Extractor Manifold on:

[Wikipedia]

[Google]

[Amazon]

In an

In an

In

In

In a

In a

File:Rotax912sDynAeroMcr01.jpg , Exhaust system for a

In an

In an internal combustion engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal co ...

, the geometry of the exhaust system can be optimised ("tuned") to maximise the power output of the engine. Tuned exhausts are designed so that reflected pressure waves arrive at the exhaust port at a particular time in the combustion cycle.

Two-stroke engines

Expansion chambers

In

In two-stroke engine

A two-stroke (or two-stroke cycle) engine is a type of internal combustion engine that completes a power cycle with two strokes (up and down movements) of the piston during one power cycle, this power cycle being completed in one revolution of t ...

s where the exhaust port is opened by being uncovered by the piston (rather than by a separate valve), a tuned exhaust system usually consists of an expansion chamber. The expansion chamber is designed to produce a negative pressure wave to assist in filling the cylinder with the next intake charge, and then to produce a positive pressure wave which reduces the amount of fresh intake charge that escapes through the exhaust port (''port blocking'').

Uniflow scavenging

An alternate design of two-stroke engines is where the exhaust port is opened/closed using apoppet valve

A poppet valve (also called mushroom valve) is a valve typically used to control the timing and quantity of gas or vapor flow into an engine.

It consists of a hole or open-ended chamber, usually round or oval in cross-section, and a plug, usual ...

and the intake port is piston-controlled (opened by being uncovered by the piston). The timing of the exhaust valve closure is designed to assist in filling the cylinder with the next intake charge (as per four-stroke engines).

An opposed piston engine uses uniflow scavenging, however this design uses piston-controlled cylinder ports with one piston controlling the inlet port and the other the exhaust port. Similarly, split-single engines use uniflow scavenging, with the piston in one cylinder controlling the transfer port (where the intake mixture enters the cylinder) and the other piston controls the exhaust port.

Four-stroke engines

In a

In a four-stroke engine

A four-stroke (also four-cycle) engine is an internal combustion (IC) engine in which the piston completes four separate strokes while turning the crankshaft. A stroke refers to the full travel of the piston along the cylinder, in either directio ...

