Enhanced oil recovery on:

[Wikipedia]

[Google]

[Amazon]

Enhanced oil recovery (abbreviated EOR), also called tertiary recovery, is the extraction of

Gas injection or miscible flooding is presently the most-commonly used approach in enhanced oil recovery. Miscible flooding is a general term for injection processes that introduce miscible gases into the reservoir. A miscible displacement process maintains reservoir pressure and improves oil displacement because the interfacial tension between oil and gas is reduced. This refers to removing the interface between the two interacting fluids. This allows for total displacement efficiency.

Gases used include CO2, natural gas or nitrogen. The fluid most commonly used for miscible displacement is carbon dioxide because it reduces the oil

Gas injection or miscible flooding is presently the most-commonly used approach in enhanced oil recovery. Miscible flooding is a general term for injection processes that introduce miscible gases into the reservoir. A miscible displacement process maintains reservoir pressure and improves oil displacement because the interfacial tension between oil and gas is reduced. This refers to removing the interface between the two interacting fluids. This allows for total displacement efficiency.

Gases used include CO2, natural gas or nitrogen. The fluid most commonly used for miscible displacement is carbon dioxide because it reduces the oil

In this approach, various methods are used to heat the crude oil in the formation to reduce its viscosity and/or vaporize part of the oil and thus decrease the mobility ratio. The increased heat reduces the surface tension and increases the permeability of the oil. The heated oil may also vaporize and then condense forming improved oil. Methods include cyclic steam injection, steam flooding and combustion. These methods improve the sweep efficiency and the displacement efficiency. Steam injection has been used commercially since the 1960s in California fields. In solar thermal enhanced oil recovery, a solar array is used to produce the steam.

In this approach, various methods are used to heat the crude oil in the formation to reduce its viscosity and/or vaporize part of the oil and thus decrease the mobility ratio. The increased heat reduces the surface tension and increases the permeability of the oil. The heated oil may also vaporize and then condense forming improved oil. Methods include cyclic steam injection, steam flooding and combustion. These methods improve the sweep efficiency and the displacement efficiency. Steam injection has been used commercially since the 1960s in California fields. In solar thermal enhanced oil recovery, a solar array is used to produce the steam.

IPCC Special Report on Carbon dioxide Capture and Storage

. Chapter 5, Underground geological storage. Intergovernmental Panel on Climate Change (IPCC), 2005.

ttps://web.archive.org/web/20090425063318/http://www.fossil.energy.gov/programs/oilgas/publications/eor_co2/Undeveloped_Oil_Document.pdf pdf// US Department of Energy, analysis of EOR potential. Game Changer Improvements Could Dramatically Increase Domestic Oil Resource Recovery. An analysis by Advanced Resources International, Arlington, VA, for the U.S. Department of Energy's Office of Fossil Energy. Advanced Resources International, February 2006. See als

press release

Enhanced Oil Recovery Institute

– University of Wyoming

Licensable Technology: Particle Stabilized Emulsions of Carbon Dioxide & Water for Enhanced Oil Recovery & Extraction Processes

– Massachusetts Technology Portal

Oilfield Glossary: Enhanced Oil Recovery

– Schlumberger, Ltd.

Center for Petroleum and Geosystems Engineering

– University of Texas at Austin

Polymer Flooding, Reservoir Sweep Improvement, New Mexico Tech {{DEFAULTSORT:Enhanced Oil Recovery Petroleum production Applications of carbon dioxide

crude oil

Petroleum, also known as crude oil or simply oil, is a naturally occurring, yellowish-black liquid chemical mixture found in geological formations, consisting mainly of hydrocarbons. The term ''petroleum'' refers both to naturally occurring u ...

from an oil field

A petroleum reservoir or oil and gas reservoir is a subsurface accumulation of hydrocarbons contained in porous or fractured rock formations. Such reservoirs form when kerogen (ancient plant matter) is created in surrounding rock by the prese ...

that cannot be extracted after primary and secondary recovery methods have been completely exhausted. Whereas primary and secondary recovery techniques rely on the pressure differential between the surface and the underground well, enhanced oil recovery functions by altering the physical or chemical properties of the oil itself in order to make it easier to extract. When EOR is used, 30% to 60% or more of a reservoir's oil can be extracted, compared to 20% to 40% using only primary

Primary or primaries may refer to:

Arts, entertainment, and media Music Groups and labels

* Primary (band), from Australia

* Primary (musician), hip hop musician and record producer from South Korea

* Primary Music, Israeli record label

Work ...

and secondary recovery.

