Lift Slab Construction on:

[Wikipedia]

[Google]

[Amazon]

Lift slab construction (also called the Youtz-Slick Method) is a method of constructing

Lift slab construction (also called the Youtz-Slick Method) is a method of constructing

Johnstone Hall, a

Johnstone Hall, a

http://cedb.asce.org/CEDBsearch/record.jsp?dockey=0086682 .

# Porter, J.B., and Building Research Institute. ''Lift-Slab Construction: Its Implications in Building Design and Engineering''. Building Research Institute, Division of Engineering and Industrial Research, National Academy of Sciences, National Research Council, 1955. https://books.google.com/books?id=aUsrAAAAYAAJ .

Northrup Hall construction

Concrete Building engineering Structural system

Lift slab construction (also called the Youtz-Slick Method) is a method of constructing

Lift slab construction (also called the Youtz-Slick Method) is a method of constructing concrete

Concrete is a composite material composed of aggregate bound together with a fluid cement that cures to a solid over time. It is the second-most-used substance (after water), the most–widely used building material, and the most-manufactur ...

buildings by casting

Casting is a manufacturing process in which a liquid material is usually poured into a mold, which contains a hollow cavity of the desired shape, and then allowed to solidify. The solidified part is also known as a casting, which is ejected or ...

the floor or roof slab on top of the previous slab and then raising (jacking) the slab up with hydraulic jack

A jack is a mechanical lifting device used to apply great forces or lift heavy loads. A mechanical jack employs a screw thread for lifting heavy equipment. A hydraulic jack uses hydraulic machinery, hydraulic power. The most common form is a car ...

s. This method of construction allows for a large portion of the work to be completed at ground level, negating the need to form floor work in place. The ability to create monolithic concrete slab

A concrete slab is a common structural element of modern buildings, consisting of a flat, horizontal surface made of cast concrete. Steel- reinforced slabs, typically between 100 and 500 mm thick, are most often used to construct floors and ...

s makes the lift slab construction technique useful in quickly creating structures with repetitive form work, like parking ramps.

History

This method of construction simultaneously began development in 1948 by both Philip N. Youtz of New York and Thomas B Slick of Texas. Although the first patent for lift slab construction was given to Slick in 1955, the method of construction is commonly referred to as the "Youtz-Slick Method". His patent called for a method that would allow for fabrication to be completed at the ground level, eliminate a large portion of theformwork

Formwork is Molding (process), molds into which concrete or similar materials are either precast concrete, precast or cast-in-place concrete, cast-in-place. In the context of concrete construction, the falsework supports the shuttering mold ...

, create uniform floors of concrete, and reduce the labor to be completed at an elevated level.

Applications of lift slab construction

The method was first used at Trinity University inSan Antonio

San Antonio ( ; Spanish for " Saint Anthony") is a city in the U.S. state of Texas and the most populous city in Greater San Antonio. San Antonio is the third-largest metropolitan area in Texas and the 24th-largest metropolitan area in the ...

, Texas

Texas ( , ; or ) is the most populous U.S. state, state in the South Central United States, South Central region of the United States. It borders Louisiana to the east, Arkansas to the northeast, Oklahoma to the north, New Mexico to the we ...

during the construction of Northup Hall in 1952. Northrup Hall was the first full scale building erected using lift slab construction. Being such, the process drew a crowd of spectators, waiting to see if the structural integrity of the building would hold.

Johnstone Hall, a

Johnstone Hall, a Clemson University

Clemson University () is a Public university, public Land-grant university, land-grant research university near Clemson, South Carolina, United States. - The blue-shaded pattern denotes university property. This shows Clemson University is ''out ...

dormitory in Clemson, South Carolina

South Carolina ( ) is a U.S. state, state in the Southeastern United States, Southeastern region of the United States. It borders North Carolina to the north and northeast, the Atlantic Ocean to the southeast, and Georgia (U.S. state), Georg ...

, was erected using this method in 1954, as did Woodrow Wilson High School in the same year. Several of the blocks from Johnstone Hall have now been demolished.

The building located at 2150 Shattuck Avenue in Berkeley, CA (or First Savings Building) is one example of lift slab construction utilized in the Bay Area in the mid-twentieth century. Built in 1969, the First Savings Building utilizes lift slab construction to support the fourteen story height of the building. The building's structural system consists of a system of trusses from which the various concrete slab floors are hung. In turn, these trusses extend out from two reinforced concrete cores which provide the main structural support for the entirety of the building.

Lift slab construction was also involved in the L'Ambiance Plaza collapse in Bridgeport

Bridgeport is the most populous city in the U.S. state of Connecticut and the fifth-most populous city in New England, with a population of 148,654 in 2020. Located in eastern Fairfield County at the mouth of the Pequonnock River on Long Is ...

, Connecticut, in 1987, and resulted in a nationwide federal investigation into this construction technique in the United States, and Connecticut imposed a temporary moratorium on lift slab construction. The failure of the structure has been primarily attributed to instability with the steel columns that were meant to support the floors. Although other factors were involved in the collapse while under construction, it is the insufficient lateral bracing that ultimately caused the structural failure.