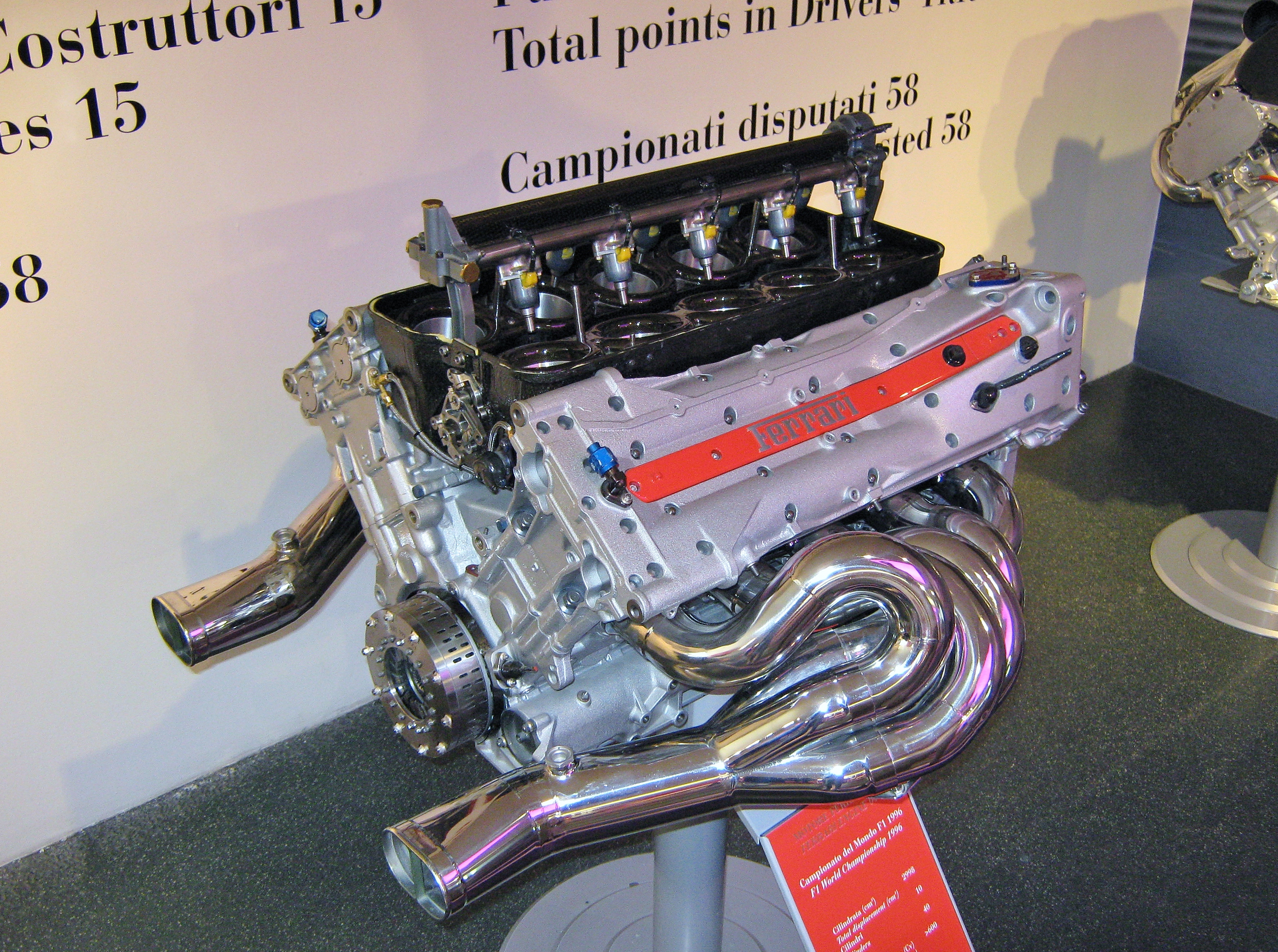

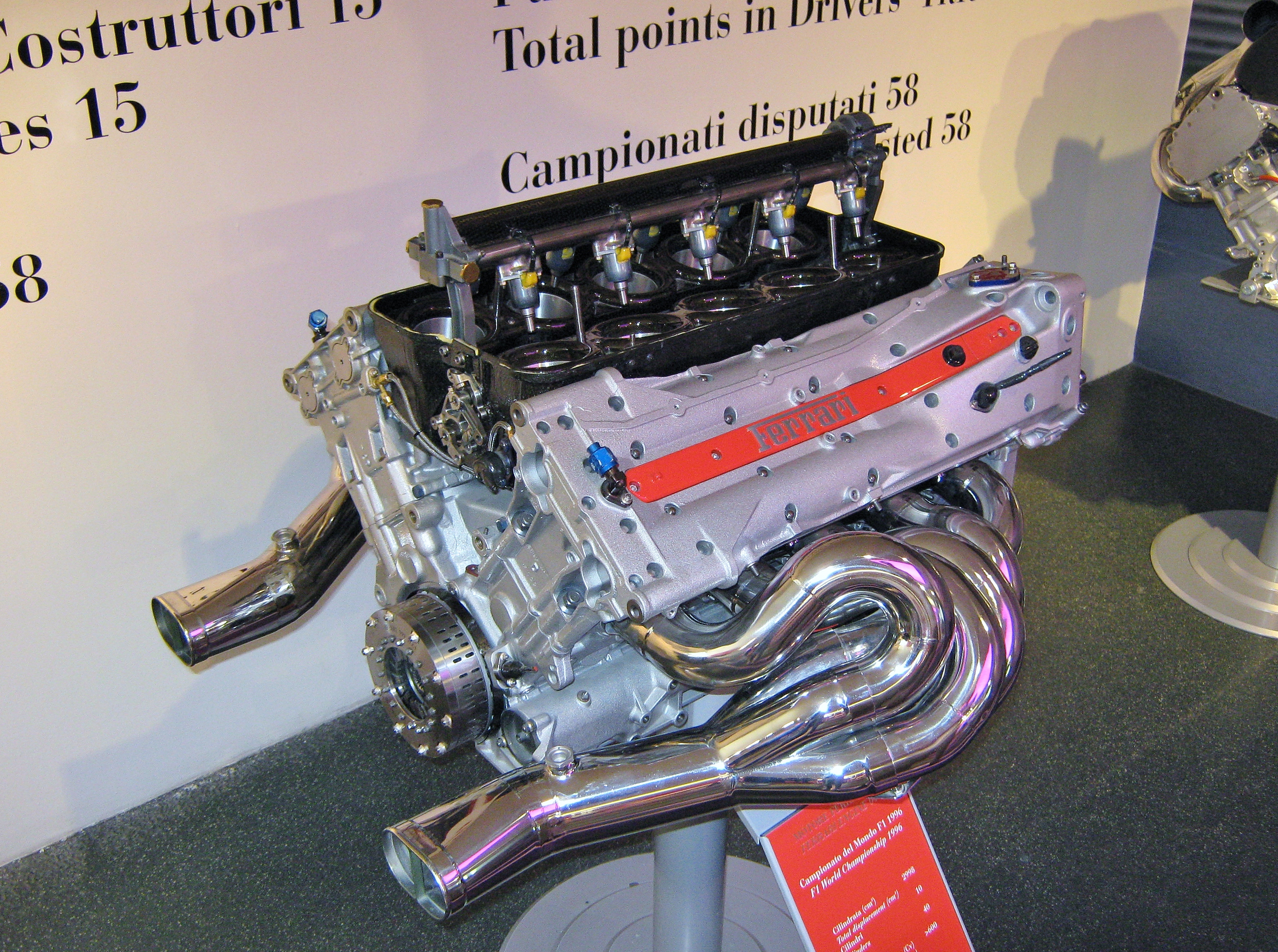

, an exhaust manifold which is designed to maximise the power output of an engine is often called "extractors" or "headers". The pipe lengths and merging locations are designed to assist in filling the cylinder with the next intake charge using exhaust scavenging. Locations where exhaust pipes from individual cylinders merge are called "collectors". The diameters of the exhaust system are designed to minimise back-pressure by optimising the gas velocity.