There are four main EOR techniques: carbon dioxide (CO2) injection, gas injection, thermal EOR, and chemical EOR. More advanced, speculative EOR techniques are sometimes called quaternary recovery. Carbon dioxide injection, known as CO2-EOR, is the most common method. In this method, CO2 is injected into a depleted oil field and is mostly left underground.

CO2-EOR is usually performed using CO2 from naturally-occurring underground deposits. It is also sometimes performed using CO2 captured from the flue gas of industrial facilities. When EOR is done using CO2 captured from flue gas, the process can prevent some emissions from escaping. However, there is controversy over whether the overall process is beneficial for the climate. EOR operations are energy-intensive, which leads to more emissions, and further emissions are produced when the recovered oil is burned.

EOR adds to the cost of producing oil but can be economically attractive if the price of oil is high. The U.S. Department of Energy estimates that 20 billion tons of captured CO2 could produce 67 billion barrels of economically recoverable oil. As a means of boosting domestic oil production, the US federal tax code began to include incentives for EOR in 1979.

Purpose

Crude oil development and production can include up to three distinct phases: primary, secondary, and tertiary (or enhanced) recovery. During primary recovery, the natural pressure of the reservoir or gravity drive oil into the wellbore, combined with artificial lift techniques (such as pumps) which bring the oil to the surface. But only about 10 percent of a reservoir's original oil in place is typically produced during primary recovery. Secondary recovery techniques extend a field's productive life generally by injecting water or gas to displace oil and drive it to a production wellbore, resulting in the recovery of 20 to 40 percent of the original oil in place. Producers have attempted several tertiary, or enhanced oil recovery (EOR), techniques that offer prospects for ultimately producing 30 to 60 percent, or more, of the reservoir's original oil in place.Methods

The main classes of EOR technologies are: * CO2 EOR: CO2 is injected into the subsurface. Text was copied from this source, which is available under a Creative Commons Attribution 4.0 International License * Other gas injection EOR: similar to CO2-EOR, but with other gases injected such as natural gas or nitrogen. * Thermal EOR: steam is used to heat the oil in the ground, reducing its viscosity and making it easier to move. This is most often applied in heavy oil reservoirs. * Chemical EOR: water soluble polymers and/or surfactants are added to water that is injected into the subsurface. Polymer-loaded water has a high viscosity and can push more oil out of the pores in the oil-bearing formation. Surfactants reduce the surface tension of the oil, improving its ability to be displaced by water. * Other EOR: this class contains all other technologies such as microbial EOR, in which micro-organisms are injected in the reservoir, or combustion EOR, which involves in-situ burning of some of the oil to generate both heat and gases that help the rest of the oil move more easily. In 2017, there were 374 EOR projects worldwide. Of these, 44% were CO2-EOR, 12% were other gas injection EOR, 32% were thermal EOR, 9% were chemical EOR, and 2% were other EOR methods.Injection of CO2 or other gases

Gas injection or miscible flooding is presently the most-commonly used approach in enhanced oil recovery. Miscible flooding is a general term for injection processes that introduce miscible gases into the reservoir. A miscible displacement process maintains reservoir pressure and improves oil displacement because the interfacial tension between oil and gas is reduced. This refers to removing the interface between the two interacting fluids. This allows for total displacement efficiency.

Gases used include CO2, natural gas or nitrogen. The fluid most commonly used for miscible displacement is carbon dioxide because it reduces the oil

Gas injection or miscible flooding is presently the most-commonly used approach in enhanced oil recovery. Miscible flooding is a general term for injection processes that introduce miscible gases into the reservoir. A miscible displacement process maintains reservoir pressure and improves oil displacement because the interfacial tension between oil and gas is reduced. This refers to removing the interface between the two interacting fluids. This allows for total displacement efficiency.

