage source it is attached to does not over influence the function of the circuit, but low enough so that it "pulls" quickly enough when the circuit is deactivated, and does not significantly alter the voltage from the source value.Electrical and thermal noise

In amplifying faint signals, it is often necessary to minimize electronic noise, particularly in the first stage of amplification. As a dissipative element, even an ideal resistor naturally produces a randomly fluctuating voltage, or noise, across its terminals. This Johnson–Nyquist noise is a fundamental noise source which depends only upon the temperature and resistance of the resistor, and is predicted by the fluctuation–dissipation theorem. Using a larger value of resistance produces a larger voltage noise, whereas a smaller value of resistance generates more current noise, at a given temperature. The thermal noise of a practical resistor may also be larger than the theoretical prediction and that increase is typically frequency-dependent. Excess noise of a practical resistor is observed only when current flows through it. This is specified in unit of μV/V/decade – μV of noise per volt applied across the resistor per decade of frequency. The μV/V/decade value is frequently given in dB so that a resistor with a noise index of 0 dB exhibits 1 μV (rms) of excess noise for each volt across the resistor in each frequency decade. Excess noise is thus an example of 1/''f'' noise. Thick-film and carbon composition resistors generate more excess noise than other types at low frequencies. Wire-wound and thin-film resistors are often used for their better noise characteristics. Carbon composition resistors can exhibit a noise index of 0 dB while bulk metal foil resistors may have a noise index of −40 dB, usually making the excess noise of metal foil resistors insignificant. Thin film surface mount resistors typically have lower noise and better thermal stability than thick film surface mount resistors. Excess noise is also size-dependent: in general, excess noise is reduced as the physical size of a resistor is increased (or multiple resistors are used in parallel), as the independently fluctuating resistances of smaller components tend to average out. While not an example of "noise" per se, a resistor may act as a thermocouple, producing a small DC voltage differential across it due to the thermoelectric effect if its ends are at different temperatures. This induced DC voltage can degrade the precision of instrumentation amplifiers in particular. Such voltages appear in the junctions of the resistor leads with the circuit board and with the resistor body. Common metal film resistors show such an effect at a magnitude of about 20 μV/°C. Some carbon composition resistors can exhibit thermoelectric offsets as high as 400 μV/°C, whereas specially constructed resistors can reduce this number to 0.05 μV/°C. In applications where the thermoelectric effect may become important, care has to be taken to mount the resistors horizontally to avoid temperature gradients and to mind the air flow over the board.Failure modes

The failure rate of resistors in a properly designed circuit is low compared to other electronic components such as semiconductors and electrolytic capacitors. Damage to resistors most often occurs due to overheating when the average power delivered to it greatly exceeds its ability to dissipate heat (specified by the resistor's ''power rating''). This may be due to a fault external to the circuit but is frequently caused by the failure of another component (such as a transistor that shorts out) in the circuit connected to the resistor. Operating a resistor too close to its power rating can limit the resistor's lifespan or cause a significant change in its resistance. A safe design generally uses overrated resistors in power applications to avoid this danger. Low-power thin-film resistors can be damaged by long-term high-voltage stress, even below maximum specified voltage and below maximum power rating. This is often the case for the startup resistors feeding a switched-mode power supply integrated circuit. When overheated, carbon-film resistors may decrease or increase in resistance. Carbon film and composition resistors can fail (open circuit) if running close to their maximum dissipation. This is also possible but less likely with metal film and wirewound resistors. There can also be failure of resistors due to mechanical stress and adverse environmental factors including humidity. If not enclosed, wirewound resistors can corrode. Surface mount resistors have been known to fail due to the ingress of sulfur into the internal makeup of the resistor. This sulfur chemically reacts with the silver layer to produce non-conductive silver sulfide. The resistor's impedance goes to infinity. Sulfur resistant and anti-corrosive resistors are sold into automotive, industrial, and military applications. ASTM B809 is an industry standard that tests a part's susceptibility to sulfur. An alternative failure mode can be encountered where large value resistors are used (hundreds of kilohms and higher). Resistors are not only specified with a maximum power dissipation, but also for a maximum voltage drop. Exceeding this voltage causes the resistor to degrade slowly reducing in resistance. The voltage dropped across large value resistors can be exceeded before the power dissipation reaches its limiting value. Since the maximum voltage specified for commonly encountered resistors is a few hundred volts, this is a problem only in applications where these voltages are encountered. Variable resistors can also degrade in a different manner, typically involving poor contact between the wiper and the body of the resistance. This may be due to dirt or corrosion and is typically perceived as "crackling" as the contact resistance fluctuates; this is especially noticed as the device is adjusted. This is similar to crackling caused by poor contact in switches, and like switches, potentiometers are to some extent self-cleaning: running the wiper across the resistance may improve the contact. Potentiometers which are seldom adjusted, especially in dirty or harsh environments, are most likely to develop this problem. When self-cleaning of the contact is insufficient, improvement can usually be obtained through the use of contact cleaner (also known as "tuner cleaner") spray. The crackling noise associated with turning the shaft of a dirty potentiometer in an audio circuit (such as the volume control) is greatly accentuated when an undesired DC voltage is present, often indicating the failure of a DC blocking capacitor in the circuit.See also

* Circuit design * Dummy load *References

External links

Color Coded Resistance Calculator

- University of Pennsylvania

- Aiken Amps

- Analog Devices

Basics of Linear Fixed Resistors

- Vishay

- PSL

- ESP {{Authority control Electrical components Electric heating Resistive components