Extractors/headers usually have equal length pipes for each cylinder, whereas a more basic exhaust manifold may have unequal length pipes.

Rotax 912

The Rotax 912 is a horizontally-opposed four-cylinder, naturally aspirated, four-stroke aircraft engine with a reduction gearbox. It features liquid-cooled cylinder heads and air-cooled cylinders. Originally equipped with carburetors, l ...

s airplane engine

File:Ceramic Coating on Performance Car.jpg , Long tube headers (in white) on a racing car

File:'27 Model T altered.JPG , "Zoomie" headers on a dragster

4-2-1 exhausts

A 4-2-1 exhaust system is a type of exhaust manifold for an engine with four cylinders per bank, such as aninline-four engine

A straight-four engine (also called an inline-four) is a four-cylinder Reciprocating engine, piston engine where cylinders are arranged in a line along a common crankshaft.

The vast majority of automotive four-cylinder engines use a straight-f ...

or a V8 engine

A V8 engine is an eight- cylinder piston engine in which two banks of four cylinders share a common crankshaft and are arranged in a V configuration.

The first V8 engine was produced by the French Antoinette company in 1904, developed and u ...

. The layout of a 4-2-1 system is as follows: four pipes (primary) come off the cylinder head

In an internal combustion engine, the cylinder head (often abbreviated to simply "head") sits above the cylinder (engine), cylinders and forms the roof of the combustion chamber.

In sidevalve engines, the head is a simple sheet of metal; whereas ...

, and merge into two pipes (secondary), which in turn finally link up to form one collector pipe.

Compared with a 4-1 exhaust system, a 4-2-1 often produces more power at mid-range engine speeds (RPM), while a 4-1 exhaust produces more power at high RPM.

Cylinder pairings

The purpose of a 4-2-1 exhaust system is to increase scavenging by merging the exhaust paths of specific pairs of cylinders. Therefore, the cylinder pairings are defined by the intervals between firing events, which is determined by thefiring order

The firing order of an internal combustion engine is the sequence of ignition for the cylinders.

In a spark ignition (e.g. gasoline/petrol) engine, the firing order corresponds to the order in which the spark plugs are operated. In a diesel engi ...

and— for engines with an unevenly spaced firing order— the firing interval.

For an inline-four engine

A straight-four engine (also called an inline-four) is a four-cylinder Reciprocating engine, piston engine where cylinders are arranged in a line along a common crankshaft.

The vast majority of automotive four-cylinder engines use a straight-f ...

with a typical firing order of 1-3-4-2, pairing cylinders 1 & 4 and cylinders 2 & 3 is considered "non-sequential", since the paired cylinders do not follow each other in the firing order. This non-sequential arrangement results in an even spacing of 360 degrees between the firing interval in each cylinder pair. A sequential pairing would result in uneven spacings, such as 180 degrees and 540 degrees for pairings of cylinders 1 & 2 and 3 & 4. This sequential pairing is used by many motorcycle engines.

For a V8 engine

A V8 engine is an eight- cylinder piston engine in which two banks of four cylinders share a common crankshaft and are arranged in a V configuration.

The first V8 engine was produced by the French Antoinette company in 1904, developed and u ...

with a typical crossplane design, 4-2-1 exhausts are often called "Tri-Y" exhausts. Traditionally, only cylinders within the same bank were paired, resulting in spacings of 90-630 degrees (sequential), 180-540 degrees or 270-450 degrees. Typically, the 270 interval is favoured, requiring different pairings in each bank; e.g. 1 & 2 and 3 & 4 in one bank, but 1 & 3 and 2 & 4 in the other - naturally such exhausts are sensitive to the specific firing order in use. Even spacings of 360-360 degrees are only possible if a cross-over exhaust manifold is used to pair cylinders from separate banks.

Pipe lengths

The combining of exhaust pressure pulses from each cylinder dictates the lengths of the pipes necessary. Generally, shorter pipes will help produce more power at higher engine rpm, and longer pipes favour low-rpm torque, thereby altering the power band. However, the gases tend to cool as they pass through longer pipes, which reduces the effectiveness of the catalytic converter. In aturbocharged

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to pro ...

engine, the key factor in the length of the exhaust pipes is providing evenly-spaced pressure pulses to the turbine of the turbocharger.

See also

Two-stroke engines * Expansion chamber * Exhaust pulse pressure charging * Kadenacy effect Four-stroke engines * Exhaust system * Exhaust manifold * Scavenging (automotive) * Pressure wave superchargerReferences

{{reflist, 30em Exhaust systems