Gases used include CO2, natural gas or nitrogen. The fluid most commonly used for miscible displacement is carbon dioxide because it reduces the oil viscosity

Viscosity is a measure of a fluid's rate-dependent drag (physics), resistance to a change in shape or to movement of its neighboring portions relative to one another. For liquids, it corresponds to the informal concept of ''thickness''; for e ...

and is less expensive than liquefied petroleum gas

Liquefied petroleum gas, also referred to as liquid petroleum gas (LPG or LP gas), is a fuel gas which contains a flammable mixture of hydrocarbon gases, specifically propane, Butane, ''n''-butane and isobutane. It can also contain some ...

. Oil displacement by carbon dioxide injection relies on the phase behavior of the mixtures of that gas and the crude, which are strongly dependent on reservoir temperature, pressure and crude oil composition.

Using CO2 for enhanced oil recovery was first investigated and patented in 1952. The process was first commercially attempted in 1977 in Scurry County, Texas

Texas ( , ; or ) is the most populous U.S. state, state in the South Central United States, South Central region of the United States. It borders Louisiana to the east, Arkansas to the northeast, Oklahoma to the north, New Mexico to the we ...

. Since then, the process has become extensively used in the Permian basin region of the US and is now more recently is being pursued in many different states. It is now being more actively pursued in China and throughout the rest of the world.

Most CO2 injected in CO2-EOR projects comes from naturally occurring underground CO2 deposits. Text was copied from this source, which is available under a Creative Commons Attribution 4.0 International License Some CO2 used in EOR is captured from industrial facilities such as natural gas processing plants, using carbon capture technology.

Supercritical carbon dioxide

CO2 is particularly effective in reservoirs deeper than 2,000 ft., where CO2 will be in a supercritical state. In high pressure applications with lighter oils, CO2 is miscible with the oil, with resultant swelling of the oil, and reduction in viscosity, and possibly also with a reduction in the surface tension with the reservoir rock. In the case of low pressure reservoirs or heavy oils, CO2 will form an immiscible fluid, or will only partially mix with the oil. Some oil swelling may occur, and oil viscosity can still be significantly reduced. In these applications, between one-half and two-thirds of the injected CO2 returns with the produced oil and is usually re-injected into the reservoir to minimize operating costs. The remainder is trapped in the oil reservoir by various means. Carbon dioxide as a solvent has the benefit of being more economical than other similarly miscible fluids such aspropane

Propane () is a three-carbon chain alkane with the molecular formula . It is a gas at standard temperature and pressure, but becomes liquid when compressed for transportation and storage. A by-product of natural gas processing and petroleum ref ...

and butane

Butane () is an alkane with the formula C4H10. Butane exists as two isomers, ''n''-butane with connectivity and iso-butane with the formula . Both isomers are highly flammable, colorless, easily liquefied gases that quickly vaporize at ro ...

.

Water-alternating-gas (WAG)

Water-alternating-gas (WAG) injection is another technique employed in EOR. Water is used in addition to carbon dioxide. A saline solution is used here so that carbonate formations in oil wells are not disturbed. Water and carbon dioxide are injected into the oil well for larger recovery, as they typically have low miscibility with oil. Use of both water and carbon dioxide also lowers the mobility of carbon dioxide, causing the gas to displace more oil. According to a study done by Kovscek, using small slugs of both carbon dioxide and water allows for quick recovery of the oil. Additionally, in a study done by Dang in 2014, using water with a lower salinity allows for greater oil removal, and greater geochemical interactions.Thermal injection

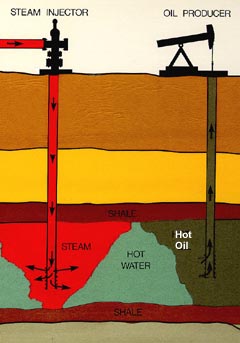

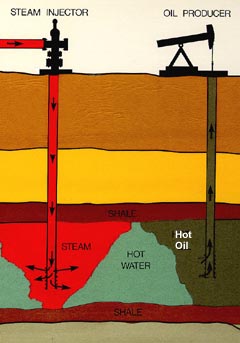

In this approach, various methods are used to heat the crude oil in the formation to reduce its viscosity and/or vaporize part of the oil and thus decrease the mobility ratio. The increased heat reduces the surface tension and increases the permeability of the oil. The heated oil may also vaporize and then condense forming improved oil. Methods include cyclic steam injection, steam flooding and combustion. These methods improve the sweep efficiency and the displacement efficiency. Steam injection has been used commercially since the 1960s in California fields. In solar thermal enhanced oil recovery, a solar array is used to produce the steam.

