Flow shop scheduling on:

[Wikipedia]

[Google]

[Amazon]

Flow-shop scheduling is an

Flow-shop scheduling is an

optimization problem

In mathematics, engineering, computer science and economics

Economics () is a behavioral science that studies the Production (economics), production, distribution (economics), distribution, and Consumption (economics), consumption of goo ...

in computer science

Computer science is the study of computation, information, and automation. Computer science spans Theoretical computer science, theoretical disciplines (such as algorithms, theory of computation, and information theory) to Applied science, ...

and operations research

Operations research () (U.S. Air Force Specialty Code: Operations Analysis), often shortened to the initialism OR, is a branch of applied mathematics that deals with the development and application of analytical methods to improve management and ...

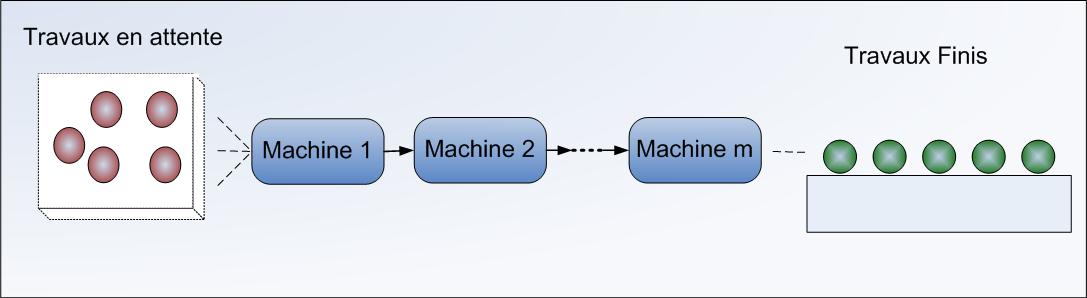

. It is a variant of optimal job scheduling. In a general job-scheduling problem, we are given ''n'' jobs ''J''1, ''J''2, ..., ''Jn'' of varying processing times, which need to be scheduled on ''m'' machines with varying processing power, while trying to minimize the makespan

In operations research

Operations research () (U.S. Air Force Specialty Code: Operations Analysis), often shortened to the initialism OR, is a branch of applied mathematics that deals with the development and application of analytical methods t ...

– the total length of the schedule (that is, when all the jobs have finished processing). In the specific variant known as ''flow-shop scheduling'', each job contains exactly ''m'' operations. The ''i''-th operation of the job must be executed on the ''i''-th machine. No machine can perform more than one operation simultaneously. For each operation of each job, execution time is specified.

Flow-shop scheduling is a special case of job-shop scheduling where there is strict order of all operations to be performed on all jobs. Flow-shop scheduling may apply as well to production facilities as to computing

Computing is any goal-oriented activity requiring, benefiting from, or creating computer, computing machinery. It includes the study and experimentation of algorithmic processes, and the development of both computer hardware, hardware and softw ...

designs. A special type of flow-shop scheduling problem is the permutation flow-shop scheduling problem in which the processing order of the jobs on the resources is the same for each subsequent step of processing.

In the standard three-field notation for optimal-job-scheduling problems, the flow-shop variant is denoted by F in the first field. For example, the problem denoted by " F3, , " is a 3-machines flow-shop problem with unit processing times, where the goal is to minimize the maximum completion time.

Formal definition

There are ''m'' machines and ''n'' jobs. Each job contains exactly ''m'' operations. The ''i''-th operation of the job must be executed on the ''i''-th machine. No machine can perform more than one operation simultaneously. For each operation of each job, execution time is specified. Operations within one job must be performed in the specified order. The first operation gets executed on the first machine, then (as the first operation is finished) the second operation on the second machine, and so on until the ''m''-th operation. Jobs can be executed in any order, however. The problem is to determine the optimal such arrangement, i.e. the one with the shortest possible total job execution makespan.Sequencing performance measurements (γ)

The sequencing problem can be stated as determining a sequence S such that one or several sequencing objectives are optimized. # (Average) Flow time, # Makespan, Cmax # (Average) Tardiness, # .... detailed discussion of performance measurement can be found in Malakooti(2013).Malakooti, B (2013). Operations and Production Systems with Multiple Objectives. John Wiley & Sons. .Complexity of flow-shop scheduling

As presented by Garey et al. (1976), most of extensions of the flow-shop-scheduling problems are NP-hard and few of them can be solved optimally in O(nlogn); for example, F2, prmu, Cmax can be solved optimally by using Johnson's Rule. Taillard provides substantial benchmark problems for scheduling flow shops, open shops, and job shops.Solution methods

The proposed methods to solve flow-shop-scheduling problems can be classified asexact algorithm In computer science and operations research, exact algorithms are algorithms that always solve an optimization problem to optimality.

Unless P = NP, an exact algorithm for an NP-hardness , NP-hard optimization problem cannot run in worst-case poly ...

such as branch and bound

Branch and bound (BB, B&B, or BnB) is a method for solving optimization problems by breaking them down into smaller sub-problems and using a bounding function to eliminate sub-problems that cannot contain the optimal solution.

It is an algorithm ...

and heuristic algorithm

A heuristic or heuristic technique (''problem solving'', '' mental shortcut'', ''rule of thumb'') is any approach to problem solving that employs a pragmatic method that is not fully optimized, perfected, or rationalized, but is nevertheless ...

such as genetic algorithm

In computer science and operations research, a genetic algorithm (GA) is a metaheuristic inspired by the process of natural selection that belongs to the larger class of evolutionary algorithms (EA). Genetic algorithms are commonly used to g ...

.

Minimizing makespan, Cmax

F2, prmu, Cmax and F3, prmu, Cmax can be solved optimally by using Johnson's Rule but for general case there is no algorithm that guarantee the optimality of the solution. The flow shop contains n jobs simultaneously available at time zero and to be processed by two machines arranged in series with unlimited storage in between them. The processing time of all jobs are known with certainty. It is required to schedule n jobs on machines so as to minimize makespan. The Johnson's rule for scheduling jobs in two-machine flow shop is given below. In an optimal schedule, job i precedes job j if ''min < min''. Where as, p1i is the processing time of job i on machine 1 and p2i is the processing time of job i on machine 2. Similarly, p1j and p2j are processing times of job j on machine 1 and machine 2 respectively. For Johnson's algorithm: :Let p1j be the processing time of job j on machine 1 :and p2j the processing time of job j on machine 2 Johnson's algorithm: # Form set1 containing all the jobs with p1j < p2j # Form set2 containing all the jobs with p1j > p2j, the jobs with p1j = p2j may be put in either set. # Form the sequence as follows: #: (i) The job in set1 go first in the sequence and they go in increasing order of p1j (SPT) #: (ii) The jobs in set2 follow in decreasing order of p2j (LPT). Ties are broken arbitrarily. This type schedule is referred as SPT(1)–LPT(2) schedule. A detailed discussion of the available solution methods are provided by Malakooti (2013).See also

* Open-shop scheduling * Job-shop schedulingReferences

{{Scheduling problems Optimal scheduling Workflow technology Engineering management