Reinforcement (composite) on:

[Wikipedia]

[Google]

[Amazon]

In

In

In

In materials science

Materials science is an interdisciplinary field of researching and discovering materials. Materials engineering is an engineering field of finding uses for materials in other fields and industries.

The intellectual origins of materials sci ...

, reinforcement is a constituent of a composite material

A composite or composite material (also composition material) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a ...

which increases the composite's stiffness

Stiffness is the extent to which an object resists deformation in response to an applied force.

The complementary concept is flexibility or pliability: the more flexible an object is, the less stiff it is.

Calculations

The stiffness, k, of a ...

and tensile strength

Ultimate tensile strength (also called UTS, tensile strength, TS, ultimate strength or F_\text in notation) is the maximum stress that a material can withstand while being stretched or pulled before breaking. In brittle materials, the ultimate ...

.

Function

Following are the functions of the reinforcement in a composite: * It increases the mechanical properties of the composite. * It provides strength and stiffness to the composite in one direction as reinforcement carries the load along the length of the fibre.Fiber reinforcement

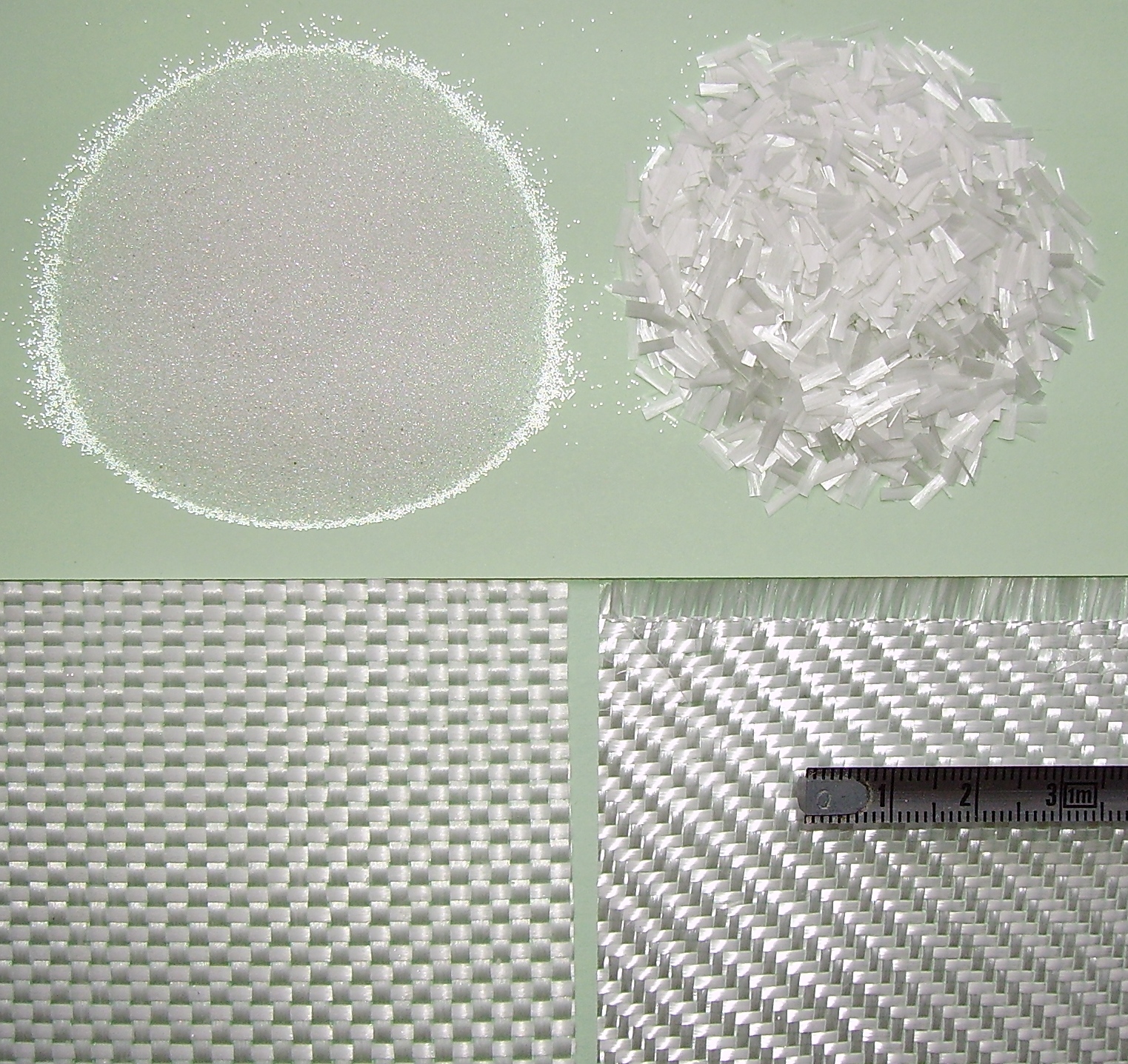

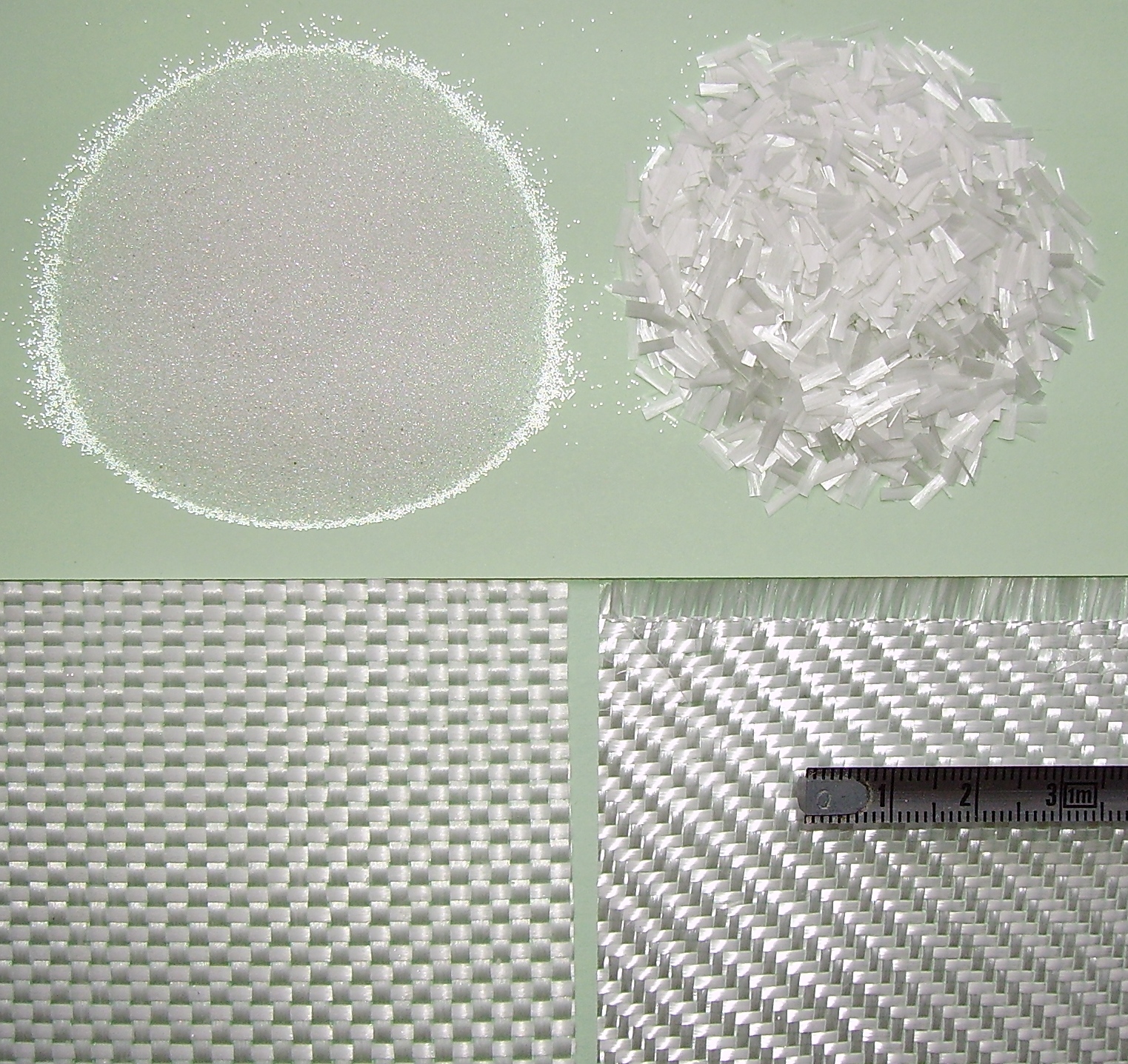

Crack propagation is prevented considerably, while rigidity is added normally by the reinforcement. Thin fibers can have very high strength, and they can increase substantially the overall properties of the composite provided they are linked mechanically to the matrix. Fiber-reinforced composites have two types, and they are short fibre-reinforced and continuous