In this approach, various methods are used to heat the crude oil in the formation to reduce its viscosity and/or vaporize part of the oil and thus decrease the mobility ratio. The increased heat reduces the surface tension and increases the permeability of the oil. The heated oil may also vaporize and then condense forming improved oil. Methods include cyclic steam injection, steam flooding and combustion. These methods improve the sweep efficiency and the displacement efficiency. Steam injection has been used commercially since the 1960s in California fields. In solar thermal enhanced oil recovery, a solar array is used to produce the steam.

Steam flooding

Steam flooding (see sketch) is one means of introducing heat to the reservoir by pumping steam into the well with a pattern similar to that of water injection. Eventually the steam condenses to hot water; in the steam zone the oil evaporates, and in the hot water zone the oil expands. As a result, the oil expands, the viscosity drops, and the permeability increases. To ensure success the process has to be cyclical. This is the principal enhanced oil recovery program in use today.Fire flooding

Fire flooding works best when the oil saturation and porosity are high. Combustion generates the heat within the reservoir itself. Continuous injection of air or other gas mixture with high oxygen content will maintain the flame front. As the fire burns, it moves through the reservoir toward production wells. Heat from the fire reduces oil viscosity and helps vaporize reservoir water to steam. The steam, hot water, combustion gas and a bank of distilled solvent all act to drive oil in front of the fire toward production wells. There are three methods of combustion: Dry forward, reverse and wet combustion. Dry forward uses an igniter to set fire to the oil. As the fire progresses the oil is pushed away from the fire toward the producing well. In reverse the air injection and the ignition occur from opposite directions. In wet combustion water is injected just behind the front and turned into steam by the hot rock. This quenches the fire and spreads the heat more evenly.Chemical injection

The injection of various chemicals, usually as dilute solutions, have been used to aid mobility and the reduction insurface tension

Surface tension is the tendency of liquid surfaces at rest to shrink into the minimum surface area possible. Surface tension (physics), tension is what allows objects with a higher density than water such as razor blades and insects (e.g. Ge ...

. Injection of alkaline

In chemistry, an alkali (; from the Arabic word , ) is a basic salt of an alkali metal or an alkaline earth metal. An alkali can also be defined as a base that dissolves in water. A solution of a soluble base has a pH greater than 7.0. The ...

or caustic solutions into reservoirs with oil that have organic acid

An organic acid is an organic compound with acidic properties. The most common organic acids are the carboxylic acids, whose acidity is associated with their carboxyl group –COOH. Sulfonic acids, containing the group –SO2OH, are re ...

s naturally occurring in the oil will result in the production of soap

Soap is a salt (chemistry), salt of a fatty acid (sometimes other carboxylic acids) used for cleaning and lubricating products as well as other applications. In a domestic setting, soaps, specifically "toilet soaps", are surfactants usually u ...

that may lower the interfacial tension enough to increase production. Injection of a dilute solution of a water-soluble

In chemistry, solubility is the ability of a substance, the solute, to form a solution with another substance, the solvent. Insolubility is the opposite property, the inability of the solute to form such a solution.

The extent of the solub ...

polymer to increase the viscosity of the injected water can increase the amount of oil recovered in some formations. Dilute solutions of surfactant

Surfactants are chemical compounds that decrease the surface tension or interfacial tension between two liquids, a liquid and a gas, or a liquid and a solid. The word ''surfactant'' is a Blend word, blend of "surface-active agent",

coined in ...

s such as petroleum sulfonate

In organosulfur chemistry, a sulfonate is a salt, anion or ester of a sulfonic acid. Its formula is , containing the functional group , where R is typically an organyl group, amino group or a halogen atom. Sulfonates are the conjugate bases of ...

s or biosurfactants such as rhamnolipids may be injected to lower the interfacial tension or capillary pressure that impedes oil droplets from moving through a reservoir, this is analyzed in terms of the bond number, relating capillary forces to gravitational ones. Special formulations of oil, water and surfactant, microemulsions, can be particularly effective in reducing interfacial tension. Application of these methods is usually limited by the cost of the chemicals and their adsorption and loss onto the rock of the oil containing formation. In all of these methods the chemicals are injected into several wells and the production occurs in other nearby wells.

