False Brinelling on:

[Wikipedia]

[Google]

[Amazon]

False brinelling is a bearing damage caused by

False brinelling is a bearing damage caused by

Bearings of modern

Bearings of modern

Emerson Bearing picture of false Brinelling

US Motors service bulletin case study, explanation, and pictures

(PDF) {{DEFAULTSORT:False Brinelling Tribology Metallurgy Bearings (mechanical)

False brinelling is a bearing damage caused by

False brinelling is a bearing damage caused by fretting

Fretting refers to wear and sometimes corrosion damage of loaded surfaces in contact while they encounter small oscillatory movements tangential to the surface. Fretting is caused by adhesion of contact surface asperities, which are subsequent ...

, with or without corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engine ...

, that causes imprints that look similar to brinelling, but are caused by a different mechanism. False brinelling may occur in bearings which act under small oscillations or vibrations.

The basic cause of false brinelling is that the design of the bearing does not have a method for redistribution of lubricant

A lubricant (sometimes shortened to lube) is a substance that helps to reduce friction between surfaces in mutual contact, which ultimately reduces the heat generated when the surfaces move. It may also have the function of transmitting forces, t ...

without large rotational movement of all bearing surfaces in the raceway. Lubricant is pushed out of a loaded region during small oscillatory movements and vibration where the bearings surfaces repeatedly do not move very far. Without lubricant, wear is increased when the small oscillatory movements occur again. It is possible for the resulting wear

Wear is the damaging, gradual removal or deformation of material at solid surfaces. Causes of wear can be mechanical (e.g., erosion) or chemical (e.g., corrosion). The study of wear and related processes is referred to as tribology.

Wear in m ...

debris to oxidize

Redox (reduction–oxidation, , ) is a type of chemical reaction in which the oxidation states of substrate change. Oxidation is the loss of electrons or an increase in the oxidation state, while reduction is the gain of electrons or a d ...

and form an abrasive compound which further accelerates wear.

Mechanism of action

In normal operation, a rolling-element bearing has the rollers and races separated by a thin layer of lubricant such as grease oroil

An oil is any nonpolar chemical substance that is composed primarily of hydrocarbons and is hydrophobic (does not mix with water) & lipophilic (mixes with other oils). Oils are usually flammable and surface active. Most oils are unsaturated ...

. Although these lubricants normally appear liquid (not solid), under high pressure they act as solids and keep the bearing and race

Race, RACE or "The Race" may refer to:

* Race (biology), an informal taxonomic classification within a species, generally within a sub-species

* Race (human categorization), classification of humans into groups based on physical traits, and/or s ...

from touching.

If the lubricant is removed, the bearings and races can touch directly. While bearings and races appear smooth to the eye, they are microscopically rough. Thus, high points of each surface can touch, but "valleys" do not. The bearing load is thus spread over much less area increasing the contact stress

Stress may refer to:

Science and medicine

* Stress (biology), an organism's response to a stressor such as an environmental condition

* Stress (linguistics), relative emphasis or prominence given to a syllable in a word, or to a word in a phrase ...

, causing pieces of each surface to break off or to become pressure-welded then break off when the bearing rolls on.

The broken-off pieces are also called ''wear debris''. Wear debris is bad because it is relatively large compared to the surrounding surface finish and thus creates more regions of high contact stress. Worse, the steel in ordinary bearings can oxidize (rust

Rust is an iron oxide, a usually reddish-brown oxide formed by the reaction of iron and oxygen in the catalytic presence of water or air moisture. Rust consists of hydrous iron(III) oxides (Fe2O3·nH2O) and iron(III) oxide-hydroxide (FeO(OH ...

), producing a more abrasive compound which accelerates wear.