fiber-reinforced. Sheet moulding and compression moulding operations usually use the long and short fibers. These are available in the form of chips, flakes and random mate (which also can be produced from a continuous fibre laid randomly till the desired thickness of the laminate/ply is attained). A laminated or layered structure is usually constituted in continuous reinforced materials. The continuous and woven fiber styles are usually available in various forms, being pre-impregnated with the given matrix (resin), dry, uni-directional tapes of different widths, plain weave, harness satins, braided, and stitched. Reinforcement uses some of the common fibers such as carbon fibres, cellulose (wood/paper fibre and straw), glass fibers and high strength polymers, for example,aramid

Aramid fibers, short for aromatic polyamide, are a class of heat-resistant and strong synthetic fibers. They are used in aerospace and military applications, for ballistic-rated bulletproof vest, body armor cloth, fabric and ballistic composites ...

. For high-temperature applications, Silicon carbide

Silicon carbide (SiC), also known as carborundum (), is a hard chemical compound containing silicon and carbon. A wide bandgap semiconductor, it occurs in nature as the extremely rare mineral moissanite, but has been mass-produced as a powder a ...

fibers are used.

Particle reinforcement

Particle reinforcement adds a similar effect to precipitation hardening in metals and ceramics. Large particles prevent dislocation movement and crack propagation as well as contribute to the composite'sYoung's Modulus

Young's modulus (or the Young modulus) is a mechanical property of solid materials that measures the tensile or compressive stiffness when the force is applied lengthwise. It is the modulus of elasticity for tension or axial compression. Youn ...