Polymer flooding

Polymer flooding consists in mixing long chain polymer molecules with the injected water in order to increase the water viscosity. This method improves the vertical and areal sweep efficiency as a consequence of improving the water/oil mobility ratio. Surfactants may be used in conjunction with polymers and hyperbranched polyglycerols; they decrease the interfacial tension between the oil and water. This reduces the residual oil saturation and improves the macroscopic efficiency of the process. Primary surfactants usually have co-surfactants, activity boosters, and co-solvents added to them to improve stability of the formulation. Caustic flooding is the addition ofsodium hydroxide

Sodium hydroxide, also known as lye and caustic soda, is an inorganic compound with the formula . It is a white solid ionic compound consisting of sodium cations and hydroxide anions .

Sodium hydroxide is a highly corrosive base (chemistry), ...

to injection water. This lowers the surface tension, reverses the rock's wettability, emulsifies and mobilizes the oil, and helps in drawing the oil out of the rock.Low salinity nanofluids

EOR processes can be enhanced withnanoparticle

A nanoparticle or ultrafine particle is a particle of matter 1 to 100 nanometres (nm) in diameter. The term is sometimes used for larger particles, up to 500 nm, or fibers and tubes that are less than 100 nm in only two directions. At ...

s in three ways: nanocatalysts, nanofluids, and nanoemulsions. Nanofluids are base fluids that contain nanoparticles in colloidal suspensions. Nanofluids perform many functions in EOR of oil fields, including pore disjoining pressure, channel plugging, interfacial tension reduction, mobility ratio, wettability alteration, and asphaltene precipitation prevention. Nanofluids facilitates disjoining pressure to remove sediment entrapped oil via aggregation at the interface. Alternatively, wettability alteration and interfacial surface tension reduction are other alternative mechanism of EOR.

Other EOR methods

Microbial injection

Microbial injection is part of microbial enhanced oil recovery and is rarely used because of its higher cost and because thedevelopment

Development or developing may refer to:

Arts

*Development (music), the process by which thematic material is reshaped

* Photographic development

*Filmmaking, development phase, including finance and budgeting

* Development hell, when a proje ...

is not widely accepted. These microbe

A microorganism, or microbe, is an organism of microscopic size, which may exist in its single-celled form or as a colony of cells. The possible existence of unseen microbial life was suspected from antiquity, with an early attestation in ...

s function either by partially digesting long hydrocarbon

In organic chemistry, a hydrocarbon is an organic compound consisting entirely of hydrogen and carbon. Hydrocarbons are examples of group 14 hydrides. Hydrocarbons are generally colourless and Hydrophobe, hydrophobic; their odor is usually fain ...

molecules, by generating biosurfactants, or by emitting carbon dioxide (which then functions as described in Gas injection above).

Three approaches have been used to achieve microbial injection. In the first approach, bacterial cultures mixed with a food source (a carbohydrate such as molasses

Molasses () is a viscous byproduct, principally obtained from the refining of sugarcane or sugar beet juice into sugar. Molasses varies in the amount of sugar, the method of extraction, and the age of the plant. Sugarcane molasses is usuall ...

is commonly used) are injected into the oil field. In the second approach, used since 1985, nutrients are injected into the ground to nurture existing microbial bodies; these nutrients cause the bacteria to increase production of the natural surfactants they normally use to metabolize crude oil underground. After the injected nutrients are consumed, the microbes go into near-shutdown mode, their exteriors become hydrophilic

A hydrophile is a molecule or other molecular entity that is attracted to water molecules and tends to be dissolved by water.Liddell, H.G. & Scott, R. (1940). ''A Greek-English Lexicon'' Oxford: Clarendon Press.

In contrast, hydrophobes are n ...

, and they migrate to the oil-water interface area, where they cause oil droplets to form from the larger oil mass, making the droplets more likely to migrate to the wellhead. This approach has been used in oilfields near the Four Corners and in the Beverly Hills Oil Field in Beverly Hills, California

Beverly Hills is a city located in Los Angeles County, California, United States. A notable and historic suburb of Los Angeles, it is located just southwest of the Hollywood Hills, approximately northwest of downtown Los Angeles. Beverly Hills ...