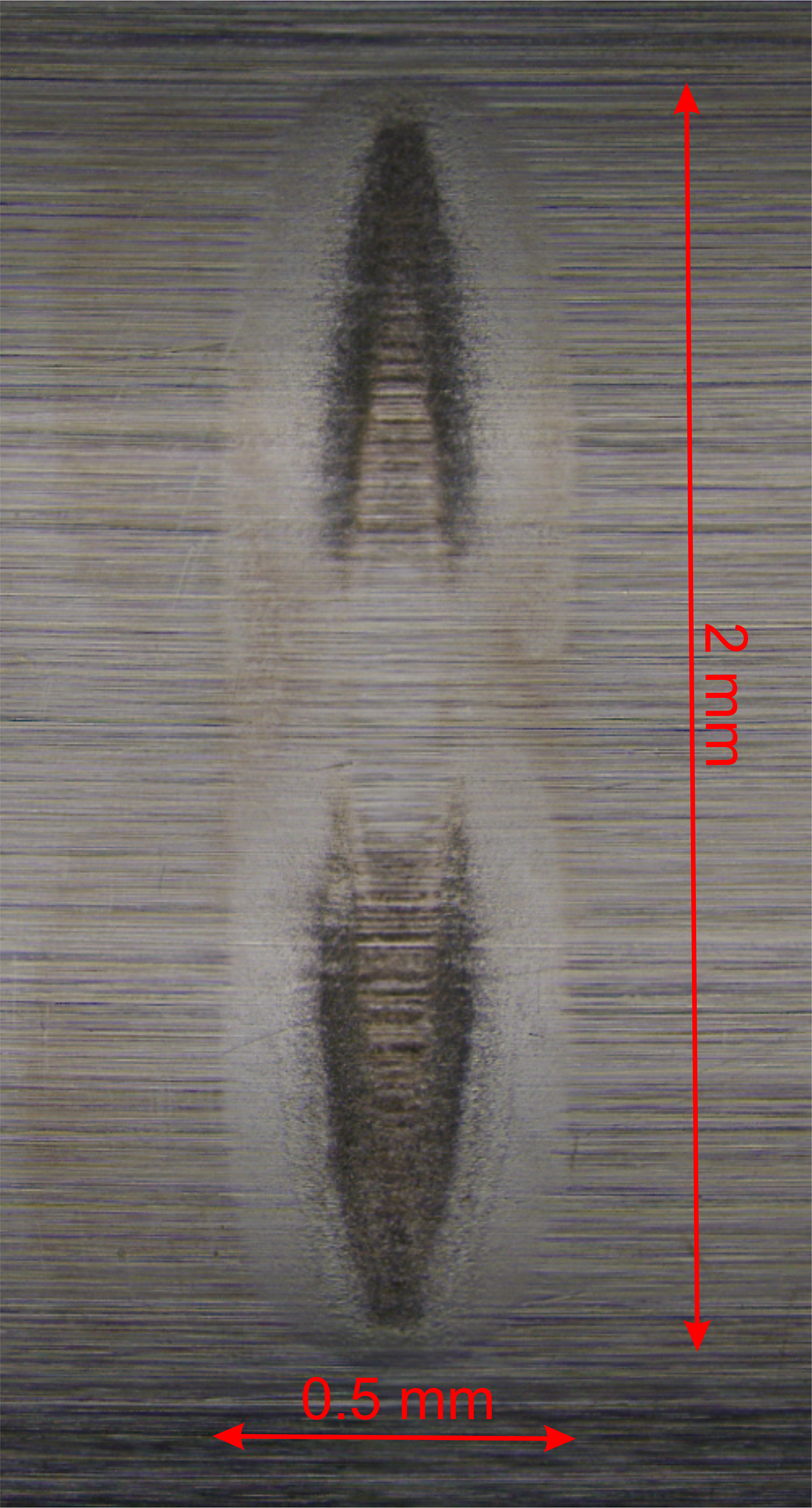

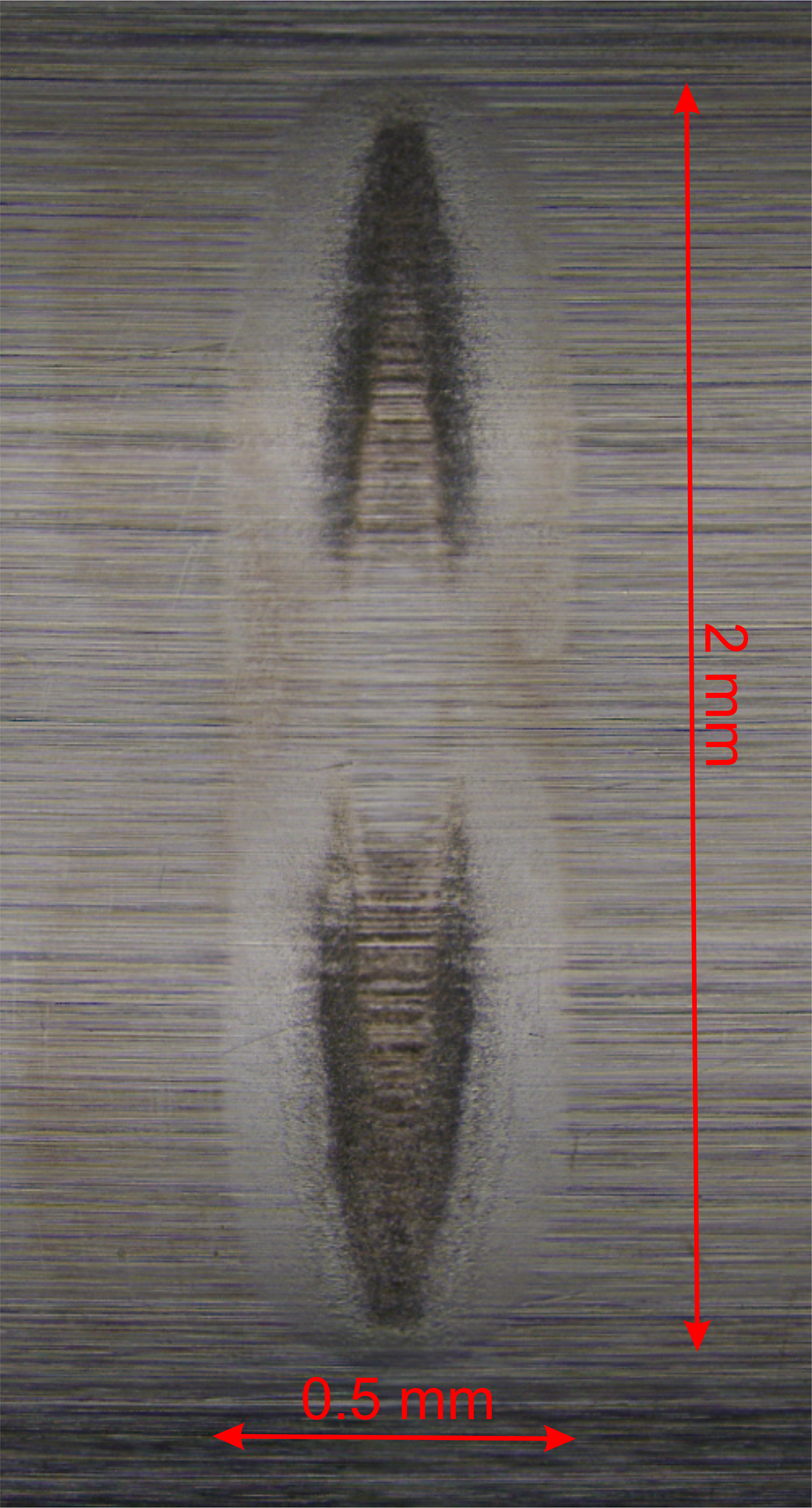

Simulation of false brinelling

The simulation of false brinelling is possible with the help of the finite element method. For the simulation, the relative displacements (slip) between rolling element and raceway as well as the pressure in the rolling contact are determined. For comparison between simulation and experiments, the friction work density is used, which is the product of friction coefficient, slip and local pressure. The simulation results can be used to determine critical application parameters or to explain the damage mechanisms.

Examples

False brinelling was first mentioned by Almen in 1937. Almen found that wheel bearings were damaged before they were used by customers. Furthermore, he found that the bearings were more damaged for long-distance shipping of the cars and that the season of shipping also had an influence. The reason for the damaged bearings were micro-oscillations which occurred due to the shipping. Because the damage has a similar look to brinelling, it was called false brinelling. Although the car-delivery problem has been solved, there are many modern examples. For example,generator

Generator may refer to:

* Signal generator, electronic devices that generate repeating or non-repeating electronic signals

* Electric generator, a device that converts mechanical energy to electrical energy.

* Generator (circuit theory), an eleme ...

s or pump

A pump is a device that moves fluids (liquids or gases), or sometimes slurries, by mechanical action, typically converted from electrical energy into hydraulic energy. Pumps can be classified into three major groups according to the method they u ...