. In general, particle reinforcement effect on Young's Modulus lies between values predicted by

as a lower bound and

as an upper bound.

Therefore, it can be expressed as a linear combination of contribution from the matrix and some weighted contribution from the particles.

Where Kc is an experimentally derived constant between 0 and 1. This range of values for Kc reflects that particle reinforced composites are not characterized by the isostrain condition.

Similarly, the tensile strength can be modeled in an equation of similar construction where Ks is a similarly bounded constant not necessarily of the same value of Kc

The true value of Kc and Ks vary based on factors including particle shape, particle distribution, and particle/matrix interface. Knowing these parameters, the mechanical properties can be modeled based on effects from grain boundary strengthening, dislocation strengthening, and Orowan strengthening.

The most common particle reinforced composite is concrete, which is a mixture of gravel and sand usually strengthened by addition of small rocks or sand. Metals are often reinforced with ceramics

A ceramic is any of the various hard, brittle, heat-resistant, and corrosion-resistant materials made by shaping and then firing an inorganic, nonmetallic material, such as clay, at a high temperature. Common examples are earthenware, porce ...

to increase strength at the cost of ductility

Ductility refers to the ability of a material to sustain significant plastic Deformation (engineering), deformation before fracture. Plastic deformation is the permanent distortion of a material under applied stress, as opposed to elastic def ...

. Finally polymers and rubber are often reinforced with carbon black, commonly used in auto tires.

References

{{Reflist Composite materials