.

The third approach is used to address the problem of paraffin wax

Paraffin wax (or petroleum wax) is a soft colorless solid derived from petroleum, coal, or oil shale that consists of a mixture of hydrocarbon molecules containing between 20 and 40 carbon atoms. It is solid at room temperature and melting poi ...

components of the crude oil, which tend to precipitate as the crude flows to the surface, since the Earth's surface is considerably cooler than the petroleum deposits (a temperature drop of 9–10–14 °C per thousand feet of depth is usual).

Plasma-pulse

In 2013, a technique called plasma-pulse technology was introduced into the United States from Russia. This technique can result in another 50 percent of improvement in existing well production.Economic costs and benefits

Adding oil recovery methods adds to the cost of oil—in the case of CO2 typically between 0.5–8.0 US$ per tonne of CO2. The increased extraction of oil on the other hand, is an economic benefit with the revenue depending on prevailingoil prices

The price of oil, or the oil price, generally refers to the spot price of a barrel () of benchmark crude oil—a reference price for buyers and sellers of crude oil such as West Texas Intermediate (WTI), Brent Crude, Dubai Crude, OPE ...

. Onshore EOR has paid in the range of a net 10–16 US$ per tonne of CO2 injected for oil prices of 15–20 US$/barrel

A barrel or cask is a hollow cylindrical container with a bulging center, longer than it is wide. They are traditionally made of wooden stave (wood), staves and bound by wooden or metal hoops. The word vat is often used for large containers ...

. Prevailing prices depend on many factors but can determine the economic suitability of any procedure, with more procedures and more expensive procedures being economically viable at higher prices. Example: With oil prices at around 90 US$/barrel, the economic benefit is about 70 US$ per tonne CO2. The U.S. Department of Energy estimates that 20 billion tons of captured CO2 could produce 67 billion barrels of economically recoverable oil.

From 1986 to 2008, the quote oil production deriving from EOR has increased from 0.3% to 5%, thanks to an increasing oil demand and a reduction of oil supply.Environmental impacts

Enhanced oil recovery wells typically pump large quantities of produced water to the surface. This water containsbrine

Brine (or briny water) is a high-concentration solution of salt (typically sodium chloride or calcium chloride) in water. In diverse contexts, ''brine'' may refer to the salt solutions ranging from about 3.5% (a typical concentration of seawat ...

and may also contain toxic

Toxicity is the degree to which a chemical substance or a particular mixture of substances can damage an organism. Toxicity can refer to the effect on a whole organism, such as an animal, bacterium, or plant, as well as the effect on a subst ...

heavy metals and radioactive substances. This can be very damaging to drinking water

Drinking water or potable water is water that is safe for ingestion, either when drunk directly in liquid form or consumed indirectly through food preparation. It is often (but not always) supplied through taps, in which case it is also calle ...

sources and the environment generally if not properly controlled. Disposal wells are used to prevent surface contamination of soil and water by injecting the produced water deep underground.

Greenhouse gas emissions

Carbon dioxide can be captured from the flue gas of an industrial facility such as natural gas processing plant or a coal power plant. If captured CO2 is used for EOR, the process is known as carbon capture-EOR (CC-EOR) and is a form ofcarbon capture and storage

Carbon capture and storage (CCS) is a process by which carbon dioxide (CO2) from industrial installations is separated before it is released into the atmosphere, then transported to a long-term storage location.IPCC, 2021Annex VII: Glossary at ...

.

When the CO2 used in EOR is sourced from underground CO2 deposits, which is usually the case, EOR provides no climate benefit.