Northminster Car Park in Peterborough, England, built using the lift slab technique, was found to be unsafe and beyond economic repair in 2019.

Process

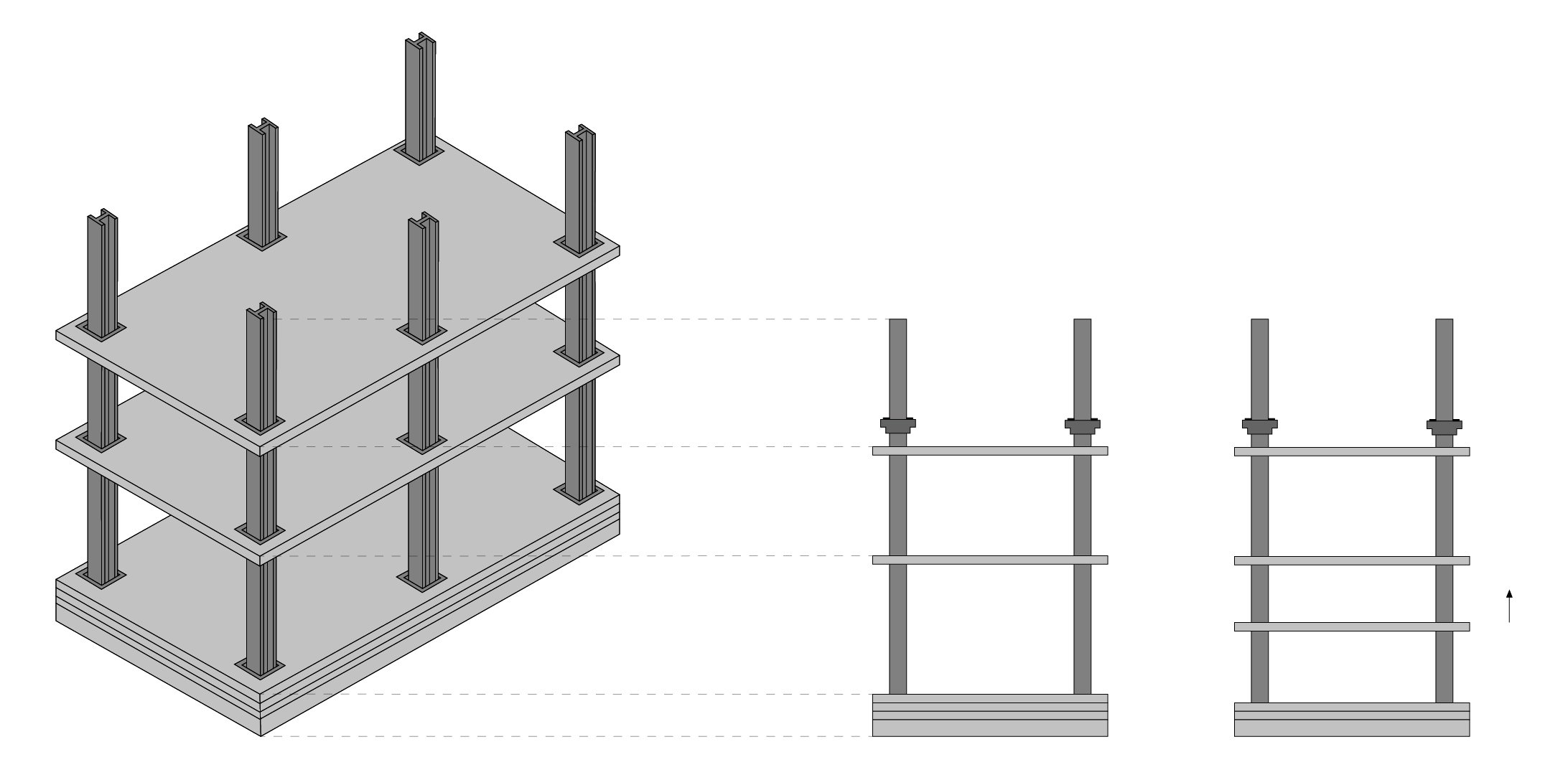

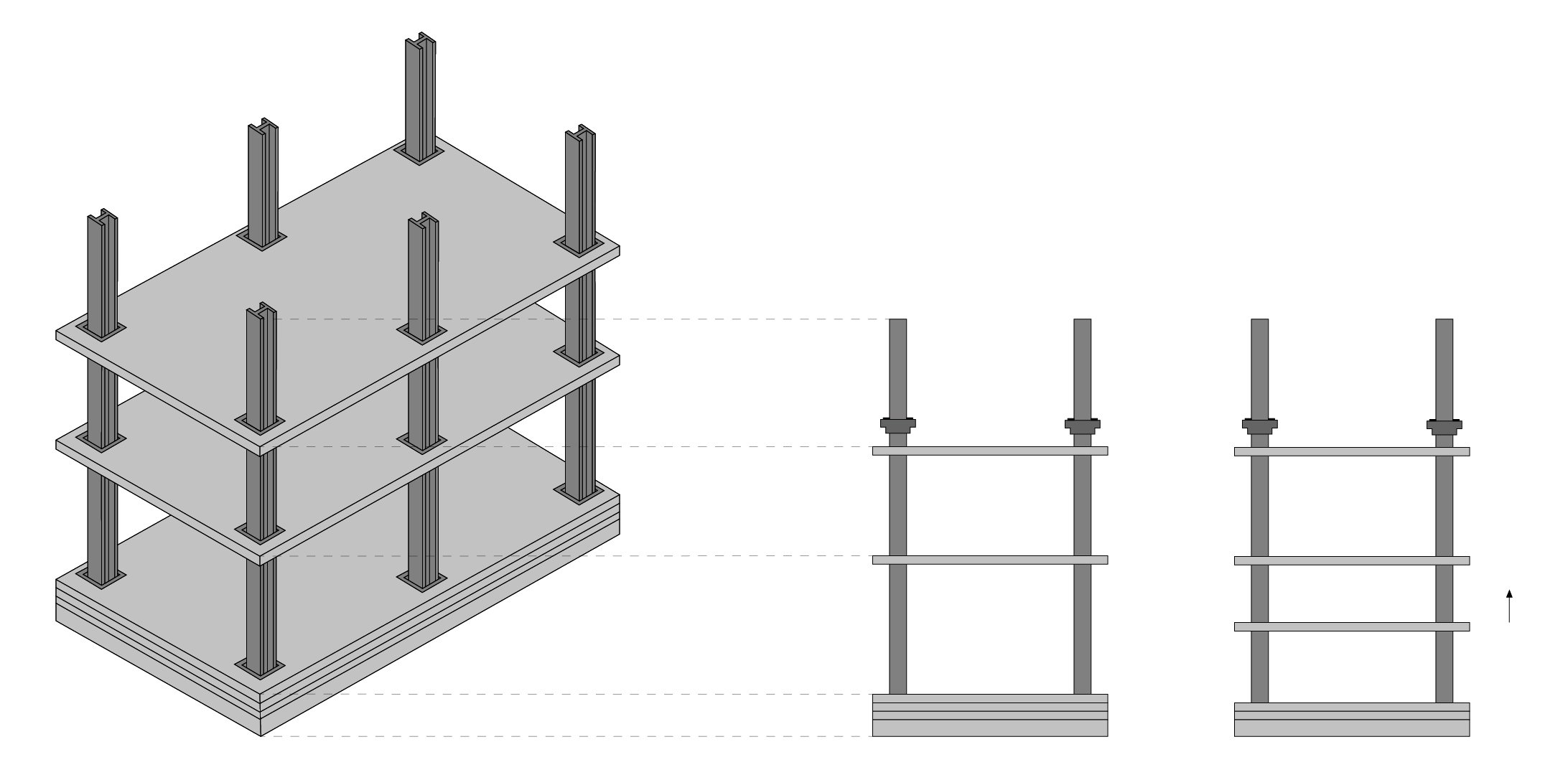

Concrete

To begin, a concrete slab is first poured on the ground level. Lifting collars are set around each of the columns and cast into place as the slab is poured around them. The lifting collars will later be used to support the slab as it is raised and secured in place. Subsequent floors and the roof are then poured and formed on top of the initial ground slab. Bond breakers are used between each floor plate to allow the slabs to separate as they are raised.Brannigan, F.L. ''Building Construction for the Fire Service''. Jones & Bartlett Learning, LLC, 2006. Along with reducing the formwork required to create the slabs, slabs can be easily protected from inclement weather since all of the slabs remain together during the curing process.Lifting

Once the slabs have been raised to their desired height the lifting collars are welded to the columns, along with shear blocks to support the slab from beneath. To assure the security of a structure during the raising of the slabs, the hydraulic jacks, attached to the top of the columns, use synchronized consoles to lift the slabs at an even rate. Conventional methods of mounting the jacks to the columns require that the jacks are removed before continuing to raise the slabs. More recent approaches utilize welded plates, separated from the columns, to support the jack.Simultaneous floor and wall construction

In Latin America, contractors have started to use a form of lift slab construction where load-bearing concrete walls are raised at the same time as the floor slabs. Both the wall panels and the floor slabs are cast on the ground. The walls are attached to the slabs through hinges formed by plastic ropes. As the floors are raised, the walls unfold into place and form the vertical support for the system.See also

* Tilt slabReferences

Further reading

# Elazouni, AM, and ME Abd El-Razek. “Adapting Lift-Slab Technology to Construct Submerged Pile Caps.” ''Journal of Construction Engineering and Management'' 126, no. 2 (March 1, 2000): 149,157. # Masih, Rusk. “Stability of Lift Slab Structure During Construction Stage,” 271–77. ASCE, 1994.External links

*{{US patent, 2715013, ''Apparatus for erecting a building'', filed July 1948, issued August, 1955Northrup Hall construction

Concrete Building engineering Structural system