s may fail or need service, so it is common to have a nearby spare unit which is left off most of the time but brought into service when needed. Surprisingly, however, vibration from the operating unit can cause bearing failure in the unit which is switched off. When that unit is turned on, the bearings may be noisy due to damage, and may fail completely within a few days or weeks even though the unit and its bearings are otherwise new. Common solutions include: keeping the spare unit at a distance from the one which is on and vibrating; manually rotating shafts of the spare units on a regular (for example, weekly) basis; or regularly switching between the units so that both are in regular (for example, weekly) operation.

Until recently, bicycle headsets

Headset may refer to:

* Headset (audio), audio headphone(s), particularly with an attached microphone

* Head Set (band), an American alternative rock band

* Headset (bicycle part), a bicycle part that connects the fork to the frame

* Head-mounte ...

tended to suffer from false brinelling in the "straight ahead" steering position, due to small movements caused by flexing of the fork. Good modern headsets incorporate a plain bearing

A plain bearing, or more commonly sliding contact bearing and slide bearing (in railroading sometimes called a solid bearing, journal bearing, or friction bearing), is the simplest type of bearing, comprising just a bearing surface and no rolli ...

to accommodate this flexing, leaving the ball race to provide pure rotational movement.

Bearings of modern

Bearings of modern wind turbine

A wind turbine is a device that converts the kinetic energy of wind into electrical energy. Hundreds of thousands of large turbines, in installations known as wind farms, now generate over 650 gigawatts of power, with 60 GW added each year. ...

s are often affected by false brinelling. Especially the pitch bearing, which is used under oscillation, shows often false brinelling damages.

References

External links

Emerson Bearing picture of false Brinelling

US Motors service bulletin case study, explanation, and pictures

(PDF) {{DEFAULTSORT:False Brinelling Tribology Metallurgy Bearings (mechanical)