Government programs and regulations

United States

In the US, regulations can both assist and slow down the development of EOR for use in carbon capture & utilization, as well as general oil production. As a means of boosting domestic oil production, the US federal tax code began to include incentives for EOR in 1979, when crude oil was still under federal price controls. A 15 percent tax credit was codified with the U.S. Federal EOR Tax Incentive in 1986, and oil production from EOR using subsequently grew rapidly. In the U.S., the 2021 Infrastructure Investment and Jobs Act designates over $3 billion for a variety of CCS demonstration projects. A similar amount is provided for regional CCS hubs that focus on the broader capture, transport, and either storage or use of captured . Hundreds of millions more are dedicated annually to loan guarantees supporting transport infrastructure. TheInflation Reduction Act

The Inflation Reduction Act of 2022 (IRA) is a United States federal law which aims to reduce the federal government budget deficit, lower prescription drug prices, and invest in domestic energy production while promoting clean energy. It was ...

of 2022 (IRA) updates tax credit law to encourage the use of carbon capture and storage. Tax incentives under the law provide up to $85/tonne for capture and storage in saline geologic formations or up to $60/tonne for used for enhanced oil recovery. The Internal Revenue Service

The Internal Revenue Service (IRS) is the revenue service for the Federal government of the United States, United States federal government, which is responsible for collecting Taxation in the United States, U.S. federal taxes and administerin ...

relies on documentation from the corporation to substantiate claims on how much is being sequestered, and does not perform independent investigations. In 2020, a federal investigation found that claimants for the 45Q tax credit failed to document successful geological storage for nearly $900 million of the $1 billion they had claimed.Text was copied from this source, which is available under a Creative Commons Attribution 4.0 International License

One of the primary regulations governing EOR is the Safe Drinking Water Act

The Safe Drinking Water Act (SDWA) is the primary federal law in the United States intended to ensure safe drinking water for the public. Pursuant to the act, the Environmental Protection Agency (EPA) is required to set standards for drinking wa ...

of 1974 (SDWA), which gives most of the regulatory power over EOR and similar oil recovery operations to the EPA. The agency in turn delegated some of this power to its own Underground Injection Control Program, and much of the rest of this regulatory authority to state and tribal governments, making much of EOR regulation a localized affair under the minimum requirements of the SDWA. The EPA then collects information from these local governments and individual wells to ensure they follow overall federal regulation, such as the Clean Air Act, which dictates reporting guidelines for any Carbon Dioxide sequestration operations. Beyond the atmospheric concerns, most of these federal guidelines are to ensure that the Carbon Dioxide injection causes no major damage to America's waterways. Overall, the locality of EOR regulation can make EOR projects more difficult, as different standards in different regions can slow down construction and force separate approaches to utilize the same technology.

EPA has issued Underground Injection Control (UIC) regulations in order to protect drinking water sources. Enhanced oil recovery wells are regulated as "Class II" wells by the EPA. The regulations require well operators to reinject the brine used for recovery deep underground in Class II disposal wells.

See also

* List of carbon capture and storage projects * Gas reinjection *Steam assisted gravity drainage Steam-assisted gravity drainage (SAGD; "Sag-D") is an enhanced oil recovery technology for producing heavy crude oil and bitumen. It is an advanced form of steam injection (oil industry), steam stimulation in which a pair of Directional drilling, ho ...

* Water injection (oil production)

In the oil industry, waterflooding or water injection is where water is injected into the oil reservoir, to maintain the pressure (also known as voidage replacement), or to drive oil towards the wells, and thereby increase production. Water inje ...

* Wikiversity:Enhanced oil recovery

References

IPCC Special Report on Carbon dioxide Capture and Storage

. Chapter 5, Underground geological storage. Intergovernmental Panel on Climate Change (IPCC), 2005.

ttps://web.archive.org/web/20090425063318/http://www.fossil.energy.gov/programs/oilgas/publications/eor_co2/Undeveloped_Oil_Document.pdf pdf// US Department of Energy, analysis of EOR potential. Game Changer Improvements Could Dramatically Increase Domestic Oil Resource Recovery. An analysis by Advanced Resources International, Arlington, VA, for the U.S. Department of Energy's Office of Fossil Energy. Advanced Resources International, February 2006. See als

press release

External links

Enhanced Oil Recovery Institute

– University of Wyoming

Licensable Technology: Particle Stabilized Emulsions of Carbon Dioxide & Water for Enhanced Oil Recovery & Extraction Processes

– Massachusetts Technology Portal

Oilfield Glossary: Enhanced Oil Recovery

– Schlumberger, Ltd.

Center for Petroleum and Geosystems Engineering

– University of Texas at Austin

Polymer Flooding, Reservoir Sweep Improvement, New Mexico Tech {{DEFAULTSORT:Enhanced Oil Recovery Petroleum production Applications of carbon dioxide